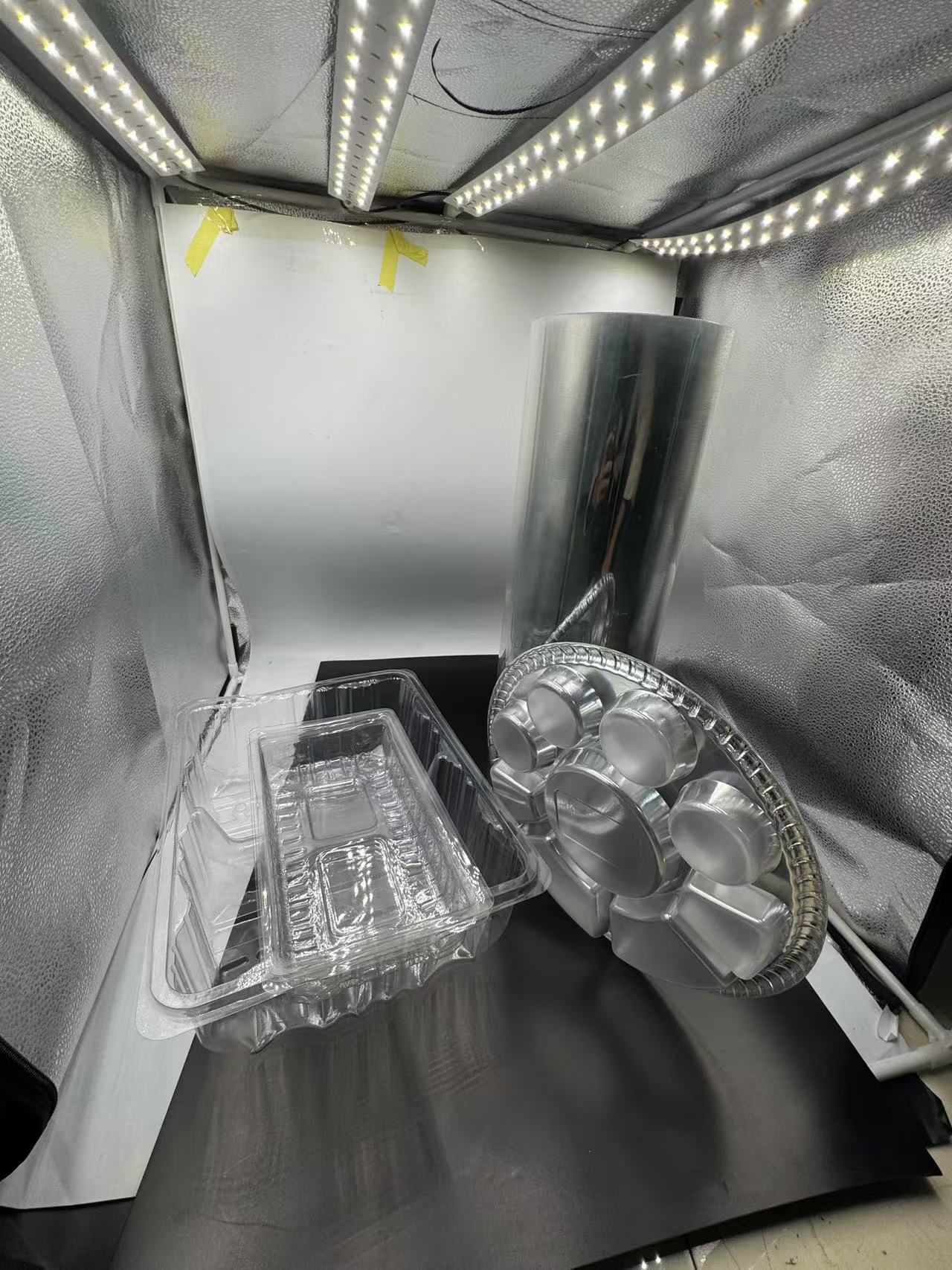

The Ver0202satile Application of Transparent PET Film in Product Blister Packaging

