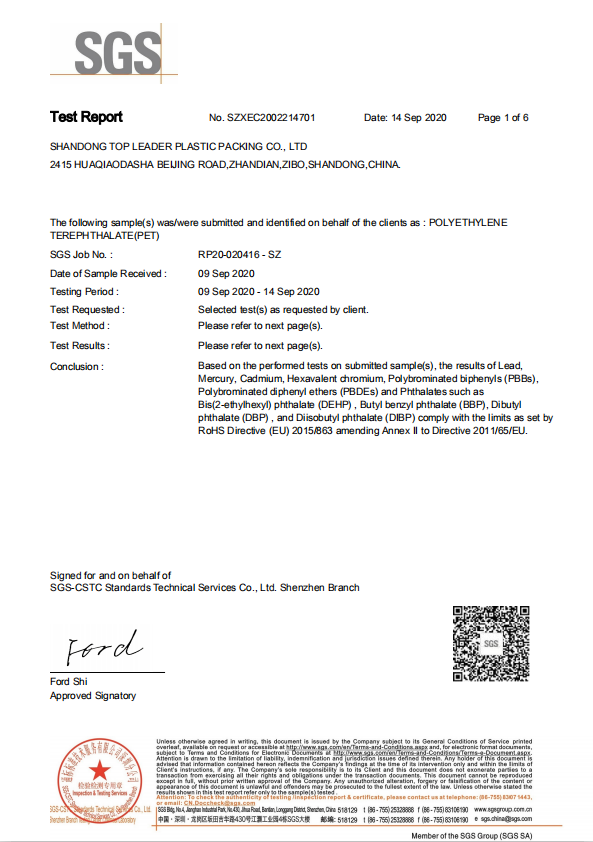

Properties and Applications of Transparent PET Film in Tableware Blister Packaging

