LDPE /HDPE713 protection films for planting house and goods , furnitures cover protections

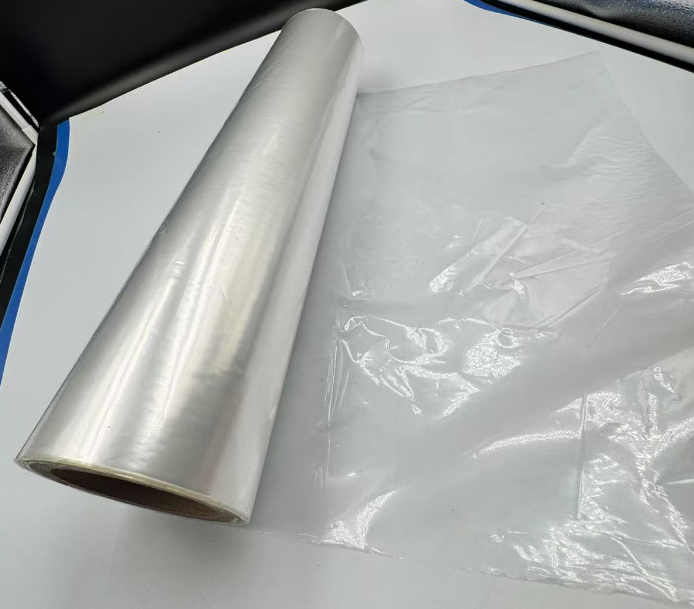

Material: LDPE film

Thickness 0.030mm/customization

Size: 1500mm/Customization

GRADE: TOP grade film

color: white/translucent customization

location: china

usage:for planting, furniture,flooring, goods protection

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

LDPE and HDPE Films: Versatility in Applications across Different Aspects

I、Introduction to LDPE and HDPE Films

Polyethylene, one of the most utilized polymers in the plastics industry, comes in various forms. The two most commonly used are Low-Density Polyethylene, known as LDPE, and High-Density Polyethylene, known as HDPE. LDPE and HDPE films have different characteristics, thus finding applications in quite varied fields.

LDPE is manufactured at high pressure and temperature, which yields a polymer with relatively lower density and more branched molecular structure. It is this branched structure that imparts characteristic flexibility and transparency to LDPE. It finds usage in applications requiring softness and stretchability, for example, in packaging films for food items, providing an excellent barrier to contents and allowing the consumer to view the contents of the pack clearly.

In contrast, HDPE is synthesized at low pressure with a more linear molecular configuration, which gives it higher density and crystallinity. HDPE films have the reputation for high strength and toughness. Because it is often used for purposes involving much torture by, and resistance against environmental factors, such as for construction films that are protective of building materials against moisture and UV radiation, heavy-duty packaging where contents inside have to be well-cocooned against their usual hazards during transportation and storage.

The manufacturing process for LDPE and HDPE films involves various methods of extrusion, wherein the molten polymer is forced through a die to produce a continuous film. Additives may be incorporated during production to enhance specific properties, such as UV stabilizers to improve resistance to sunlight degradation or slip agents to reduce surface friction.

These films are playing a vital role in modern society. They are contributing much in the field of goods' preservation and protection, easy packaging and storage, and are also widely used in many industries such as agriculture, building and construction, food and beverage, and consumer goods. Understanding the properties and applications of both LDPE and HDPE films will be useful for the manufacturers, engineers, and consumers in decision-making regarding the selection of materials and their usage.

II. Differences between LDPE and HDPE Films

1. Physical Properties

One of the major differences between LDPE and HDPE films is in their physical properties. LDPE has a lower density, normally between 0.910 and 0.940 g/cm³, which allows it to be very flexible. This flexibility enables LDPE films to be stretched and bent without breaking, hence suitable for applications requiring a high degree of conformability. LDPE films, for example, can wrap snugly around the product in the packaging of food items with irregular shapes, such as fruits and vegetables, thereby providing a tight yet gentle seal. Besides, LDPE films exhibit a relatively high degree of transparency that can enable consumers to clearly view the contents inside the package. This property is highly valued in the food and consumer goods industries, as it enhances the visual appeal of the product and allows for easy inspection.

