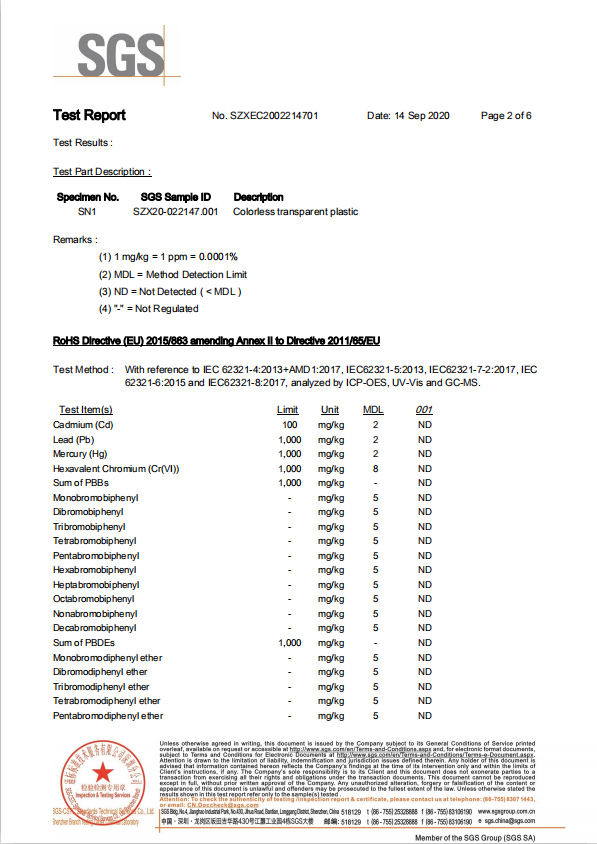

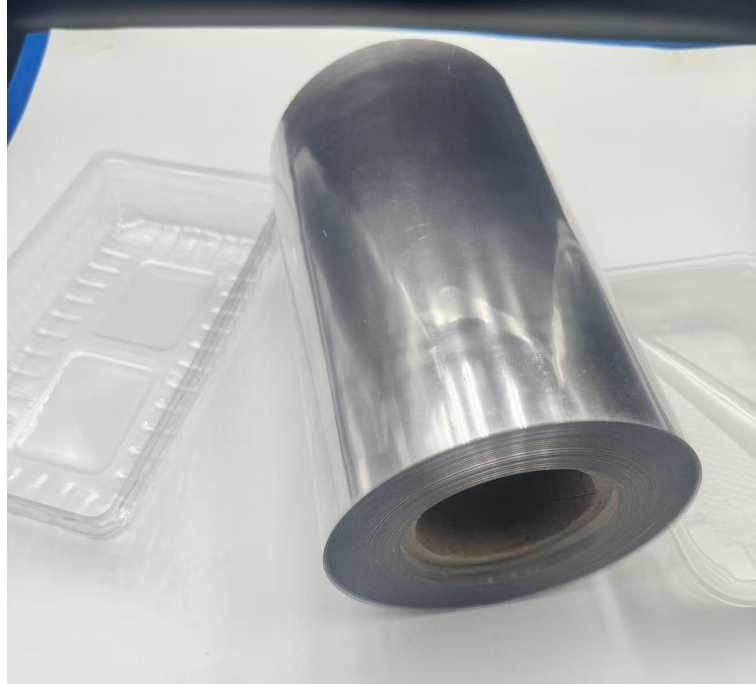

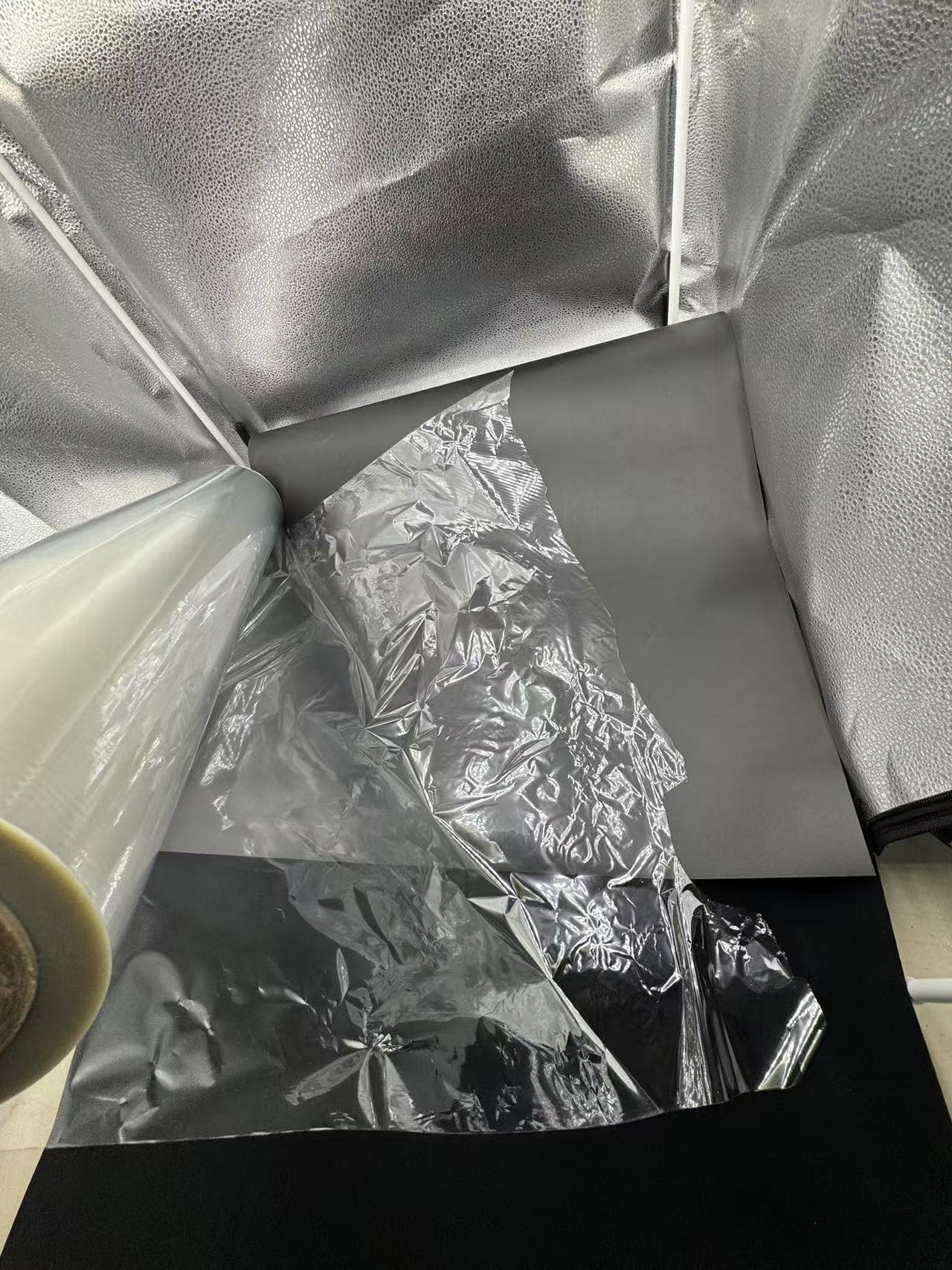

194printable PCRPET film for food bags ,decorative printing

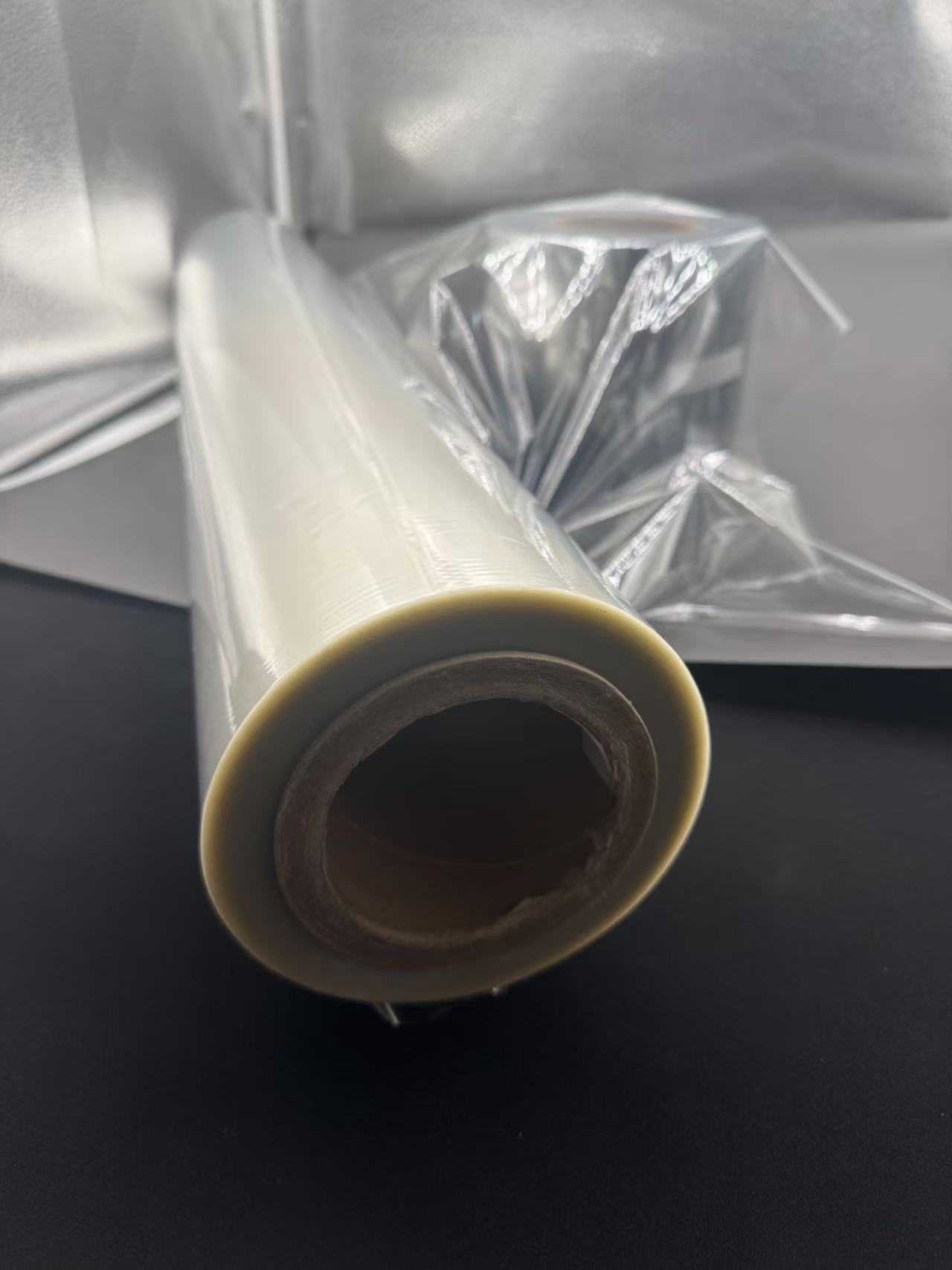

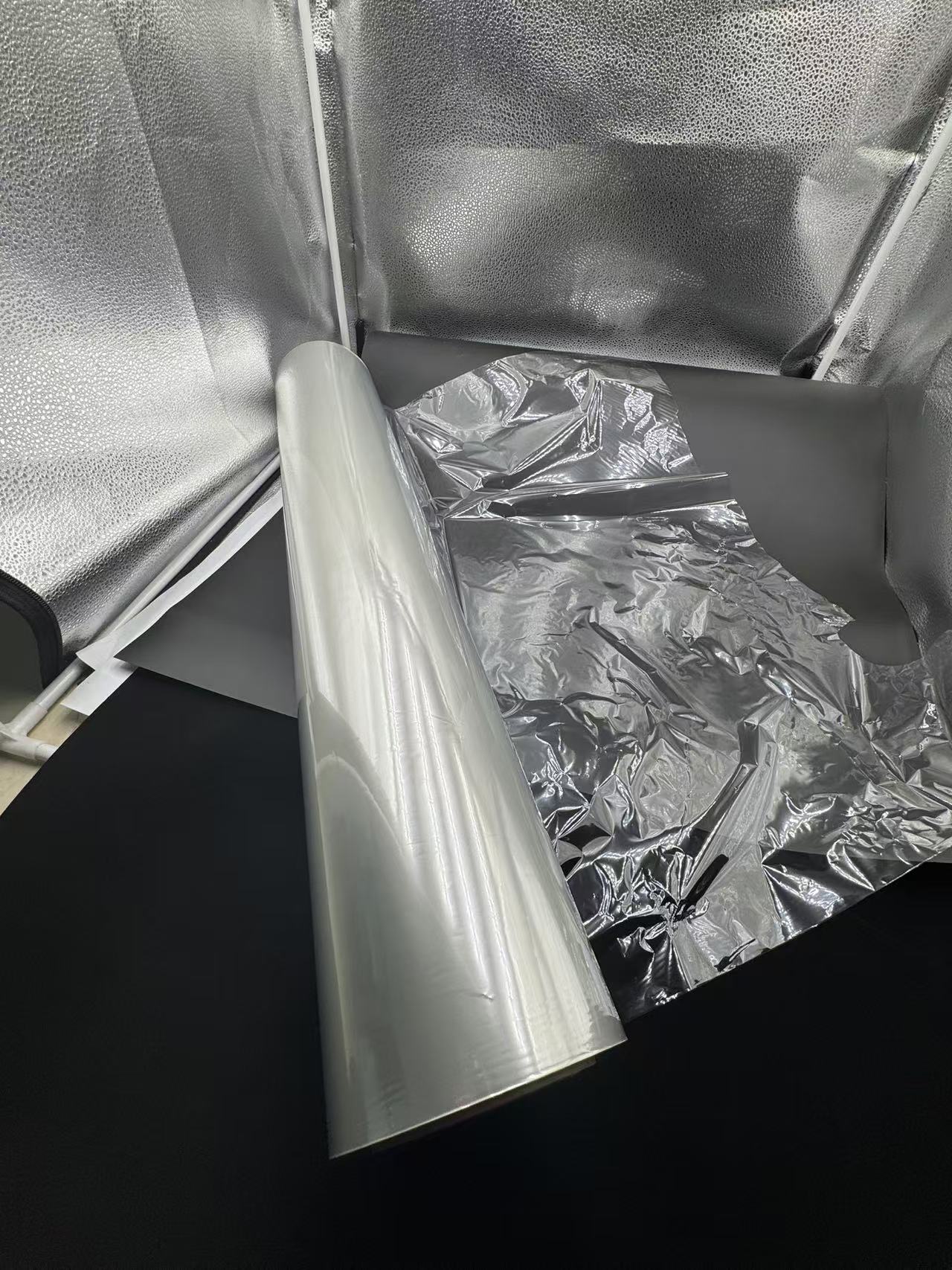

Material: PCR PET FILM ROLL

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

usage :for food tray plant tray

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

Transparent PCR PET Film: Unveiling the Epitome of Versatility and Excellence

1. Introduction

In the modern world of materials, the transparent PCR PET film is one true wonder that has been able to fascinate industries and consumers alike with its unmatched blend of properties and undisputed potential. This exciting film has been sweeping across several industries, changing the way