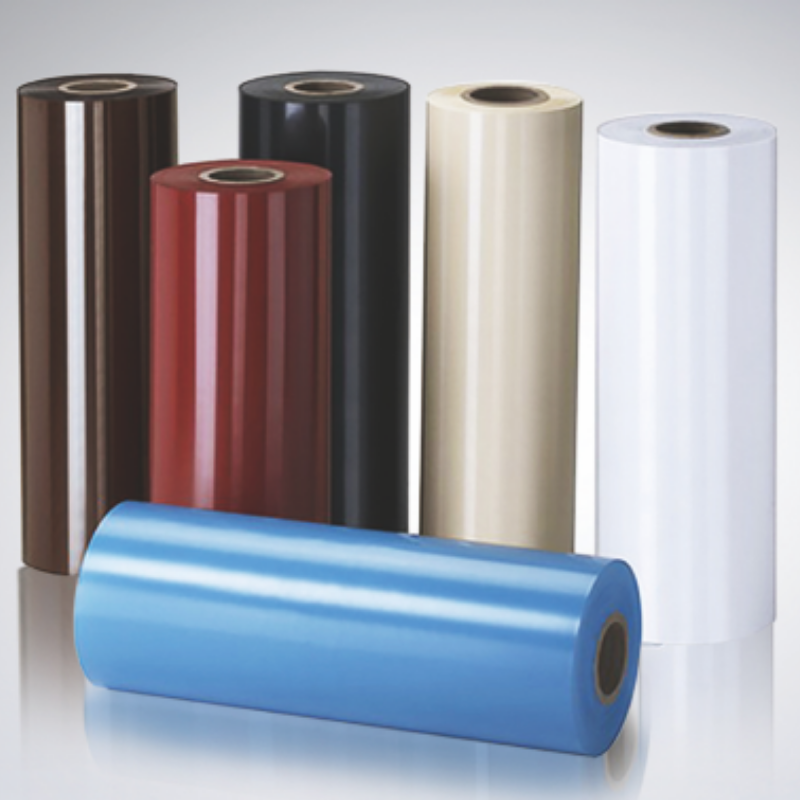

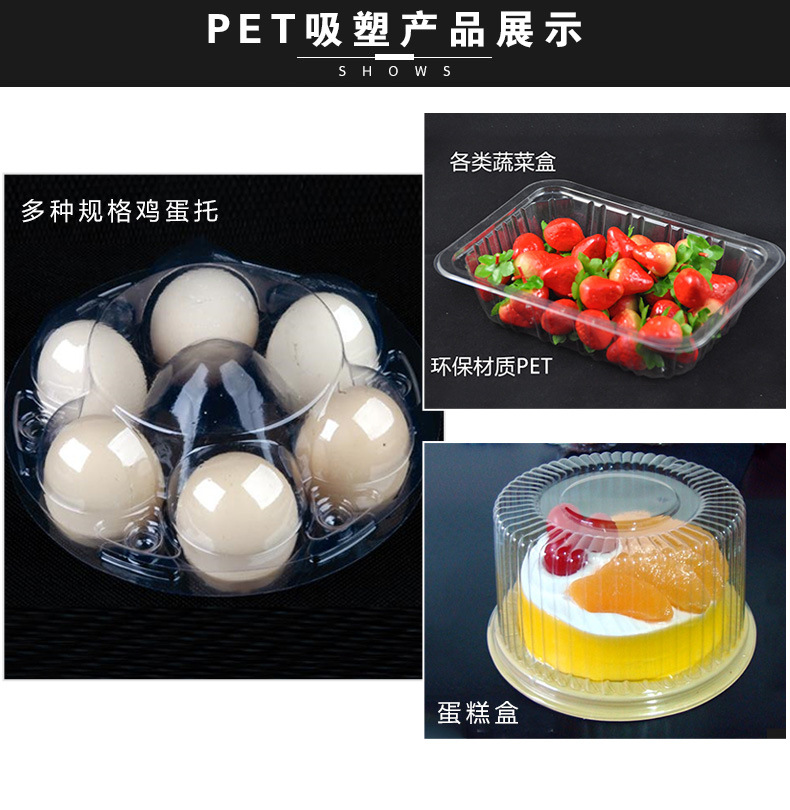

PET Film: From Colors to Varied Applications Such as Tableware, Blister Packaging, and Antistatic Sheets

