718 BOPE Transparent Film: Unraveling Its Exceptional Properties and Diverse Applications

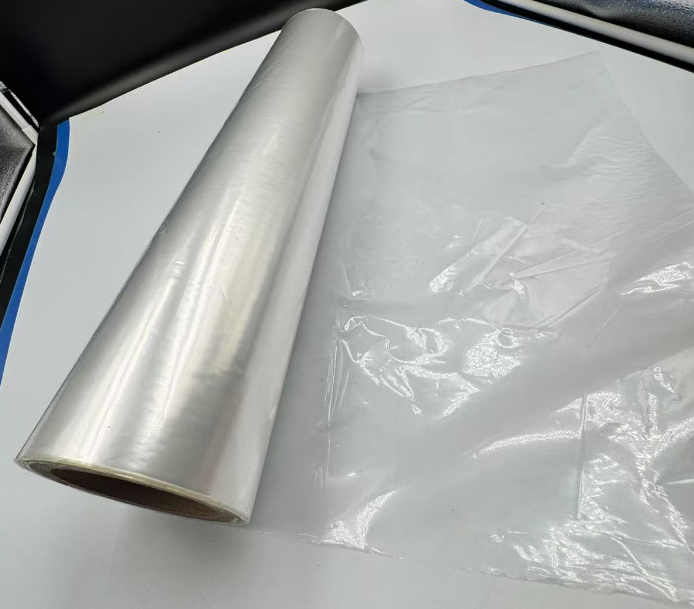

Material: BOPE film roll

Thickness 0.012mm/customization

Size: 200MM Customization

GRADE: Food grade film

color: white/fog/matt/ clear customization

location: china

usage: for food protection, food heat-sealing box,lamination

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

BOPE Transparent Film: Unraveling Its Exceptional Properties and Diverse Applications

In this modern material world, Biaxially Oriented Polyethylene-BOPE transparent film has been an astonishing development in recent years and has revolutionized numerous aspects of human life. This value-added film is made from PE resin with a special molecular structure and is manufactured by using the existing flat-film biaxial stretching production line, generally through the BOPP film production line.

I. Excellent Properties of BOPE Film

Mechanical Strength

High Tensile and Puncture Resistance: BOPE film has a unique combination of outstanding mechanical properties. It is highly oriented in molecular and crystalline structure, making it outstanding in impact and puncture resistance. The puncture strength is higher by about 2 - 5 times than conventional films. Surprisingly, even when an intense impact is applied, the amount of deformation that occurs is very minimal. This makes it highly reliable for applications where integrity in packaging needs to be maintained, as is the case in transportation and storage of sharp or heavy objects.

Improved Tensile Strength: Whereas the blown films have a tensile strength 2-8 times higher than the existing ones, BOPE can reach over 100 Mpa in both directions. This strength allows it to withstand high forces without tearing or overstretching and thus protects packages and products from damage.

