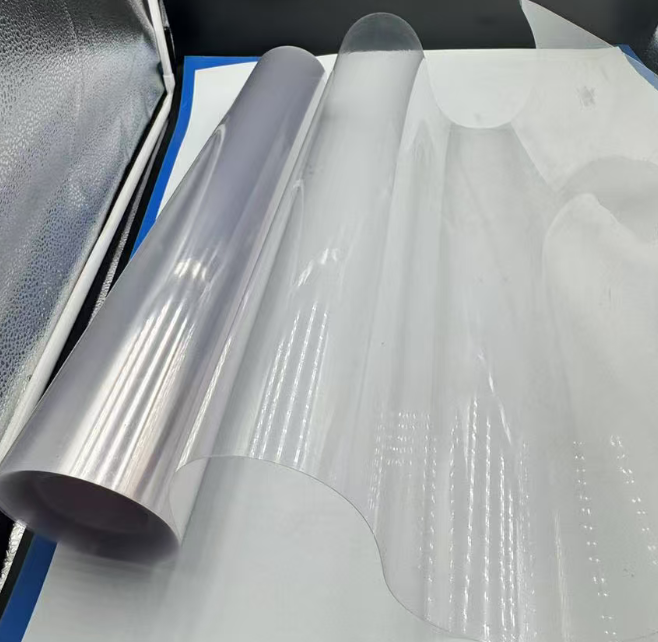

Properties and Applications of Transparent PVC/PE Composite Film in Blister Packaging for Liquid Aromatics, Pharmaceuticals, and Nutritional Liquids