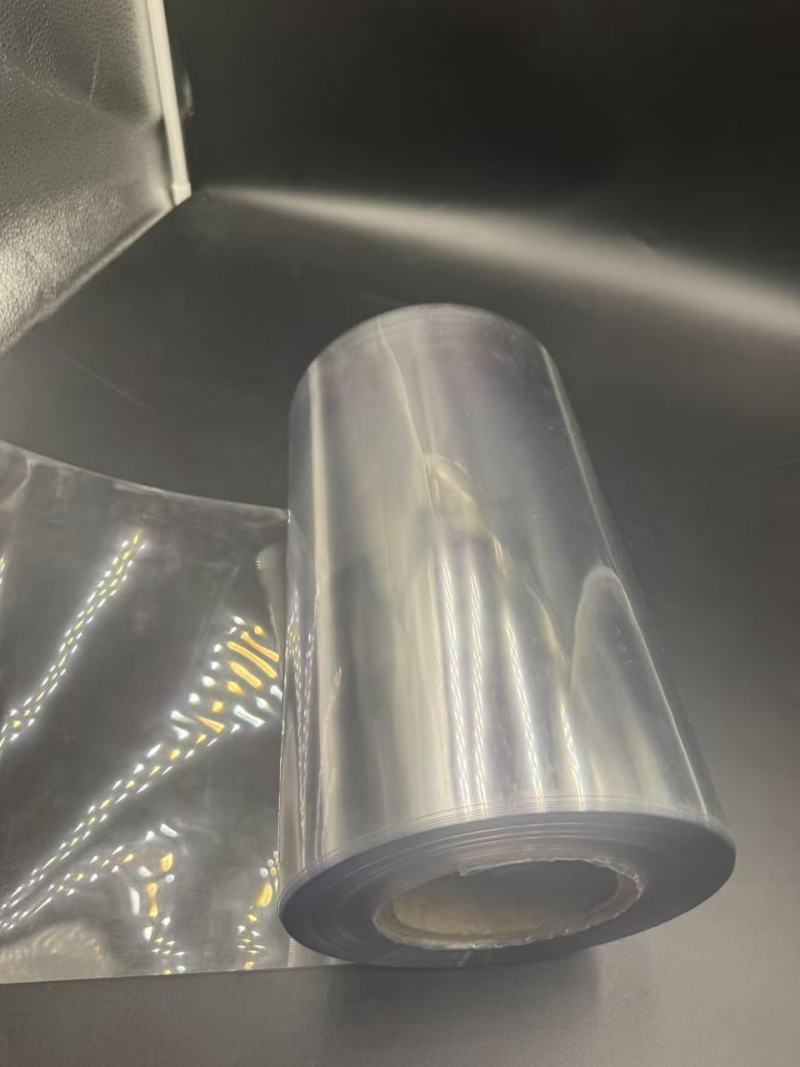

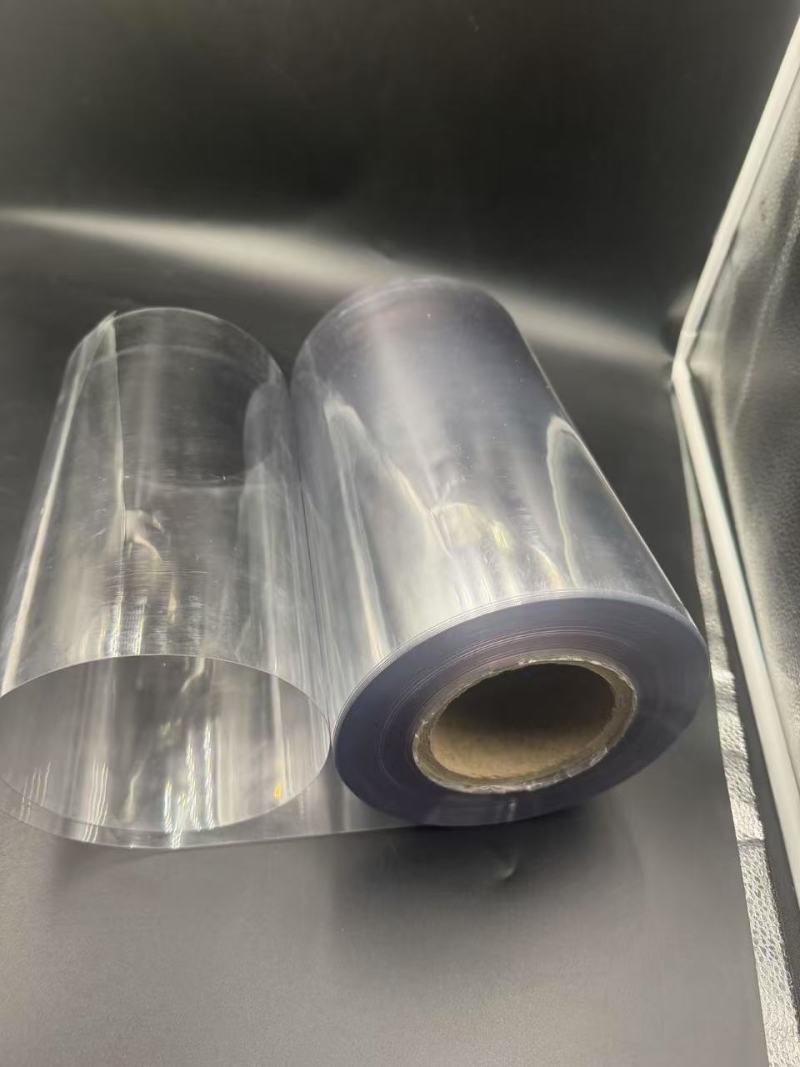

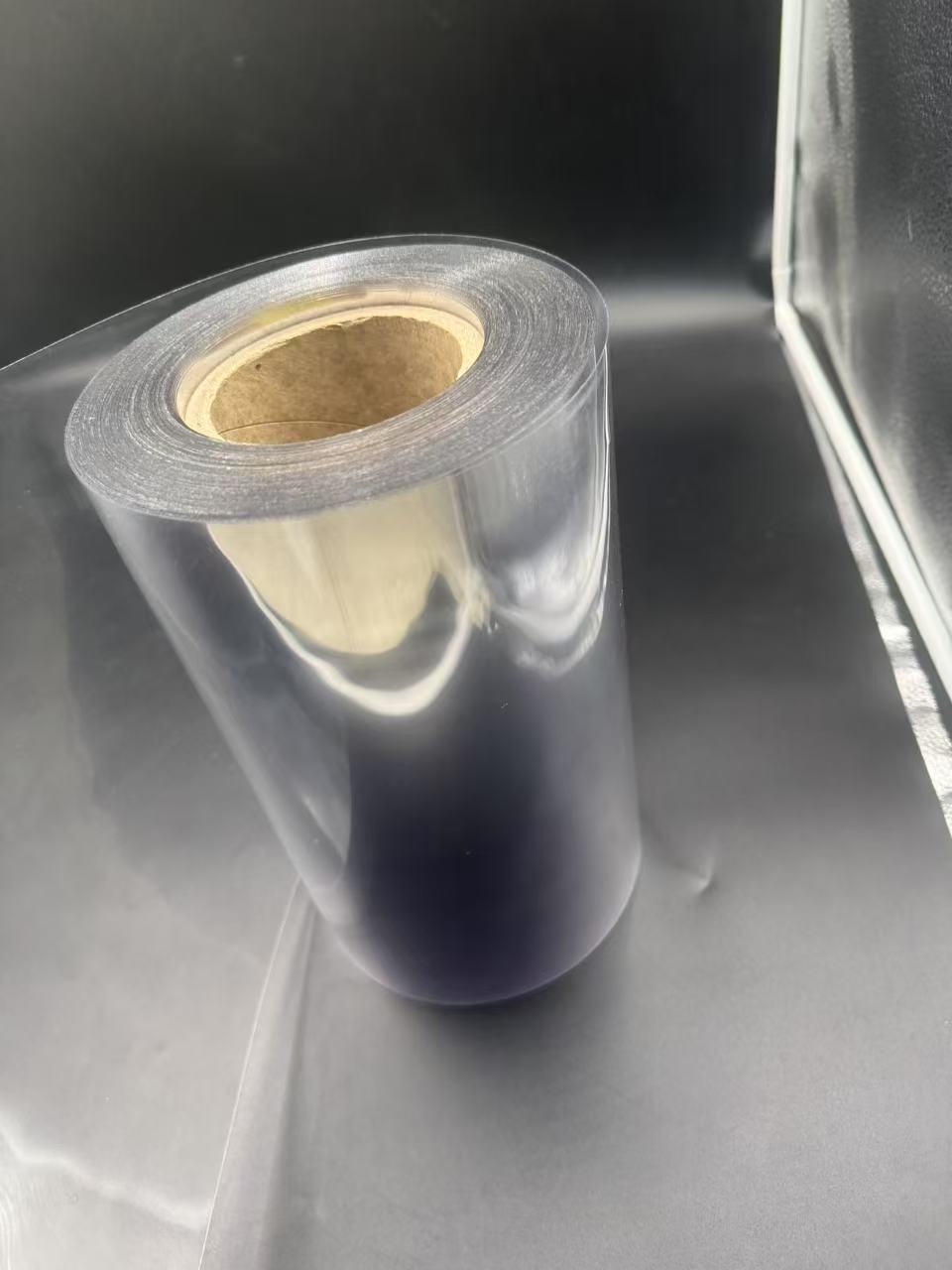

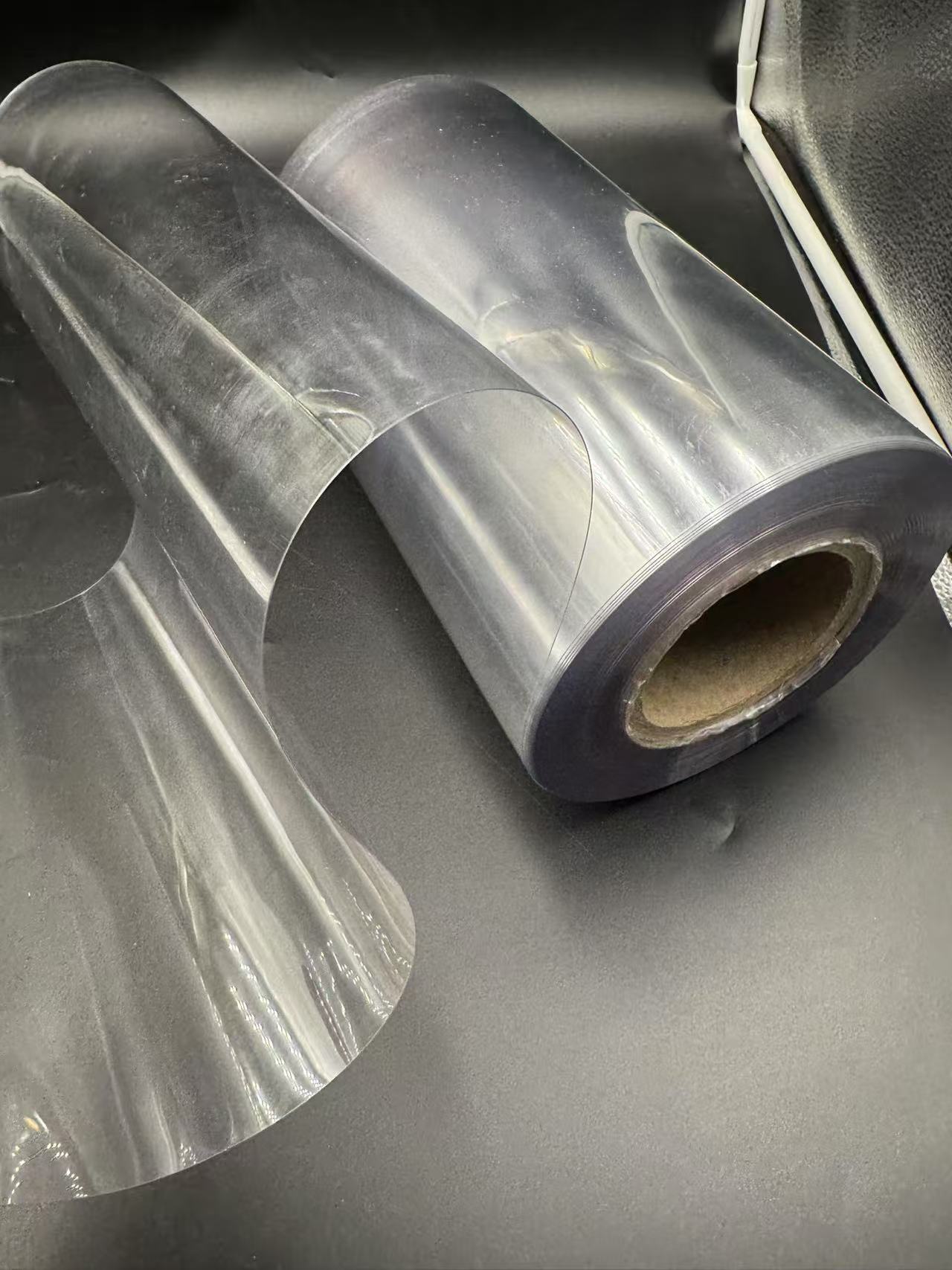

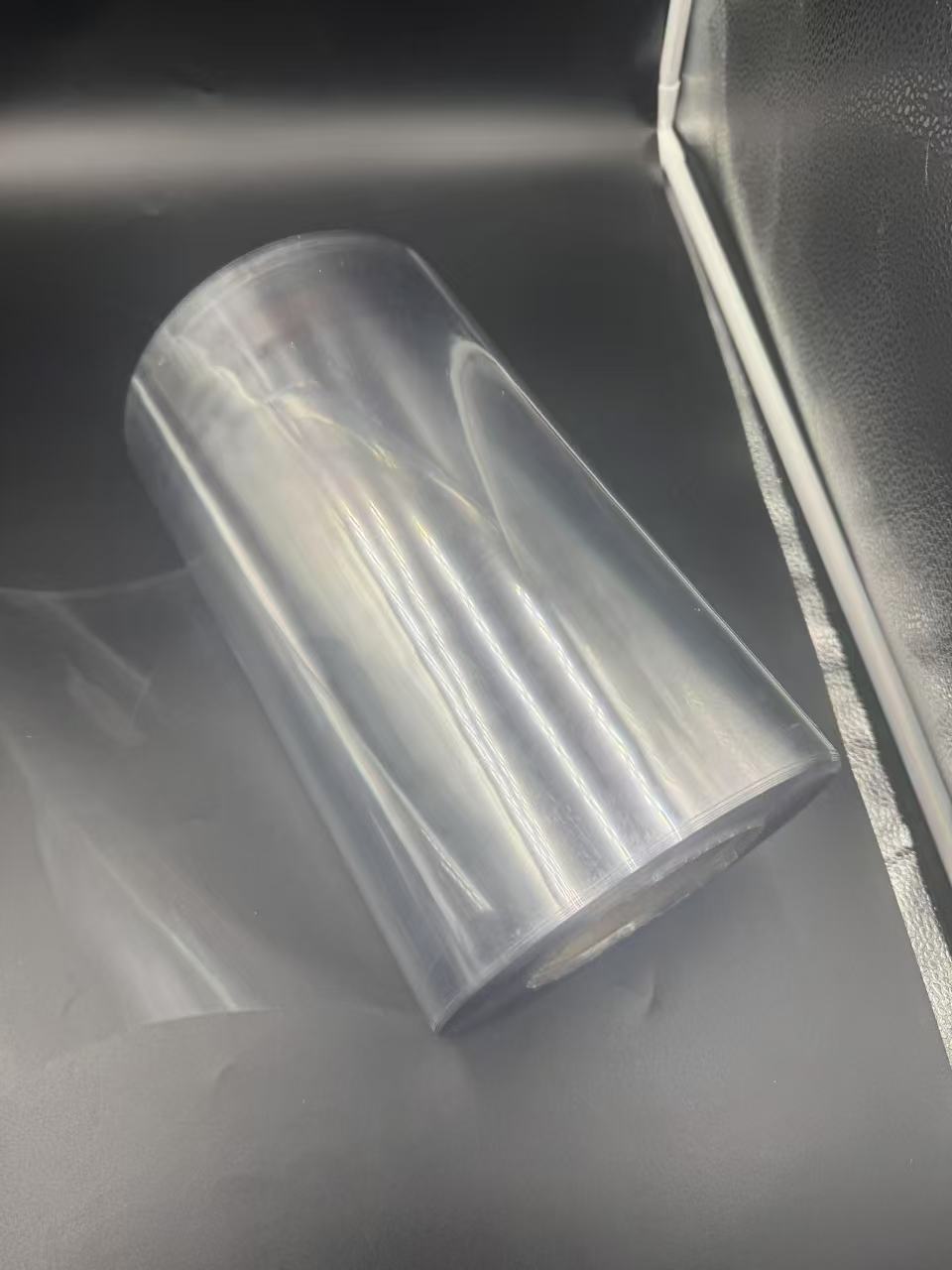

