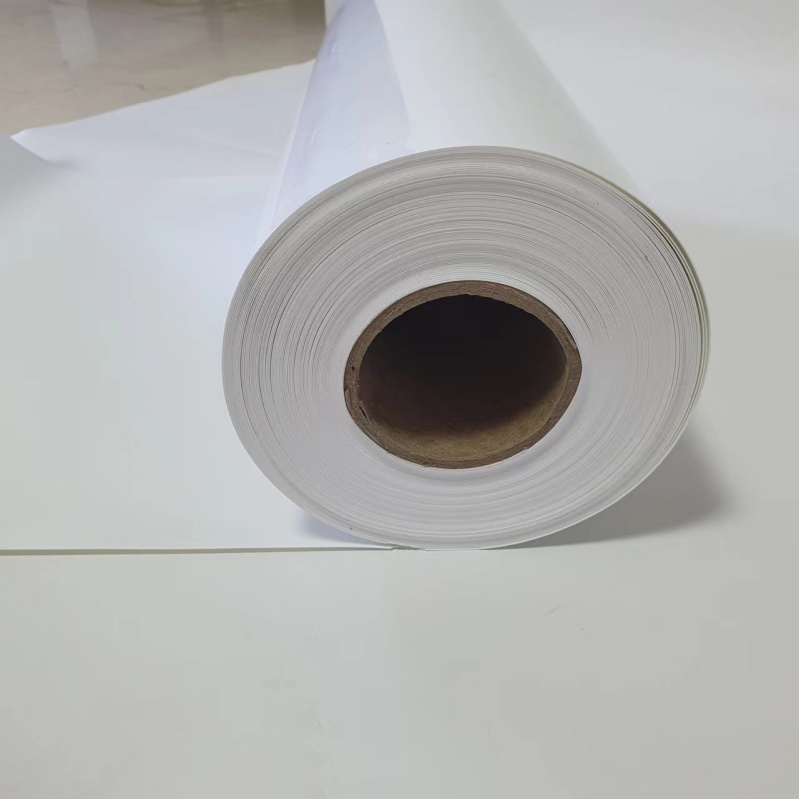

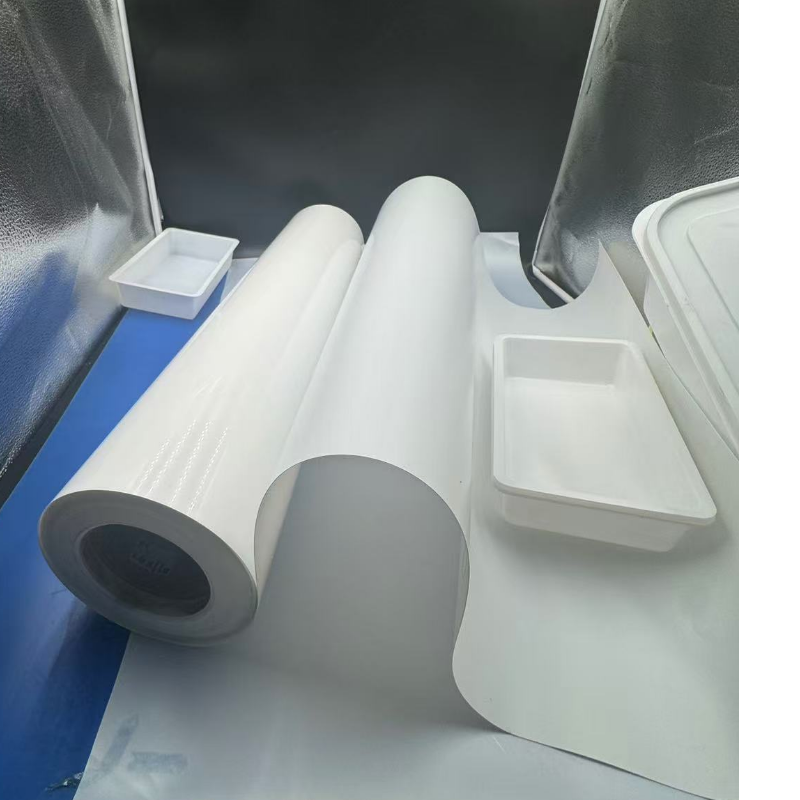

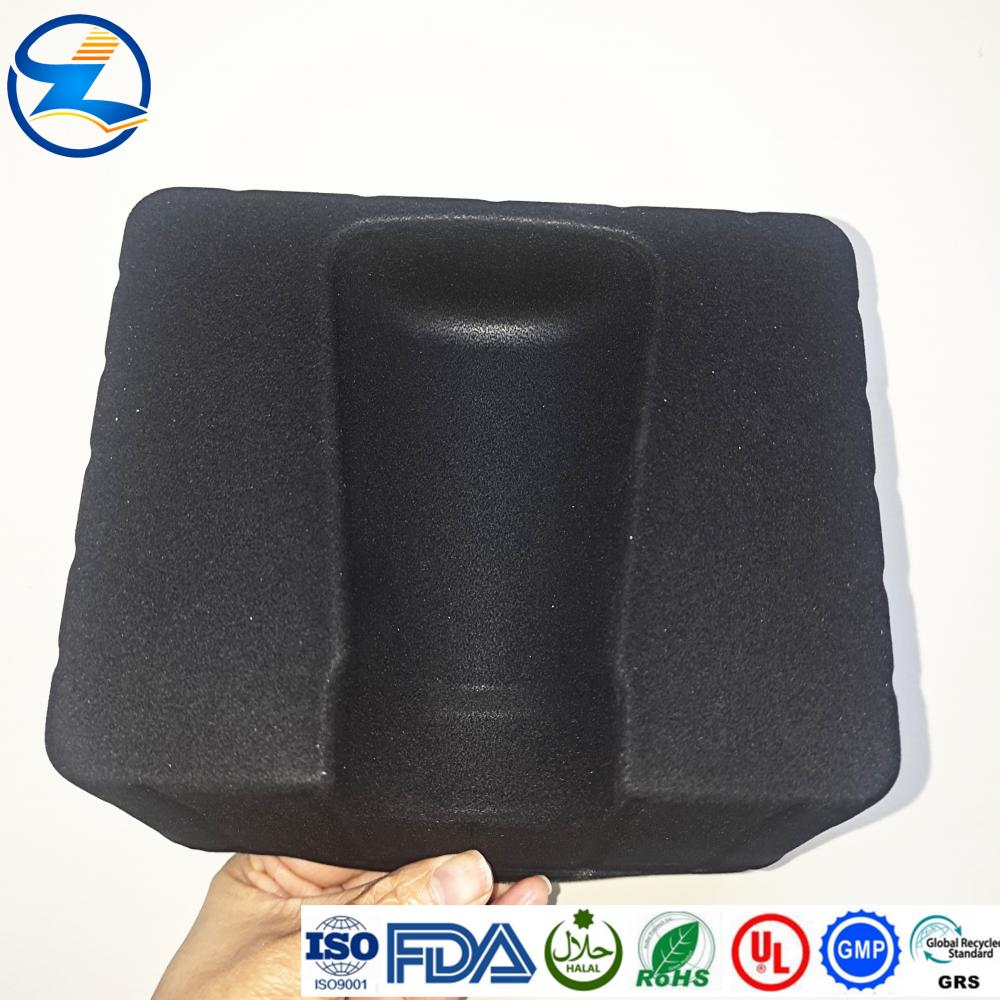

HIPS Sheet for Thermoforming Electronic Tray

HIPS is known for its high impact strength, which means it can withstand physical shocks and impacts better than regular polystyrene. This property makes it ideal for trays that need to protect delicate electronic components during transportation or handling.

- TOP LEADER

- CHINA

- 7-15 Working days

- 5000t/Month

- Information

HIPS (High Impact Polystyrene) sheets are commonly used in the manufacturing of electronic trays due to their advantageous properties. Here are some key benefits of using HIPS sheets for electronic trays:

1. Impact Resistance: HIPS is known for its high impact strength, which means it can withstand physical shocks and impacts better than regular polystyrene. This property makes it ideal for trays that need to protect delicate electronic components during transportation or handling.

2. Cost-Effectiveness: HIPS is generally less expensive compared to other engineering plastics like ABS or PVC. This makes it a cost-effective material choice for mass production of electronic trays without compromising on performance.

3. Processability: HIPS has good processability, meaning it can be easily molded into various shapes and sizes. It also allows for easy trimming, cutting, and forming, which simplifies the manufacturing process.

4. Good Insulation Properties: HIPS provides good electrical insulation, which is crucial for protecting electronic components from short circuits or static electricity.

5. Surface Finish: HIPS can be finished to have a smooth surface, which is aesthetically pleasing and can also help in minimizing dust accumulation, an important factor in electronic applications where cleanliness is critical.

Get the latest price? We'll respond as soon as possible(within 12 hours)