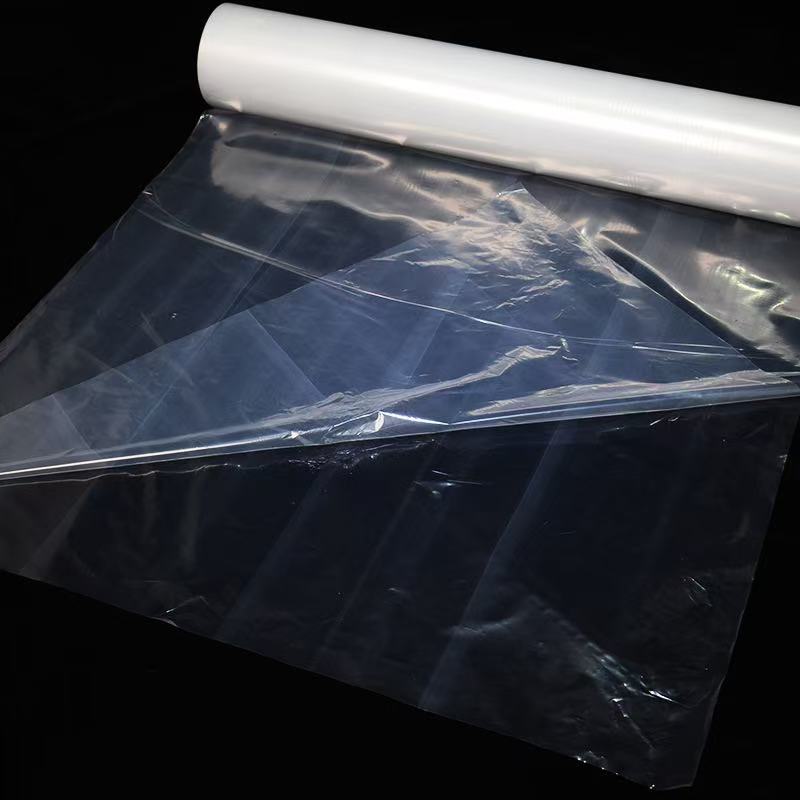

2. Optical Excellence

Because the processing of BOPE, with producing by casting sheets followed by rapid cooling, gives it a very fine crystalline structure, the films thus prepared show superior clarity and a low haze: 30%-85% less than ordinary grades. With a high degree of transparency and gloss and minor crystal points, it serves perfectly in the packaging of consumer goods which are needed to be presented more attractively or even display applications. It makes the contents inside transparent for the consumers, adding to its presentation.

3. Processing Advantages

Uniform Thickness for High-Speed Operations: The process of flat-film stretching in BOPE production maintains excellent thickness uniformity. This characteristic is very important to modern high-speed printing and composite processes. With precise control over thickness, ink in printing can be evenly distributed to offer sharp and consistent images. The same allows composite bonding to other materials seamlessly, ultimately enhancing the quality of the final product.

Tearability and Versatility: BOPE film also exhibits a degree of tearability, which is useful in some packaging applications. An example includes allowing easy opening of packages without compromising the integrity of the sealed portion for end-user convenience.

