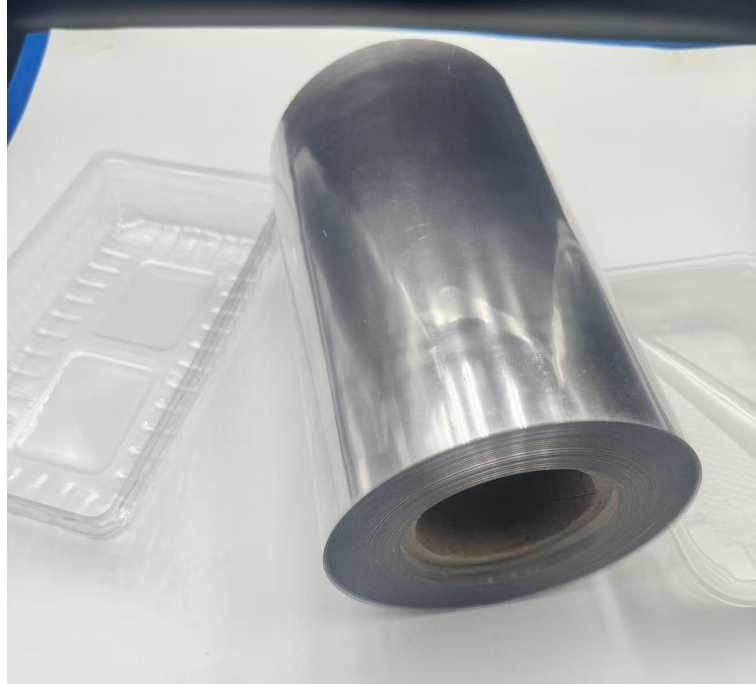

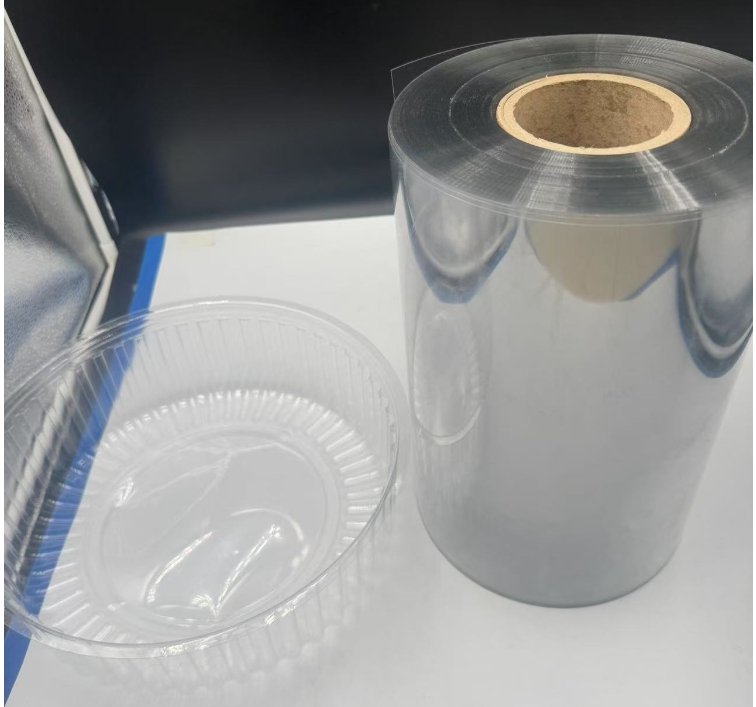

Natural Colored Transparent PET Rigid Film

high tensile strength, good dimensional stability, and resistance to moisture and gases

- TL

- 中国

- 2025.02.28

- 1000 tons

- Information

No. | Index Name | Unit | Index |

| 1 | Density | g/cm3 | 1.36±0.1 |

| 2 | Melting Point | ℃ | ≥256 |

3 | Tensile Strength | MPa | 15-100mm≥150 100-190mm≥140 190≥110 |

| 4 | Elongation | % | ≥40-80 |

| 5 | Heat Shrinkage | % | ≤3.5-2.0 |

| 6 | Volume Resistivity | MΩ/m | ≥1.0x108 |

| 7 | Relative Dielectric Constant | Hz | 2.9-3.4 |

| 8 | Dielectric Strength | V/um | ≥250-50(6m-350m) |

| 9 | Heat resistance grade | E 120℃ |

PET (Polyethylene Terephthalate) rigid film is a type of plastic film known for its excellent mechanical properties, including high tensile strength, good dimensional stability, and resistance to moisture and gases. It's widely used in various industries due to its versatility and beneficial characteristics. Here are some key points about PET rigid film:

### Properties:

1. **Strength and Durability**: PET films are strong and durable, making them suitable for applications that require a tough, long-lasting material.

