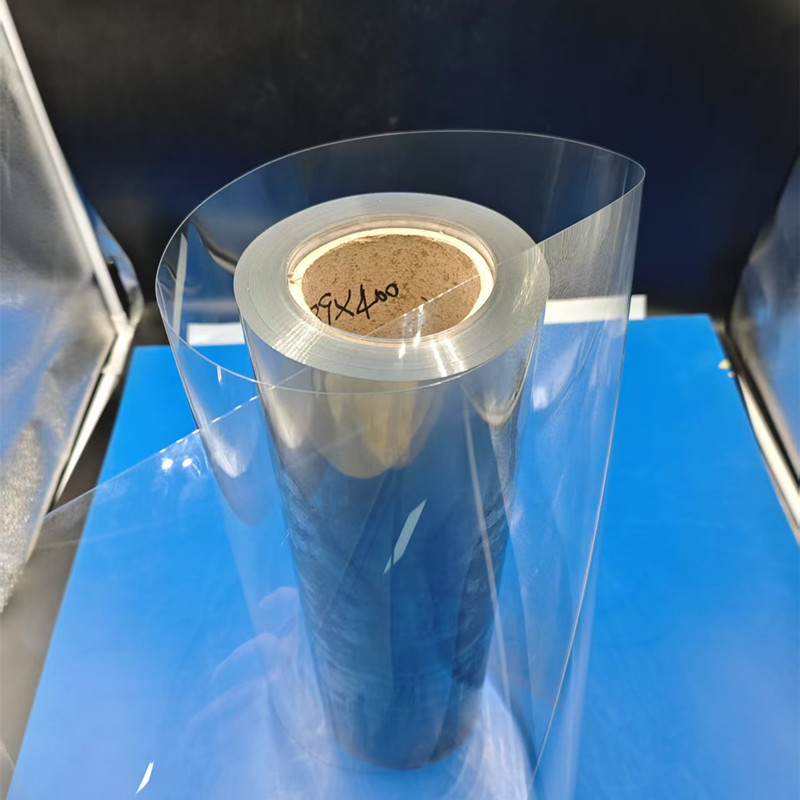

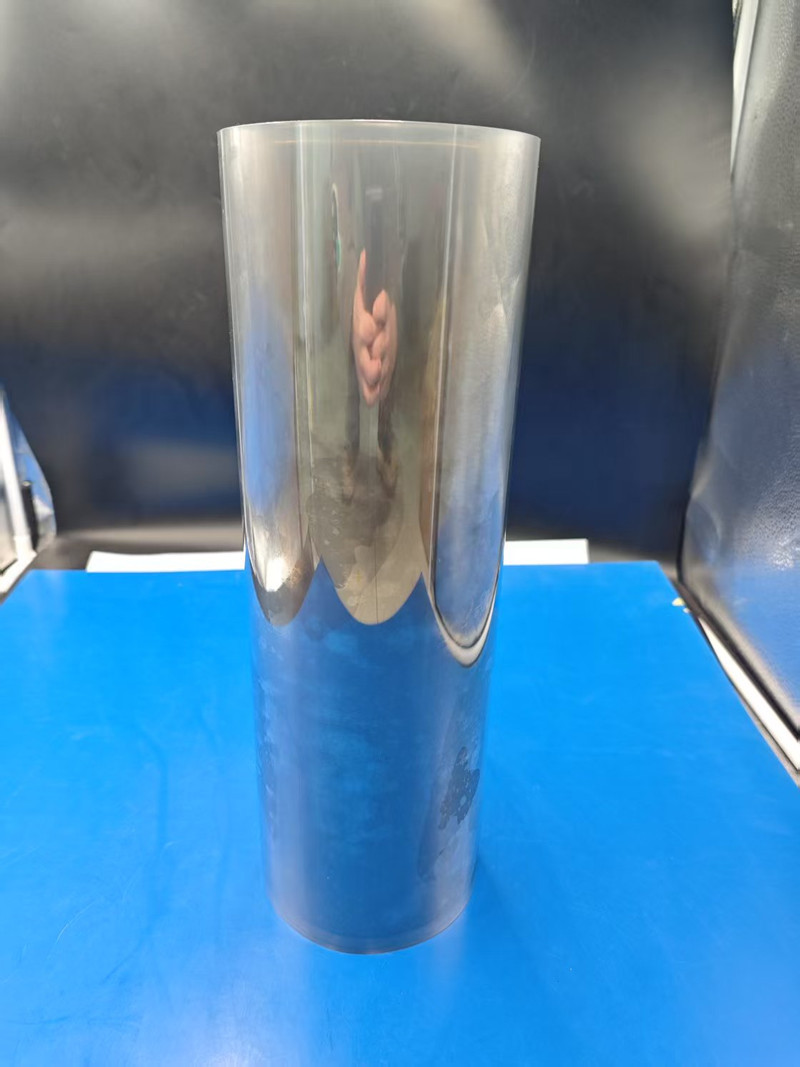

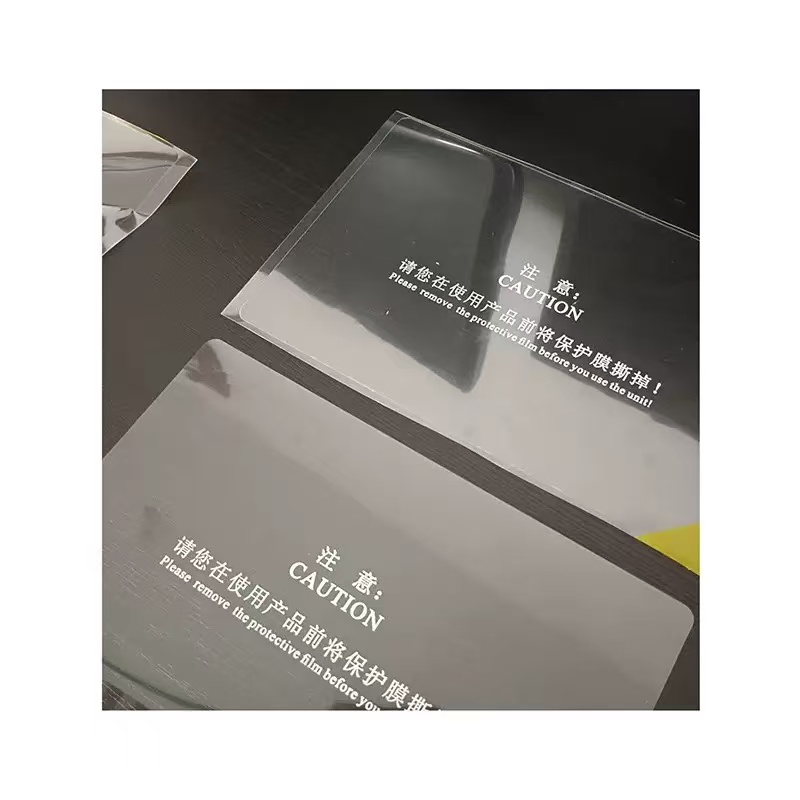

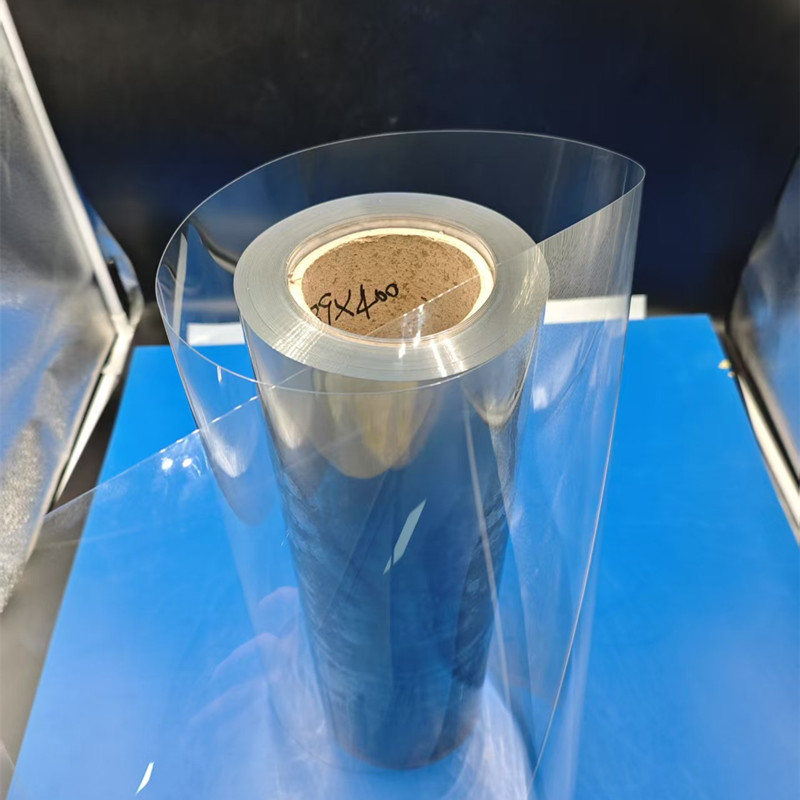

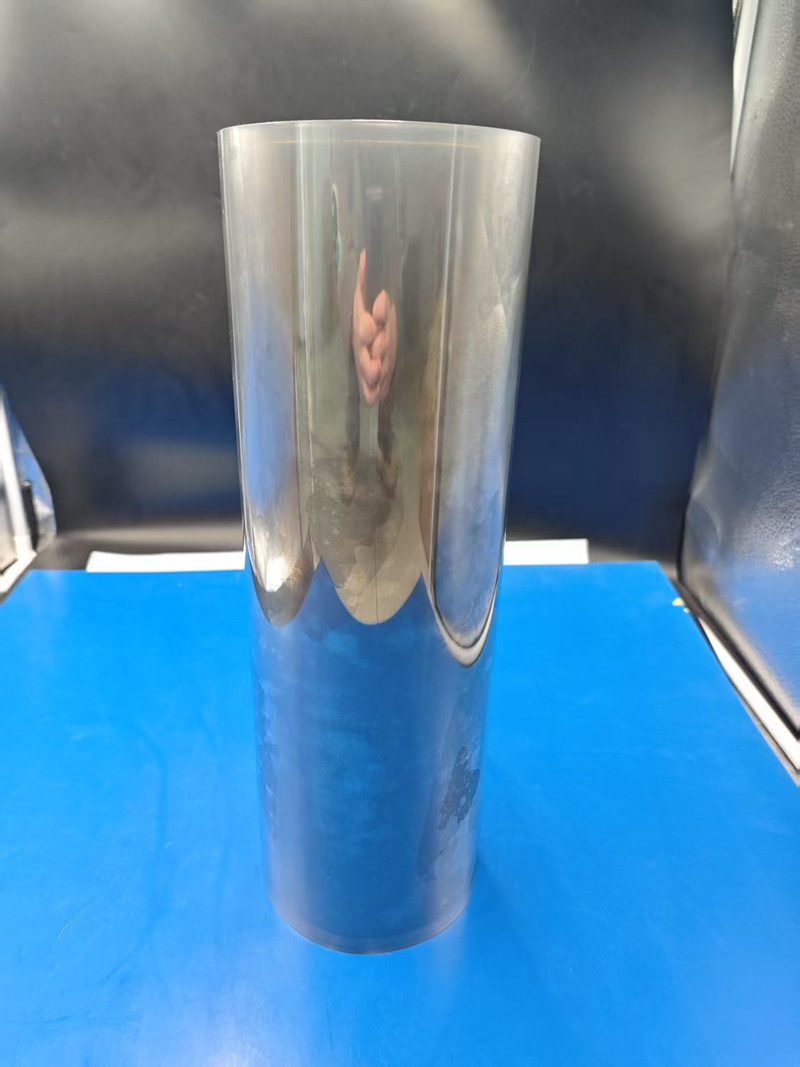

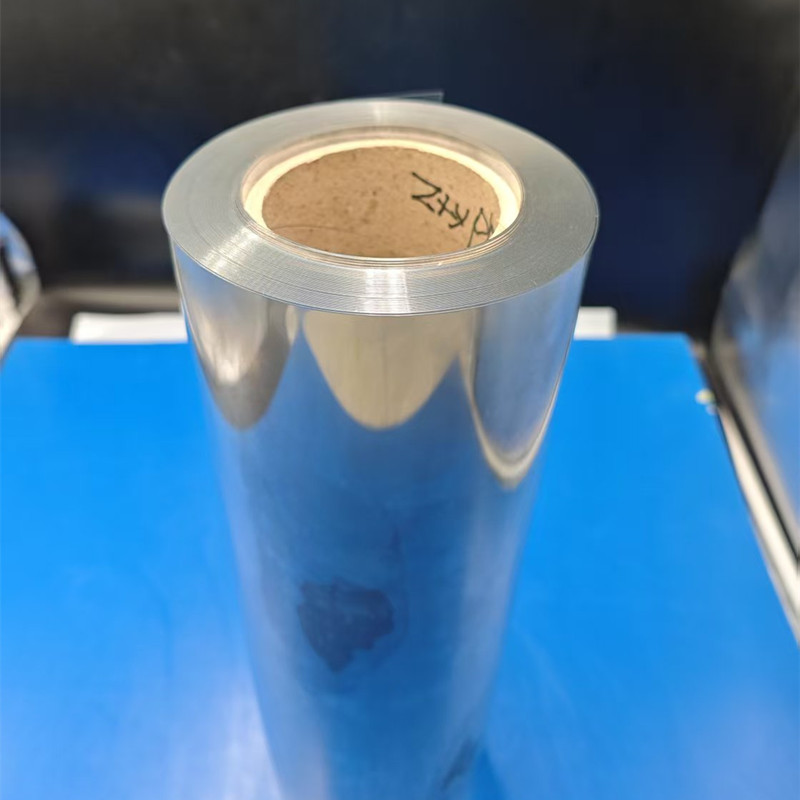

PET sheet roll for thermoforming products

PET (Polyethylene Terephthalate): A thermoplastic polymer known for its clarity, durability, and versatility. PET sheet rolls come in various thicknesses, typically ranging from 0.15 mm to 3 mm.

- TOP LEADER

- CHINA

- 7-15 Working days

- 5000t/Month

- Information

Pet sheet rolls, specifically designed for thermoforming, are a type of plastic material that is widely used in the manufacturing and packaging industries. PET (Polyethylene Terephthalate) is a popular choice due to its excellent physical