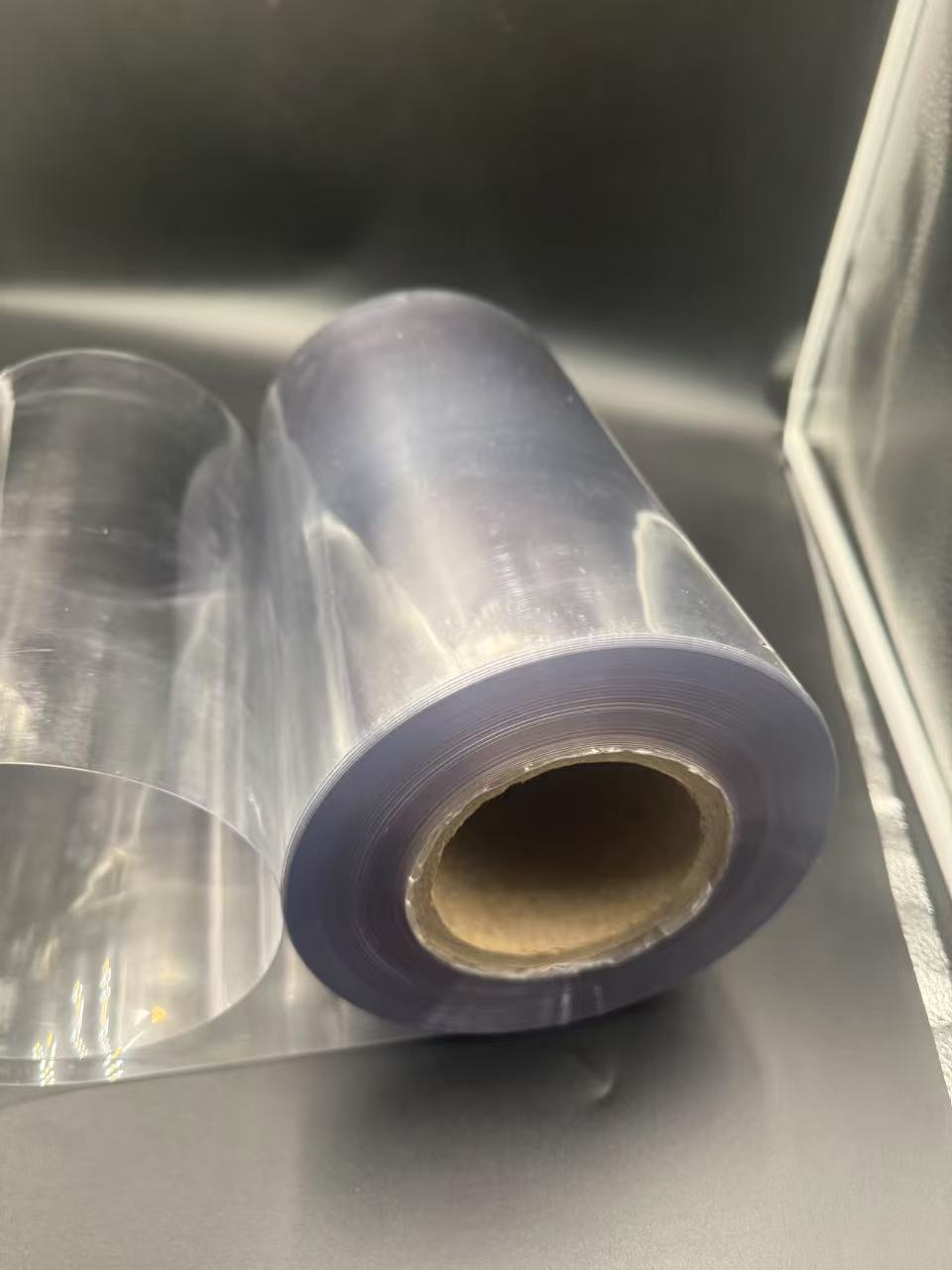

NamePET Plastic film roll

SizeTk:0.1-0.9mm, h100-1200mm

MaterialPET/PP/Customized

Color/printingTransparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

UsageVegetable/Fruit/Meat

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

Transparent polyethylene terephthalate (PET) film is a versatile, high-performance material widely used across industries for its exceptional clarity, strength, and adaptability. In the context of tableware blister packaging, PET film serves as a critical component, offering both aesthetic appeal and functional reliability. This article explores the key properties of transparent PET film and its specific applications in blister packaging for tableware, providing a detailed and evidence-based analysis of its advantages, challenges, and practical uses.