In contrast, HDPE films possess a higher density, usually between 0.941 and 0.960 g/cm³, resulting in greater rigidity and strength. HDPE films are significantly tougher and more resistant to punctures and tears compared to LDPE films. This robustness makes them suitable for heavy-duty packaging applications, such as in the shipping and storage of industrial equipment, where the contents need to be protected from external forces and rough handling. However, HDPE films are less transparent than LDPE films, having a more opaque or milky appearance. This reduced transparency is due to the higher crystallinity of HDPE, which scatters light more effectively.

2. Chemical Resistance

Resistance properties for LDPE and HDPE films against chemicals are very good, but partial resistance varieties are observed for individual films in specific substances. Generally, LDPE resists most acids, a broad variety of alcohols, bases, and esters. It is resistant against many common food acids like citric acid, acetic acid, and also the range of alcohols that are used within food and pharmaceutical applications. The resulting resistance makes the LDPE films quite suitable for packaging the food products that are highly acidic or alkaline since it serves to preserve the freshness and integrity of the content. The LDPE also shows very good resistance to aldehydes, ketones, and vegetable oils, though not as great in certain cases as compared to HDPE.

HDPE, for its part, is resistant to hydrocarbons, solvents, and most of the chemicals that a product is generally exposed to in an industrial environment. It is very resistant to gasoline, diesel fuel, and a lot of aromatic and chlorinated hydrocarbons. The fact itself makes HDPE films suitable for applications with expected exposure to such chemicals in the packaging of chemicals, pesticides, and fertilizers. The chemical resistance of HDPE extends to durability in bad weather conditions; it doesn't degrade from UV radiation and moisture. For this reason, HDPE is widely used outdoors in geomembranes for landfills and in pond liners. 3. Melting Points There are significant differences between LDPE and HDPE film melting points. LDPE exhibits a relatively low melting point, usually between 105°C to 115°C. This lower melting point allows LDPE to be processed at lower temperatures, which is advantageous in certain manufacturing processes. It enables the use of LDPE in heat-sealing applications where a lower temperature is required to avoid damaging heat-sensitive products. For example, in the packaging of chocolates or other confectionery items that have a low melting point, LDPE films can be heat-sealed without melting the contents.

In contrast, HDPE has a higher melting point, usually between 130°C and 135°C. The higher melting point of HDPE gives it greater heat resistance, making it suitable for applications where the film may be exposed to higher temperatures during use or processing. HDPE films can withstand the heat generated during sterilization processes, such as in the packaging of medical devices or food products that require high-temperature treatment. This property also makes HDPE more suitable for applications where the film needs to maintain its structural integrity in hot environments, such as in automotive parts or hot water pipe insulation.

III、Industrial Applications of LDPE Films

1. Packaging Industry

LDPE films have found extensive use in the packaging industry due to their excellent flexibility and good moisture resistance. In the packaging of food items, LDPE films are widely used for wrapping different products. For example, they are suitable for packaging fresh produce such as fruits and vegetables. The flexibility of LDPE film allows it to conform well to the irregular shapes of such items, providing a close wrapping that maintains freshness by preventing loss of moisture and excluding air contaminants. LDPE films are also utilized in the packaging of baked goods, such as bread and pastries. Their soft and pliable nature ensures that the delicate texture of the baked items is not damaged during the packaging process. Besides, the transparency of LDPE films enables consumers to clearly see the contents, which is an important factor in attracting customers and allowing them to assess the quality and appearance of the food.

