PET187 The Versatile Applications of Transparent Coated PET Printable Rigid Film Introduction

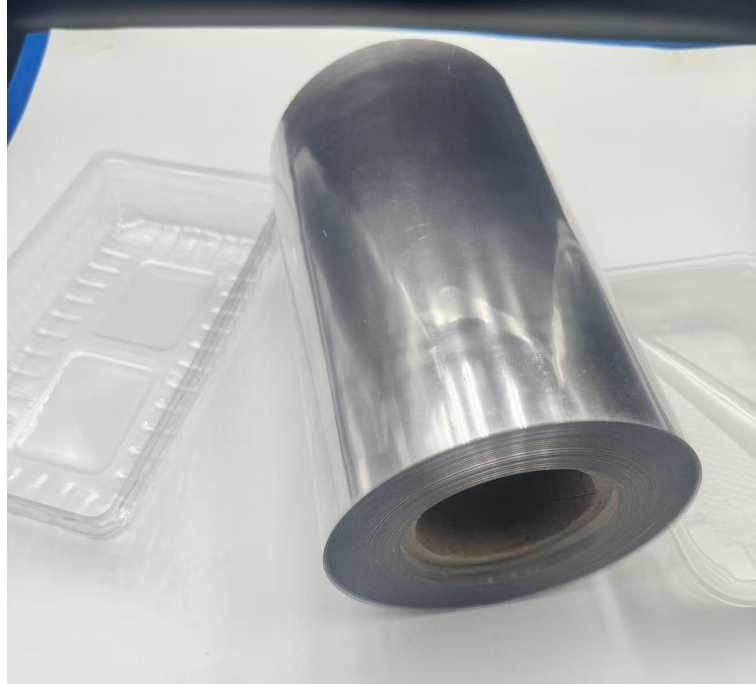

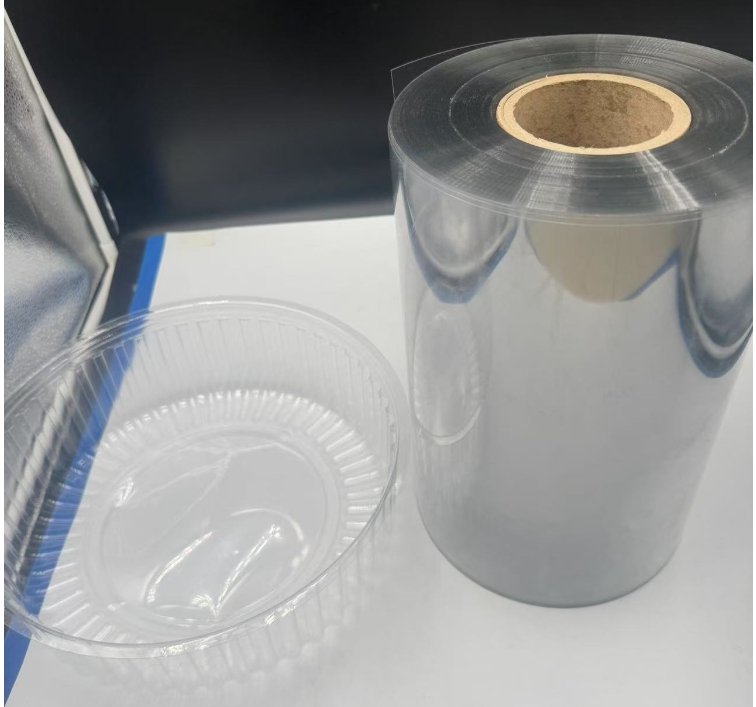

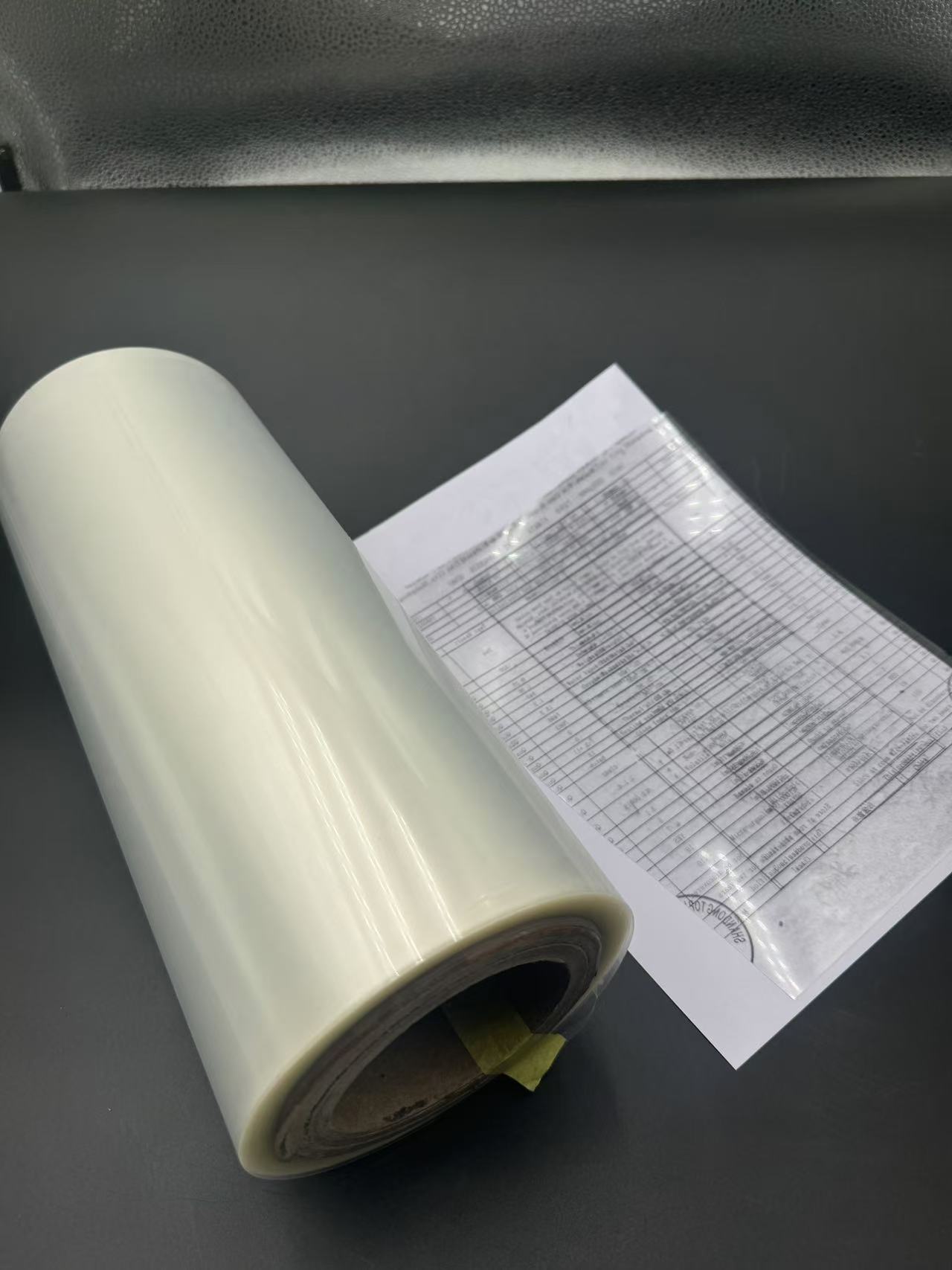

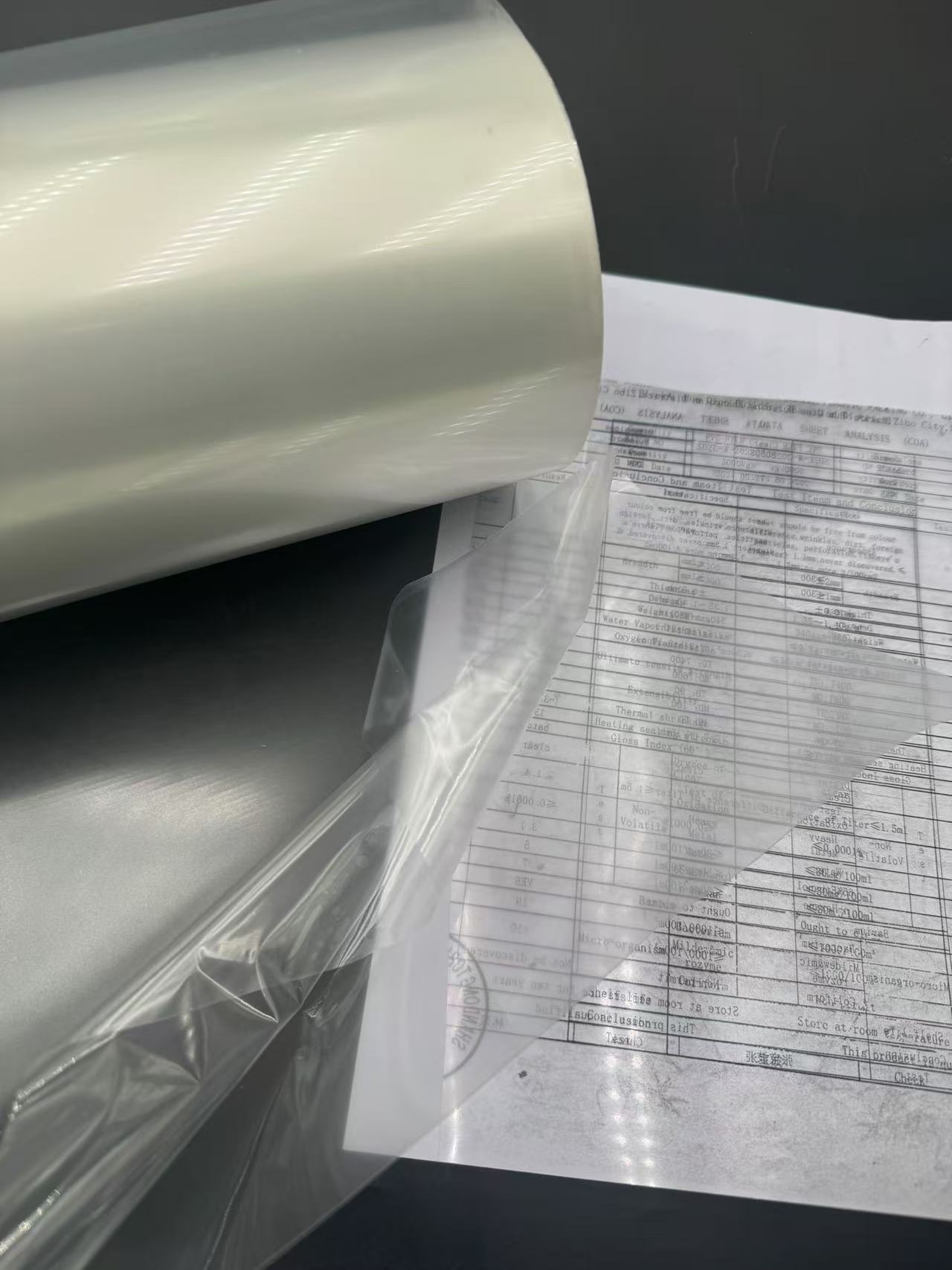

Material: PET Printable sheet

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

usage :for food tray plant tray

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

The Versatile Applications of Transparent Coated PET Printable Rigid Film

Introduction

In the modern world of printing and labeling, the demand for high-quality, durable, and versatile materials has been constantly on the rise. Transparent coated PET (polyethylene terephthalate) printable rigid film has emerged as a game-changer, finding extensive use in a plethora of applications ranging from everyday product labels to critical medical printing. This article delves into the fascinating realm of this remarkable material, exploring its properties, manufacturing process, diverse applications, advantages, and the challenges it overcomes in each domain.

Material Properties of Transparent Coated PET Printable Rigid Film

Chemical Composition and Structure

Transparent coated PET printable rigid film is based on the well-known PET polymer, which consists of repeating units of ethylene glycol and terephthalic acid. The molecular chains of PET are highly oriented during the manufacturing process, providing the film with inherent strength and rigidity. The coating applied on its surface further augments its functionality. This coating is typically a blend of resins, additives, and sometimes nanoparticles, carefully formulated to enhance printability, adhesion, and durability. For instance, a UV-curable coating might be used to improve scratch resistance and protect the printed layer from fading due to exposure to sunlight or other environmental factors.

