TL-PET-184 The Application of Black PET in High - Temperature - Resistant, Insulating, and Heat - Insulating Electronic Components

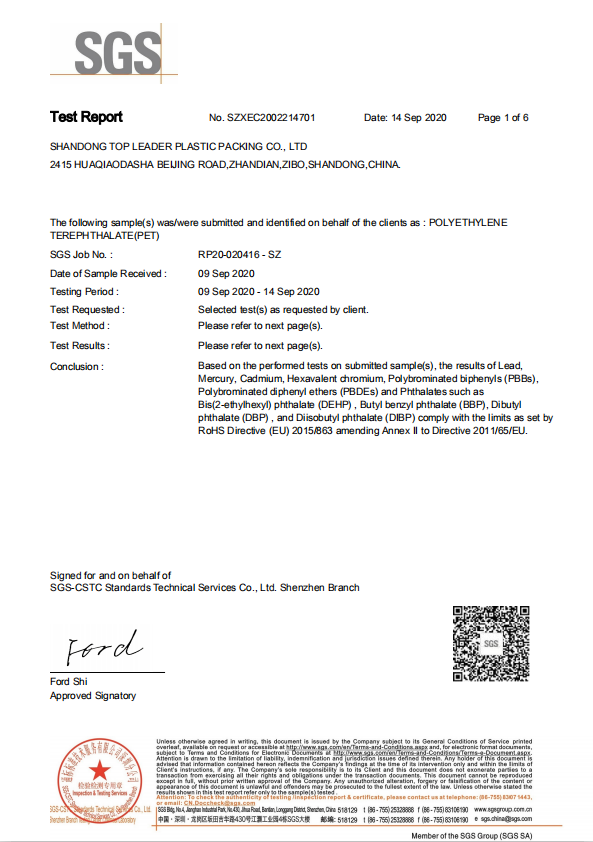

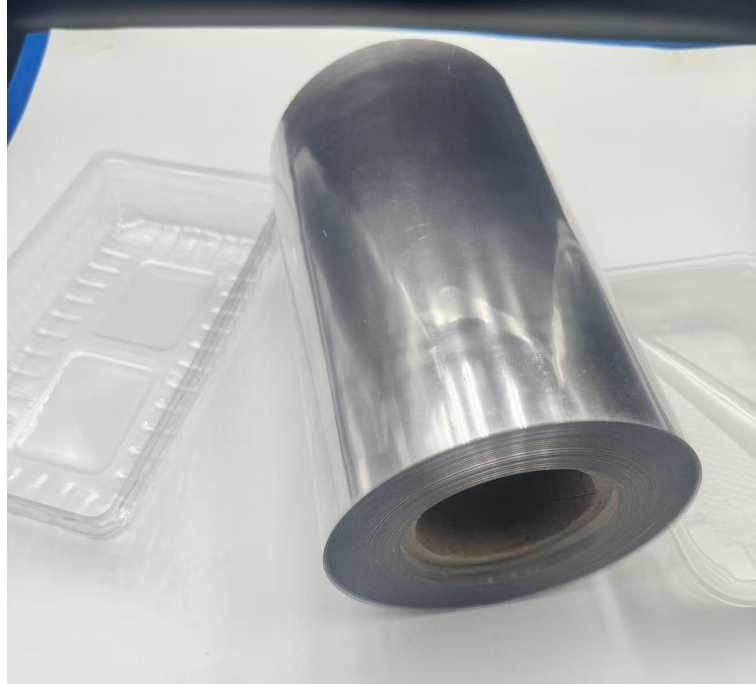

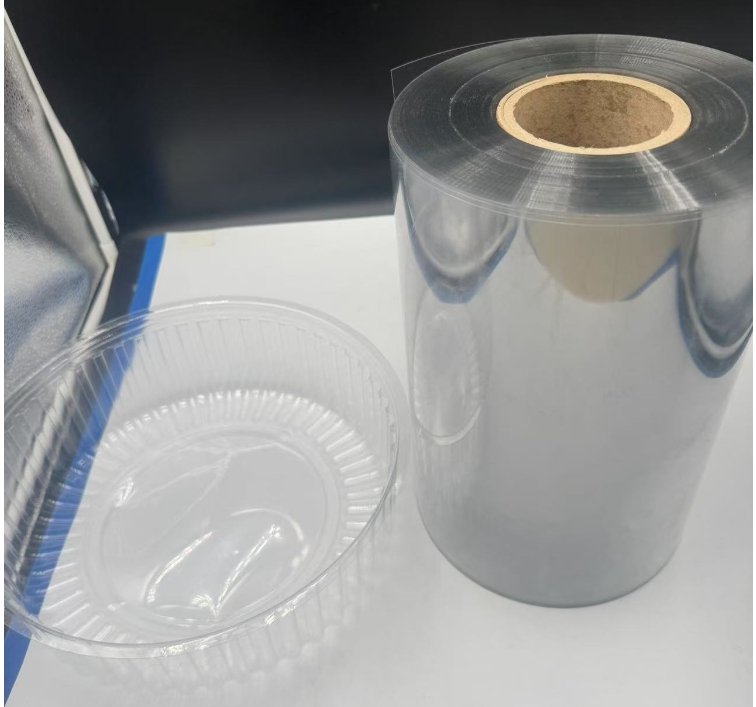

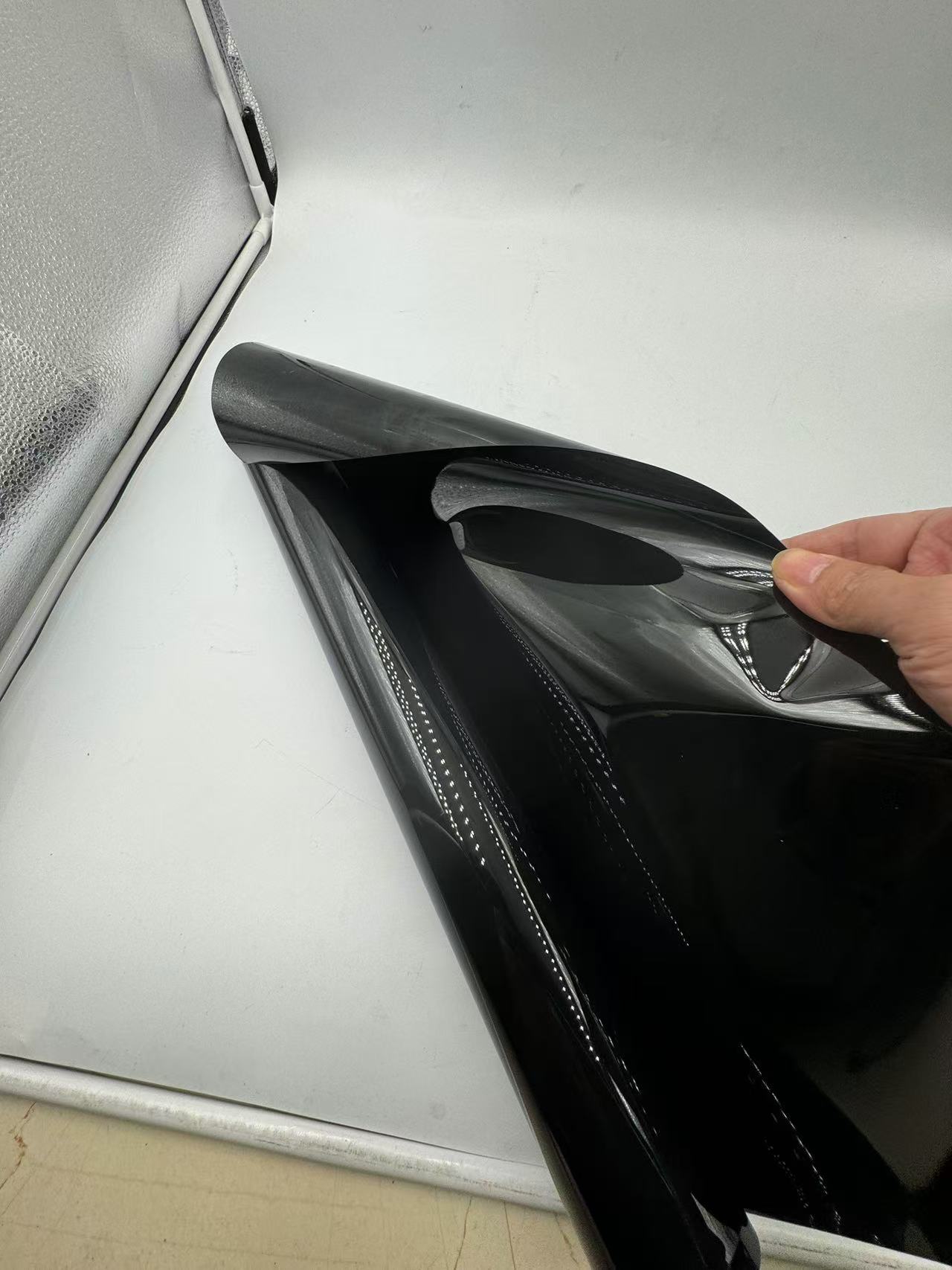

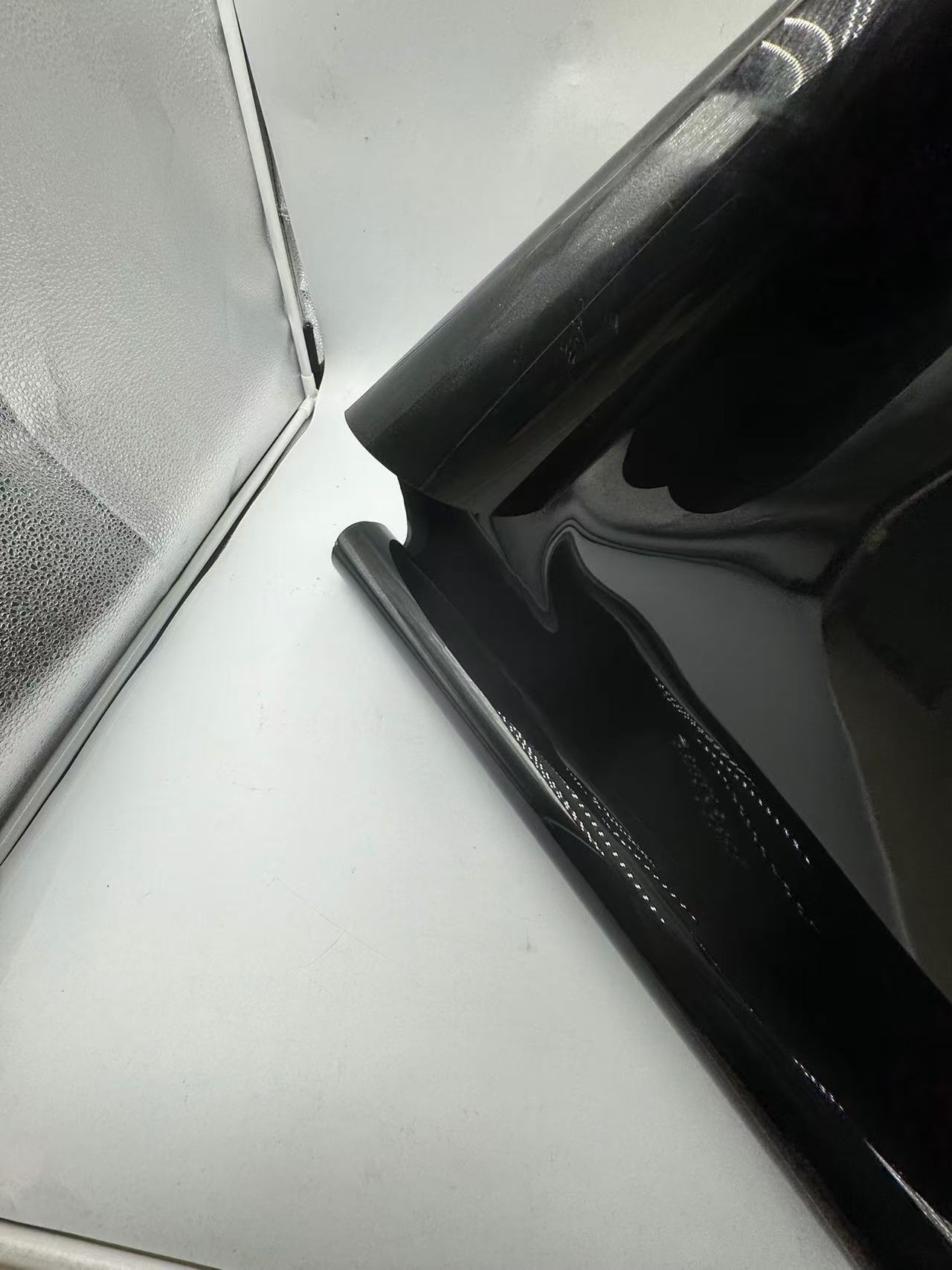

Material: PET temprature resistant film

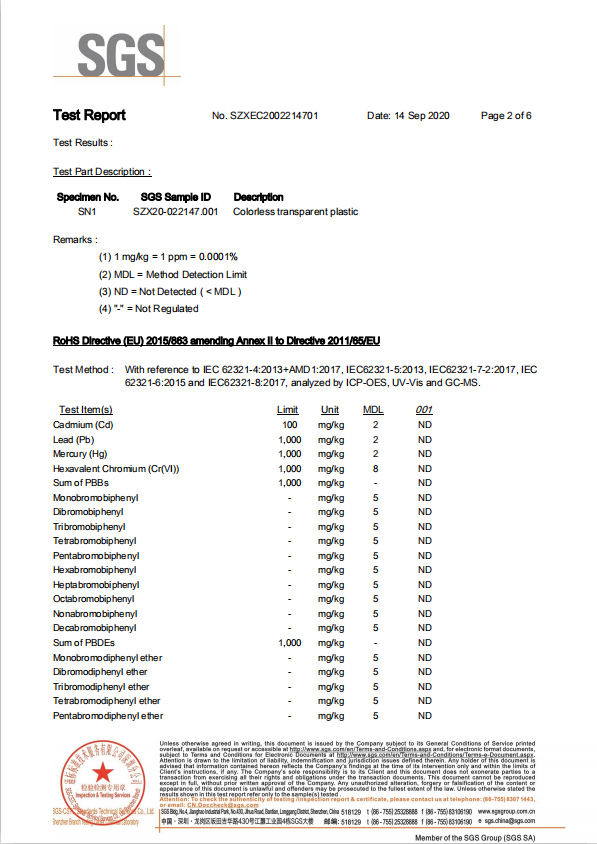

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: temprature resistant grade film

color: transparent/black/ customization

location: china

usage :Temperature - Resistant, Insulating, and Heat - Insulating Electronic Components

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