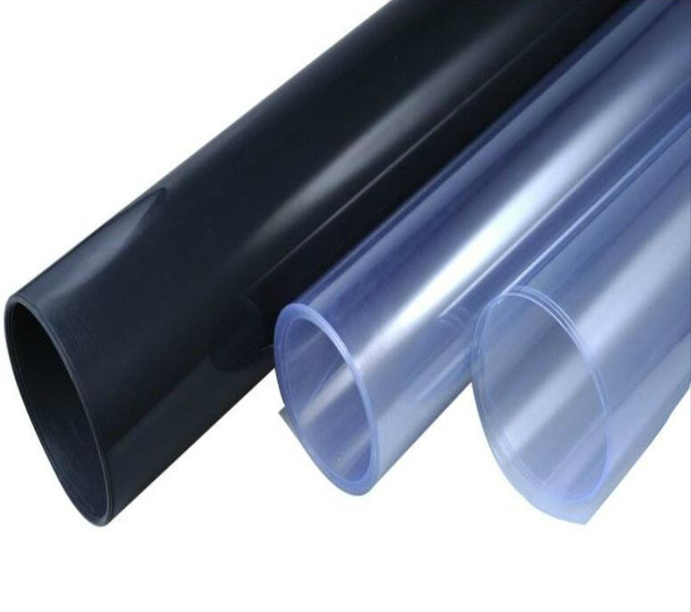

Material: PET Printable sheet

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

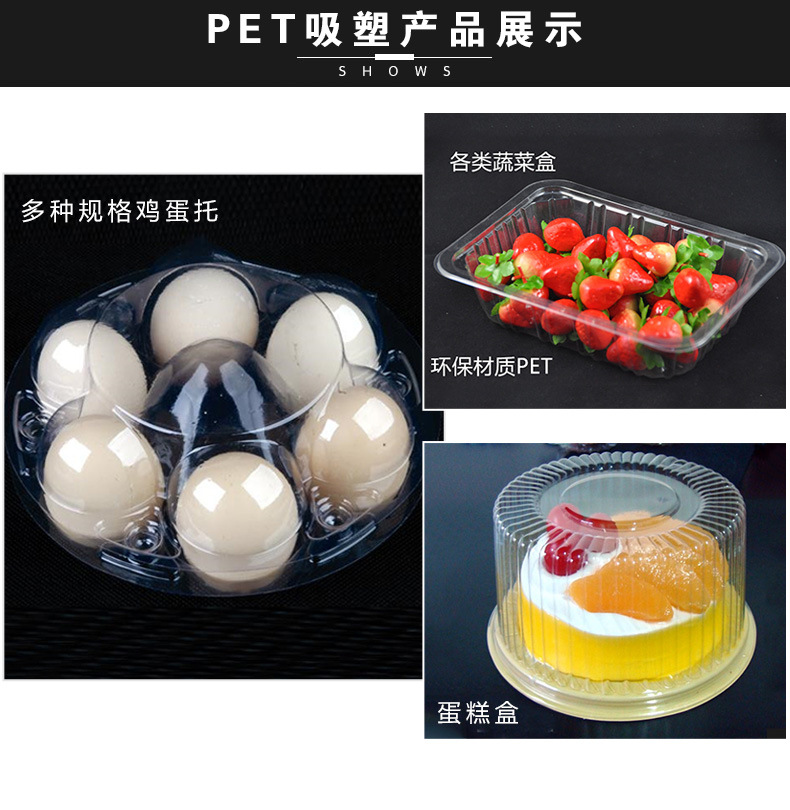

usage :for food tray plant tray

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Introduction

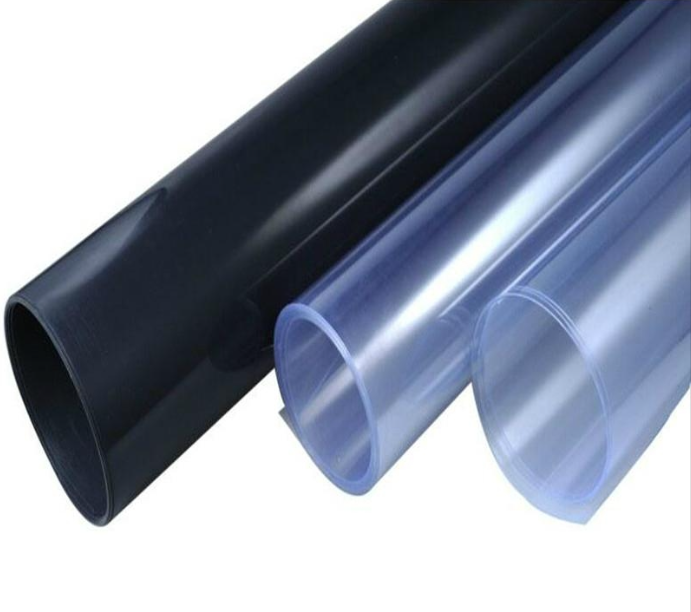

In the world of polymers, Polyethylene Terephthalate film is outstanding for its versatility, strength, and lately for its rainbow of colors. This article explores what makes colored PET films unique in their characteristics and specific applications related to tableware blister packaging, antistatic sheets

Characteristics of Colored PET Film

Optical Clarity and Color:

PET film is intrinsically clear and can be dyed or pigmented into a wide array of colors. This not only adds to aesthetic appeal but also offers functional advantages such as UV protection or colored visibility for safety applications.