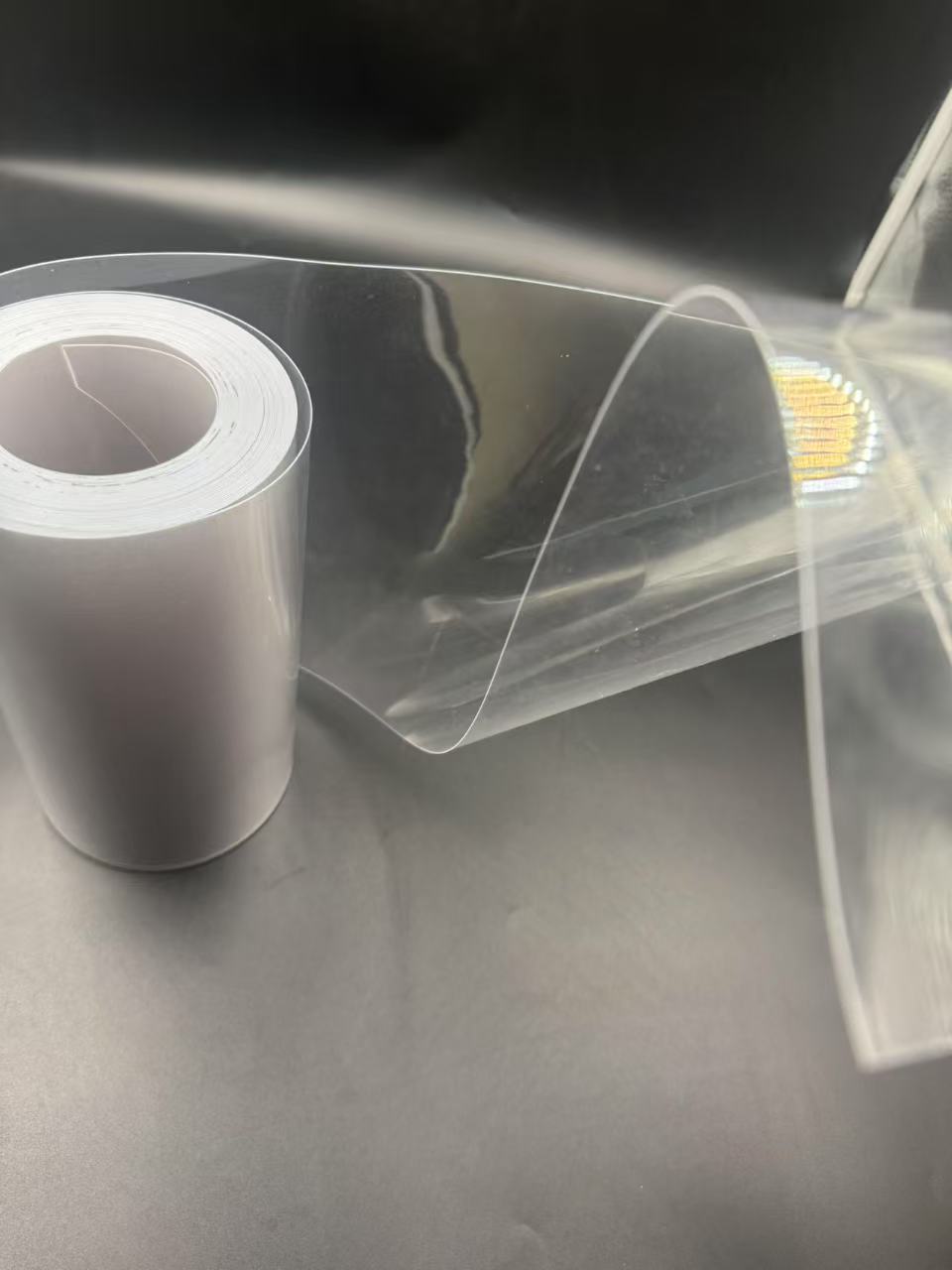

NamePVC/PE Plastic film roll

SizeTk:0.1-0.9mm, h100-1200mm

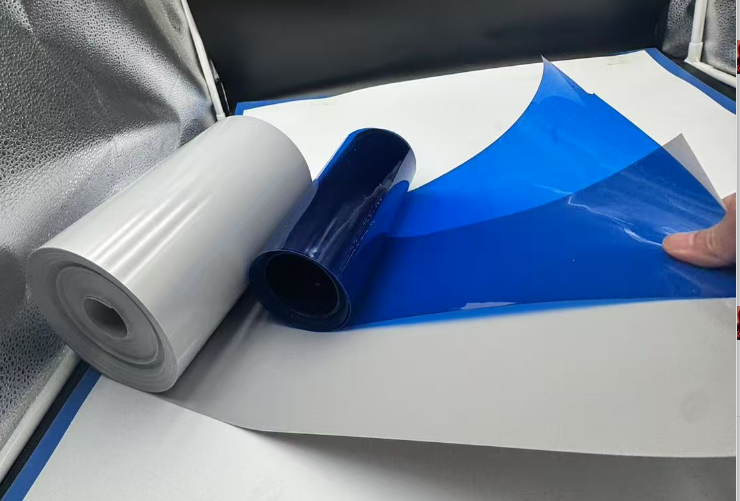

MaterialPVC/PE PET/PE/Customized

Color/printingTransparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

UsageLiquid packing

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

Transparent PVC/PE composite film, a multilayer material combining polyvinyl chloride (PVC) and polyethylene (PE), is a cornerstone in specialized packaging due to its unique blend of rigidity, flexibility, and barrier properties. In blister packaging for liquid aromatics (e.g., essential oils), liquid pharmaceuticals (e.g., oral medications), and nutritional liquids (e.g., vitamin shots), PVC/PE***film offers exceptional performance, ensuring product safety, visibility, and shelf stability. This article delves into the properties of PVC/PE composite film and its tailored applications in these sectors, supported by evidence and vivid examples to highlight its significance.

In blister packaging for liquid aromatics (e.g., essential oils), liquid pharmaceuticals (e.g., oral medications), and nutritional liquids (e.g., vitamin shots), PVC/PE***film offers exceptional performance, ensuring product safety, visibility, and shelf stability. This article delves into the properties of PVC/PE composite film and its tailored applications in these sectors, supported by evidence and vivid examples to highlight its significance.