LDPE films are used to package components and products within the electronics industry. This helps protect against dust, moisture, and static electricity. For example, minor electronic components like chips and connectors are commonly packaged in LDPE films to avoid possible damage during storage and transport. The films create a barrier that protects the sensitive electronic components from environmental factors, which may affect their performance. LDPE films find a wide range of packaging applications in the consumer goods industry, from toys to household products. They are used to create blister packs for small items, providing a clear and protective enclosure. The flexibility of LDPE films allows for easy shaping and molding around the products, creating an attractive and functional packaging solution. LDPE films are also widely used in the manufacture of flexible packaging materials such as pouches and bags. These are popular for packaging snacks, liquids, and other consumer products since they are lightweight, easy to handle, and can be customized in terms of size and shape.

LDPE films also play an important role in the manufacture of industrial liners and protective covers. In the line of industry, LDPE films are mainly used as linings of containers and tanks. Such as, in the chemical industries for lining drums and barrels carrying any kind of chemical because it is highly resistant to various chemical attacks: LDPE may resist its degradation when in contact with most kinds of chemicals without degradation or chemical attack. LDPE films are also used in the manufacture of machinery and equipment protective covers. These covers protect the equipment from dust, dirt, and moisture, hence giving them a longer life. This also cuts down on the frequency of maintenance and repairs needed for such equipment. The strength and flexibility of LDPE films make them quite suitable for such protective uses since they can be easily cast over and tied around the equipment.

2. Agricultural Sector

In the agricultural sector, LDPE films are widely used for making greenhouse films and mulch films. Greenhouse films made from LDPE are essential for creating a controlled environment for plant growth. The transparency of LDPE allows sunlight to penetrate through the film, providing the plants with the necessary light for photosynthesis. While doing this, the film prevents heat from escaping outside the greenhouse, hence providing a warm microclimate. This is very helpful during cold weather or in colder regions of the world, and it allows farmers to grow those plants that cannot survive under the temperature outside the greenhouse. LDPE greenhouse films offer protection to the plants from the rough weather conditions of wind, rain, and hail. They break the turgid gusty winds reaching the plants, which would have their leaves and stems broken by the impact. In a similar vein, they sometimes prevent the excessive evaporation of water from the ground, which may result in constant soil moisture, as very necessary for plant growth.

Mulch films are put on the ground where the plant is growing. The primary uses of LDPE-mulch films include several important ones. Firstly, they help to suppress weed growth by blocking sunlight from reaching the weed seeds, thereby preventing them from germinating. This reduces the competition for nutrients, water, and sunlight between the weeds and the cultivated plants, leading to improved crop yields. Secondly, LDPE mulch films help to conserve soil moisture by reducing evaporation. The film forms a barrier over the soil, preventing water from escaping into the atmosphere. This is very important, especially for the arid and semi-arid regions of the world. Thirdly, the application of LDPE mulch films may bring about an increase in the soil temperature. Black-colored LDPE mulch film absorbs sunlight and warms the soil, thus possibly promoting earlier plant growth and maturity. In summary, the properties of LDPE films play a vital role in plant growth and soil protection in agricultural uses.

IV、HDPE Films Used in Industry

1. Heavy-Duty Packaging

HDPE films are used in the manufacture of heavy-duty packaging because of their high strength and durability. They can resist mechanical stress to a considerable extent, hence are suitable for packaging items that require higher strength and durability during transportation and storage. HDPE films have various applications, packaging different substances in the industrial chemicals sector. Applications could be made on packaging corrosive chemicals such as acids and bases. Since HDPE has excellent resistance to chemicals, it prevents its reaction with the chemicals hence it provides a very safe and reliable method of packaging. The films are also used on packages for construction materials. All products from the likes of steel rods to metal sheets and even to building blocks are then able to be wrapped into HDPE films, giving total scratch protection against moisture or any other environmental phenomenon. The toughness of the HDPE films prevents puncture or tear even when laid out against sharp edges or generally rough surfaces of packaged material. Besides, HDPE film packaging is often required to package large and heavyweight machinery parts. These can be tailor-made to suit the dimensions of the parts for a tight and close wrap that prevents damage when handling and shipping. With high tensile strength, HDPE allows the film to bear the weight and tension that comes with moving and storing these heavy components.