one perceives and uses packaging, electronics, and many other fields. Let us undertake a journey of discovery into the exciting world of transparent PCR PET film and try to find out why it has become an indispensable factor in modern technological and industrial developments.

2. The Birth of Transparent PCR PET Film: A Technological Triumph

The production of transparent PCR PET film stands as a mark of human ingenuity combined with highly developed manufacturing processes. It all starts with the selection of proper raw materials, usually PET resin, which is noted for very good chemical stability and mechanical strength. It gets melted and extruded through a precision die into a thin, molten sheet, which is then rapidly chilled and stretched in both machine directions and transverse direction in a process called biaxial orientation. This stretching not only imparts the film with its characteristic transparency but also enhances its physical properties, making it stronger, more rigid, and dimensionally stable.

Manufacturing is done under tight quality control in order to have consistent and uniform thickness of the film, optical clarity, and mechanical performance. The production lines of leading manufacturers boast the most modern sensors and monitoring systems to analyze and control every little parameter continuously, like temperature, speed, and tension, so that a quality film product is manufactured. The results are clear: transparent PCR PET films meeting and outperforming even the stringent requirements in many industries.

3. Unparalleled Optical Clarity: A Window to Perfection

One of the most striking features of transparent PCR PET film is its quite excellent optical clarity. It's like a crystal-clear pane of glass, allowing light to pass through with minimal distortion or scattering. This property makes it an ideal choice for applications where visual appearance and product display are of utmost importance.

In the packaging industry, for instance, products packaged in transparent PCR PET film are presented in all their glory, enticing consumers by the colors and minute details of the product. Be it an expensive cosmetic, a scrumptious food item, or a fragile electronic component, the film acts as a transparent showcase for every product, enhancing its look and appeal to catch the consumer's eye. Besides, clarity of the film enables consumers to view the contents inside with ease and builds confidence in the quality of the product.

