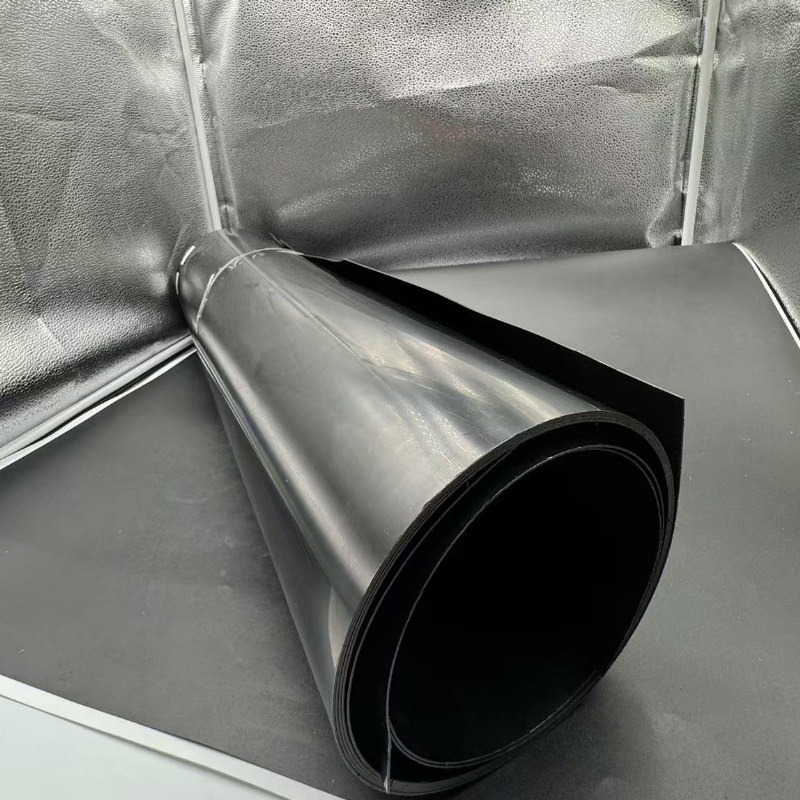

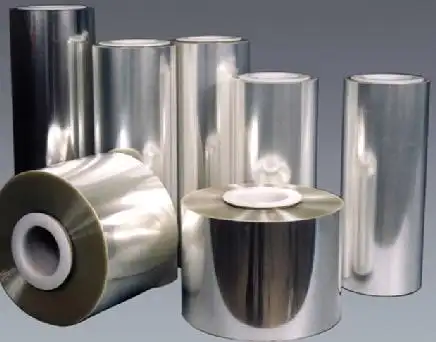

198Metalized BOPET film for lamination film packaging

Material: BOPET roll

Thickness: 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: Metalized /transparent/white/ customization

location: china

usage :for lamination, deco, flowers food

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

The Versatile Application of BOPET Aluminized Film in Pharmaceutical, Food Packaging, and Composite Films