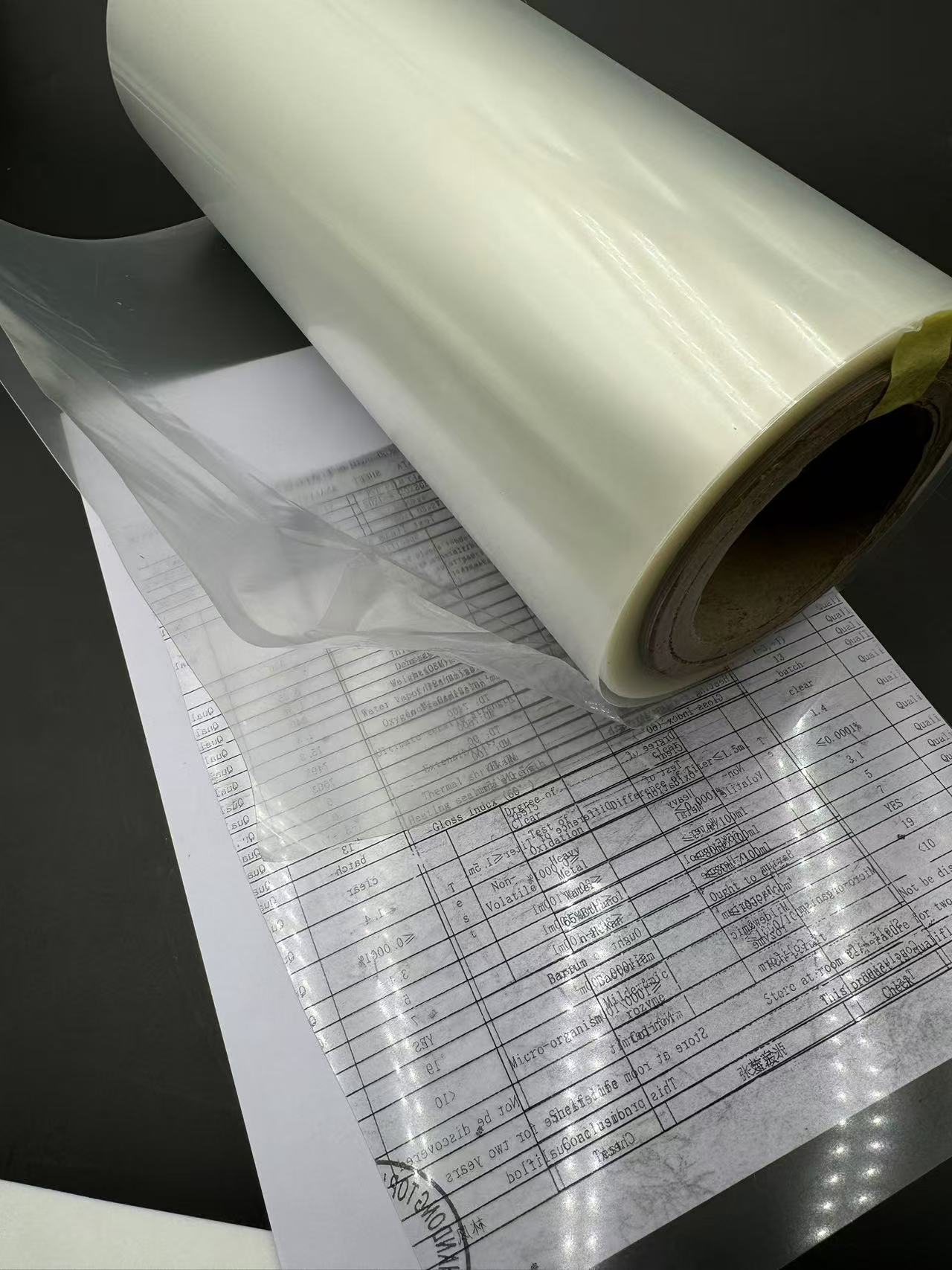

Transparency and Clarity

One of the most alluring features of this film is its exceptional transparency and clarity. The absence of impurities and the precisely controlled manufacturing conditions ensure that light passes through the film with minimal distortion. In applications like product labels, this transparency allows consumers to have a clear view of the underlying product, enhancing visual appeal. In medical imaging prints, where accurate visualization of minute details is crucial, the high clarity of the film enables healthcare professionals to make precise diagnoses. For example, in the printing of ultrasound or MRI images, the film faithfully reproduces the intricate patterns and shades, providing a reliable medium for analysis.

Mechanical Properties

The film exhibits impressive mechanical strength, courtesy of the PET base material. It has a high tensile strength, which means it can withstand significant pulling and stretching forces without tearing or deforming. This property is vital during the printing process, as the film is subjected to tension while passing through printers. Additionally, its rigidity ensures that it maintains its shape and flatness, preventing wrinkling or curling that could mar the printed output. The surface hardness, enhanced by the coating, makes it resistant to scratches and abrasions, safeguarding the printed information even in harsh handling conditions.

Printability

The coated surface of the PET film is engineered to offer excellent printability. It has an optimal surface energy that allows inks to wet and adhere evenly, resulting in sharp, vibrant, and long-lasting prints. Whether it's the use of solvent-based inks for outdoor signage that demands weather resistance, or water-based inks for indoor applications where low VOC (volatile organic compound) emissions are preferred, the film accommodates a wide variety of ink types. The coating also provides a smooth yet receptive substrate, enabling fine details and high-resolution images to be reproduced faithfully, be it the intricate logo of a luxury brand or the microscopic structures in a medical illustration.

Barrier Properties

While primarily known for its printing capabilities, the transparent coated PET film also possesses decent barrier properties. It offers resistance against moisture, gases such as oxygen and carbon dioxide, and contaminants. In food labeling applications, for instance, it helps maintain the integrity of the label by preventing moisture absorption that could lead to smudging or peeling of the printed text. In medical packaging with printed instructions or identification labels, the barrier against gases and microbes ensures the sterility and legibility of the information over time.

Chemical Resistance

PET, in its inherent structure, has good chemical resistance, and the coating further bolsters this property. It can withstand exposure to a range of chemicals, including common solvents, acids, and alkalis. In industrial settings where labels may come into contact with cleaning agents, lubricants, or other chemicals, the film remains intact, protecting the printed content. In medical laboratories, where reagents and disinfectants are prevalent, the chemical resistance of the film ensures that the printed labels on equipment, samples, and storage containers stay legible and unaffected.