2. Geomembranes in Environmental Protection

HDPE films are a common material in environmental protection projects as geomembranes. HDPE geomembrane plays a very important role in landfills for lining the bottom and sides of cells. The excellent impermeability prevents leakage of a liquid called leachate, which is formed out of the decomposition of discarded wastes containing harmful substances. Because of HDPE geomembrane, the leachates confined within the landfill do not contaminate the local soil and groundwater. Similarly, HDPE geomembranes are used in the wastewater treatment plants for varied applications. They can be used to line the treatment ponds and basins so that there is no percolation of wastewater through the ground. This prevents the deterioration of the integrity of the treatment process; thus, the treated water will be of the required standards. HDPE geomembranes are also used for reservoir linings. They conserve water by reducing seepage loss from the reservoir, which is of particular importance in areas where water is in short supply. The durability and chemical stability of HDPE geomembranes make them suitable for long-term exposure to the generally harsh conditions found in these environmental protection applications. They can resist UV radiation, temperature fluctuations, and the chemical effects of the substances in contact with them and provide a reliable and long-lasting solution for environmental protection.

V、Daily Life Applications of LDPE Films

LDPE films are found everywhere around us, playing an important role in everyday life for their unique combination of properties. One of the most common manifestations of LDPE films is in the form of plastic bags. These bags come in a host of sizes and thicknesses for a variety of purposes: from carrying groceries to storing and moving personal items, their softness and flexibility make them easy to handle and fold while their durability ensures that they are able to withstand a reasonable amount of weight and stress. The ability of LDPE films to be sealed easily by heat or adhesive strips is an added reason for using them as a packaging material. For instance, used in food packaging, these LDPE bags keep their contents fresh, protect them against external contaminants, and allow a convenient way of storing or transporting them.

Another familiar usage of LDPE films in everyday life is as wrappings and cling films of food. These are thin, transparent films used in the kitchen for covering food items and preserving them. The clinginess in LDPE films is due to their static charge; hence, these can stick to almost anything, whether glass, plastic, or metal, and are perfect for wrapping leftovers, covering bowls and plates, and protecting food in the refrigerator from drying out or taking on odors. The transparency of LDPE food wraps also provides users with the ability to easily view the contents without necessarily having to open a package. This saves time and minimizes wastage. Secondly, LDPE films are chemically non-reactive to food substances and hence keep the items to be wrapped safe and fresh.

Other than plastic bags and food wraps, LDPE films are used in a variety of other everyday items. Other LDPE disposable tableware includes cups, plates, and cutlery. Being lightweight and not expensive, they are ready for use in all picnic and outdoor parties. It finds application in food contact due to its resistance to moisture and chemicals, thus avoiding the absorption of liquids into the product and the leaching of harmful components from the packaging into food. Besides that, small containers for leftovers, snacks, or other household items are made from LDPE films. These can be flexible, collapsible containers that occupy minimum space when not in use and can be easily sealed for keeping the contents fresh and intact. Their transparency allows ease in locating and identifying what is stored. VI、HDPE Films Applied in Our Daily Life

HDPE films are also very much present in our everyday lives, especially where the application requires strength and durability. Garbage bags are one of the most common uses of HDPE films. These are manufactured in such a way that they can bear the weight and sharp edges of various waste products without tearing or puncturing. The high strength of HDPE films means that they can carry substantial weights, thus making them useful for both household and commercial waste disposal. Resistance of HDPE to moisture and chemicals ensures that the bags do not leak or degrade upon contact with various kinds of wastes, which prevents environmental contamination.

The other application with which people are more familiar is shopping bags made from HDPE films. These bags are often used by grocery stores and other retailers due to their durability and reusability. HDPE shopping bags can carry a substantial amount of groceries and other items without breaking, providing a convenient and reliable means of transporting purchases. Their toughness also enables them to be reused multiple times, reducing the need for single-use plastic bags and contributing to environmental sustainability. These added features are used on some of the HDPE shopping bags that come in reinforced handles and/or gussets in order to give this type of product more strength as well as functionality.