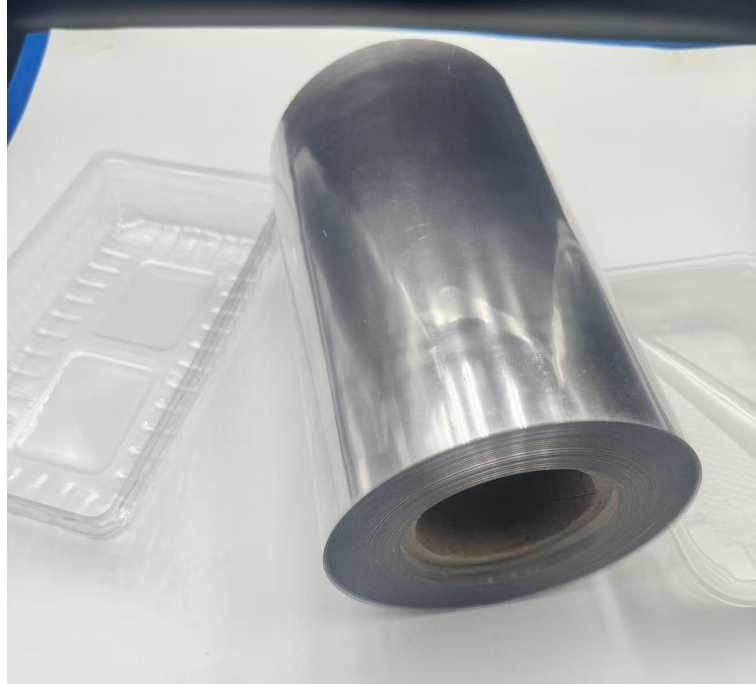

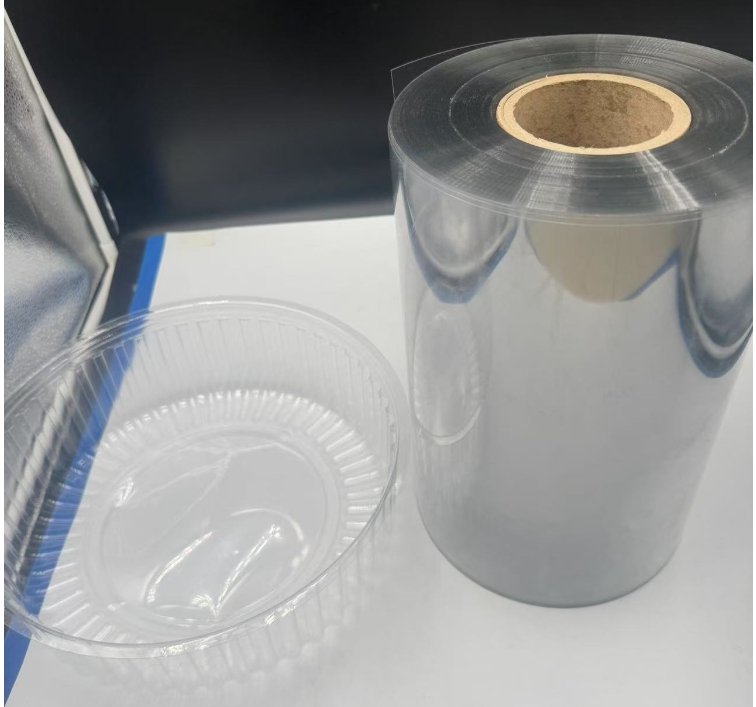

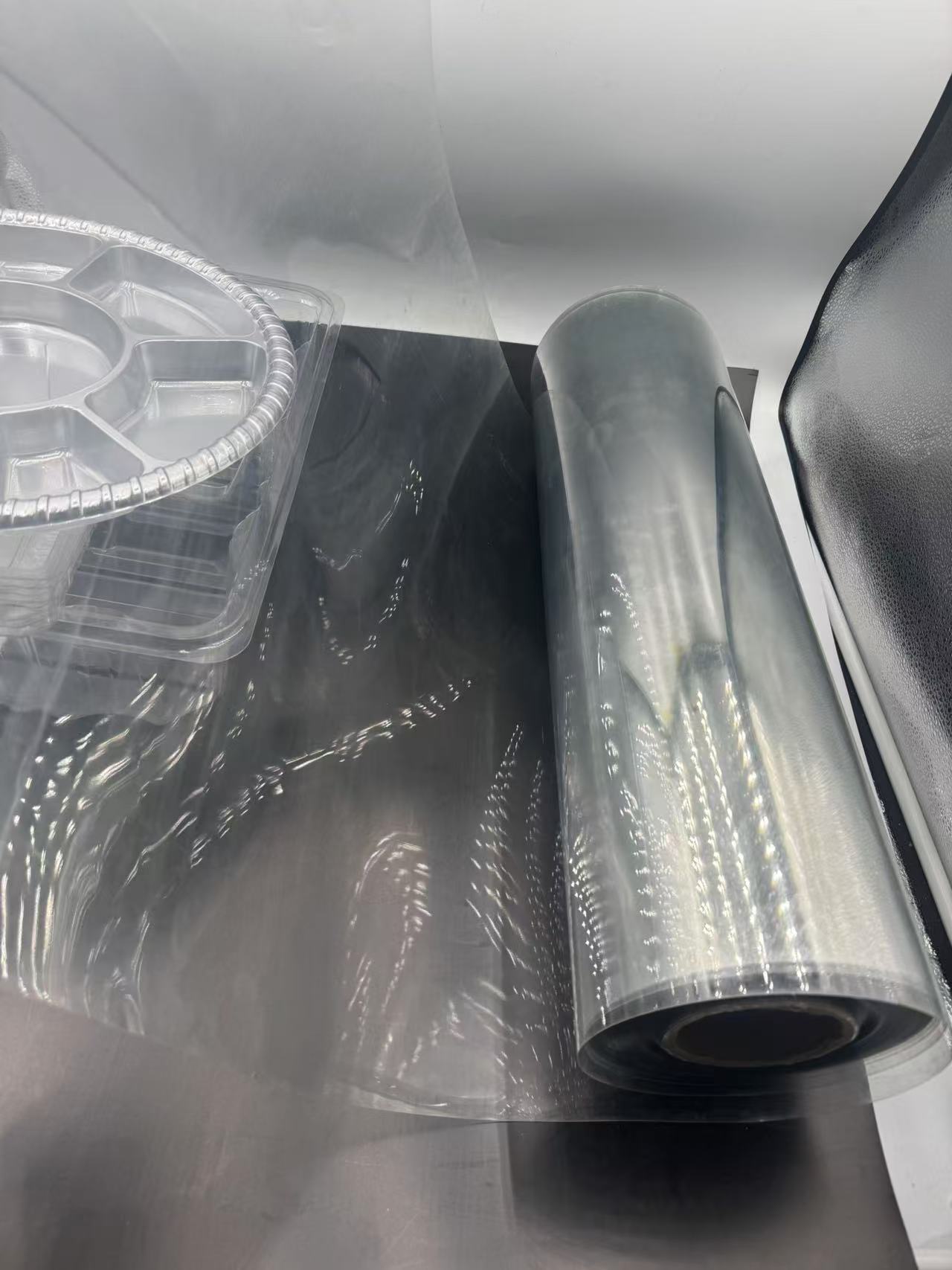

Material: PET Printable sheet

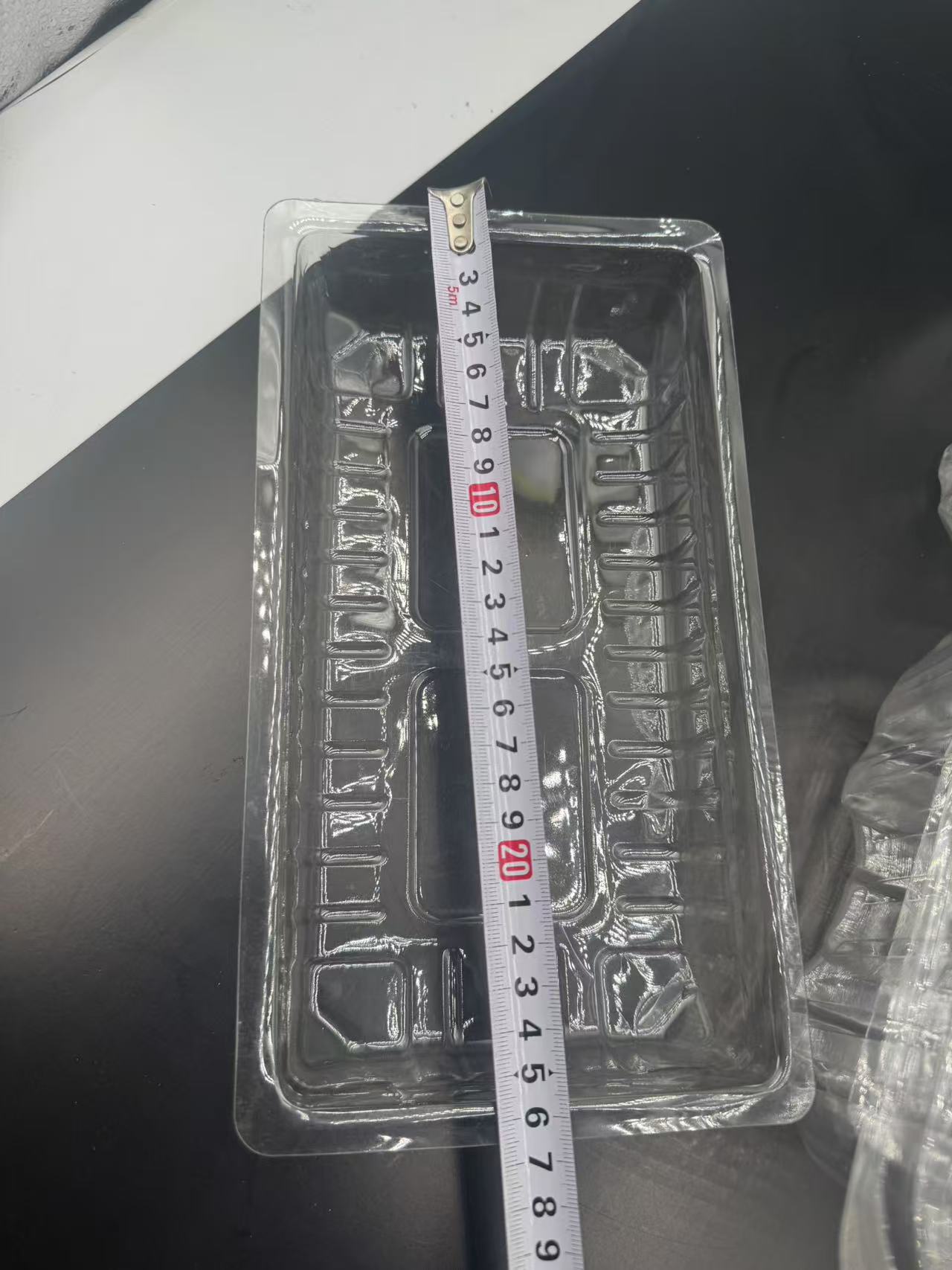

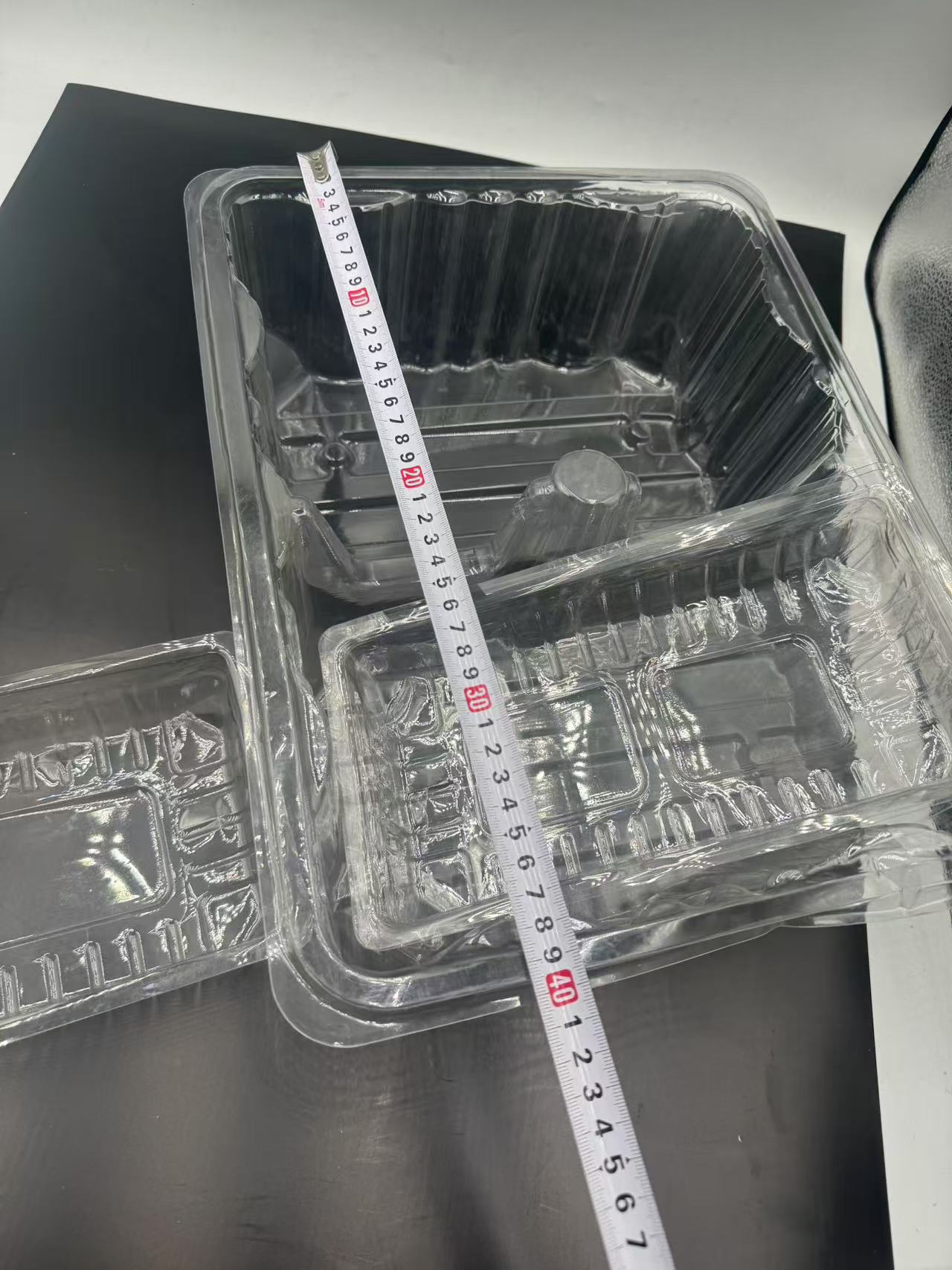

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

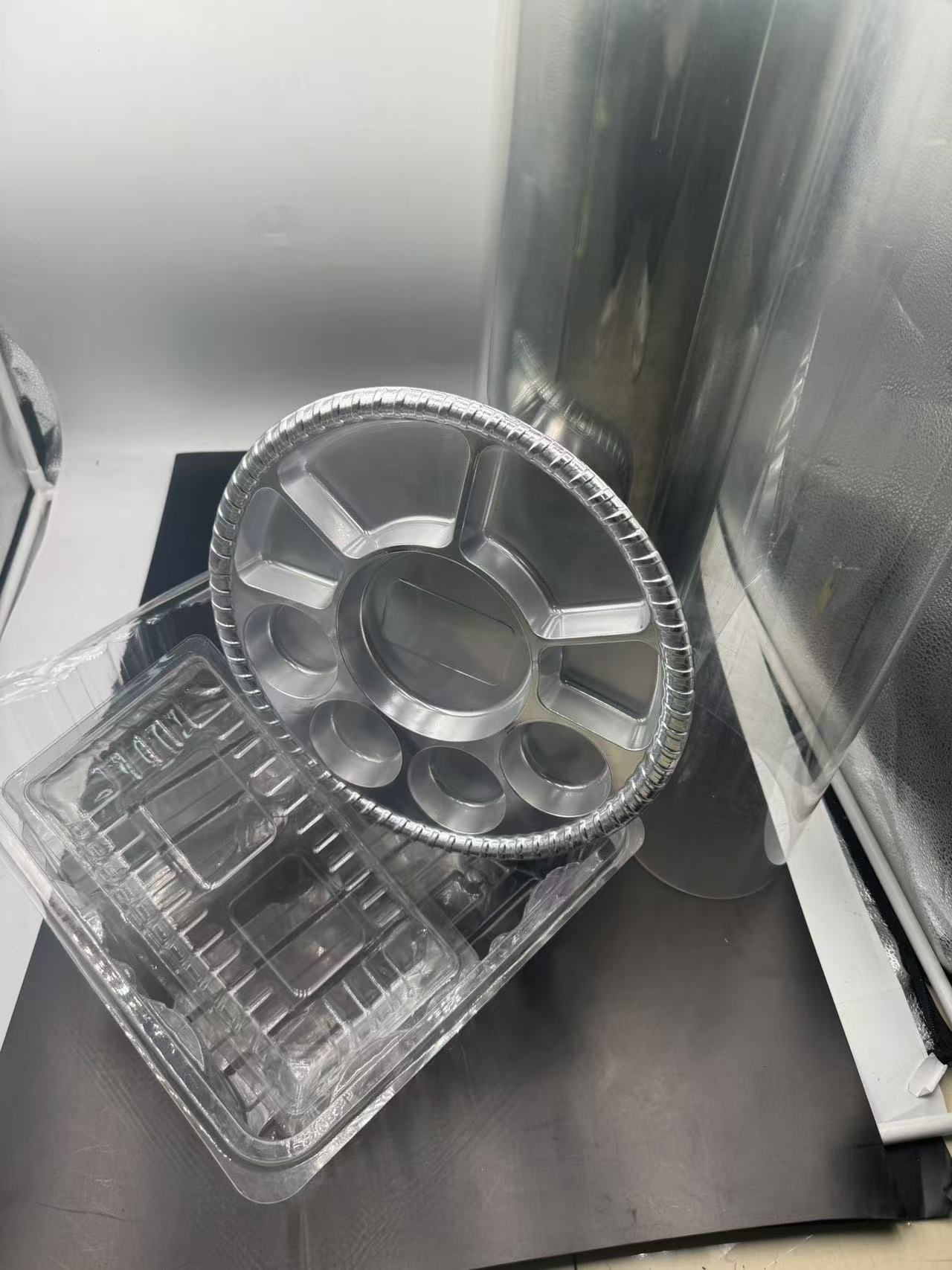

usage :pet-blister-food-tray-fruit-plate-meat-plate-vegetable-container

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