Transparent PCR PET film is used in the making of touch screens, LCD panels, and OLED displays in display technology. Its ability to accurately and uniformly transmit light makes images and text sharp and vivid for an immersive viewing experience. The optical properties of the film are precisely engineered to minimize glare and reflection, even in bright ambient light conditions, making it suitable for use in everything from sunny outdoor locations to dimly lit indoor spaces. 4. Robust Mechanical Properties: Strength and Durability Redefined

Transparent PCR PET film is not only visually appealing but is also mechanically strong. It touts very high tensile strength, meaning that it can bear high pulling without tearing or breaking. Such strength is vital in places where the film undergoes much stress during handling, transportation, or use.

For example, in flexible packaging, the film provides a reliable barrier against exterior forces, thus protecting the content from possible damage. The film is able to support the vigor of automated packaging, such as high-speed filling and sealing, without losing its integrity. Its good puncture resistance adds more durability to the film by not allowing sharp objects to penetrate the package.

Transparent PCR PET film is also applied in glazing, like skylights and curtain walls, within the construction industry. Its resistance to wind loads, impact, and extreme temperature fluctuations makes it tough and durable, with a long lifespan, thus competing with traditional glass. The light weight of the film facilitates ease of installation and reduces the overall structural load, hence being cost-effective and practical for modern building designs.

5. Barrier Properties: Preserving Quality and Freshness

Another striking feature of transparent PCR PET film is its barrier properties. It shields the contents from moisture, oxygen, and other gases by not allowing them to pass through, thus preventing degradation and spoilage.

In the food and beverage industry, this barrier function is of utmost importance. By preventing the ingress of oxygen and moisture, the film helps extend the shelf life of perishable products, maintaining their flavor, texture, and nutritional value. It also protects against the loss of volatile compounds, keeping the product fresh with its characteristic aroma. Transparent PCR PET film is used to package snacks, dried fruits, coffee, and many other food products, along with bottling beverages, for which it is used as a liner or label material.

In the pharmaceutical and electronics industries, the barrier properties of the film are just as important. It provides protection for sensitive drugs and electronic components from environmental factors that may affect their efficacy and performance. The film can be laminated with other materials to create a multi-layered packaging structure that provides enhanced protection against moisture, light, and contaminants.

6. Chemical Resistance: Standing Strong Against the Elements

The main features of transparent PCR PET film are its outstanding chemical resistance and stability against a wide variety of chemicals and solvents. All these reasons make this material a perfect candidate for application in harsh industrial environments and cases where the film may be in contact with aggressive media.

It is also used in the chemical processing industry for lining tanks, pipes, and containers against corrosion and chemical attack. The film has also been used in the production of chemical-resistant labels and packaging to ensure information on products remains legible and intact even in the presence of corrosive chemicals.

In the automotive and aerospace industries, wherever components are exposed to different kinds of fluids and chemicals, transparent PCR PET film is used in coatings and laminates to protect against rust, oxidation, and chemical degradation. The resistance of the film to chemicals also makes it a very good material to be used in printed circuit boards and electronic assemblies for preventing the migration of deleterious substances and ensuring long-term reliability of the device.

7. Thermal Stability: Withstanding the Heat

Transparent PCR PET film has very good thermal stability, maintaining its physical and chemical properties in a wide range of temperatures from low to high. Without significant distortion or deterioration, it can support both high and low temperatures.

In food applications, this thermal stability is demanded for uses like microwaveability and oven-safeness. It is used in packaging to be heated either in a microwave or conventional oven for consumer convenience in heating or cooking their food without having to transfer it to another container. The thermal resistance of the film makes it suitable for use in hot-fill applications, where the packaging is filled with hot liquids and then sealed.

In the electronics industry, transparent PCR PET film is used in components that are exposed to high temperatures during manufacturing or operation. It can withstand the heat generated during soldering processes and the thermal cycling that occurs in electronic devices, ensuring the reliability and performance of the circuitry. The thermal stability of this film also makes it quite viable for application in solar panels and other renewable energy systems where it is exposed to sunlight and temperature fluctuations.

8. Versatility in Applications: A Material for All Seasons

The unique combination of properties of transparent PCR PET film makes it incredibly versatile, finding applications in a vast array of industries and products.

