Metallized PET Film: A Marvel in Many Ways-Various Applications

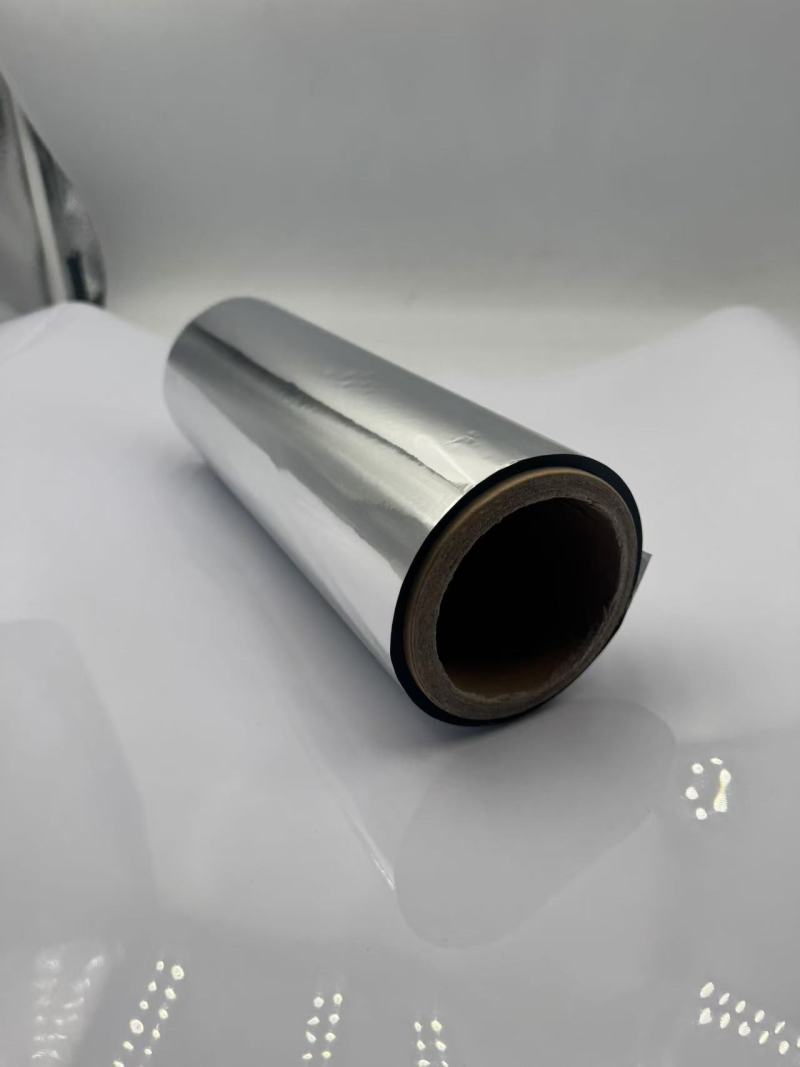

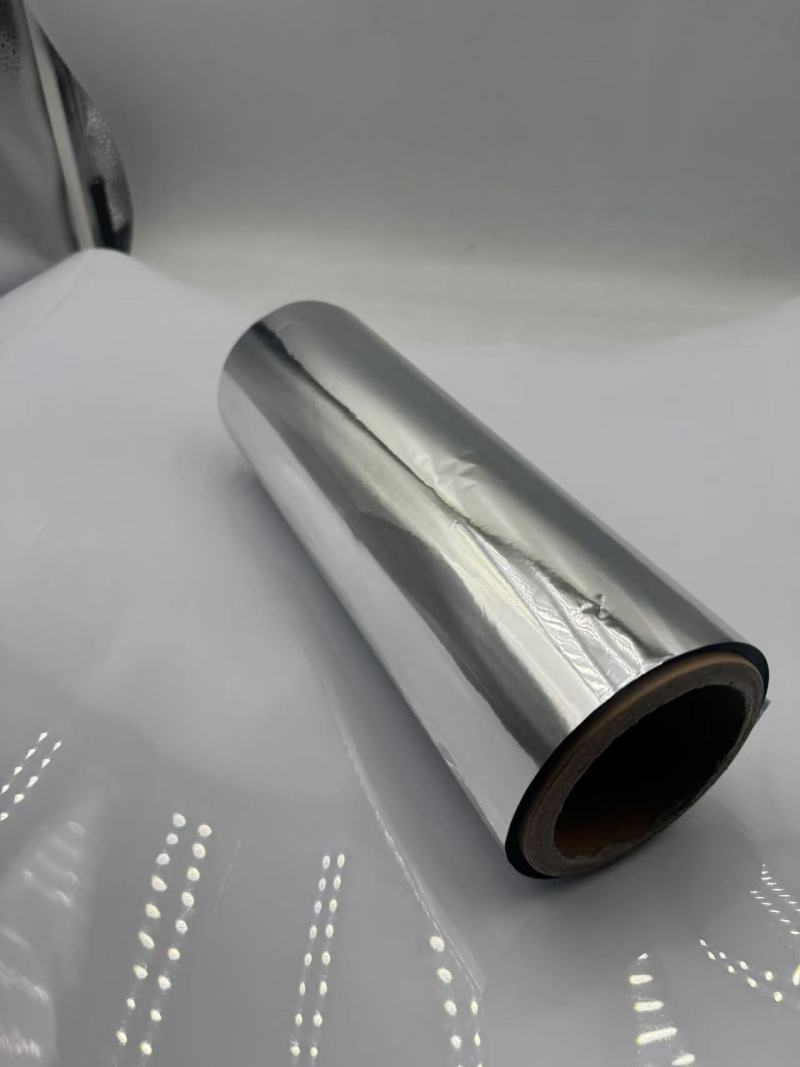

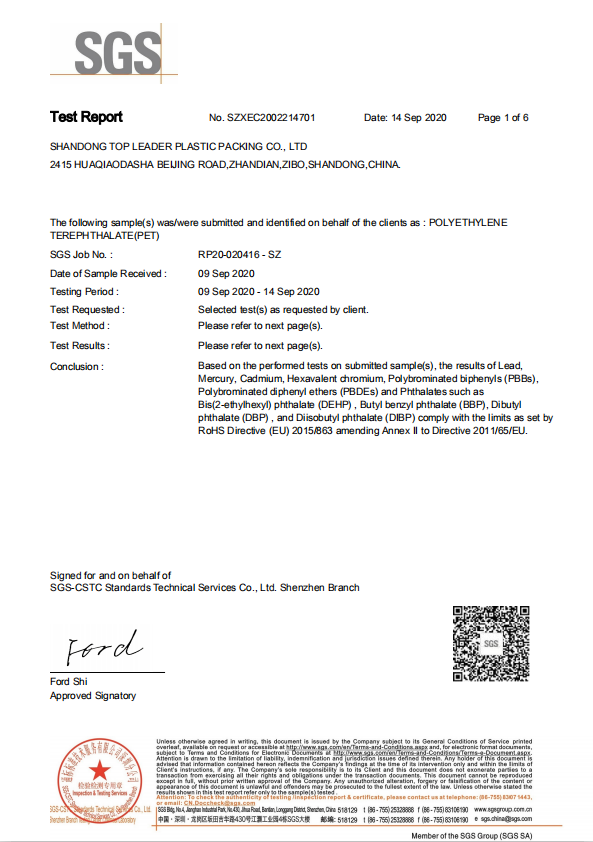

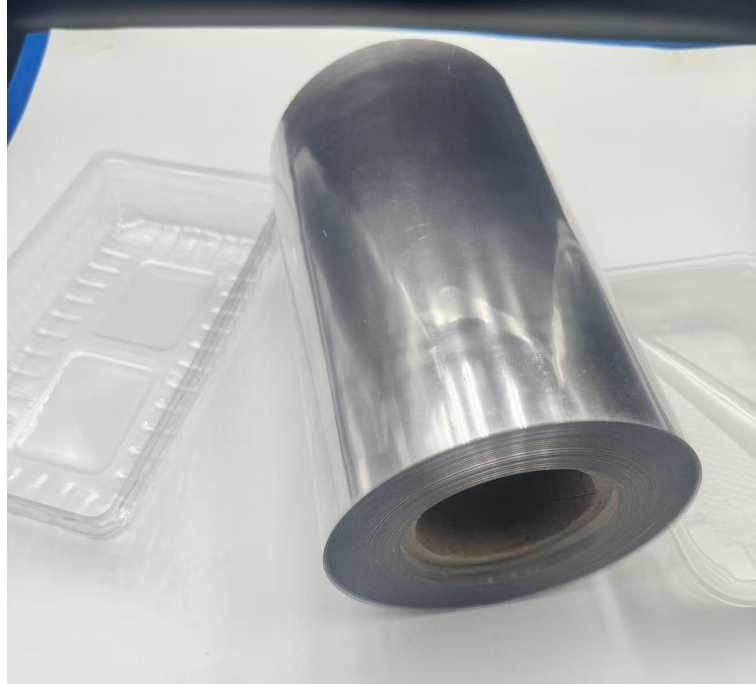

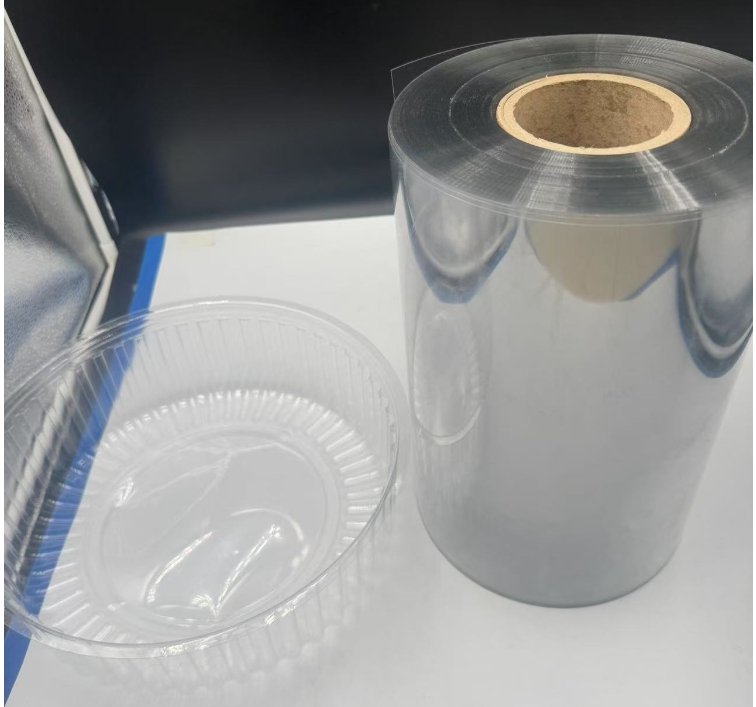

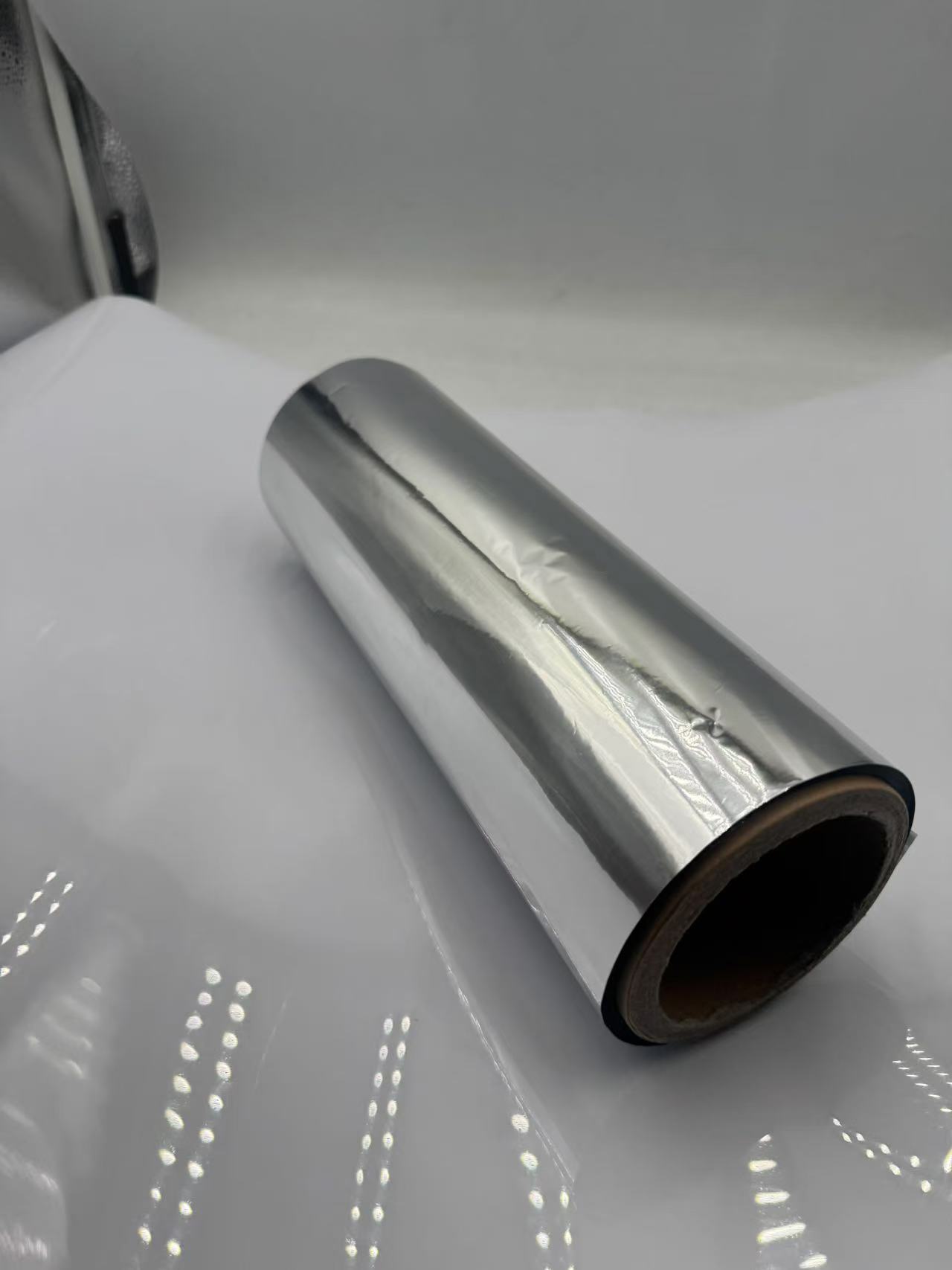

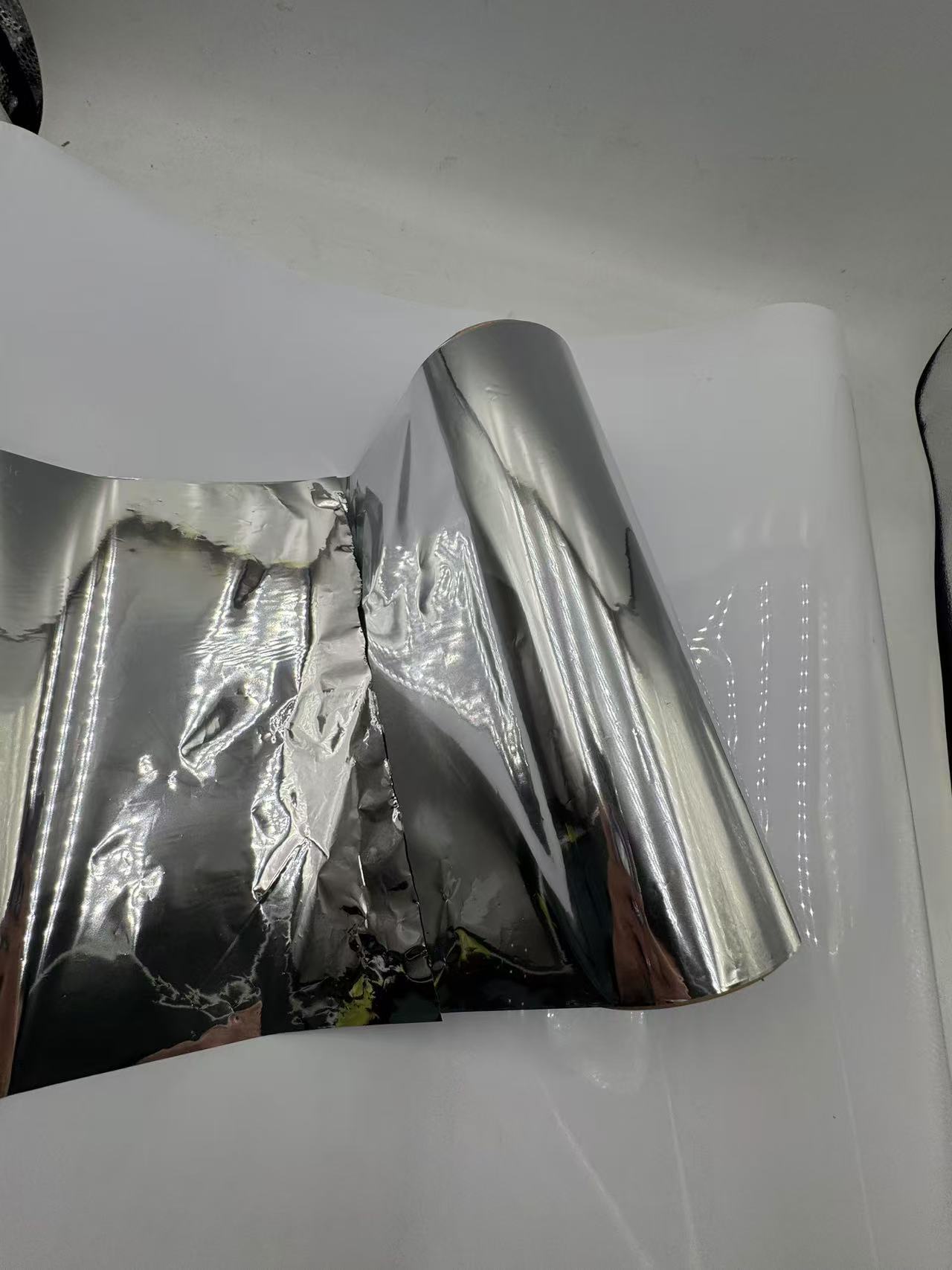