properties, including strength, transparency, and chemical resistance. Here’s an introduction to PET sheet rolls for thermoforming:

What is Thermoforming?

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and then trimmed to create a usable product. This process is commonly used to produce various types of packaging, such as blister packs, clamshells, trays, and containers.

Key Features of PET Sheet Rolls for Thermoforming

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and then trimmed to create a usable product. This process is commonly used to produce various types of packaging, such as blister packs, clamshells, trays, and containers.

Key Features of PET Sheet Rolls for Thermoforming

1. Material Composition:

- PET (Polyethylene Terephthalate): A thermoplastic polymer known for its clarity, durability, and versatility.

- Additives: Depending on the application, PET sheets may include additives for enhanced properties such as UV resistance, anti-static, or barrier properties.

2. Thickness:

- PET sheet rolls come in various thicknesses, typically ranging from 0.15 mm to 3 mm. The thickness is chosen based on the specific requirements of the final product.

3. Surface Finish:

- Clear and Transparent: Ideal for applications where visibility of the packaged product is important.

- Opaque or Colored: Available in different colors and opacities for branding and aesthetic purposes.

- Textured: Some sheets may have a textured surface for improved grip or visual appeal.

4. Mechanical Properties:

- High Strength and Rigidity: PET sheets offer excellent mechanical strength, making them suitable for a wide range of applications.

- Flexibility: Despite their rigidity, PET sheets can be easily formed into complex shapes during the thermoforming process.

5. Chemical Resistance:

- PET is resistant to many common chemicals, including acids, alkalis, and solvents, making it suitable for food and pharmaceutical packaging.

6. Barrier Properties:

- PET provides good barrier properties against gases and moisture, which is crucial for preserving the quality and shelf life of packaged products.

7. Recyclability:

- PET is a highly recyclable material. Many PET sheets are made from recycled content, and the end products can also be recycled, contributing to sustainability efforts.

Get the latest price? We'll respond as soon as possible(within 12 hours)