Introduction

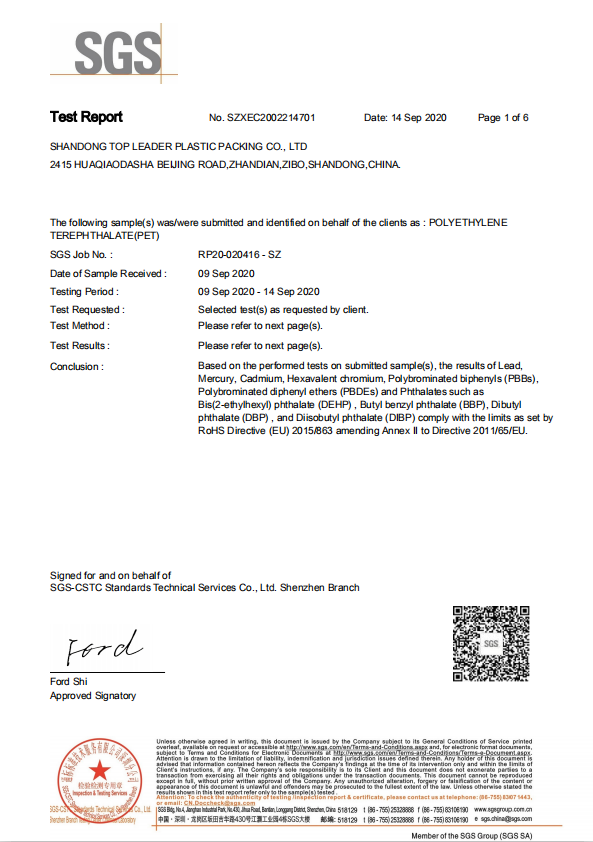

In the modern packaging industry, the demand for materials that offer a combination of excellent barrier properties, visual appeal, and durability is ever-increasing. BOPET (biaxially oriented polyethylene terephthalate) aluminized film has emerged as a remarkable solution, finding extensive use in pharmaceutical, food packaging, and as a crucial component in composite films. This article delves into the unique characteristics of BOPET aluminized film, its manufacturing process, diverse applications, associated advantages, and the challenges it overcomes in these vital sectors.