Within the home, HDPE films are part of the storage bins and containers manufacturing process. Containers made out of HDPE are designed for storing anything from clothes, toys, to even various tools and types of food. The rigidity and strength of HDPE films make them ideal for creating durable storage solutions that can withstand the weight and pressure of the stored items. HDPE storage bins are often stackable, allowing for efficient use of space in closets, garages, and other storage areas. They are also resistant to moisture and pests, helping to protect the stored contents from damage. Moreover, the smooth surface of HDPE films makes them easy to clean and maintain, ensuring that the storage bins remain in good condition over time.

VII、Medical and Pharmaceutical Applications of LDPE Films

LDPE films are widely used in medical and pharmaceutical packaging due to their nontoxic nature and excellent barrier properties against moisture and air. They are widely used in the medical field to package disposable medical devices like syringes, needles, and catheters. The flexibility of LDPE allows for easy shaping and conformation to the contours of these devices, providing a snug and protective enclosure. For instance, LDPE films can be heat-sealed into sterile pouches used for surgical instruments to maintain them free from contamination at use. LDPE is also applied in the packaging of certain pharmaceutical products, such as tablets and capsules. It can serve as a barrier to moisture, which plays an important role in keeping drugs stable and potent; that is, it will prevent degradation resulting from the effects of humidity.

LDPE films make very significant contributions to the integrity and sterility of medical and pharmaceutical items during storage and transportation. They provide a very trusted guard against external impurities such as bacteria, viruses, and dust particles. This is important in keeping off infections and ensuring that the patient is safe from them. Besides, the LDPE films can be produced to have tamper-proof characteristics, such as tear strips or seals, enabling visible evidence whether the package has been opened or compromised. This helps to ensure the chain of custody and integrity of the medical products, thereby giving confidence to the healthcare providers and consumers of the quality and safety of the items they use.

VIII. Medical and Pharmaceutical Applications of HDPE Films

HDPE films have huge and significant applications in the medical and pharmaceutical fields. They are normally used in the production of medical containers, including medicine bottles and larger packaging of medical equipment. HDPE's excellent chemical resistance is considered paramount in these applications because it ensures that the container does not react with the contents, be it some pharmaceutical drugs or even medical devices. This resistance helps maintain the integrity and potency of the medications and protects the quality and sterility of the medical equipment. As such, HDPE bottles are widely used for storing tablets, capsules, and liquid medications. The toughness of HDPE films provides a reliable shield against external impacts during handling, transportation, and storage, reducing the risk of damage to the delicate medical products inside.

Hygiene and safety are of utmost importance in medical and pharmaceutical applications, and HDPE films satisfy these strict requirements. HDPE is a non-toxic material that does not migrate harmful substances into the content, hence safe for usage in contact with drugs or any other medical device. The manufacturing processes of HDPE films for medical applications follow strict quality control and sterilization standards. These features, such as tamper-evident seals in the films, help assure integrity for medical products and provide confidence for healthcare providers and patients. Besides this, HDPE films offer resistance to moisture and bacteria, which helps in preventing items from contamination and keeps up their sterility. This is most critical in the case of surgical instruments and other sterile medical devices that need protection from microbial growth and environmental pollutants. Overall, HDPE films play a vital role in safeguarding the quality, safety, and efficacy of medical and pharmaceutical products.