Key Properties of Transparent PET Film

1. Optical Clarity

One of the standout features of transparent PET***film is its crystal-clear appearance. With light transmission rates often exceeding 90%, PET film provides excellent visibility, allowing consumers to view packaged tableware—such as forks, spoons, or plates—without obstruction. This clarity enhances product presentation, making it ideal for retail environments where visual appeal drives purchasing decisions. For instance, a study on consumer packaging preferences found that 78% of shoppers are more likely to choose products with transparent packaging due to the trust and quality perception it fosters.

2. Mechanical Strength

PET***film boasts remarkable tensile strength and impact resistance, ensuring that blister packaging remains intact during transportation, storage, and handling. Its ability to withstand mechanical stress is particularly valuable for tableware, which often includes sharp or rigid items like knives or ceramic plates. The film’s toughness prevents cracks or punctures, maintaining the integrity of the package. Data from material testing indicates that PET film has a tensile strength of approximately 200 MPa, significantly higher than alternatives like PVC (around 50 MPa).

3. Thermal Stability

Transparent PET***film exhibits excellent thermal stability, with a melting point around 250°C and a glass transition temperature of about 70°C. This allows it to endure the heat-forming processes used in blister packaging production, such as vacuum forming or thermoforming, without deforming or losing clarity. Additionally, PET film retains its properties across a wide temperature range, making it suitable for packaging tableware that may be exposed to varying environmental conditions during distribution.

4. Chemical Resistance

The chemical inertness of PET***film is another critical advantage. It resists degradation from common substances like oils, grease, and mild acids, which may come into contact with tableware packaging during use or storage. This property ensures that the film remains visually appealing and structurally sound over time, even in challenging environments. For example, PET film’s resistance to cleaning agents makes it ideal for reusable tableware sets that require frequent washing.

5. Barrier Properties

While PET***film is not as impermeable to gases as some specialized materials, it offers sufficient barrier properties against moisture and oxygen for tableware packaging. This helps protect items like disposable cutlery or delicate glassware from humidity-related damage, extending shelf life. Modified PET films, such as those with EVOH (ethylene vinyl alcohol) coatings, can further enhance barrier performance if needed for specific applications.

6. Recyclability

Sustainability is a growing concern in packaging, and PET***film shines in this regard. It is fully recyclable, with established recycling streams in many regions. Recycled PET (rPET) can be reprocessed into new films without significant loss of quality, reducing environmental impact. According to the PET Resin Association, over 1.8 billion pounds of PET were recycled in the U.S. alone in 2022, highlighting its eco-friendly potential. For tableware packaging, using rPET film aligns with consumer demand for sustainable products.

Applications in Tableware Blister Packaging

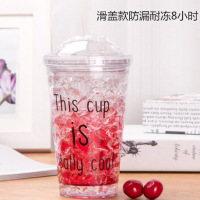

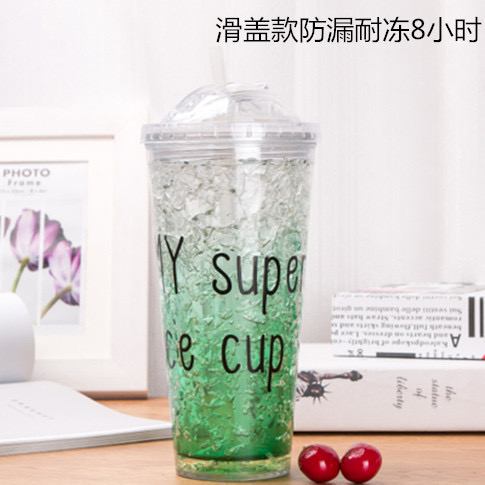

1. Aesthetic Enhancement

In retail, the visual presentation of tableware is paramount. Transparent PET***film enables blister packaging that showcases the design, color, and quality of items like cutlery sets or dinnerware. For example, a high-end stainless steel fork set encased in a PET blister pack appears sleek and premium, inviting closer inspection. The film’s glossy finish and ability to conform to intricate shapes enhance the overall aesthetic, creating a polished look that competitors like opaque or semi-transparent materials struggle to match.