Material Properties of BOPET Aluminized Film

Chemical Composition and Structure

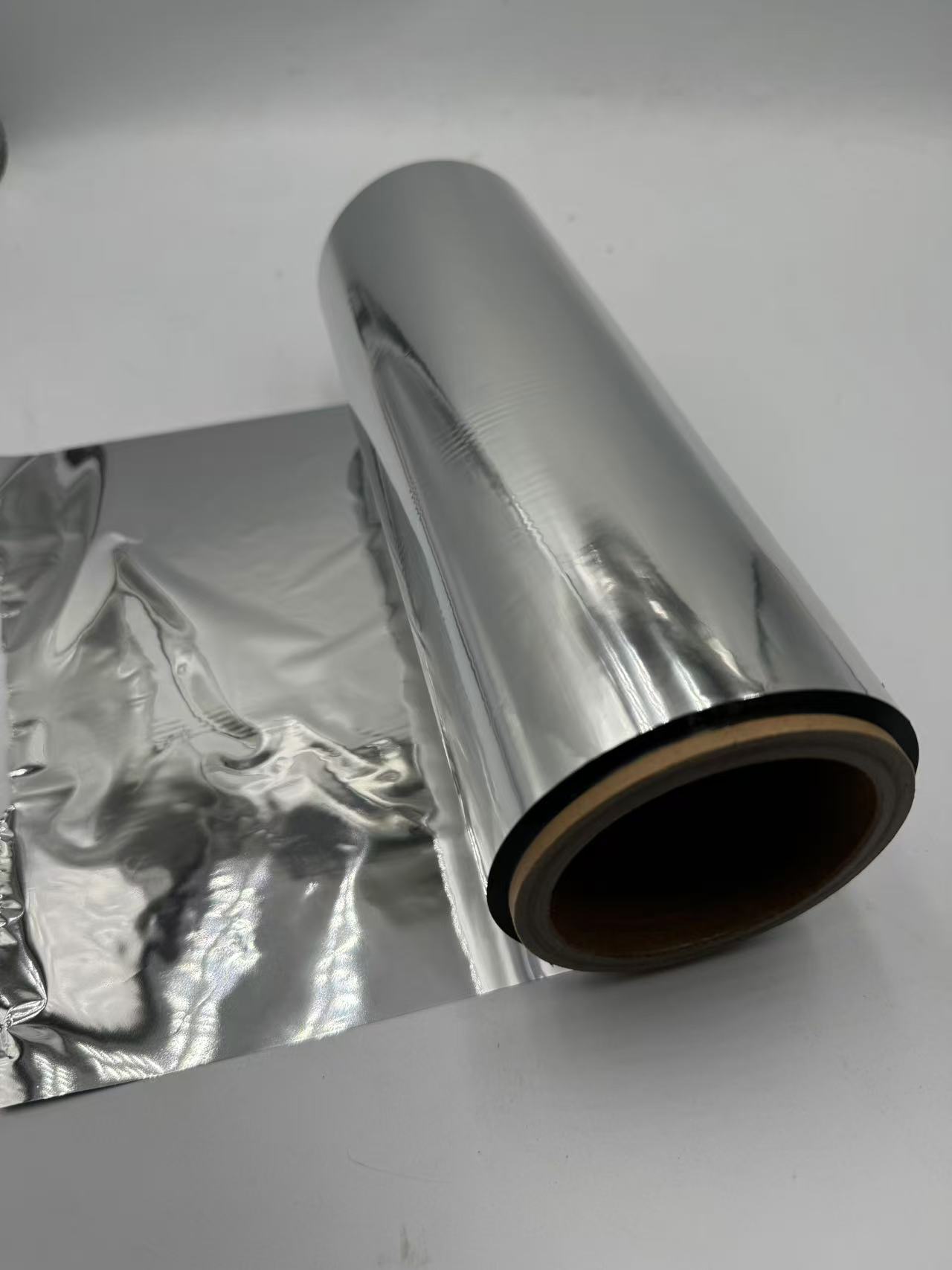

BOPET aluminized film is based on the well-known PET polymer, which is synthesized from ethylene glycol and terephthalic acid monomers. The PET resin is first formed into a film through extrusion and then undergoes a biaxial orientation process, stretching it in both the machine direction (MD) and the transverse direction (TD). This orientation imparts remarkable strength, dimensional stability, and clarity to the film. The aluminization process follows, where a thin layer of aluminum is deposited onto the BOPET substrate, typically through vacuum metallization. The aluminum layer, usually just a few nanometers to micrometers thick, adheres tightly to the PET surface, enhancing the film's properties in multiple ways.

Barrier Properties

The most outstanding feature of BOPET aluminized film is its exceptional barrier capabilities. The aluminum coating acts as an impermeable shield against gases, such as oxygen, carbon dioxide, and water vapor. In pharmaceutical packaging, this is of utmost importance as it prevents the ingress of oxygen and moisture that could lead to the degradation of drugs, maintaining their potency and stability. For instance, in the packaging of sensitive medications like antibiotics or vitamins, the film's low oxygen and moisture transmission rates ensure that the active ingredients remain intact for an extended period, safeguarding the efficacy of the treatment. In food packaging, it keeps food products fresh by retarding spoilage caused by oxidation and moisture absorption. A bag of potato chips packaged with BOPET aluminized film stays crispy for longer, as the film inhibits the entry of moisture that would otherwise make the chips soggy.

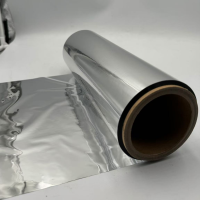

Optical Properties

The aluminized surface of the film gives it a shiny, metallic appearance, which has both aesthetic and practical implications. Visually, it catches the eye on store shelves, making products packaged with it stand out. In the food industry, this can enhance the perceived value of the product, attracting consumers. For example, confectionery items or luxury food products like premium chocolates packaged in BOPET aluminized film look more enticing. Functionally, the reflective nature of the aluminum layer helps in protecting light-sensitive products. In pharmaceutical applications, drugs that are prone to degradation upon exposure to light, such as certain ophthalmic solutions or photolabile medications, are well-protected within BOPET aluminized packaging, as the film reflects a significant portion of the incident light, reducing the risk of photochemical reactions.

Mechanical Properties

Thanks to the biaxial orientation of the PET base, BOPET aluminized film possesses high tensile strength and excellent tear resistance. It can withstand the rigors of manufacturing processes, such as being formed into various shapes during thermoforming for blister packs in the pharmaceutical industry or being used in flexible packaging applications in food. During transportation and handling, it protects the contents from physical damage, whether it's delicate tablets in a medicine pack or fragile food items like crackers. The film's dimensional stability ensures that it retains its shape and size, providing a consistent and reliable packaging solution over time.

Thermal Properties

The film exhibits good thermal stability, which allows it to endure a range of temperatures without significant deformation or degradation. In food packaging, it can withstand the heat involved in processes like pasteurization or sterilization, making it suitable for packaging heat-treated products. In pharmaceutical applications, it can handle the temperatures associated with certain manufacturing and storage conditions, such as in the case of products that require warm or cool storage environments. Moreover, the film's heat resistance enables it to be used in heat-sealing operations, creating airtight and tamper-evident packages for both food and pharmaceuticals.

Chemical Resistance

BOPET aluminized film demonstrates strong chemical resistance to a variety of substances. It can withstand exposure to common acids, alkalis, and solvents, which is crucial in both the pharmaceutical and food sectors. In pharmaceuticals, it ensures that the packaging does not react with the active ingredients or excipients of the drugs, maintaining the purity and safety of the medication. In food packaging, it resists interactions with food components and any cleaning agents or substances it may encounter during processing or handling, preventing contamination and ensuring the integrity of the packaged food.