4. Thermal and Environmental Properties

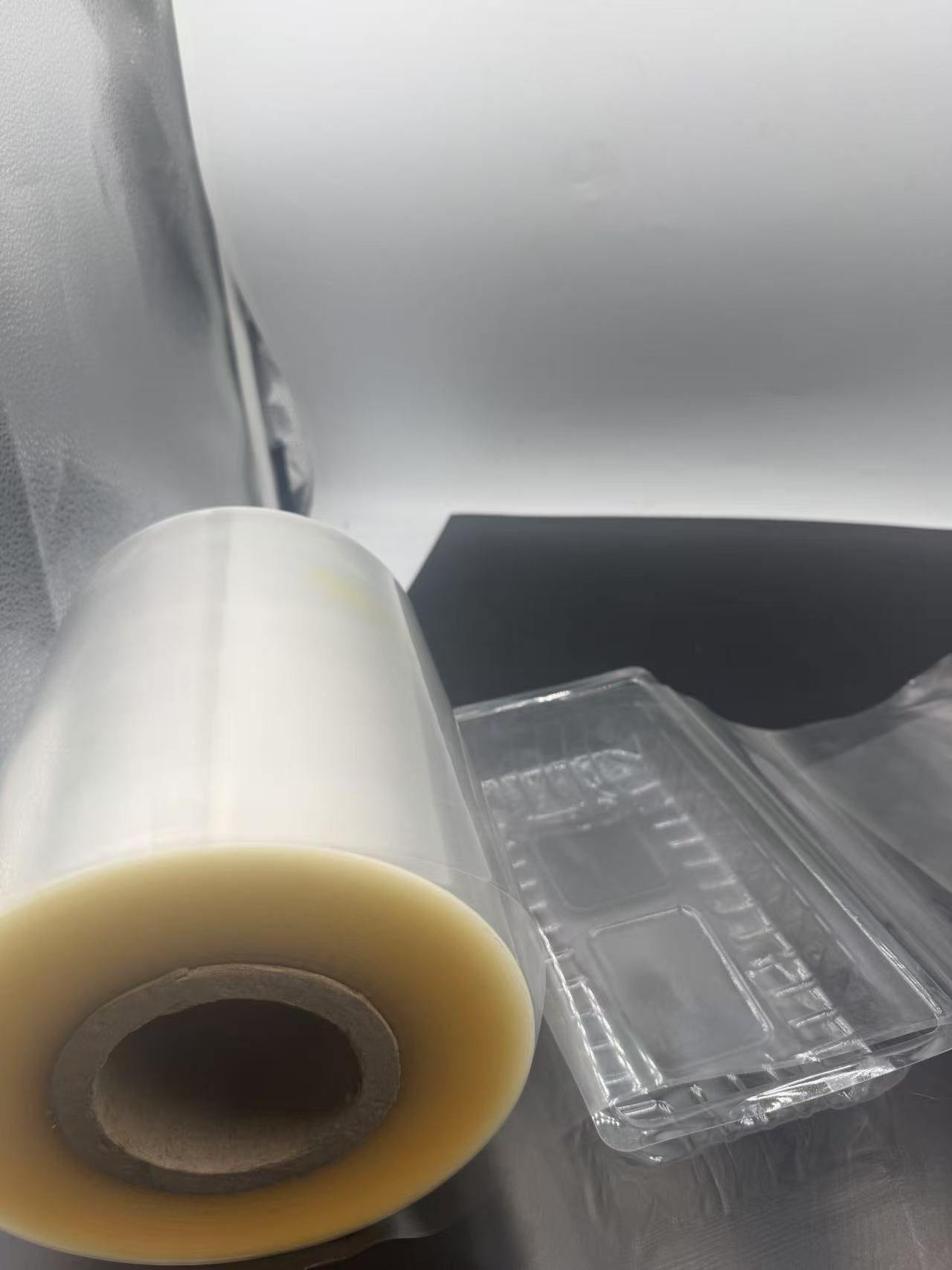

High Heat Seal Strength: BOPE is able to achieve the same heat seal strength as traditional films in packaging, but at half the thickness. This will not only reduce material usage but also ensure a tight seal that prevents leakage or spoilage of the contents. Be it food, pharmaceuticals, or any other sensitive product, the reliable heat seal is an important aspect.

Freeze resistance: BOPE gives freeze resistance in packaging of frozen foods stored at temperatures as low as -18℃. Due to the above-explained attributes of good low-temperature impact strength, resistance to pinholes, and very good low-temperature flexibility, it gives far lower rates of bag breakage upon substitution for blown or cast CPE films combined with BOPA in dry composite packaging.

Long Wetting Tension Retention and Good Printability: BOPE films retain wetting tension for a long period, which assists in very good printing performance. The ink adheres properly, and colors remain vibrant even after a long time under various environmental conditions. This is beneficial for branded packaging where the maintenance of the visual identity is important.

II. Applications in Daily Life

Packaging Industry

Food Packaging: Within the food sector, the properties of BOPE are a game-changer. Given that it is a high gas barrier, it may act for perishable items like fresh produce to extend shelf life by regulating the exchange of oxygen and carbon dioxide. When applied to frozen foods, as mentioned above, resistant to low temperatures without cracking or losing integrity will see to it that the products remain intact, freezer burn-free. Its transparency further aids consumers in identifying the content contained within the package with much ease for a better shopping experience.

Packaging of Pharmaceuticals: Pharmaceuticals require packing, which is protective against moisture, light, and other forms of physical damage. BOPE boasts excellent barrier features, combined with sterility and resistance to chemicals, suitable for blister packs, pouches, and other formats in pharmaceutical packaging. The precise thickness control and printability further allow for clear labeling of the dosage instructions and product information in a legible manner.

Consumer Goods Packaging: From electronics and electronics, BOPE imparts added sleekness and strength to the packaging of products. Its high gloss and transparency enhance the on-shelf appearance of packaged goods through luring consumers toward it. Full-fledged cosmetic brands could showcase their products in BOPE packaging and protect them against scratch or any sort of impact during transportation.

2. Agricultural Applications

Greenhouse Films: The BOPE film can also be used in agriculture for greenhouse films. High transparency allows for maximum penetration of sunlight to increase the growth rate of the plants. Besides that, durability and resistance to wind, rain, and UV radiation provide a longer lifetime compared to conventional films, reducing replacement frequency and conserving both cost and labor for farmers.

Mulching Films: The BOPE mulching films serve effectively in the inhibition of weed growth, retention of soil moisture, and regulation of soil temperature. Their tearability can be an asset at the end of a growing season when it will be time to remove the film. With enhanced mechanical properties, they are resilient enough not to tear under the rigors of the installation and use process in fields.

3. Medical Field

Sterile packaging: BOPE can be processed under sterile conditions and is resistant to microbial penetration; hence, it is suitable for medical device packaging. This provides a sound barrier for sensitive instruments and implants against any kind of contamination. The clear nature of the film will further enable the clear visual inspection of the contents for the integrity of the packaged medical items.

Wound Dressings: BOPE films, due to their biocompatibility and control of moisture vapor transmission rate, can be incorporated in some advanced wound dressing designs. They will be able to create an environment that is conducive for wound healing while protecting the wound from external contaminants.

4. Industrial and Other Applications

Printing and Laminating: BOPE is preferred in printing and laminating due to its thickness uniformity and excellent printability. It can serve for high-quality posters, labels, and packaging inserts. Among the features highly valued by them is the possibility of achieving good color reproduction and sharp images.

Electronics Packaging: BOPE, with anti-static and cushion properties after having been blended with suitable additives, avoids the damages of sensitive electronics during shipment and storage. Besides that, transparency will allow inspections to be easily carried out by technicians without necessarily having to open the package.

From our food and medicines to developing farming yield, right up to the revolutionary medical implementations, there's nothing in which the transparent films by BOPE have ever disappointed. Besides, providing room for its application development due to continued research and improvements of its raw material processing consolidates a well-deserved position among popular plastics usage in modern everyday life.

Within 15-20 days after received payment...more