Manufacturing Process of Transparent Coated PET Printable Rigid Film

PET Film Formation

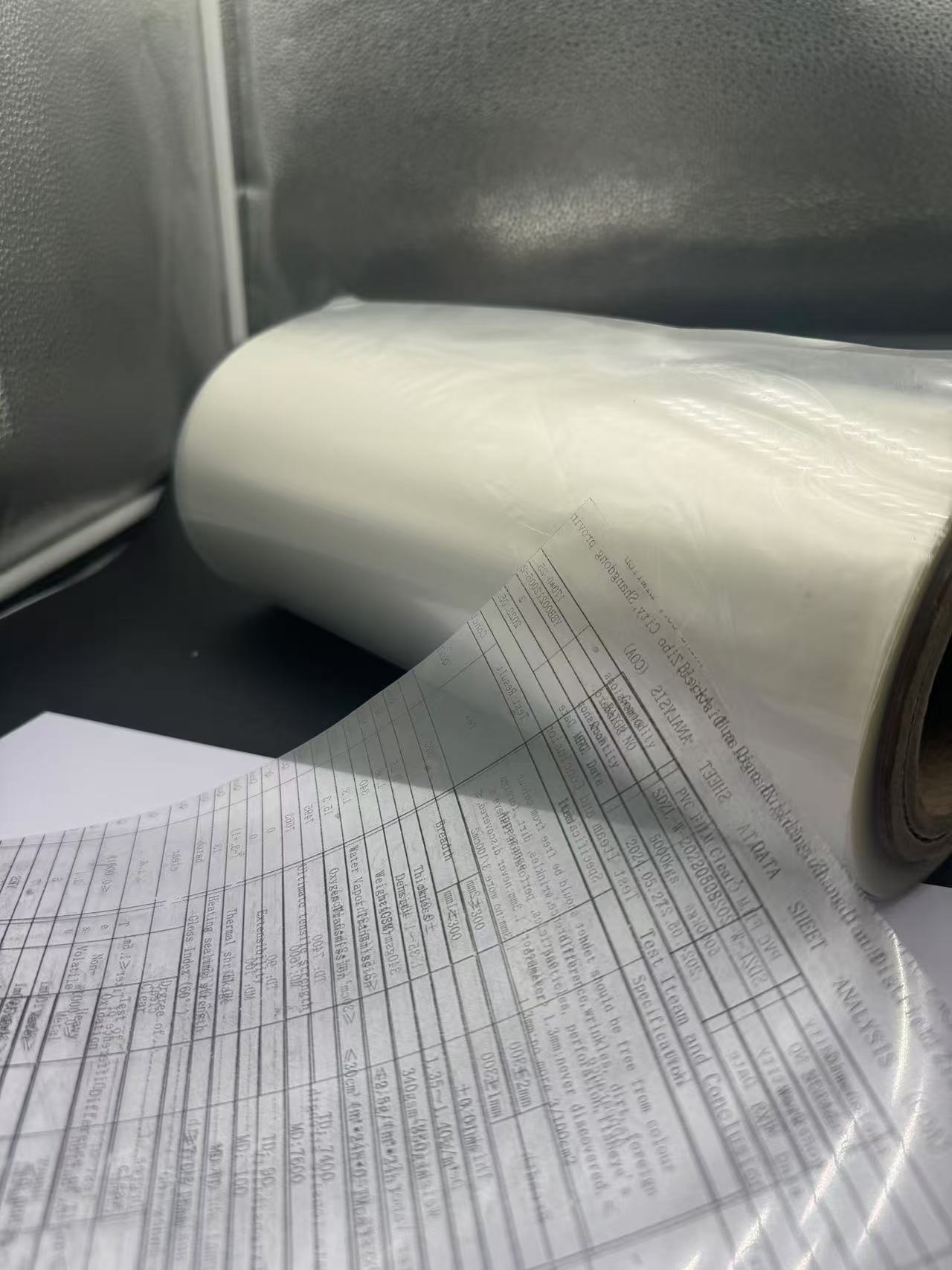

The journey of the transparent coated PET printable rigid film begins with the production of the base PET film. High-quality polyethylene terephthalate resin pellets are melted in an extruder, where the temperature is precisely controlled to achieve a uniform molten state. The molten PET is then forced through a flat die, creating a continuous sheet of film. This nascent film is cooled rapidly to solidify, and during this cooling process, the molecular chains align, imparting the film with its characteristic strength and rigidity. The thickness of the film can be adjusted by varying the die gap and the extrusion speed, catering to different application requirements, from thin films for delicate labels to thicker ones for more durable signage.

Coating Application

Once the PET film is formed, the coating process takes center stage. The coating material, which is a carefully formulated blend of resins, additives, and sometimes nanoparticles, is applied to the surface of the PET film. There are several methods of coating application, with gravure coating and slot die coating being commonly used. In gravure coating, an engraved roller picks up the coating material from a reservoir and transfers it onto the film surface in a controlled, patterned manner. Slot die coating, on the other hand, involves the extrusion of the coating material through a narrow slit onto the moving film, ensuring an even and continuous layer. The thickness of the coating can be adjusted by modifying the coating parameters, such as the speed of the film, the pressure of the coating application, and the viscosity of the coating material.

Curing and Drying

After the coating is applied, it needs to be cured or dried to achieve its final properties. For coatings that are UV-curable, the film passes through a UV irradiation chamber where the ultraviolet light triggers a polymerization reaction, hardening the coating and enhancing its scratch resistance, adhesion, and durability. In the case of solvent-based coatings, the film is passed through a drying tunnel where hot air circulates, evaporating the solvent and leaving behind a solid, protective layer. The curing or drying process is meticulously controlled to ensure uniform treatment across the entire film surface, eliminating any potential for defects such as uneven coating thickness or incomplete curing.