The Application of Black PET in High - Temperature - Resistant, Insulating, and Heat - Insulating Electronic Components

Introduction

In the fast - evolving field of electronics, the demand for materials with excellent performance under high - temperature conditions and with superior insulating and heat - insulating properties has been steadily increasing. Black PET (polyethylene terephthalate) has emerged as a remarkable material that meets these requirements and has found extensive use in various electronic components. This article will explore in detail the application of black PET in high - temperature - resistant, insulating, and heat - insulating electronic components, covering its material properties, manufacturing process, specific applications, advantages, and future prospects.

Material Properties of Black PET

Chemical Composition and Structure

Black PET is a modified form of polyethylene terephthalate. The basic structure of PET consists of repeating units of ethylene terephthalate. The addition of specific additives to create the black color does not significantly alter the fundamental chemical structure but imparts additional properties relevant to its use in electronic applications. These additives are carefully selected to ensure compatibility with the PET matrix and to enhance the desired characteristics.

High - Temperature Resistance

One of the most crucial properties of black PET for electronic applications is its high - temperature resistance. PET has a relatively high melting point, and through appropriate modifications and processing, black PET can withstand elevated temperatures without significant deformation or degradation. This property allows it to be used in environments where electronic components are subjected to heat generated during operation, such as in power electronics, automotive electronics, and high - power LED lighting systems. For example, in power transistors that can generate a significant amount of heat during normal operation, black PET can maintain its integrity and performance even at temperatures well above the ambient conditions.