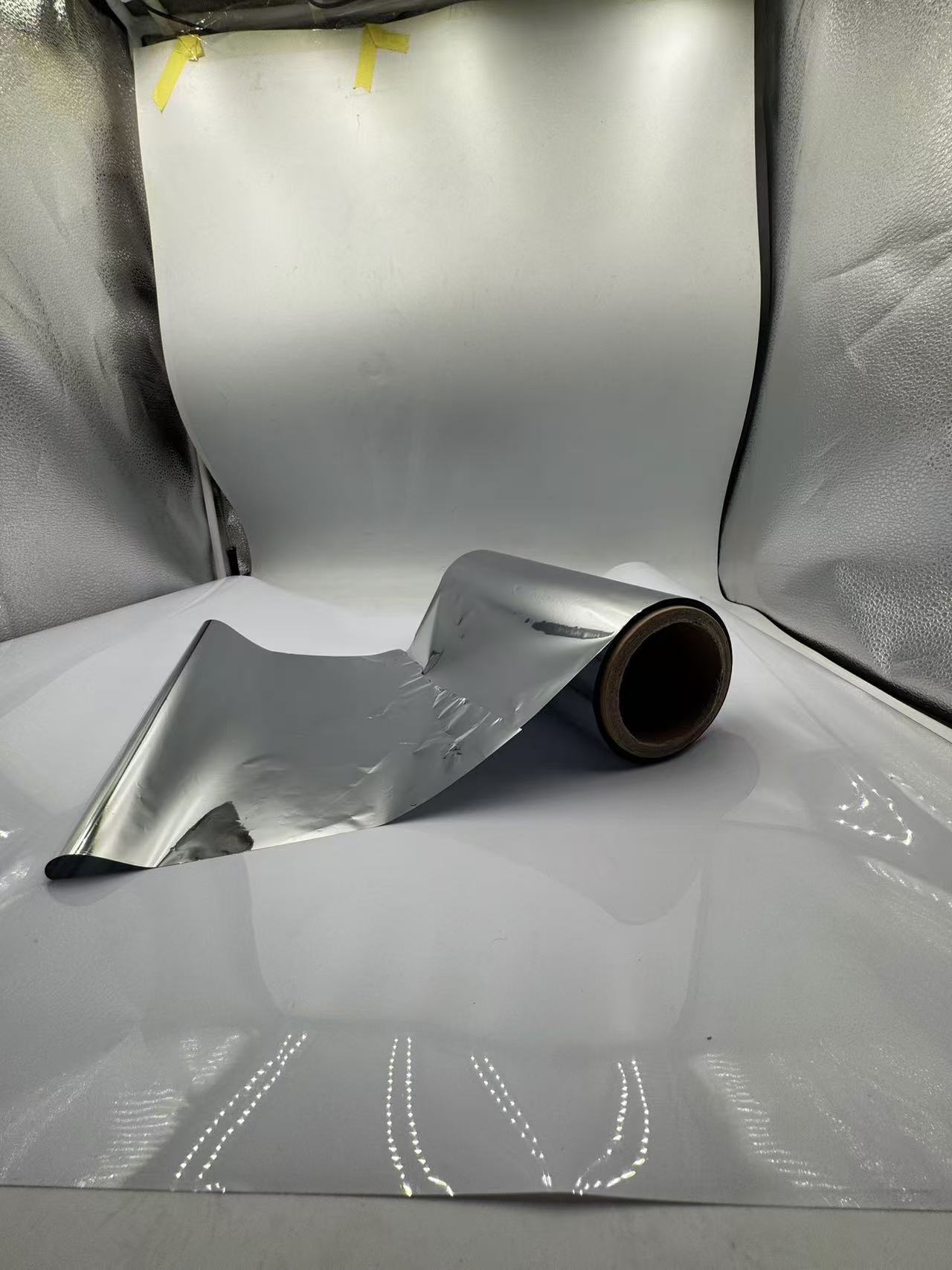

Material: PET metalized sheet

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: silver/ transparent/white/ customization

location: china

usage :for food tray plant tray

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Metallized PET Film: A Marvel in Many Ways-Various Applications