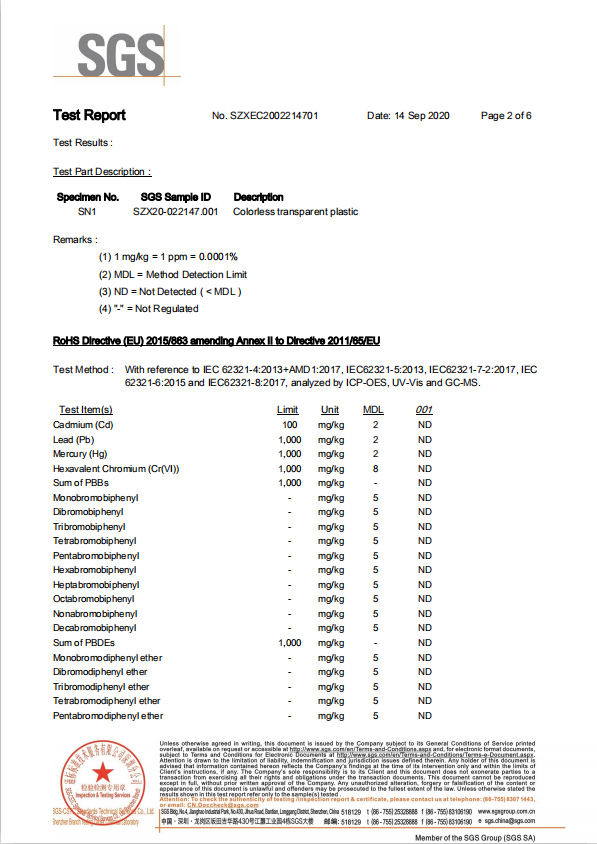

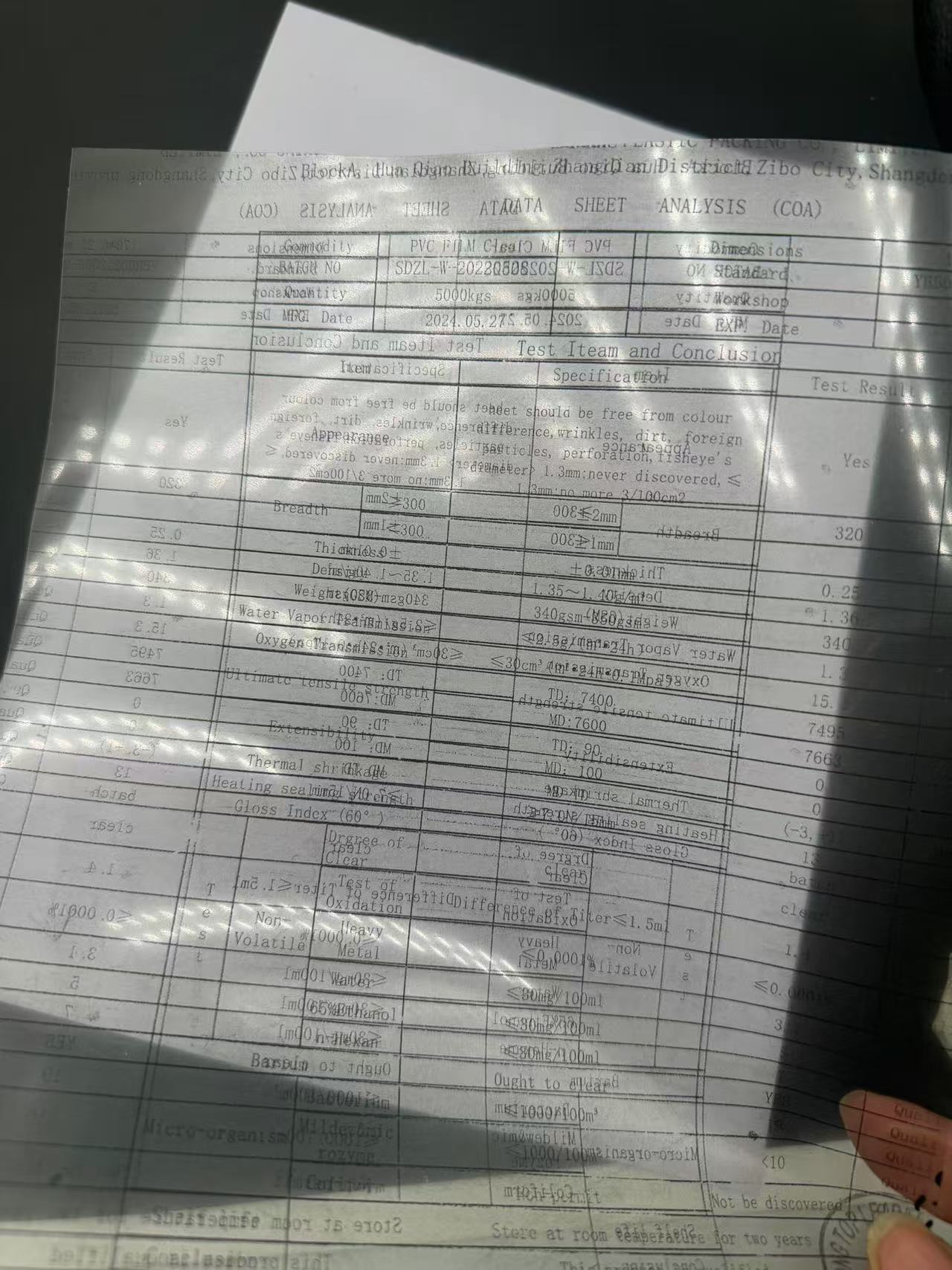

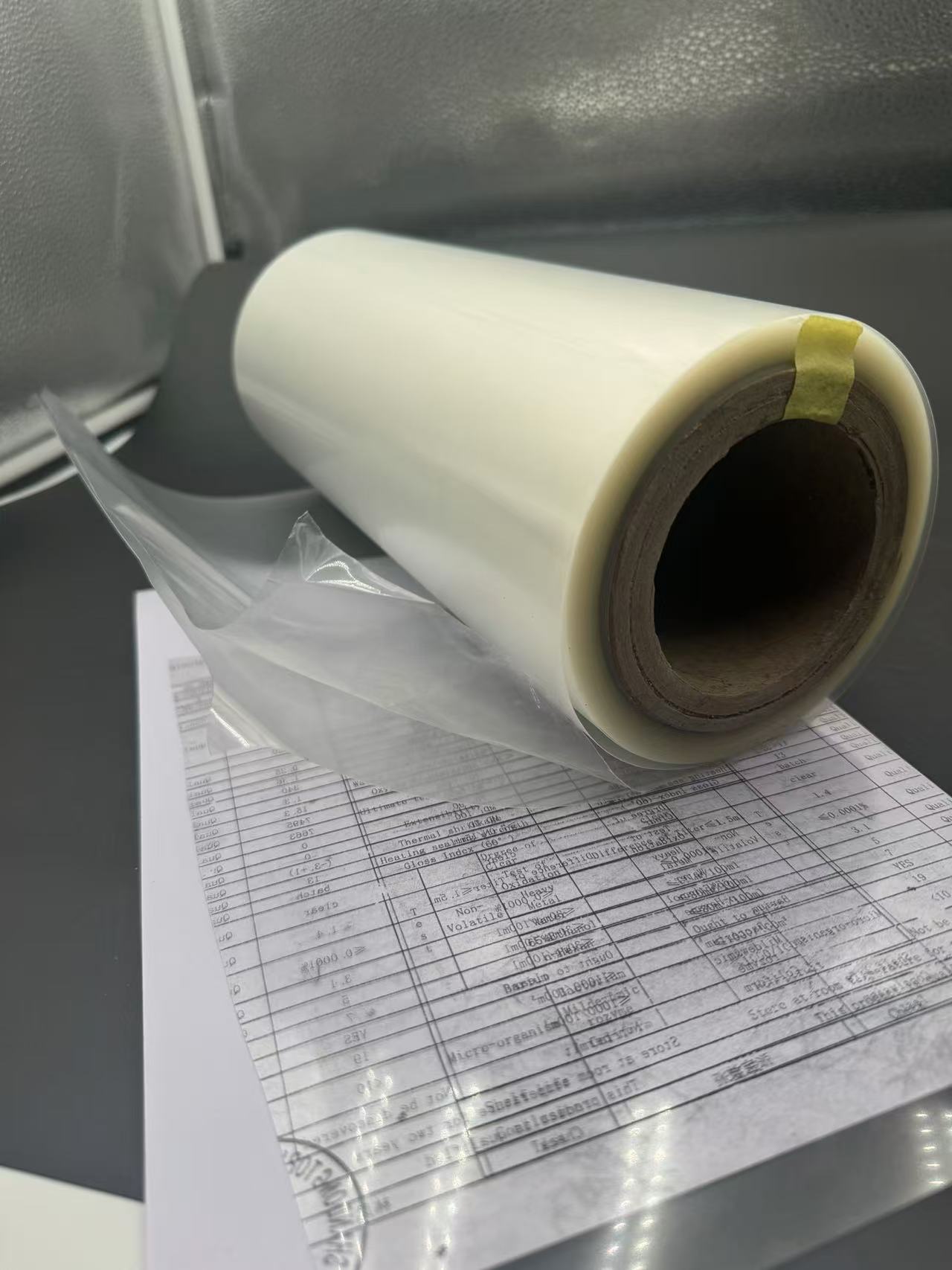

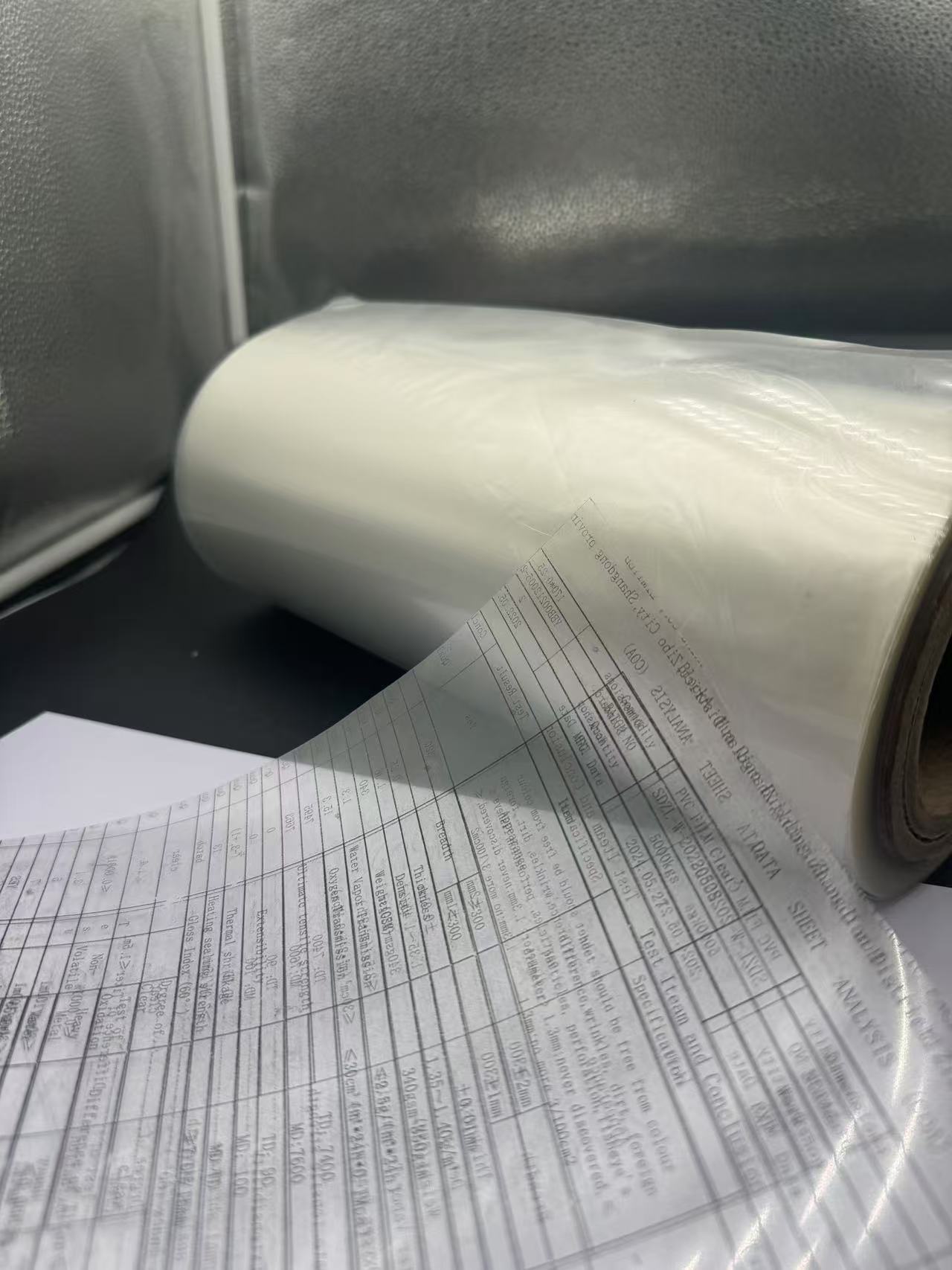

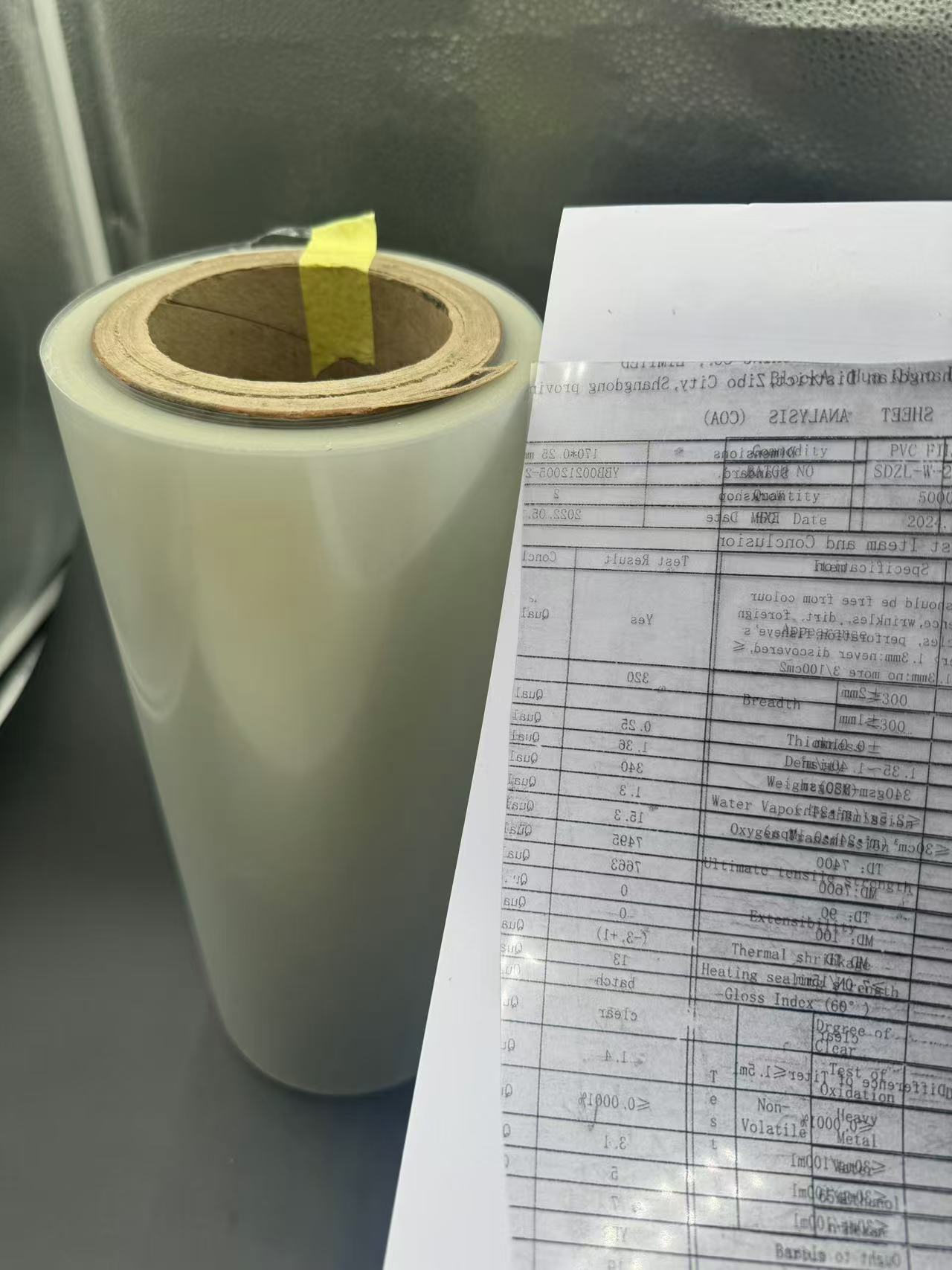

Quality Control and Finishing

The finished transparent coated PET printable rigid film undergoes rigorous quality control procedures. The thickness of both the PET base film and the coating layer is measured using precision instruments to ensure compliance with the specified standards. The transparency, printability, and mechanical properties are tested through a series of laboratory assays and practical printing trials. Any film that fails to meet the quality benchmarks, such as those with pinholes, scratches, or poor ink adhesion, is rejected. The approved film is then wound onto rolls of varying widths and lengths, ready for distribution to printers, label manufacturers, and other end-users.