Manufacturing Process of BOPET Aluminized Film

Raw Material Preparation

The journey of BOPET aluminized film production begins with the careful selection of high-quality PET resin. The resin is sourced, ensuring its purity and consistency, as any impurities can affect the final film's properties. Additives such as antioxidants are incorporated to protect the resin from degradation during processing and subsequent storage. The resin and additives are then thoroughly blended in a mixer to create a homogeneous mixture, ready for the extrusion step.

Extrusion and Orientation

The well-mixed raw materials are fed into an extruder, a cylindrical device equipped with a rotating screw. As the material passes through the heated barrel of the extruder, it is melted under controlled temperature and pressure conditions. The molten PET is then forced through a flat die, forming a continuous sheet of film. This nascent film is immediately cooled and then enters the orientation phase. In the orientation process, the film is reheated to a temperature above its glass transition point but below its melting point, making it pliable. It is then stretched in both the MD and TD directions, either simultaneously or sequentially, depending on the manufacturing technique. This biaxial stretching aligns the polymer chains, enhancing the film's strength, clarity, and dimensional stability.

Aluminization

After orientation, the BOPET film is ready for the aluminization process. The film is placed in a vacuum chamber, and aluminum is vaporized under high vacuum conditions. The aluminum atoms then deposit onto the surface of the BOPET film, forming a thin, uniform coating. The thickness of the aluminum layer can be precisely controlled during this process, depending on the specific requirements of the end application. The adhesion between the aluminum and the BOPET substrate is carefully optimized through surface treatments and process parameters to ensure a durable and reliable bond.

Annealing and Cooling

Following aluminization, the film undergoes an annealing process to relieve the internal stresses generated during the previous manufacturing steps. Annealing involves heating the film to a specific temperature below its melting point and then slowly cooling it. This step helps to stabilize the molecular structure of the film, improving its mechanical properties and dimensional stability. After annealing, the film is cooled to room temperature and wound onto large rolls, ready for further processing into packaging materials for pharmaceutical and food products or for use in composite films.

Quality Control

Throughout the manufacturing process, rigorous quality control procedures are implemented. The thickness of the BOPET base film, the thickness and uniformity of the aluminum coating, the barrier properties, and the mechanical strength are all measured and tested using advanced analytical techniques and instruments. Any film that fails to meet the strict quality standards is rejected, ensuring that only high-quality BOPET aluminized film reaches the market for critical applications in pharmaceutical and food packaging.

Applications of BOPET Aluminized Film in Pharmaceutical Packaging

Blister Packs

Blister packs are a common and crucial application of BOPET aluminized film in the pharmaceutical industry. The film is thermoformed to create individual cavities that snugly hold tablets, capsules, or other solid dosage forms. The excellent barrier properties of the film protect the drugs from moisture, oxygen, and light, maintaining their potency and stability. The shiny, metallic appearance also gives a professional and hygienic look to the packaging, instilling confidence in consumers. For example, a blister pack of allergy medications packaged with BOPET aluminized film not only keeps the tablets in pristine condition but also makes it easy for patients to identify and access their doses, with the added visual appeal enhancing the overall product perception.

Strip Packs

Strip packs made from BOPET aluminized film are used for packaging multiple doses of a medication in a linear format. The film is folded and sealed around the tablets or capsules, creating a convenient and portable packaging option. The barrier against moisture and oxygen ensures that the drugs remain effective during storage and transportation. The reflective surface of the film can also have a practical use in some cases, for instance, helping to identify the pack easily in a cluttered medicine cabinet or pharmacy shelf. Strip packs of pain relievers or daily supplements packaged with this film provide a reliable and user-friendly solution for patients to manage their medications on the go.

Secondary Packaging

In pharmaceutical packaging, BOPET aluminized film is often used as secondary packaging material. It can be applied as a shrink wrap or a tamper-evident seal around bottles, vials, or cartons. The film's barrier properties protect the primary packaging and its contents from external environmental factors, while the metallic appearance gives an added layer of security and professionalism. For example, a box of injectable medications wrapped with BOPET aluminized film as a secondary packaging not only safeguards the drugs from potential damage but also clearly indicates if any tampering has occurred, ensuring the safety and integrity of the pharmaceutical product.