The Versatile Application of Transparent PET Film in Product Blister Packaging

In the dynamic world of product packaging, transparent Polyethylene Terephthalate-PET-film has emerged to be a star player, especially when relating to blister packaging. Such a marvelous material has redefined the presentation, protection, and merchandising of products, offering a benefit profile cut across many industries.

I. Understanding Transparent PET Film

Transparent PET film is produced with a thermoplastic polymer that exhibits clarity, strength, and versatility. It is made by the polymerization of ethylene glycol and terephthalic acid into a highly crystalline material. This structure provides excellent mechanical properties to the film while maintaining its optical transparency and allowing the packaged product to be showcased full.

The film is available in various thicknesses, starting from 12 microns to 500 microns, depending on the application. Thinner films are preferred for their cost and flexibility, while thicker films offer better strength and rigidity and hence can be used for heavier or fragile products that require more protection.

II. Benefits of Transparent PET Film for Blister Packaging

Exceptional Clarity and Aesthetics

Among the most striking characteristics of clear PET film, brilliant transparency is one. In blister packaging, clear PET film provides consumers with maximum view of the product encapsulated within. This is, therefore, of utmost importance in consumer electronics, cosmetics, and confectionery. If it were high-end smartphones or tablets, for instance, their sleek design and fine details would be fully visible and alluring to prospective buyers. Cosmetic firms also make use of the transparency of the film to show colors and textures-be it some high-end lipstick or an eyeshadow palette shining with shades. The appearance given by the film enables products to stand out on crowded store shelves, therefore hugely elevating their appeal to customers and chances of purchase.