Strength and Durability:

PET films have gained broad usage due to their high tensile strength, good resistance against chemicals, and against physical impacts. Colored variants retain these properties, hence assuring product integrity across various usages.

Barrier Properties:

PET provides great resistance to moisture, oxygen, and other gases, which is important in packaging applications that require long shelf life for products.

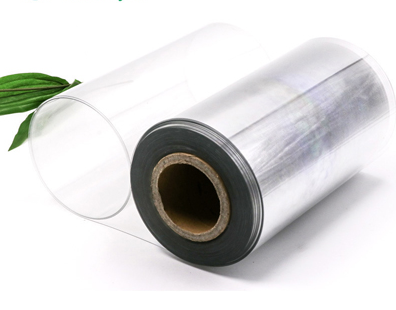

Thermoformability:

The possibility of thermoforming into complicated shapes-which makes PET a material of choice for blister packs and customized containers-adds color as another dimension for design possibilities.

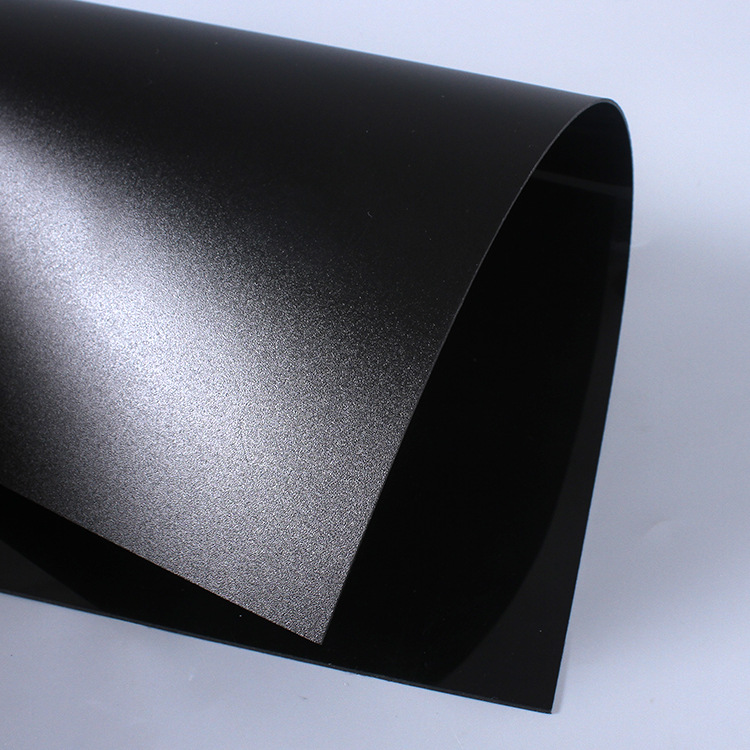

Antistatic Capabilities:

When engineered with specific additives, PET films can resist static cling, crucial for packaging electronic components to prevent static-induced damage.