Introduction

Metallized PET film is a very versatile material in today's world, as it embodies excellent properties of PET with added benefits due to metalization. The process consists of depositing a thin layer of metal-usually aluminum-on the surface of the PET film, thus forming a unique combination of features that make it suitable for a wide range of applications.

II Properties of Metallized PET Film

A. Physical and Mechanical properties

Strength and durability

Metallized PET film has high tensile strength that makes it difficult to tear and puncture. Extra protection is provided by the metal layer that enhances the resilience of the film in withstanding mechanical tension, for example, in the case of packaging that can offer protection for certain products against sharp objects or poor handling.

Further, abrasion resistance enhances the resistance of the film to wear and tear. This makes it apt for applications where friction or rubbing of the film may take place, such as manufacturing of industrial products or in the packaging of high -end consumer goods.

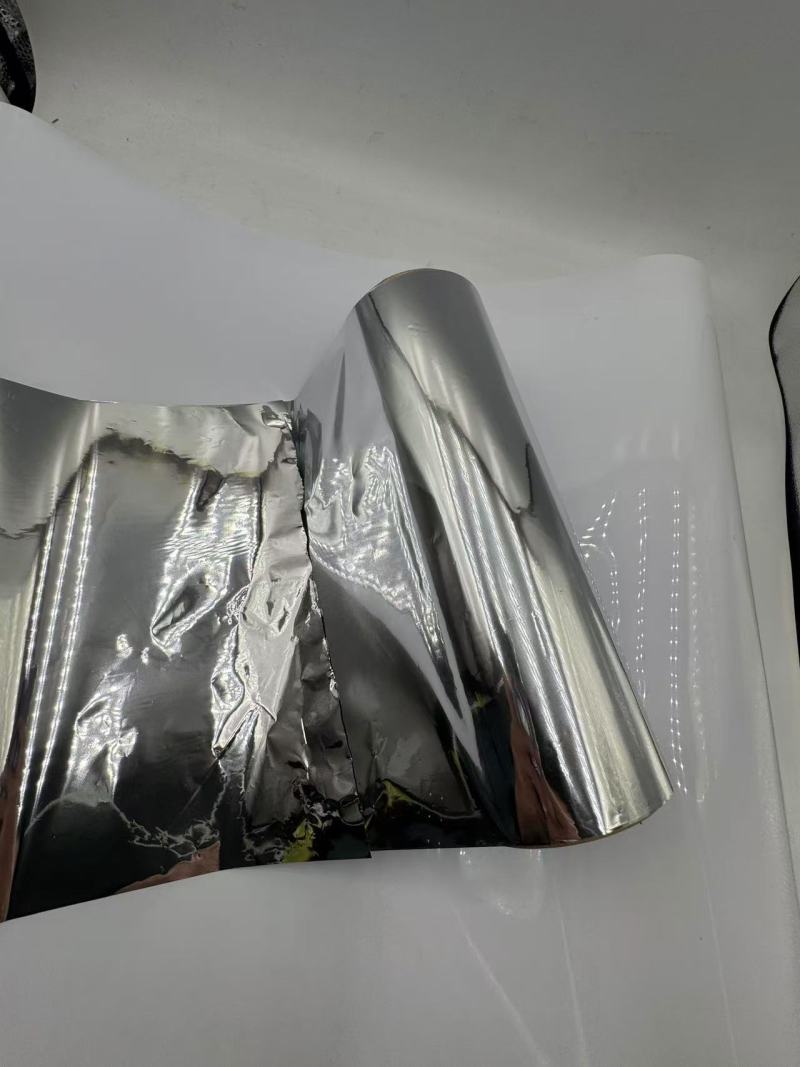

Flexibility

Metallized PET film is quite flexible; it can be bent, molded in so many ways, rolled into various forms, and therefore wrapping, laminating, or packaging will not be a problem, which again allows it to fit different shapes and sizes for various product designs.