Superb Mechanical Strength

Transparent PET film is much more mechanically strong, though looking so feeble. The tensile strength gives the degree of resistance to bending, stretching, and shock the material can support without tearing or cracking. This strength is quite instrumental in blister packaging for shielding the product during transportation, handling, and storage. Just imagine packaging glass ornaments or some precision-engineered medical devices. Here, PET film would act like a good protector by absorbing such shocks that might cause damage due to rough handling or accidental falls. Besides, the tensile strength prevents the blister from bursting and ensures that the blister pack maintains its integrity up to when it reaches the hands of an end-user. Barrier Properties: Transparent PET film exudes a good barrier to moisture, gases, and odor. This is important to those products that are critical to environmental factors. In the food industry, for example, PET film can help extend the shelf life of perishable items like baked goods, chocolates, and dried fruits. By creating a barrier against moisture, it prevents sogginess and spoilage, while also keeping out oxygen that can cause oxidation and rancidity. Similarly, in the pharmaceutical sector, it safeguards medications from humidity and air, preserving their potency and effectiveness. The ability to control ingress and egress of substances makes PET film the ideal choice for maintaining quality and freshness in a wide variety of products.

Thermoforming Capabilities

PET film is highly amenable to thermoforming, which is at the heart of blister packaging. This film becomes pliable and can be molded into precise shapes and sizes when heated within a specific temperature range, usually between 120°C to 180°C, enabling it to closely fit around the contours of the product. This gives custom-designed blister packs that fit snugly around the item being packaged, thus providing protection as well as a good aesthetical presentation. The thermoforming process is very efficient and lends itself to automation, whereby high-volume production runs can be manufactured with ease and with consistent quality. There is also a design flexibility in the blister format manufactured by the producers, including different depths, cavities, and shapes according to every product's specific needs and requirements.

Printability and Branding Opportunities

Another major advantage of using transparent PET film concerns its printability features. It presents a smooth surface that easily takes ink, thus allowing colorful and complex printing. This extends to a wide array of options in branding for companies. Logos, product descriptions, usage instructions, and promotional messages can be printed on the film for brand identification and imparting information to the consumer. In the beverage industry, for example, PET bottles often have elaborate labels printed on transparent PET film sleeves. These labels not only identify the product but tell a story, whether it be the heritage of the brand, the unique brewing process of a craft beer, or even the health benefits of a functional drink. This makes PET film go from a simple packaging material to a powerful marketing tool.

Recyclability and Sustainability

Considering today's environmental concerns, it is a plus that the transparent PET film can be recycled. Among all the plastics, PET is one of the most widely recycled types. All over the world, most recycling facilities have established processes of how to handle PETs. As products packaged within the blister packs of the PET reach their end-of-life stage, the film may be collected, sorted out, and recycled into other new products. This closed-loop recycling system reduces the demand for virgin materials, conserves energy, and minimizes waste. Many companies are now actively promoting their use of recyclable PET packaging in the name of sustainability initiatives dear to the hearts of environmentally conscious consumers and helping clean up the future.

III. Applications in Different Industries

Consumer Electronics

The consumer electronics industry requires packaging that will not only protect expensive and sensitive devices but also highlight their features. Transparent PET film is in wide application for blister packs of smartphones, tablets, headphones, and other gadgets. In the case of smartphones, it allows potential buyers to see the size of the screen, the quality of the camera, and the overall design without even opening the package. It also provides a layer of protection against scratches and minor impacts during transit. Moreover, the printability of the PET film also enables the manufacturer to print the technical specification, warranty details, and brand logos on the packaging that enhances the consumer experience.