Applications of BOPET Aluminized Film in Food Packaging

Snack Packaging

For snack foods like chips, popcorn, and pretzels, BOPET aluminized film offers an ideal packaging solution. The film's barrier to moisture keeps the snacks crunchy and fresh, while the barrier to oxygen prevents rancidity, prolonging the shelf life of the products. The shiny, metallic look gives the snacks a premium appearance on store shelves, attracting consumers. A bag of flavored popcorn packaged with BOPET aluminized film retains its delicious taste and texture for weeks, and the eye-catching packaging entices shoppers to pick it up, enhancing the marketability of the snack.

Coffee and Tea Packaging

In the packaging of coffee beans, ground coffee, and tea leaves, BOPET aluminized film plays a vital role. The film protects the products from moisture, which could lead to mold growth or loss of flavor, and from oxygen, which causes oxidation and spoilage of the aromatic compounds. The reflective nature of the film also helps in shielding the contents from light, preserving the freshness and aroma of the coffee and tea. A pouch of specialty coffee beans packaged with BOPET aluminized film keeps the beans at their peak flavor, ensuring that consumers enjoy a rich and aromatic brew every time.

Confectionery Packaging

Confectionery items such as chocolates, candies, and gummies benefit from the properties of BOPET aluminized film. The film's barrier to moisture prevents the sweets from melting or becoming sticky, while the protection from oxygen maintains their taste and quality. The shiny appearance adds a touch of luxury to the packaging, making the confectionery products more appealing for gifting or retail sales. A box of fine chocolates wrapped with BOPET aluminized film not only looks elegant but also keeps the chocolates in perfect condition, ready to be savored.

Applications of BOPET Aluminized Film in Composite Films

Pharmaceutical Composite Films

In the pharmaceutical industry, composite films incorporating BOPET aluminized film are designed to meet specific and stringent requirements for drug protection and delivery. For example, a composite film might consist of a layer of BOPET aluminized film laminated with a layer of polyethylene or polypropylene. The BOPET aluminized layer provides the excellent barrier properties against gases, moisture, and light, while the other layer offers flexibility, heat-sealing capabilities, and additional protection. This combination is useful for packaging drugs that require a high level of protection, such as biopharmaceuticals or drugs with complex formulations, ensuring their stability and efficacy throughout their shelf life.

Food Packaging Composite Films

In food packaging, BOPET aluminized film is often combined with other materials to create composite films with enhanced properties. For instance, it can be laminated with a layer of ethylene - vinyl alcohol (EVOH) to further improve the barrier against gases, especially for products like fresh meats or dairy products that are highly sensitive to oxygen and moisture. The BOPET aluminized layer provides the visual appeal and initial barrier protection, while the EVOH layer augments the gas barrier function, resulting in a packaging solution that significantly extends the shelf life of the food item and maintains its quality.

Industrial and Technical Composite Films

Beyond pharmaceutical and food applications, BOPET aluminized film is used in industrial and technical composite films. In the electronics industry, it can be part of a composite film used to protect sensitive components from electromagnetic interference (EMI), moisture, and dust. The aluminum layer provides EMI shielding, while the BOPET substrate offers mechanical strength and protection from physical damage. In the construction industry, it can be used in roofing or insulation materials, where the film's barrier properties and durability are advantageous in protecting buildings from moisture ingress and heat transfer.

Advantages of Using BOPET Aluminized Film in Packaging

Superior Barrier Protection

The film's ability to block gases, moisture, and light is unrivaled, ensuring the quality and stability of the packaged products in pharmaceutical and food applications. This leads to longer shelf lives, reduced waste, and maintenance of product efficacy, which is crucial for medications and freshness for food.

Visual Appeal and Branding

The shiny, metallic appearance of the film makes products stand out on store shelves, enhancing their visual impact and perceived value. In food packaging, it can create a sense of luxury or quality, while in pharmaceutical packaging, it gives a professional and hygienic look, helping to build brand recognition and consumer trust.

Mechanical and Thermal Stability

With high tensile strength, tear resistance, and good thermal stability, the film can withstand the rigors of manufacturing, transportation, and storage. It protects the contents from physical damage and can endure a range of temperatures, making it suitable for various packaging processes and storage conditions.