Key Properties of Transparent PVC/PE Composite Film

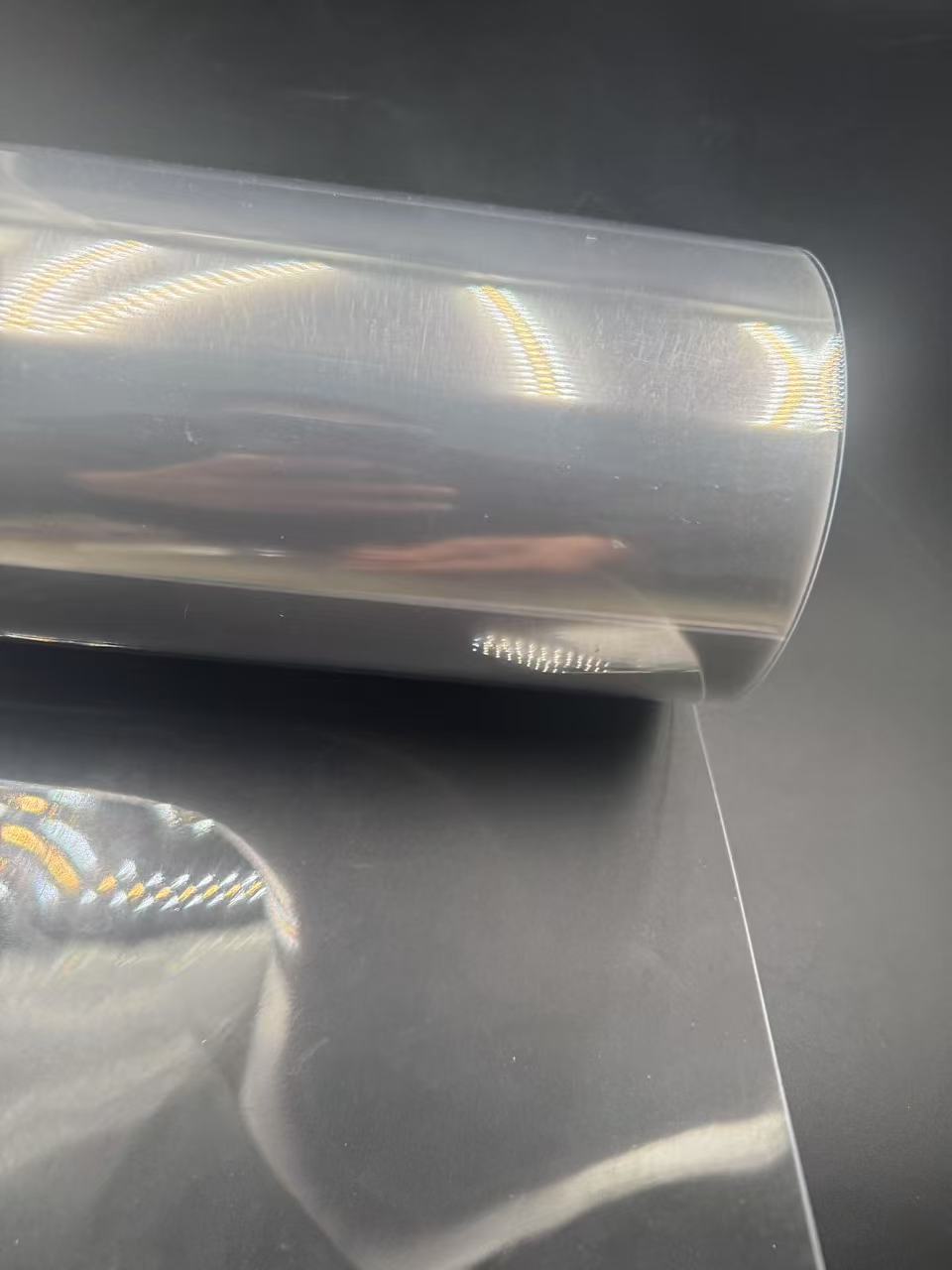

1. Optical Clarity

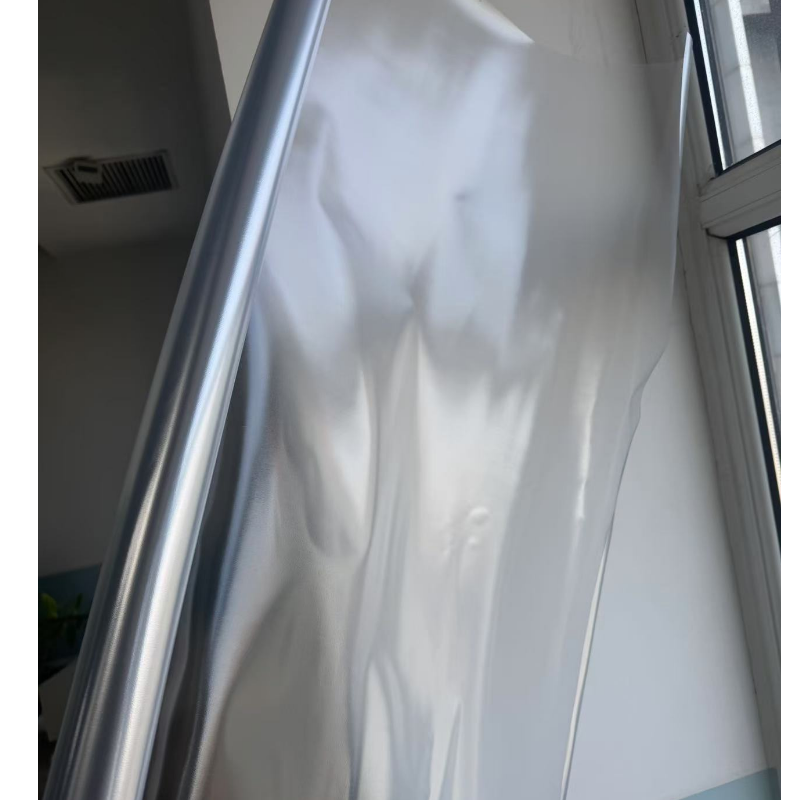

The transparency of PVC/PE***film is a defining feature, with light transmission rates typically above 85%. This clarity allows consumers to see the vibrant colors or clarity of liquid aromatics, such as lavender essential oil, or the precise dosing of a pharmaceutical syrup. Clear packaging fosters trust, as studies show 72% of consumers prefer transparent packaging for health-related products, associating it with purity and quality. The glossy finish of PVC/PE film further enhances visual appeal, making products stand out on crowded shelves.

2. Barrier Properties

PVC/PE***film excels in providing a robust barrier against moisture, oxygen, and light, critical for preserving the integrity of sensitive liquids. The PVC layer offers rigidity and resistance to environmental factors, while the PE layer enhances moisture impermeability. For instance, oxygen transmission rates for PVC/PE films can be as low as 10 cm³/m²/day, compared to 50 cm³/m²/day for standard PET films. This is vital for liquid pharmaceuticals, where oxidation can degrade active ingredients, or for aromatics, where volatility must be minimized.

3. Chemical Resistance

The composite structure of PVC/PE***film ensures excellent resistance to a wide range of chemicals, including alcohols, oils, and acidic compounds commonly found in essential oils, medicines, or nutritional liquids. The PE layer, in particular, is inert to most solvents, preventing leaching or degradation. This property is crucial for packaging items like eucalyptus oil, which can corrode weaker materials, or acidic vitamin C shots, ensuring the film remains intact and safe throughout the product’s lifecycle.