In the packaging industry, it has been presented in many forms: a flexible pouch, wrap, label, and lamina. High-quality artwork and text can be printed on them to create striking packages that show brand messages and communicate product information. Its flexibility and ability to be formed into difficult shapes enable its use for complex shapes in packaging geometry, such as stand-up pouches and vacuum-sealed bags.

In the electronics industry, transparent PCR PET film is used in touch screens, display panels, flexible printed circuits, and insulation materials. It plays a crucial role in the miniaturization and performance enhancement of electronic devices, enabling the development of thinner, lighter, and more energy-efficient products. The film's optical and electrical properties make it an ideal material for use in transparent conductive electrodes and optical coatings.

It finds applications in interior and exterior trim, window films, and head-up displays in the automotive industry. The durability, chemical resistance, and optical clarity of the film further improve the aesthetic and functional features of automotive parts to offer comfort and safety in driving. It can also be used in automotive lighting systems where it improves the distribution and intensity of light.

In the construction industry, architectural glazing, roofing membranes, and insulation materials use transparent PCR PET film. It provides a lightweight, energy-efficient, and durable substitute for conventional building materials while contributing to sustainable building design. The solar control properties can be tailored to reduce heat gain and glare, therefore improving the energy efficiency and comfort of buildings.

In the textile industry, it shows its use in laminated and coated fabrics for imparting additional strength, water resistance, and durability. The waterproof and breathable textiles made with the film would be very usable in outdoor apparel and sportswear. It has other applications in upholstery, home furnishings, and as a fabric enhancer of appearance and performance.

Medical device packaging, sterile wraps, and pharmaceutical labels all make use of transparent PCR PET film in the medical industry. Barrier properties with sterility will ensure the safety and integrity of medical products for the protection of patients against infection or contamination. It is also used in diagnostic equipment and in imaging systems, where its optical clarity and resistance to chemicals become imperative.

9. Sustainable Aspects: A Greener Future with PCR PET Film

In the time of growing environmental awareness, the sustainability of materials is at the forefront. Transparent PCR PET film has various benefits regarding sustainability.

The first important point is that it is recyclable; numerous programs for recycling were established for collecting and reprocessing used PCR PET film. The recycled material can be used in the production of new films or other plastic products, reducing the demand for virgin raw materials and minimizing waste. Second, the long life span and durability of the film mean that products with PCR PET film have to be replaced less frequently, leading to a reduction in overall consumption and waste generation. Besides, the light weight of the film minimizes transport costs and, consequently, carbon dioxide emission due to the movement of goods.

Manufacturers are also constantly exploring ways to improve the environmental performance of PCR PET film. This includes the development of bio-based PET resins, which are derived from renewable resources such as plants, and the use of more energy-efficient manufacturing processes. These initiatives aim to further reduce the carbon footprint of PCR PET film and make it an even more sustainable choice for the future.

Manufacturers are also constantly exploring ways to improve the environmental performance of PCR PET film. This includes the development of bio-based PET resins, which are derived from renewable resources such as plants, and the use of more energy-efficient manufacturing processes. These initiatives aim to further reduce the carbon footprint of PCR PET film and make it an even more sustainable choice for the future.

10. Future Trends and Innovations: Pushing the Boundaries

The future of transparent PCR PET film is very bright, and continuous research and development are underway for realizing further potential and its application areas.

One area of active exploration is the development of smart PCR PET films. These films can be integrated with sensors and other functional elements, enabling them to respond to changes in the environment, such as temperature, humidity, or the presence of certain chemicals. Smart films could be used in food packaging to monitor the freshness of the product or in medical applications to detect changes in a patient's condition.

Other trends include the miniaturization and high-performance optimization of PCR PET film. The more the technology advances, the higher the requirement for thinner, flexible, and high-resolution films, which will enable further advancement in the development of electronic devices such as foldable smartphones and wearable electronics.

Besides, there is an increasing interest in the application of PCR PET film in 3D printing and additive manufacturing. The excellent mechanical properties and thermal stability of the film make it suitable for the creation of complex 3D structures and prototypes. This may open up new frontiers in rapid prototyping and customized manufacturing.

Finally, the combination of transparent PCR PET film with other emerging materials and technologies, such as graphene and nanotechnology, holds great promise for the development of next-generation materials with

Within 15-20 days after received payment...more