Cosmetics and Personal Care

Cosmetics companies use packaging as one of the major means of attracting consumers. Transparent PET film is a standard product in the industry. The product finds its application for lipsticks, mascaras, compacts, and skincare products. The clarity of the film enables the brilliant colors and rich textures of cosmetics to pop up for irresistible visual appeal. Take, for instance, this luxury lipstick in a sleek blister pack made of PET film-the package could easily show off as an eye-catcher on any cosmetics counter. This film protects such delicate products against damage or other contamination to ensure the arrival of perfect conditions for consumers. Moreover, the ability to print complex designs and brand elements on the film has also enabled cosmetics brands to build brand identity and appeal to their target groups.

Food and Beverage

In the food and beverage industry, transparent PET film plays a major role in maintaining product freshness and safety, along with improving display. For bakery products like cookies and pastry, PET blister packs keep them crisp and moisture-free, thereby increasing their shelf life. In the case of chocolates, the film acts as a barrier to heat and humidity which prevents the chocolate from melting and producing bloom. Many beverage firms make use of PET film sleeves or labels on bottles for branding and product information. Also, recyclability makes PET comply with the growing consumer demand for sustainable packaging in food and beverage industries.

Pharmaceuticals and Medical Devices

The pharmaceutical and medical device applications are demanding as there are a number of regulatory standards on sterility, protection, and dissemination of information. The clear film of PET is used in blister packs for wafers, capsules, syringes, and a lot of other medical products. Its barrier properties protect the medication against environmental aspects that could degrade its efficacy. The transparent nature of the film will enable practitioners and patients to easily identify the content to avoid medication errors. Furthermore, the possibility of printing even in detail dosage instructions and warnings on the film will assure that the patient has at their fingertips all necessary information. For medical devices, PET film offers clean and safe packaging during storage and transportation.

Toys and Collectibles

Toys and collectibles require a kind of packaging that will offer protection while looking appealing for both collectors and kids. The clear PET film is commonly in blister packages for action figures, model kits, trading cards, and other collectibles. The film allows enthusiasts to view the item details and quality inside the package without opening it, hence increasing anticipation and excitement. Besides, it protects the toys and collectibles from dust, scratches, and damages during shipment and display. Printing possibilities of PET film are utilized to feature character names, brand logos, and limited edition markings that increase the value of the items for collectors.

IV. Future Trends and Innovations

With the continuous development of technology and changing consumer preferences, transparent PET film used in blister packaging is bound for further improvements.

Nanotechnology Enhancements

Researchers continue to embed nanotechnology into PET film to make it even better. Nanoparticles can be added to give the film improved barrier properties, making it an even more resistant film to moisture, gases, and contaminants. This may extend shelf life for perishable products even longer. Nanocoatings may also be used on the film to apply anti-microbial properties that would be especially useful within the food and medical areas.

Smart Packaging Features: Smart packaging is now on its way and will include PET film as one of its potential players. For example, it is easy to embed sensors into the film to track the freshness of food products, which detect temperature, humidity, or gas composition changes. These sensors would, in turn, send signals to consumers through their smartphones, displaying in real-time the quality and safety of the product in question. In the pharmaceutical industry, smart packaging using PET film could help track the authenticity and integrity of medications, preventing counterfeiting and ensuring patient safety.

Sustainable Innovations

In the future, developments in transparent PET film will focus on further reduction of its environmental footprint, as the emphasis on sustainability continues to grow. This might involve the use of bio-based PET, sourced from renewable sources such as plant-based materials. Besides this, advances in recycling technologies will be channeled toward making the recycling process more effective and economically viable, with an increased percentage of PET film being recycled and reused.

Design and Customization

There will be change in the fact that consumers want unique and personalized products, and due to this, packaging will have to change. Manufacturers will continue to push the envelope with see-through PET film by offering more complex shapes, embossing, and even holographic effects. Another potential trend may be customizable packaging where the consumer can offer their own choice of design or personal message, especially in gift and luxury items.

In the final analysis, transparent PET film revolutionized product blister packaging with clarity, strength, barrier characteristics, and versatility found in no other packaging substrate. It has found use in a wide variety of industries, enhancing the protection, presentation, and ultimately the marketability of many products. As we proceed into the future, even further innovation in this sector will continue to bring more added value, further securing this product as the cornerstone of modern packaging.

Within 15-20 days after received payment...more