IX、Construction and Building Applications of LDPE Films

1. Vapor Barriers and Waterproofing Membranes

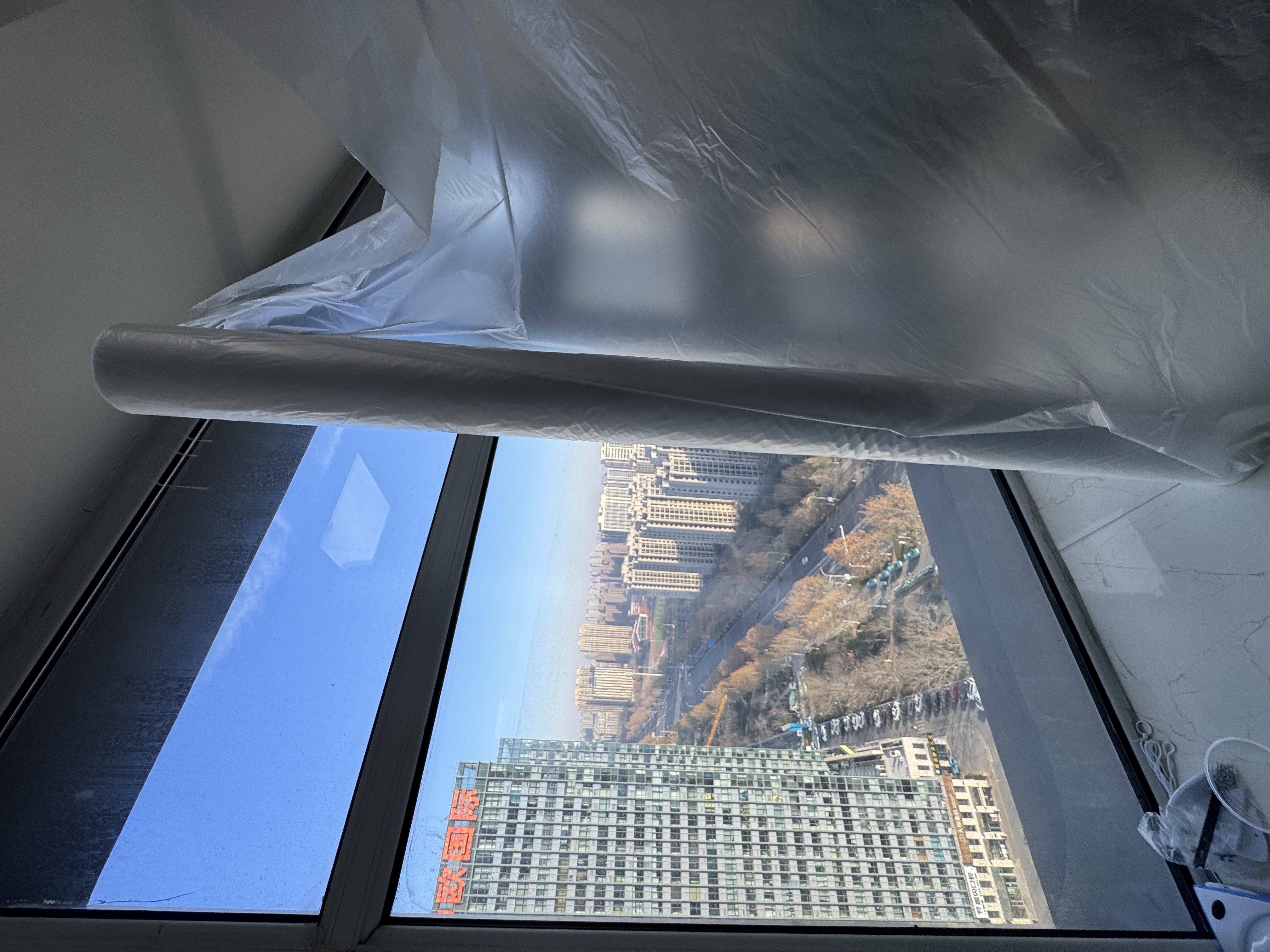

LDPE films are widely used in building construction as vapor barriers and waterproofing membranes. The low permeability to water vapor makes them useful in preventing moisture from seeping into the structure of buildings. LDPE films are used to shield with reliability and, therefore, help in protecting the structural integrity of buildings by reducing possible damage caused by moisture that may result in rotting, mold growth, or corrosion. That is particularly crucial in high humidities or where the differences in vapor pressure are greater between the interior and the exterior of the building. In such places, basements, and crawl spaces, LDPE films create one continuous barrier to prevent the intrusion of moisture for maintaining a dry and stable environment. Besides that, LDPE films are also used in roofing to prevent water from seeping into the structure, increasing its durability and lifespan. Their flexibility allows them to be laid on roofs of irregular surfaces, which turns out to be effective in waterproofing. Furthermore, the application of LDPE films as a vapor barrier could also help promote energy efficiency within buildings. By reducing moisture infiltration, they maintain a more consistent indoor temperature, hence reducing the need for excessive heating or cooling and lowering energy consumption in the process.

2. Interior Decoration Materials and Temporary Protection

LDPE films also find their application in certain interior decoration materials. They can be used as a protective layer or backing for wallpapers and wall coverings. The smooth surface of LDPE films provides a stable base, allowing wallpapers to adhere more easily and evenly. It also helps to protect the underlying wall surface from damage during the installation and removal of wallpapers. Besides, LDPE films are sometimes incorporated into decorative laminates and panels, enhancing their durability and resistance to scratches and moisture. During construction processes, LDPE films serve as temporary protection for various surfaces. They are used to protect floors, countertops, and fixtures from scratches, soiling, or damage that may be caused by the construction activities. For example, in a newly being built building, LDPE films are spread on the newly laid hardwood floors to protect them from the impact of heavy construction equipment and from the debris produced during the construction process. Similarly, LDPE films are utilized at renovation sites to avoid paint splatters, dust, and other potential damages on kitchen countertops and bathroom fixtures. The ease of applying them and removing them easily and conveniently makes them good to use for temporary protection and can be replaced as soon as they get torn off or soiled during the construction period.