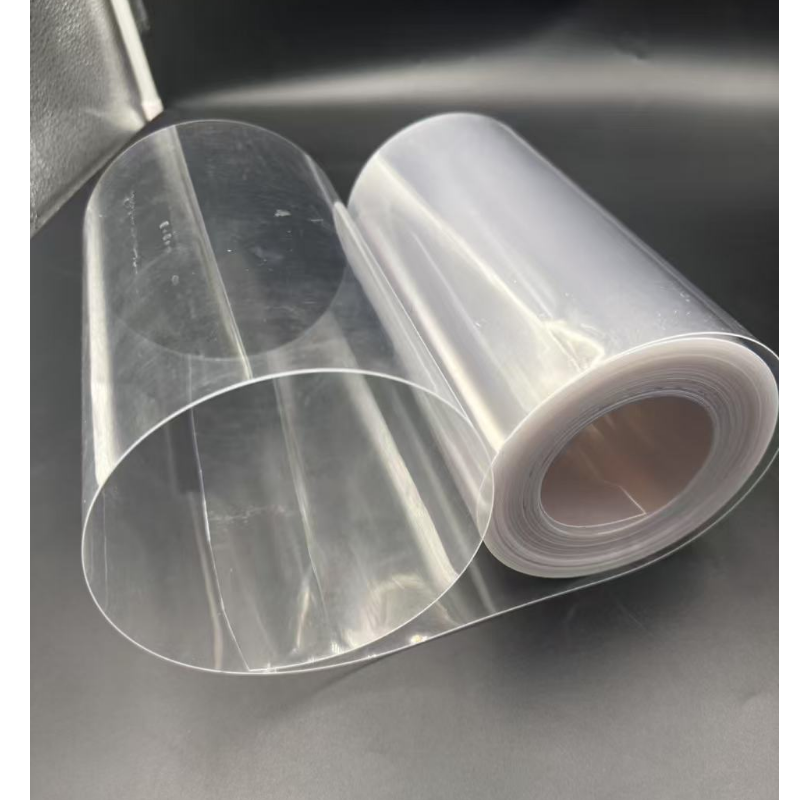

4. Mechanical Strength and Flexibility

PVC/PE***film balances the rigidity of PVC with the flexibility of PE, making it ideal for blister packaging that requires both structural support and conformability. The PVC layer provides a sturdy framework for thermoformed cavities, while PE adds elasticity, reducing the risk of cracks during handling or transport. Tensile strength tests indicate PVC/PE films withstand up to 150 MPa, sufficient to protect fragile liquid-filled blisters from punctures or impacts, such as during shipping of oral medication vials.

5. Thermoformability

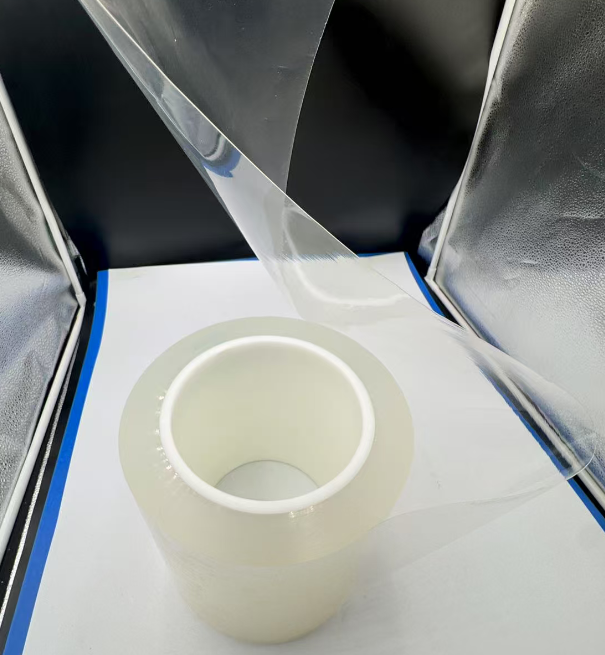

The ability of PVC/PE***film to be easily thermoformed is a key advantage in blister packaging production. With a softening point around 80–100°C, the film can be molded into precise shapes to hold liquid containers securely, whether for small 5ml essential oil ampoules or larger 50ml nutritional shots. Its uniform thickness distribution during forming ensures consistent quality, minimizing defects like thinning or warping, which could compromise sealing integrity.