Applications of Transparent Coated PET Printable Rigid Film in Labeling

Consumer Product Labels

In the bustling aisles of supermarkets and retail stores, transparent coated PET printable rigid film is a ubiquitous presence on consumer product labels. From food and beverage containers to personal care products and household items, the film offers a winning combination of aesthetics and functionality. Its transparency allows the product's color, texture, and contents to shine through, creating an enticing visual display. The printed information, whether it's the product name, ingredients list, or usage instructions, remains crisp and legible, even after exposure to moisture, handling, and temperature fluctuations. For example, a high-end shampoo bottle labeled with this film showcases the luxurious liquid inside while the elegant print communicates the brand's quality and care instructions.

Industrial Product Labels

In industrial settings, where durability and information integrity are paramount, the film serves as an ideal label material. Machinery, equipment, and tools are often labeled with transparent coated PET film to indicate their model numbers, operating instructions, safety warnings, and maintenance schedules. The film's resistance to abrasion, chemicals, and harsh environmental conditions ensures that the labels remain intact and readable throughout the long lifespan of the industrial assets. In a manufacturing plant, the labels on heavy-duty machinery made from this film can withstand the vibrations, dust, and occasional chemical spills, providing crucial information to operators and maintenance crews at a glance.

Wine and Spirits Labels

The world of wine and spirits demands packaging that exudes elegance and sophistication, and transparent coated PET printable rigid film fits the bill perfectly. The film's transparency allows the rich colors of the beverages to peek through, enhancing the visual allure on the store shelf. The smooth surface and excellent printability enable the reproduction of intricate designs, vintage motifs, and detailed tasting notes. Moreover, the film's resistance to moisture and its ability to maintain print quality even in the humid conditions of a wine cellar ensure that the labels stay pristine, whether the bottle is stored horizontally or vertically. A fine bottle of aged red wine with a label crafted from this film not only looks regal but also provides all the necessary information to the discerning connoisseur.

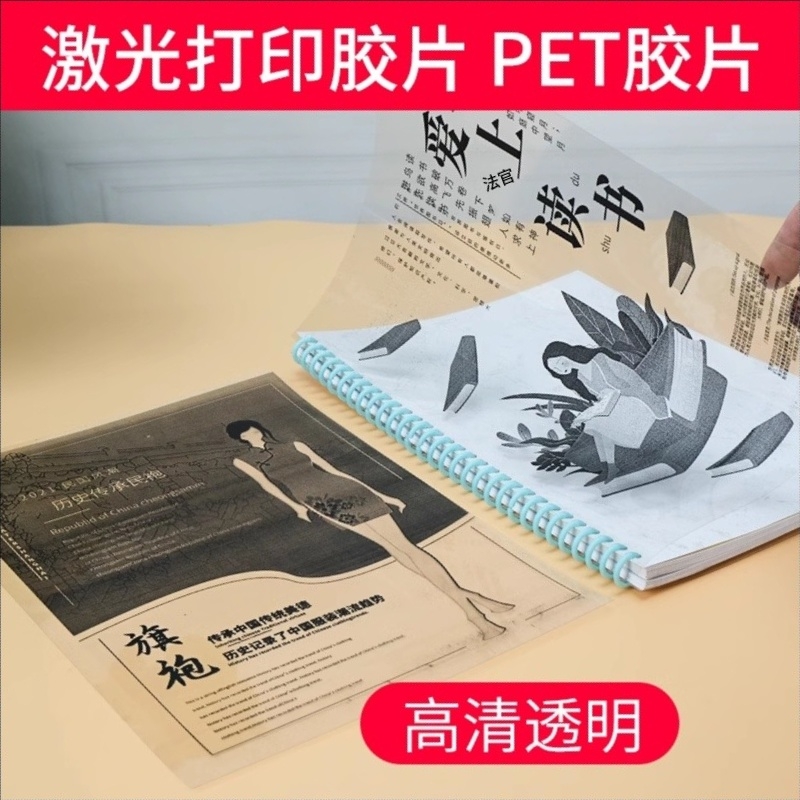

Applications of Transparent Coated PET Printable Rigid Film in Printing

Graphic Arts and Advertising Prints

In the realm of graphic arts and advertising, the film opens up a world of creative possibilities. Posters, banners, and promotional materials printed on transparent coated PET film command attention with their vibrant colors, sharp details, and unique visual effects. The film can be used to create see-through prints that add an element of intrigue, such as a cityscape poster where the printed image overlays the actual view through the film, or a promotional banner for a new smartphone where the device's features are highlighted against a transparent backdrop. The durability of the film ensures that these prints can withstand outdoor exposure to sunlight, wind, and rain, maintaining their visual impact for extended periods.

Architectural Prints

Architects and interior designers have embraced the use of transparent coated PET printable rigid film for presenting their designs in a novel and engaging way. Floor plans, elevation drawings, and 3D renderings can be printed on the film, allowing clients to overlay the prints on the actual site or building model, providing a more immersive and tangible understanding of the proposed design. The film's rigidity and flatness make it easy to handle and display, while its printability ensures that the fine lines, textures, and color gradients of the architectural illustrations are faithfully reproduced. In a design studio, a large-format print of a luxury hotel's interior on the film can be draped over a scale model, giving stakeholders a vivid preview of the space's ambiance and layout.

Educational Prints

In educational institutions, the film is being increasingly used for creating interactive and durable teaching materials. Science diagrams, historical maps, and language learning charts printed on transparent coated PET film can be overlaid, compared, and manipulated, enhancing the learning experience. For example, a biology teacher can use prints of cell structures on the film to layer different organelles, explaining their functions and relationships in a more hands-on manner. The film's resistance to wear and tear means that these educational prints can be reused semester after semester, saving resources and providing a consistent visual aid for students.

Applications of Transparent Co 单刷 PET Printable Rigid Film in Medical Printing

Medical Imaging Prints

In hospitals and clinics, the accurate reproduction and preservation of medical imaging results are of utmost importance. Transparent coated PET printable rigid film is used to print X-ray, CT scan, MRI, and ultrasound images, providing healthcare professionals with a high-quality medium for diagnosis and patient record-keeping. The film's transparency and clarity allow for precise visualization of the anatomical structures and any pathologies present. The coating protects the printed images from fading, smudging, and damage due to handling and exposure to light. A radiologist can examine a printed MRI image on the film, confident in the integrity of the visual information and able to make informed decisions about the patient's treatment.