Insulating Properties

Black PET exhibits excellent electrical insulating properties. The molecular structure of PET provides a stable and non - conductive environment. This is essential for preventing electrical short - circuits between different conductive parts within an electronic component or system. In applications such as printed circuit boards (PCBs), where multiple electrical paths need to be isolated, black PET can be used as an insulating layer. It has a high dielectric strength, which means that it can withstand high electric fields without breaking down. This property ensures the reliable operation of electronic devices and protects them from electrical failures.

Heat - Insulating Properties

The heat - insulating ability of black PET is another significant advantage. It has a relatively low thermal conductivity, which enables it to act as a barrier against heat transfer. In electronic components, this property is valuable for reducing the impact of heat on sensitive parts. For instance, in integrated circuits (ICs), heat - insulating materials are needed to prevent heat from spreading to adjacent components or to the surrounding environment. Black PET can effectively isolate the heat - generating elements, improving the overall thermal management of the system.

Mechanical Properties

Black PET also has good mechanical strength. It has sufficient tensile strength to withstand the mechanical stresses that may occur during the manufacturing process of electronic components or during their normal operation. This includes handling, insertion, and any vibrations or mechanical shocks that the components may experience. The material's flexibility can also be adjusted during the manufacturing process, allowing it to conform to different shapes and sizes of electronic components. This combination of strength and flexibility makes it a versatile material for various electronic applications.

UV Resistance and Color Stability

In some electronic applications, components may be exposed to ultraviolet (UV) light. Black PET has good UV resistance, which helps to maintain its physical and chemical properties over time. The black color, which is often important for aesthetic or functional reasons in electronic components, remains stable under UV exposure. This ensures that the appearance and performance of the components are not affected by sunlight or other UV sources, making it suitable for outdoor or exposed electronic equipment.

Manufacturing Process of Black PET for Electronic Components

Raw Material Preparation

The production of black PET for electronic applications begins with the selection of high - quality PET resin. The resin is carefully chosen based on its molecular weight, purity, and other characteristics that influence the final properties of the material. Along with the PET resin, colorants and other additives are selected. These additives may include stabilizers to enhance the high - temperature stability, antioxidants to prevent oxidation during processing, and agents to improve the UV resistance. The colorants used to achieve the black color are of high quality to ensure color uniformity and stability. The raw materials are then mixed thoroughly in precise proportions to obtain a homogeneous blend.

Extrusion Process

The prepared raw material blend is fed into an extruder. The extruder heats the mixture to a molten state under carefully controlled temperature and pressure conditions. The temperature profile within the extruder is adjusted to ensure uniform melting of the PET resin and proper dispersion of the additives. The molten black PET is then forced through a die to form a continuous sheet, rod, or other desired shapes. The die design determines the cross - sectional shape and size of the extruded product. During the extrusion process, the speed of the extruder screw and the take - up speed of the extruded product are carefully controlled to achieve the required dimensions and quality.

Molding and Forming

Once the black PET is extruded, it may undergo further molding and forming processes to create the specific shapes required for electronic components. Injection molding is commonly used for producing complex - shaped parts. In injection molding, the molten black PET is injected into a mold cavity under high pressure. The mold is designed with precision to create the final shape of the electronic component, such as a housing for a sensor or a bracket for a circuit board. Compression molding can also be employed for certain applications, especially when a higher density or specific mechanical properties are required. During these molding processes, the temperature, pressure, and cooling time are carefully controlled to ensure the proper formation of the component and to achieve the desired physical and mechanical properties.

Surface Treatment and Finishing

After the basic shape of the black PET component is formed, it may undergo surface treatment and finishing operations. These can include polishing to improve the surface smoothness, which is important for applications where a good electrical contact or a clean appearance is required. In some cases, coatings may be applied to further enhance the properties of the black PET. For example, a thin layer of a heat - reflective coating can be added to improve the heat - insulating performance, or an anti - static coating can be used to prevent the accumulation of static electricity on the surface of the component. Finishing operations also involve quality control checks to ensure that the dimensions, physical properties, and appearance of the component meet the required standards.