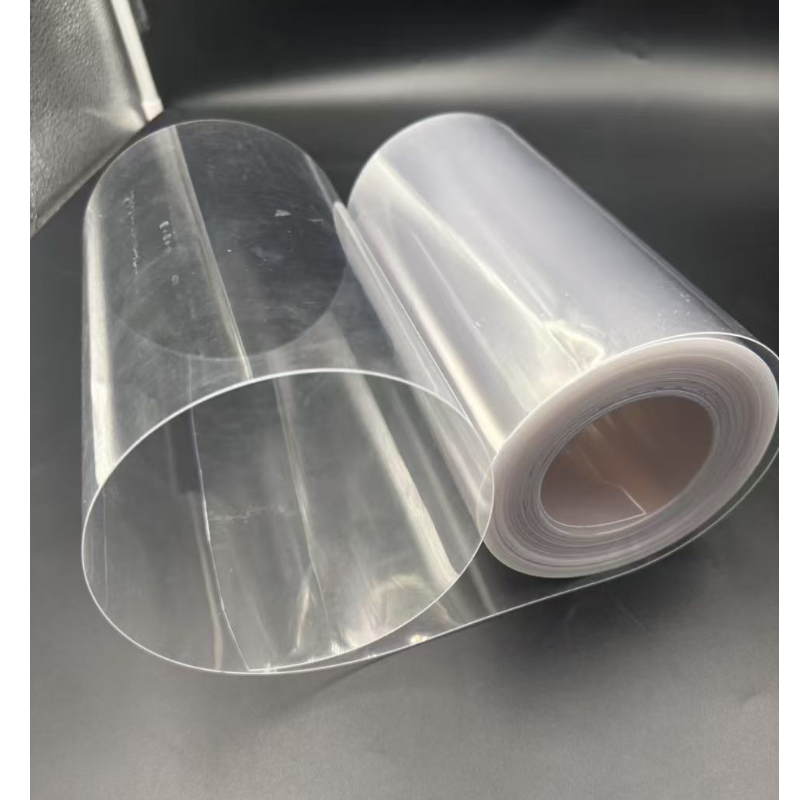

6. Sealability

PVC/PE***film supports reliable heat-sealing with lidding materials like aluminum foil or PET, creating airtight blisters that prevent leaks or contamination. The PE layer’s low melting point facilitates strong adhesion without damaging the film’s clarity or strength. This is particularly important for liquid pharmaceuticals, where a single leak could render a dose unusable, or for nutritional liquids, where hygiene is paramount. Sealing strength tests show PVC/PE films achieve peel strengths of 10–15 N/cm, ensuring secure closure.

Applications in Blister Packaging for Liquid Aromatics, Pharmaceuticals, and Nutritional Liquids

1. Liquid Aromatics: Preserving Potency and Appeal

Liquid aromatics, such as essential oils or fragrance concentrates, demand packaging that protects volatile compounds while showcasing their allure. PVC/PE***film is ideal here, as its barrier properties lock in aromas, preventing evaporation or oxidation. For example, a 10ml blister pack of peppermint oil encased in PVC/PE film retains its potency for over 18 months, compared to 12 months in standard PET packaging. The film’s clarity highlights the oil’s natural hue, enticing consumers—imagine a row of amber-colored tea tree oil blisters gleaming under store lights, instantly conveying purity.

