PC plastic sheet, short for Polycarbonate plastic sheet, is a high-performance thermoplastic material renowned for its exceptional impact resistance, transparency, and thermal stability. With a CAS number of 25037-45-0 and a repeating unit molecular formula of (C₁₆H₁₄O₃)ₙ, it is synthesized through the polycondensation of bisphenol A and phosgene. Processed via methods like extrusion, calendering, or co-extrusion, it forms sheets with versatile properties, making it a preferred choice across multiple industries.

Superior Impact Resistance: PC sheet has impact strength 200-300 times that of ordinary glass and 20-30 times that of acrylic sheet. It is unbreakable under normal impact, earning it the nickname "unbreakable glass".

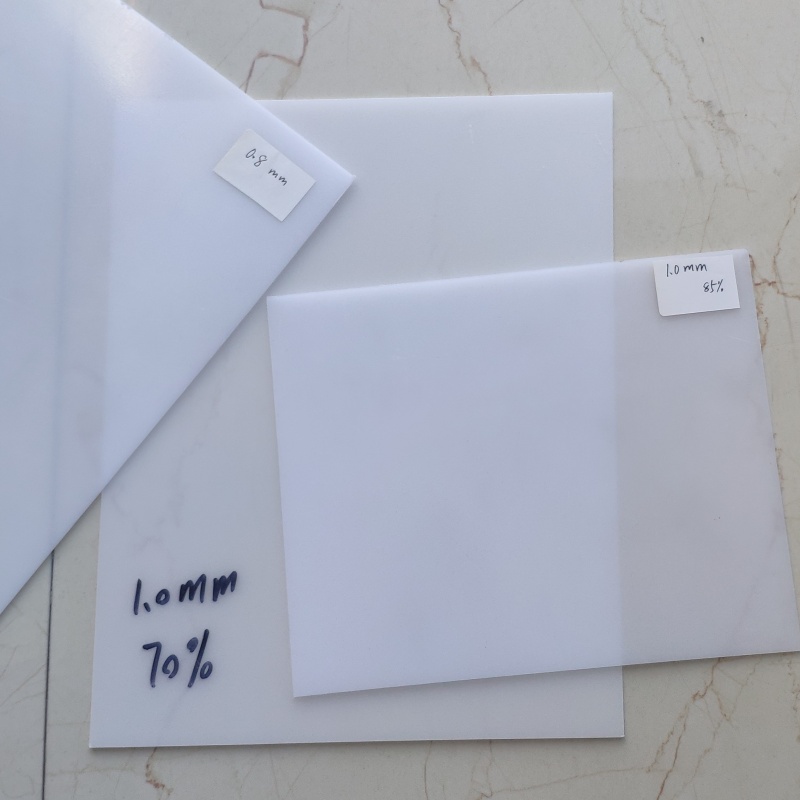

Excellent Transparency: It offers high light transmittance, typically 88-92% (comparable to glass), with good light diffusion and no yellowing under long-term use (for UV-stabilized grades).

Broad Thermal Adaptability: It maintains stable performance in a wide temperature range, from -40°C to +120°C for long-term use. Short-term heat resistance can reach up to +135°C, and it has low thermal shrinkage (≤0.5% at 120°C).

Chemical & Environmental Resistance: It resists dilute acids, alkalis, oils, and most organic solvents. UV-stabilized PC sheets (with a co-extruded UV layer) can withstand outdoor UV radiation for 5-10 years without aging, while non-UV grades are suitable for indoor use.

Mechanical & Processing Advantages: It has good tensile strength, bending strength, and creep resistance. It is easy to process—supporting cutting, drilling, thermoforming, printing, and bonding without damaging its inherent properties.

Safety & Flame Retardancy: Most PC sheets meet flame retardant standards (e.g., UL94 V-2 or V-0 rating). It is non-toxic and compliant with food contact regulations (e.g., FDA 21 CFR 177.1580), making it safe for food packaging and medical applications.

What's your delivery time?

Within 15-20 days after received payment

...more