Applications of Black PET in Electronic Components

Power Electronics

Heat Sinks and Insulating Washers

In power electronics, such as power converters and inverters, heat management is of utmost importance. Black PET is used to make heat sinks and insulating washers. The heat - insulating properties of black PET in the heat sink help to direct the heat away from sensitive components and towards the cooling fins. The insulating washers made from black PET prevent electrical contact between different conductive parts while providing thermal isolation. For example, in a power converter, the insulating washer made of black PET separates the heat - generating power semiconductor from the metal chassis, ensuring safe and efficient operation.

High - Temperature Cable Insulation

Power electronics often involve high - current - carrying cables that generate heat during operation. Black PET is used as an insulation material for these cables. Its high - temperature resistance and excellent electrical insulating properties make it ideal for this application. The cable insulation made from black PET can withstand the heat generated by the current flowing through the cable and prevent electrical leakage, ensuring the reliable transmission of power within the system.

Automotive Electronics

Engine Control Unit (ECU) Housing

In automotive electronics, the engine control unit (ECU) is a critical component. The ECU housing made from black PET provides protection against heat, moisture, and mechanical shocks. The high - temperature resistance of black PET allows it to withstand the heat generated by the engine compartment. The insulating properties protect the internal electronic circuits of the ECU from electrical interference. The black color also helps in absorbing heat and reducing the temperature inside the housing, contributing to the overall reliability of the ECU.

Sensor Protective Covers

Automotive sensors, such as temperature sensors, pressure sensors, and oxygen sensors, are often exposed to harsh environmental conditions. Black PET protective covers are used to shield these sensors. The covers provide thermal insulation to protect the sensitive sensor elements from the heat of the engine or the environment. They also offer electrical insulation and mechanical protection, ensuring the accurate and reliable operation of the sensors.

High - Power LED Lighting

LED Heat - Sinking Components

High - power LED lighting systems generate a significant amount of heat during operation. Black PET is used in the design of heat - sinking components. The heat - insulating and heat - conducting properties of black PET are utilized to effectively manage the heat generated by the LEDs. For example, in LED street lights or high - bay lights, black PET - based heat sinks help to dissipate the heat away from the LED chips, improving their lifespan and luminous efficiency.

Reflective and Insulating Layers

In some LED lighting applications, black PET is used as a reflective and insulating layer. The material's ability to reflect light and its heat - insulating properties are combined to enhance the performance of the lighting system. The black PET layer can direct the light emitted by the LEDs towards the desired direction while reducing heat transfer to the surrounding environment. This improves the overall efficiency of the LED lighting system and helps to maintain a stable operating temperature.

Advantages of Black PET in Electronic Applications

Improved Thermal Management

The heat - insulating and heat - conducting properties of black PET contribute to better thermal management in electronic components. By effectively controlling heat transfer, it helps to maintain the optimal operating temperature of the components. This reduces the risk of thermal - related failures, such as overheating of semiconductor devices or degradation of electrical insulation due to high temperatures. Improved thermal management also leads to increased lifespan and reliability of the electronic components.

Enhanced Electrical Safety

The excellent electrical insulating properties of black PET ensure electrical safety within electronic systems. It prevents electrical short - circuits and leakage currents, protecting both the components themselves and the users of the electronic devices. In applications where high voltages and currents are present, such as power electronics, the reliable electrical insulation provided by black PET is crucial for the safe operation of the system.

High - Temperature Performance

Black PET's ability to withstand high temperatures allows electronic components to operate in harsh environments. This is particularly important in applications such as automotive electronics and high - power LED lighting, where components are exposed to heat generated during normal operation or from external sources. The high - temperature resistance of black PET ensures that the components continue to function properly under these conditions, reducing the need for frequent replacements and maintenance.

Design Flexibility

The manufacturing process of black PET allows for a high degree of design flexibility. It can be molded into various shapes and sizes, making it suitable for different types of electronic components. The ability to produce complex - shaped parts using injection molding or other forming techniques enables designers to optimize the design of electronic components for better performance, space utilization, and integration with other parts of the system.