X、Construction and Building Applications of HDPE Films

1. Use in Underground Structures

HDPE films have very impressive anti-seepage characteristics and durability, thus are in high demand in underground structures. In the basement, for instance, waterproofing is done by laying HDPE films on the walls and floors of the basement continuously to block water from seeping through. Water does not have a chance to creep into the basement area due to this fact. A waterproofing membrane effectively resists moisture damage in basement construction, which may otherwise induce mold growth, metal fastener corrosion, and also weakening of the concrete framework. The durability of HDPE films ensures they bear the long-term pressure from the surrounding soil and ground waters without tearing or degrading.

HDPE films also present an important contribution when talking about tunnel linings. They are installed on the inner surface of the tunnel walls to avoid water infiltration from the surrounding rock formations. This contributes not only to maintaining a dry and safe environment inside the tunnel during construction but also to guaranteeing the long-term stability of the tunnel structure once it is in use. For example, in most subway tunnel projects, HDPE films are utilized to enhance waterproof performance in service, especially in areas with a high groundwater table. 2. Roofing Systems and Exterior Wall Protection HDPE films are gaining increased usage in modern building design in roofing systems. They can be utilized as part of a multi-layer roofing assembly. For instance, HDPE films are laid as a waterproofing layer beneath roofing materials such as asphalt shingles or metal panels in some flat roofing systems. Their flexibility makes it easy for them to adopt the shape of the roof deck, even if that happens to be somewhat irregular, providing a seamless and effective waterproofing solution. This helps in prolonging the life of the roof by ensuring that water does not seep through and damage the structure underneath.

HDPE films are also used for exterior wall protection. HDPE films can be applied as a protective coating or membrane on the exterior walls of buildings, especially in those areas that are exposed to harsh weather conditions such as heavy rain, strong winds, and intense sunlight. These films act to block the moisture from being absorbed by wall materials such as bricks or concrete blocks, thus preventing problems like cracking or spalling. At the same time, they provide partial protection against UV radiation, which reduces fading and degradation of the exterior wall finishes. In some contemporary architectural designs, HDPE films are integrated into the wall systems to enhance the overall performance and aesthetics while providing long-term protection to the building envelope.