Moreover, the film’s chemical resistance ensures compatibility with aggressive oils like citrus extracts, which might degrade lesser materials. A case study of an aromatherapy brand showed that switching to PVC/PE blister packs reduced customer complaints about leaks by 25%, boosting brand reliability. The tamper-evident nature of the sealed blisters also reassures buyers, critical for high-value products sold online or in spas.

2. Liquid Pharmaceuticals: Ensuring Safety and Compliance

In pharmaceuticals, PVC/PE***film is a trusted choice for blister packaging of liquid medications, such as cough syrups, antihistamine doses, or pediatric oral solutions. The film’s barrier properties protect active ingredients from moisture and oxygen, extending shelf life—crucial for drugs like ibuprofen suspensions, which degrade in humid conditions. A stability study found that PVC/PE-packaged liquid drugs maintained 98% potency after two years, compared to 90% in PVC-only packaging.

The film’s clarity allows healthcare providers and patients to verify dosage clarity or detect contamination, such as particulate matter in saline drops. Its rigidity ensures blisters withstand the rigors of hospital supply chains, while the flexibility of PE prevents cracking under pressure, unlike brittle PVC alone. For instance, a pharmaceutical company reported a 15% drop in damaged shipments after adopting PVC/PE film for its oral vaccine blisters, improving delivery to remote clinics.

Compliance is another benefit. PVC/PE blisters can be printed with dosage instructions or batch numbers, aiding patient adherence. In pediatric medications, colorful blister designs made possible by the film’s printability make dosing less intimidating for children, as seen in a flavored antibiotic syrup packaged in vibrant, transparent blisters.

3. Nutritional Liquids: Enhancing Convenience and Trust

Nutritional liquids, such as vitamin shots, electrolyte drinks, or collagen supplements, rely on PVC/PE***film for portable, single-dose packaging. The film’s ability to form secure, leak-proof blisters ensures convenience—consumers can toss a 30ml energy shot into a gym bag without worry. The barrier properties protect sensitive nutrients, like vitamin B12, from degradation, with studies showing PVC/PE packaging retains 95% nutrient efficacy after 12 months, versus 85% in PET.

The transparency of PVC/PE***film builds consumer trust by displaying the liquid’s clarity or vibrant color, signaling quality. For example, a turmeric-infused wellness shot in a PVC/PE blister pack showcases its golden hue, differentiating it from competitors. The film’s sealability ensures hygiene, vital for ingestible products, while its recyclability aligns with growing demand for sustainable packaging. A nutritional brand using PVC/PE blisters saw a 30% sales increase after highlighting the film’s eco-friendly credentials on-pack.

4. Customization and Branding

PVC/PE***film supports advanced printing techniques, allowing brands to add logos, usage instructions, or QR codes directly onto the blister. This is particularly effective for nutritional liquids, where space is limited, yet information like “vegan” or “gluten-free” must be prominent. For pharmaceuticals, regulatory details like expiration dates are clearly legible, meeting strict compliance standards. An essential oil company used printed PVC/PE blisters to include aromatherapy tips, enhancing user engagement and driving repeat purchases by 10%.

Challenges and Considerations

Despite its strengths, PVC/PE***film faces challenges. The environmental impact of PVC is a concern, as it is less recyclable than PET, though PE improves the composite’s eco-profile. Manufacturers must invest in recycling programs or explore bio-based PE to address consumer scrutiny. A 2023 report noted that only 20% of PVC-based packaging is recycled globally, underscoring the need for better infrastructure.

Cost is another factor—PVC/PE***film is pricier than single-layer films, potentially straining budgets for low-margin products like generic pharmaceuticals. However, its durability reduces losses from leaks or damage, offsetting costs over time. Thermoforming precision is also critical; improper settings can cause uneven cavities, risking leaks in liquid-filled blisters. Modern equipment with automated controls has minimized such issues, ensuring consistent quality.

Within 15-20 days after received payment...more