Chemical Resistance

The film's resistance to acids, alkalis, and solvents ensures that it does not react with the packaged products or encounter any issues during handling and processing, maintaining the purity and integrity of the pharmaceutical or food items.

Versatility in Packaging Design

BOPET aluminized film can be used in various forms, such as blister packs, strip packs, and composite films, and can be combined with other materials to meet different packaging requirements. It offers flexibility in creating custom packaging solutions for a wide range of products.

Case Studies of BOPET Aluminized Film in Packaging Applications

Case Study 1: Pharmaceutical Company's Packaging Improvement

A pharmaceutical company was facing issues with the stability of its oral medications due to moisture and oxygen ingress in the existing packaging. They switched to using BOPET aluminized film for their blister packs. The new packaging significantly reduced the degradation of the drugs, increasing their shelf life by over 30%. Patients also reported that the new packaging was easier to use and looked more professional, leading to increased satisfaction and loyalty. The company saw a reduction in product returns and an improvement in market share as a result.

Case Study 2: Food Manufacturer's Shelf Life Extension

A food manufacturer of potato chips was struggling with the short shelf life of their product due to moisture absorption. They adopted BOPET aluminized film for packaging. The film's excellent moisture barrier properties kept the chips crispy for an additional two weeks compared to the previous packaging. The shiny appearance also attracted more consumers on the store shelf, resulting in a 20% increase in sales within the first six months of implementation.

Case Study 3: Electronics Component Protection

An electronics company needed to protect its sensitive microchips from EMI and moisture during storage and transportation. They used a composite film with a layer of BOPET aluminized film. The EMI shielding provided by the aluminum layer and the moisture protection from the BOPET substrate ensured that the microchips arrived at their destination in perfect condition, reducing the defect rate by over 50% and improving the overall reliability of their products.

Challenges and Solutions in Using BOPET Aluminized Film in Packaging

Adhesion and Lamination Issues

When used in composite films, ensuring proper adhesion between the BOPET aluminized film and other layers can be challenging. If the adhesion is weak, delamination can occur, compromising the integrity of the packaging. To address this, manufacturers carefully select adhesives based on the chemical compatibility of the materials and optimize the lamination process parameters, such as temperature, pressure, and curing time. Rigorous testing and quality control are implemented to ensure consistent adhesion quality.

Recycling and Environmental Impact

Although BOPET is recyclable, the aluminized film presents some challenges in recycling due to the presence of the aluminum layer. Separation of the aluminum from the PET substrate during recycling processes can be difficult. To mitigate this, research is focused on developing more efficient separation techniques, such as chemical or mechanical methods. Additionally, manufacturers are exploring ways to design packaging that is more easily recyclable, such as using thinner aluminum coatings or alternative materials that can provide similar properties with better recyclability.

Cost Considerations

The production of BOPET aluminized film, especially with its complex manufacturing process involving aluminization, can be relatively costly compared to some other packaging materials. However, when considering the long-term benefits in terms of product protection, extended shelf life, and reduced waste, the cost can be justified. Manufacturers can also work on optimizing production processes to reduce costs, such as improving the efficiency of the aluminization step and minimizing material waste during manufacturing.

Printing and Labeling Difficulties

Printing on BOPET aluminized film can be tricky due to its smooth and non - porous surface, which can lead to poor ink adhesion. To overcome this, surface treatment methods such as corona treatment or plasma treatment are used to increase the surface energy of the film, improving ink adhesion. Special inks and printing techniques, such as UV-curable inks and flexographic printing, are also employed to ensure clear and durable printing of product information and branding on the film.

Conclusion

BOPET aluminized film has proven to be a highly versatile and valuable material in pharmaceutical, food packaging, and composite film applications. Its unique combination of properties, including exceptional barrier protection, visual appeal, mechanical and thermal stability, and chemical resistance, makes it an ideal choice for a wide variety of products. Despite the challenges it faces, such as adhesion issues, recycling concerns, cost, and printing difficulties, there are solutions available to address them. With continued research and development, the performance and sustainability of BOPET aluminized film-based packaging can be further enhanced, ensuring its continued prominence in safeguarding the quality and integrity of products in numerous industries.

Within 15-20 days after received payment...more