Applications in Tableware

In tableware, colored PET films bring both function and flair:

Disposable Cups and Containers: Bright, vibrant colors can indicate types of content (e.g., blue for cold drinks, red for hot foods) or simply make meals more appealing.

Food Trays: Colored PET, while colored, can give aesthetic presentations of foods without sacrificing its barrier properties.

Blister Packaging

Colored PET adds an esthetic touch and protective feature in blister packaging:

Pharmaceutical: Color identification allows for easy differentiation at one glance. This provides much safer and more convenient handling.

Consumer Goods: Colorants in PET will add extra marketing appeal on products ranging from toys to hardware.

For electronic components, colored PET films have two main uses:

Protection: Antistatic properties are required, and the color can denote specific levels of static protection or be used for branding.

Identification: In manufacturing, different colors can mean different types of components, streamlining assembly processes.

Color Beyond Functionality

Decorative Uses: Colored PET films are used in laminations, labels, and even as decorative elements in interior design, where they can simulate more expensive materials.

Safety Signs: High-visibility colors like yellow or red in PET films are used for warning signs or safety gear where visibility is crucial.

Environmental Considerations

While durability strengthens the nature of PET, environmental considerations have become very concerning nowadays:

Recyclable: PET is a good material to be recycled, and colored films are not an exception, although it can be really challenging in a recycling process by sorting them out with colors.

Sustainability: Some development of biodegradable or compostable variants has been done, although this happens more on clear PET.

Material Recovery: There is ongoing research in making colored PET more recyclable or at least ensuring that the colors used do not contaminate recycling streams.

Challenges and Innovations

Color Consistency: Consistency in color between batches creates a very real challenge both in manufacturing and consumer perception.

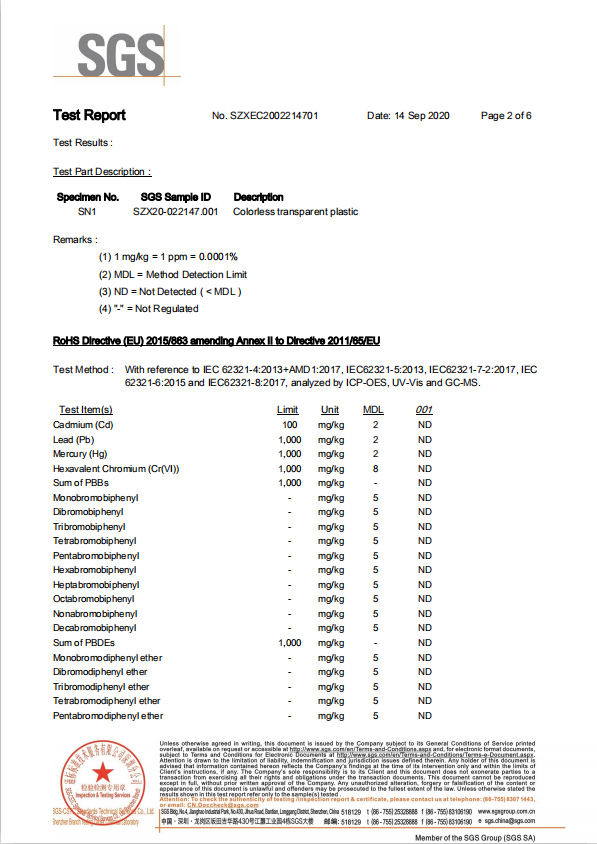

Dye Migration: Some colors might migrate into food or react with substances over time, necessitating rigorous testing for food-contact applications.

Advanced Antistatic Formulations: Research continues to enhance the antistatic properties of colored PET without compromising color or clarity.

Conclusion

Colored PET films have dramatically increased the scope of material applications by marrying functionality and aesthetics. From the mundane to the high-tech, these films are integral parts of modern packaging, providing both protection and branding opportunities.

In our drive toward sustainability, however, the industry needs to balance color's benefits with environmental stewardship, fostering those innovations that keep PET the material of choice for the future.

This journey into the colorful world of PET film not only illustrates its utility but begins to discuss how we can evolve these materials to meet current demands and future goals of sustainability.

Within 15-20 days after received payment...more