Medical Device Labels

Medical devices, from simple syringes to complex surgical equipment, require labels that are not only informative but also durable and sterile. The transparent coated PET film is used to print labels that contain device identification, operating instructions, sterilization dates, and safety warnings. The film's chemical resistance ensures that the labels remain legible even when exposed to disinfectants and cleaning agents used in medical facilities. The barrier properties protect the printed information from moisture and microbes, maintaining the sterility of the device and the clarity of the label throughout its use and storage. A surgical implant labeled with this film provides clear instructions to the medical team while remaining intact during the sterilization process and storage in the operating room.

Pharmaceutical Packaging Prints

Pharmaceutical companies rely on the film for printing labels and inserts for drug packaging. The printed information, such as dosage instructions, contraindications, and expiration dates, must be accurate and legible at all times. The film's printability allows for the clear reproduction of small text and complex diagrams, while its resistance to moisture and chemicals ensures that the printed content remains intact during the drug's shelf life. In a pharmacy, a pill bottle with a label printed on transparent coated PET film provides patients with all the necessary information in a clear and durable format, reducing the risk of misinformation and ensuring safe medication use.

Advantages of Using Transparent Coated PET Printable Rigid Film

Visual Appeal and Marketing Impact

The transparency and excellent printability of the film create a visually stunning effect that captivates consumers and clients alike. In product labels, it showcases the product itself while presenting the brand's messaging in a sharp and attractive manner, enhancing brand recognition and recall. In advertising prints, the ability to produce vibrant, detailed, and unique visuals sets the film apart, making marketing materials stand out in a crowded marketplace and driving customer engagement.

Durability and Longevity

The combination of the PET base material's strength and the protective coating's properties results in a film that can withstand a wide range of environmental conditions. Whether it's exposure to sunlight, moisture, chemicals, or physical abrasion, the film retains its integrity and the printed information remains legible. This durability translates to longer lifespan for labels, prints, and medical applications, reducing the need for frequent replacement and ensuring consistent communication of information.

Versatility in Ink Compatibility

The specially designed coating on the film allows it to work well with various ink types, from solvent-based inks for outdoor applications with high weather resistance requirements to water-based inks for indoor use with environmental and safety considerations. This versatility gives printers and manufacturers the freedom to choose the most suitable ink for their specific projects, whether it's a large-format outdoor billboard or a delicate medical label.

Information Integrity and Preservation

In critical applications such as medical imaging, device labels, and pharmaceutical packaging, the film's ability to protect the printed information from fading, smudging, and damage is invaluable. It ensures that vital medical and product information remains accurate and accessible, safeguarding patient safety and regulatory compliance in the healthcare and pharmaceutical industries.

Recyclability

PET is a recyclable material, and although the coated version requires specific recycling processes to separate the coating from the base film, it still offers an environmentally friendly option compared to many non-recyclable printing and labeling materials. This aspect aligns with the growing global focus on sustainable manufacturing and waste reduction, making it an attractive choice for conscientious businesses.

Case Studies of Transparent Coated PET Printable Rigid Film in Practice

Case Study 1: Food Labeling for a Premium Brand

A renowned food company that specializes in high-quality, artisanal products decided to revamp its product labels using transparent coated PET printable rigid film. The previous paper labels were prone to smudging and losing their visual appeal after exposure to refrigeration and handling. With the new film, the product's freshness and artisanal details were on full display through the transparent film, while the printed information about ingredients, nutritional facts, and origin remained sharp and legible. The brand noticed a significant increase in shelf appeal, leading to higher sales and customer loyalty, especially among consumers who value quality and aesthetics.

Case Study 2: Architectural Firm's Presentation Upgrade

An architectural firm was looking for a better way to present their designs to clients and stakeholders. They switched to using transparent coated PET printable rigid film for printing their floor plans and 3D renderings. The film's rigidity and clarity allowed the prints to be easily overlaid on building models, providing a more immersive and interactive experience. Clients could visualize the proposed designs more vividly, leading to quicker approvals and a more collaborative design process. The durability of the film also meant that the prints could be reused in multiple meetings and presentations, saving time and resources.

Case Study 3: Hospital's Medical Imaging Solution

A large hospital was facing issues with the fading and damage of printed medical imaging results, which affected the accuracy of diagnoses and patient record-keeping. By adopting transparent coated PET printable rigid film for imaging prints, the hospital saw a remarkable improvement in the quality and longevity of the prints. Radiologists and other healthcare professionals could rely on the clear, intact images for diagnosis, and the records were better preserved over time. The film's resistance to handling and environmental factors reduced the need for reprints, streamlining the medical workflow and enhancing patient care.

Challenges and Solutions in Using Transparent Coated PET Printable Rigid Film

Coating Adhesion and Uniformity

Ensuring proper adhesion of the coating to the PET base film and maintaining a uniform coating thickness can be challenging. Inadequate adhesion can lead to delamination or peeling of the coating, affecting the film's performance. To address this, manufacturers carefully optimize the coating formulation, adjusting the resin ratios and adding adhesion promoters. The coating application process is also tightly controlled, with precise monitoring of parameters like temperature, pressure, and speed to achieve consistent results.

Ink Drying and Curing Issues

Depending on the ink type and the coating's properties, ink drying and curing may pose problems. Slow drying can lead to smudging or ink transfer during handling, while improper curing can result in reduced print durability. To overcome this, printers must match the ink with the appropriate coating and adjust drying and curing conditions, such as temperature, air circulation, and UV exposure time. Using inkjet inks optimized for the film's coating and investing in advanced drying and curing equipment can also enhance the process.

Environmental Impact of Coating Materials

Some coating materials used in the film may have environmental concerns, especially if they contain volatile organic compounds (VOCs) or are difficult to recycle. To mitigate this, research is focused on developing eco-friendly coatings, such as water-based or bio-based formulations that have lower VOC emissions and are more amenable to recycling. Manufacturers are also exploring ways to improve the recyclability of the coated film by designing coatings that can be easily separated from the PET base during recycling processes.

Cost Considerations

The production of transparent coated PET printable rigid film, especially with high-quality coatings, can be more expensive than some alternative materials. However, considering its long-term benefits in terms of durability, print quality, and information preservation, the cost can be justified. Manufacturers can work on optimizing production processes to reduce costs, such as improving coating efficiency and minimizing waste. End-users can also explore bulk purchasing options and long-term supply agreements to manage costs effectively.

Conclusion

Transparent coated PET printable rigid film has carved a niche for itself in the world of labeling, printing, and medical applications. Its unique blend of properties, from transparency and printability to durability and chemical resistance, makes it an invaluable asset in diverse industries. Despite the challenges it faces, continuous innovation in manufacturing processes and coating technologies is paving the way for improved performance and sustainability. As businesses and institutions increasingly demand materials that combine

Within 15-20 days after received payment...more