Its flexibility also extends the area of application to include areas where the film has to be folded and bent. In food packaging for example, folding is used in achieving a seal around the product.

B. Chemical and barrier properties

Water barrier

The metal layer in the PET film works to block moisture. Water vapor cannot permeate through the film with it, hence the product remains dry and safe. This is critical in packaging applications like food, wherein moisture may either spoil or degrade the product completely.

The barrier against moisture further assists in improving the shelf life of products through reducing the rate of moisture absorption. Similarly, pharmaceutical products will have their drugs retain integrity and would not get affected by the humidity due to the moisture - proof properties of metallized PET film.

Gas and oxygen barrier

This metallized PET film provides excellent barriers to gases, such as oxygen. Actually, the metal layer stops all kinds of gas passing, including oxygen, carbon dioxide, and nitrogen. These are important for retaining qualities and freshness in food items or drugs, whichever might be susceptible to oxidation.

The barrier properties against gases in metallized PET film packaging prevent the growth of microbes, especially bacteria, by not allowing oxygen to reach the bacteria for their respiration related to growth. Flavor and aroma are also preserved by preventing the loss of the volatile compounds.

Chemical resistance

The film has characteristics of resistance against a great deal of chemicals-from acids and alkali to organic solvents. Therefore, the film is suitable for applications where exposure to different substances may well happen. For example, in the packaging of industrial products, the film provides an effective barrier against possible chemical corrosion.

The chemical resistance of the metallized PET film also extends the possibility of its application in various fields where sterilization is required. This film is resistant to heat, radiation, and chemical disinfectants applied for sterilization.

III Applications in Different industries

A. Packaging industry

Food packaging

Metallized PET is being used in food packaging applications for its excellent barrier value. The packaging of several snack foods, baked foods, and frozen foods involves various types of food product presentations. The film protects food against moisture, oxygen, and other contaminants that spoil the food, extending their shelf life.

The film is used as a wrap to seal products in snack packaging because it does not allow the entry of air and moisture, which may destroy the freshness of snacks. It can keep such snacks crunchy for a longer time. Because of its transparency, one can view the inside product and find the product more attractive.

For frozen foods, the resilience of the film to low temperatures makes it suitable for packaging. It can be used to protect the food against freezer burn and maintain quality. The flexibility of the film also makes it easy to be wrapped around the product for easy storage and transportation.

Pharmaceutical packaging

The reason metallized PET film is used for pharmaceutical packaging is that, to a great extent, this will protect the drugs against moisture, oxygen, and other contaminants. This acts in barriers to maintain the integrity of drugs and prevent their susceptibility to environmental changes.

The film can be used in the packaging of tablets and capsules to seal around the product, preventing the ingress of air and moisture. This keeps the drugs fresh and stable. The transparency of the film allows the health provider to easily see the product inside, thus making it easier to dispense the drugs.

The ability of the film to be sterilized makes it suitable for use in the packaging of medical devices. It can be used to protect the devices from contamination and ensure their sterility.

Consumer goods packaging

Of late, different types of metallized PET films are used in the packaging of cosmetics, household products, and even electronic goods. This protects the product against moisture, oxygen, and other contaminants that can affect quality and appearance.

The film can be extended to form a seal which covers the product without allowing air or moisture to permeate inside the package, thus keeping the product fresh and free from the effects of bacteria. Its transparency allows one to view the product inside, which makes it quite appealing.

In the case of electronics products, the film will protect the product from dust and moisture. It also creates a seal around the product to avoid air and moisture ingress. This will maintain the performance of the product and extend the life span.

B. Automotive industry

Automotive interior components

PET metallized film is also extensively used in car interior substrates, such as dashboard panels, seat covers, and door trims. The barrier against moisture and heat from the metalized layer helps prevent the components from being damaged.

Some of the decorative properties also make the film suitable for use in automotive interior design. It can be used to create a lot of patterns and textures, enhancing the aesthetic appeal of the interior of the vehicle.