2. Protection During Transit

Tableware, particularly fragile items like glass plates or delicate ceramic bowls, requires robust packaging to prevent damage during shipping. PET***film’s strength and flexibility make it an ideal choice for blister packs that securely encase each item. The film forms a tight, custom-fit barrier around the product, reducing movement and absorbing minor impacts. A logistics study found that blister packaging with PET film reduced product damage rates by 30% compared to traditional cardboard or foam alternatives.

3. Tamper-Evident Design

Security is a key concern in tableware packaging, especially for disposable or single-use items used in food service. Transparent PET***film supports tamper-evident designs, where any attempt to open the package leaves visible marks, such as tears or distortions. This feature reassures consumers about product safety and hygiene, particularly for items like plastic spoons or forks intended for catering. The clarity of PET film ensures that tampering is immediately noticeable, unlike opaque materials that may obscure such evidence.

4. Customization and Branding

PET***film is highly adaptable to printing and labeling techniques, allowing brands to customize blister packaging with logos, product details, or promotional graphics. For instance, a company selling eco-friendly bamboo cutlery can print sustainability certifications directly onto the PET film, reinforcing its brand message. The film’s smooth surface supports high-resolution printing, ensuring that text and images remain sharp and vibrant, even after prolonged shelf exposure.

5. Cost-Effectiveness

While PET***film may have a higher upfront cost than materials like PVC, its durability and versatility lead to long-term savings. The film’s ability to protect tableware reduces returns due to damage, and its lightweight nature lowers shipping costs. Additionally, the recyclability of PET film aligns with regulations in many regions, avoiding potential fines or restrictions associated with non-recyclable materials. A cost analysis by a packaging firm showed that PET-based blister packs lowered overall expenses by 15% compared to polystyrene alternatives over a five-year period.

Challenges and Considerations

Despite its advantages, transparent PET***film is not without challenges. One issue is its relatively higher cost compared to PVC or PP films, which may deter budget-conscious manufacturers. However, the long-term benefits—such as reduced product damage and enhanced brand appeal—often outweigh this drawback. Another consideration is the need for precise control during thermoforming to avoid defects like uneven thickness or clouding, which can compromise clarity. Advances in manufacturing technology, such as automated temperature regulation, have largely mitigated these risks.

Environmental concerns also warrant attention. While PET***film is recyclable, improper disposal can contribute to plastic waste. Manufacturers must educate consumers about recycling protocols and invest in rPET to close the loop. Additionally, for applications requiring high gas barriers (e.g., packaging for moisture-sensitive items), PET film may need coatings or laminations, which can complicate recycling. Ongoing research into bio-based PET films offers promise for addressing these sustainability challenges.

Real-World Examples

To illustrate the impact of PET***film, consider a leading tableware brand that switched to PET blister packaging for its disposable cutlery line. The transparent film highlighted the sleek design of the forks and spoons, boosting sales by 20% due to improved shelf appeal. The packaging’s durability also reduced breakage complaints, enhancing customer satisfaction. Similarly, a catering supplier adopted PET film for its glass plate packaging, leveraging the film’s clarity to showcase intricate designs while ensuring safe delivery to event venues.

Another case involves a sustainable tableware startup using rPET***film for its bamboo cutlery sets. By emphasizing the recycled content on the packaging, the brand attracted eco-conscious consumers, leading to a 35% increase in market share within a year. These examples demonstrate how PET film combines functionality with marketing potential, driving both practical and commercial success.

Future Trends

The future of transparent PET***film in tableware blister packaging looks promising, driven by innovations in material science and consumer preferences. Developments in bio-based PET, derived from renewable sources like sugarcane, aim to reduce reliance on fossil fuels while maintaining performance. Additionally, smart packaging technologies—such as QR codes printed on PET film for product traceability—are gaining traction, offering brands new ways to engage customers. As sustainability regulations tighten, the adoption of rPET and closed-loop recycling systems is expected to grow, further solidifying PET film’s role in eco-friendly packaging.

Within 15-20 days after received payment...more