Cost - effectiveness

Compared to some other materials with similar high - temperature, insulating, and heat - insulating properties, black PET can be a cost - effective solution. The raw materials for black PET are relatively inexpensive, and the manufacturing processes, such as extrusion and molding, are well - established and can be scaled up easily. This cost - advantage makes it an attractive option for mass - production of electronic components without sacrificing performance.

Case Studies of Black PET in Electronic Component Applications

Case Study 1: Power Converter in Renewable Energy Systems

In a solar power generation system, the power converter is a key component that converts the direct current (DC) generated by the solar panels into alternating current (AC) for grid connection. The power converter used in this system incorporated black PET - based heat sinks and insulating washers. The heat sinks effectively managed the heat generated by the power semiconductors, reducing the operating temperature of the converter by 20%. The insulating washers provided reliable electrical isolation between different conductive parts, preventing electrical failures. As a result, the power converter had a higher efficiency and a longer lifespan, contributing to the overall reliability of the solar power generation system.

Case Study 2: Automotive Engine Control Unit

An automotive manufacturer redesigned the engine control unit (ECU) housing using black PET. The new housing withstood the high - temperature environment of the engine compartment without any signs of deformation or degradation. The insulating properties of black PET protected the internal circuits of the ECU from electrical interference caused by the engine's electrical system. The black color of the housing also helped in heat absorption, reducing the internal temperature of the ECU by 15%. This led to improved performance and reliability of the ECU, resulting in fewer engine malfunctions and better fuel efficiency.

Case Study 3: High - Power LED Street Lights

A city upgraded its street lighting system to high - power LED street lights. The heat - sinking components of these LED lights were made from black PET. The black PET heat sinks effectively dissipated the heat generated by the LED chips, improving their luminous efficiency by 30%. The heat - insulating properties of black PET also reduced the heat transfer to the surrounding environment, preventing damage to the light fixtures. The use of black PET in the LED street lights resulted in energy savings and better lighting quality, enhancing the safety and aesthetics of the city streets.

Challenges and Solutions in Using Black PET in Electronic Components

Compatibility with Other Materials

In some electronic applications, black PET may come into contact with other materials, such as metals, adhesives, or other polymers. Compatibility issues can arise, such as chemical reactions or poor adhesion. To address this, compatibility tests should be conducted during the design phase. If necessary, surface treatments or the use of intermediate layers can be employed to improve the compatibility between black PET and other materials. For example, a primer layer can be applied before bonding black PET to a metal surface to enhance the adhesion.

Processing Difficulties

The processing of black PET, especially in complex molding operations, can present challenges. The high - temperature and high - pressure conditions required during injection molding or compression molding need to be carefully controlled. If the temperature or pressure is not properly adjusted, it can lead to issues such as incomplete filling of the mold, warping of the component, or degradation of the material. To overcome these difficulties, manufacturers should optimize the processing parameters based on the specific grade of black PET and the design of the component. Advanced simulation software can be used to predict and optimize the molding process.

Environmental Concerns

Although PET is a relatively stable and inert material, there are still environmental concerns associated with its production and disposal. To address these concerns, manufacturers can adopt more sustainable production practices, such as using recycled PET or reducing energy consumption during the manufacturing process. In terms of disposal, efforts should be made to recycle black PET components at the end of their life cycle. Recycling programs can be established to collect and process used black PET electronic components, reducing the environmental impact.

Conclusion

Black PET has become an indispensable material in the development of high - temperature - resistant, insulating, and heat - insulating electronic components. Its unique combination of material properties, including high - temperature resistance, excellent electrical insulation, heat - insulating capabilities, good mechanical strength, and UV resistance, makes it suitable for a wide range of applications in power electronics, automotive electronics, and high - power LED lighting. The manufacturing process of black PET allows for design flexibility, and its cost - effectiveness further enhances its appeal in the electronics industry. Despite the challenges related to material compatibility, processing difficulties, and environmental concerns, continuous efforts in research and development are addressing these issues. As the electronics industry continues to advance, the use of black PET in electronic components is expected to grow, contributing to more reliable, efficient, and environmentally friendly electronic systems.

Within 15-20 days after received payment...more