2. **Clarity and Gloss**: They offer high transparency and gloss, which makes them ideal for packaging where product visibility is important.

3. **Chemical Resistance**: PET films resist many chemicals, including oils, fats, and water, making them suitable for food and beverage packaging.

4. **Thermal Stability**: They can withstand a wide range of temperatures, from freezing to moderate heat, without deforming or losing their properties.

5. **Barrier Properties**: PET films provide good barrier protection against oxygen, carbon dioxide, and moisture, which is crucial for preserving the quality and freshness of packaged goods.

### Applications:

1. **Packaging**: Used in food, beverages, and pharmaceutical packaging. Common examples include blister packs, lidding films, and trays.

2. **Electronics**: PET films are used as insulating materials, protective overlays, and in flexible printed circuits.

3. **Labels and Graphics**: Due to their printability and durability, PET films are used for labels, signage, and other graphic applications.

4. **Industrial Uses**: In the manufacturing of tapes, adhesives, and other industrial products.

5. **Medical Devices**: Used in medical packaging and as components in medical devices due to their biocompatibility and sterilization capabilities.

### Types of PET Rigid Films:

- **Amorphous PET (APET)**: This type is clear and has good optical properties, often used in packaging and displays.

- **Crystalline PET (CPET)**: This type is more heat-resistant and is often used in ovenable trays and containers.

- **Coated and Metallized PET**: These films have additional layers or coatings to enhance specific properties such as barrier performance or aesthetics.

### Environmental Considerations:

- **Recyclability**: PET is recyclable, and many recycling programs accept PET bottles and containers. However, the recycling of PET films can be more challenging due to their thinness and potential contamination with other materials.

- **Sustainability**: There is increasing interest in using recycled PET (rPET) to reduce environmental impact. Some manufacturers also explore bio-based alternatives to traditional PET.

### Manufacturing Process:

- **Extrusion**: The most common method involves melting PET resin and extruding it through a die to form a sheet, which is then cooled and rolled.

- **Biaxial Orientation**: For enhanced properties, the film can be stretched in both the machine and transverse directions, creating a biaxially oriented PET (BOPET) film.

### Properties:

1. **Strength and Durability**: PET films are strong and durable, making them suitable for applications that require a tough, long-lasting material.

2. **Clarity and Gloss**: They offer high transparency and gloss, which makes them ideal for packaging where product visibility is important.

3. **Chemical Resistance**: PET films resist many chemicals, including oils, fats, and water, making them suitable for food and beverage packaging.

4. **Thermal Stability**: They can withstand a wide range of temperatures, from freezing to moderate heat, without deforming or losing their properties.

5. **Barrier Properties**: PET films provide good barrier protection against oxygen, carbon dioxide, and moisture, which is crucial for preserving the quality and freshness of packaged goods.

### Applications:

1. **Packaging**: Used in food, beverages, and pharmaceutical packaging. Common examples include blister packs, lidding films, and trays.

2. **Electronics**: PET films are used as insulating materials, protective overlays, and in flexible printed circuits.

3. **Labels and Graphics**: Due to their printability and durability, PET films are used for labels, signage, and other graphic applications.

4. **Industrial Uses**: In the manufacturing of tapes, adhesives, and other industrial products.

5. **Medical Devices**: Used in medical packaging and as components in medical devices due to their biocompatibility and sterilization capabilities.

### Types of PET Rigid Films:

- **Amorphous PET (APET)**: This type is clear and has good optical properties, often used in packaging and displays.

- **Crystalline PET (CPET)**: This type is more heat-resistant and is often used in ovenable trays and containers.

- **Coated and Metallized PET**: These films have additional layers or coatings to enhance specific properties such as barrier performance or aesthetics.

### Environmental Considerations:

- **Recyclability**: PET is recyclable, and many recycling programs accept PET bottles and containers. However, the recycling of PET films can be more challenging due to their thinness and potential contamination with other materials.

- **Sustainability**: There is increasing interest in using recycled PET (rPET) to reduce environmental impact. Some manufacturers also explore bio-based alternatives to traditional PET.

### Manufacturing Process:

- **Extrusion**: The most common method involves melting PET resin and extruding it through a die to form a sheet, which is then cooled and rolled.

- **Biaxial Orientation**: For enhanced properties, the film can be stretched in both the machine and transverse directions, creating a biaxially oriented PET (BOPET) film.

Get the latest price? We'll respond as soon as possible(within 12 hours)