XI、Transportation and Logistics Applications of LDPE Films

LDPE films play a crucial role in the transportation and logistics industry. Their flexibility and ability to conform to different shapes make them ideal for packaging and protecting goods during transit. Whenever there are fragile items, such as glassware or electronic ones, which need to be wrapped up, LDPE films help in shock absorption, thus cushioning against further damage. The softness and flexibility of the film mean that items will not break because of too much pressure applied by the films while wrapping. For instance, in the shipment of fragile porcelain figurines, LDPE films are wrapped around each piece for protection, which cushions them from bumps and jolts during shipment. Besides protecting fragile items, LDPE films also serve as an effective moisture barrier for products sensitive to humidity. This is quite important for items like food products, pharmaceuticals, and even some forms of machinery. For example, in the packaging of foodstuffs or spice powders that easily get spoiled or lose quality if exposed to moisture, LDPE films create a completely sealed environment that keeps out humidity. This will contribute to maintaining freshness and ensuring the integrity of the packed products to reach consumers in the best state. The barrier properties against moisture of LDPE films further prevent the condensed formation of water that would lead to the corrosion of or damage to metal pieces in machinery during storage and transportation. Another major field of application of LDPE films in transportation and logistics consists of wrapping pallets or unitizing cargo. It means the tight wrapping of a pallet load of goods using LDPE film for keeping the pallet stable and hence avoiding possible damage during manipulation and shipment. The film holds the individual items on the pallet together and minimizes the shifting or falling off of items when in movement. This is very important during the transportation of heavy or bulky items. For instance, in a construction company's logistics, where building materials like bricks, tiles, or even lumber are palletized and shipped, LDPE films are used to secure the load. Wrapping the pallet tightly with the film helps in even distribution of weight and further supports the contents, thereby minimizing the chances of damage due to rough handling or vibrations during transit. The transparency of LDPE films also allows for easy identification and inspection of the contents on the pallet without having to unwrap the entire package, saving time and effort in the supply chain process.

XII. HDPE Films Used in Transportation and Logistics

1. Heavy-Duty Packaging for Automotive and Machinery

HDPE films are also widely used to manufacture heavy-duty packaging required for automobiles and big machinery during the time of transit. Their high strength and durability ensure strong protection against impacts and environmental factors. In the automobile industry, HDPE films are often used to pack various parts like engines, transmissions, and body parts. These films can bear the rigors of handling, loading, and unloading without sustaining damage from collisions and vibrations. For instance, when an engine is being shipped, HDPE film is wrapped around it to create a secure and protective enclosure. The toughness of the film ensures resistance to punctures and tears that may occur during transport and protects the valuable and delicate components of the engine. Large and heavy machinery parts, such as gears, shafts, and housings, are packaged using HDPE films in machinery manufacturing. Packaging of machinery parts with HDPE prevents physical damage and protects it from dust, moisture, or any other contaminant that would affect its performance. Their performance, which allows them to remain intact even under the highest of loads and at extremely harsh conditions, renders them very apt for protection during the transportation of parts related to automobiles and machinery through the supply chain. 2. Usage in Transport Infrastructure Projects HDPE films have their applications in various ways in certain transportation infrastructure projects. In the construction of bridges and tunnels, HDPE films are used for waterproofing and corrosion protection. HDPE films are installed in bridge construction under the bridge deck to prevent water from infiltrating into the structure. This protects the concrete and steel from corrosion, greatly reducing the life of the bridge. The impermeable nature of HDPE films ensures that moisture is effectively barred, even in areas characterized by high levels of rainfall or water exposure. In tunnel projects, HDPE films are utilized to line the interior walls and ceilings. These help in many ways, from preventing water infiltration through surrounding rock formations into the tunnels, to protection against corrosion within the structure of the tunnel itself, and overall beautification.

Within 15-20 days after received payment...more