Besides, mouldability and easy shaping properties of the film make it fit for use in the manufacture of vehicle interior parts. This material can be used in producing custom-shaped parts to suit particular designs of vehicles.

Car body parts

The metallized PET film is also used in body panels, windshield wipers, and even headlights of cars. The ability of this film to provide a barrier against moisture and UV radiation helps shield such components from destruction.

Because the film provides reflective properties, it is suitable for automotive exterior uses. The film can be used in making a shiny surface that reflects sunlight, improving the visibility of the vehicle.

Furthermore, the tendency of the film to adhere easily to other materials allows the application of this material in the production of external parts for automobiles. This product allows a continuous transition between sections of the vehicle.

C. Electronics industry

Electronic components' packaging

It finds application in metallized PET film used to package electronic gadgets like smartphones, tablets, and different components of computers. Therefore, the films protect against moisture, oxygen, and other contaminants that can quickly deteriorate performance and reliability in these devices.

The film can easily be moulded and shaped; hence, the film is used in packaging electronic devices. It is good for making custom-shaped parts that exactly fit the requirements of the device.

Due to the electrical conductive properties of the film, it also finds an important application in the packaging of electronic appliances. It is used for the creation of grounding layers that shield the device from electrostatic discharge.

Solar panels

For this reason, the metallized PET film is used as a protective layer for solar panels. The barrier properties of the film against moisture and UV radiation protect the solar cells against some sort of damage.

Reflective properties of the film make it suitable for application on solar panels, too. This is used to reflect sunlight on the solar cells and considerably increases the efficiency of the solar panel.

Furthermore, the tendency of the film to easily stick to other materials is another added advantage in the manufacture of solar panels. This will provide a perfect avenue where smooth connections between different parts of the solar panel can be achieved.

IV Challenges and future trends

A. Challenges

Cost - effectiveness

Regarding cost, metallized PET can be relatively expensive compared to many other packaging materials because of the processes involved in its creation: metalization and expensive raw materials. However, there are those instances whereby protection and performance benefits it is accorded with may balance off costs in some cases.

One factor is the hurdle facing manufacturers to try and minimize their cost of production. This could either be by optimizing the metalization process or finding cheaper materials that will help reach the same results.

Recyclability

Metallized PET film cannot be directly recycled due to the metal layer. The metal layer needs to be separated from the PET film for recycling to occur. This can be cumbersome and costly.

To overcome this hurdle, manufacturers must develop effective, efficient, and cost-effective recycling methods. The firms must also raise awareness on the importance of recycling to consumers and encourage them to recycle metallized PET films.

Environmental impact

The processing of metallized PET film tends to have a great environmental impact resulting from the energy and material usage. The metalization processes also tend to emit some greenhouse gases.

A. Impact on design

Manufacturers will have to make the production methods greener and cleaner by minimizing energy and resource usage. They should also develop ways of minimizing greenhouse gas emissions.

B. Future trends

Development of new materials

Presently, there is a developing trend in the establishment of fresh materials that may replace metallized PET film with better performance and environmental properties. The development of biodegradable materials is an example that can be used for packaging applications.

As new materials are developed, there will be an improvement of the existing materials. For instance, nanotechnology can be used to enhance the properties of metallized PET film even further.

Integration of technology

It is expected that with advanced integration of technology, performance and functionality will be enriched in the metallized PET film. For instance, the embedding of sensors or any device that will serve the purpose of monitoring the environment for any alteration in the product can be done in the film.

The integration of technology will also lead to new application development. For example, the film in medicine or biotechnology will result in developing new products.

Increased demand for sustainable packaging: Due to growing environmental awareness, sustainable packaging is a highly demanded packaging type. In this regard, it will be a huge task for metallized PET film to fulfill the demand with sustainable packaging options.

The demand for sustainable packaging has also facilitated innovations in various types of packaging materials and technologies. The usage of recycled material has also been practiced hugely nowadays, and biodegradable packaging is in demand.

V Conclusion

Metallized PET film has been a flexible and highly useful material within an array of industries. From its special properties, this material can be used on a wide scale for packaging, automobile, and electronic purposes. However, issues related to cost-effectiveness, recyclability, and environmental impact have yet to be resolved. Future trends in the development of new materials and integration of technology therefore promise good prospects for further development of metallized PET film. With continuous research and innovation, the use of metallized PET film will remain important in modern life.

Within 15-20 days after received payment...more