352The characteristics and application of PET/PA/EVOH/PE transparent film.

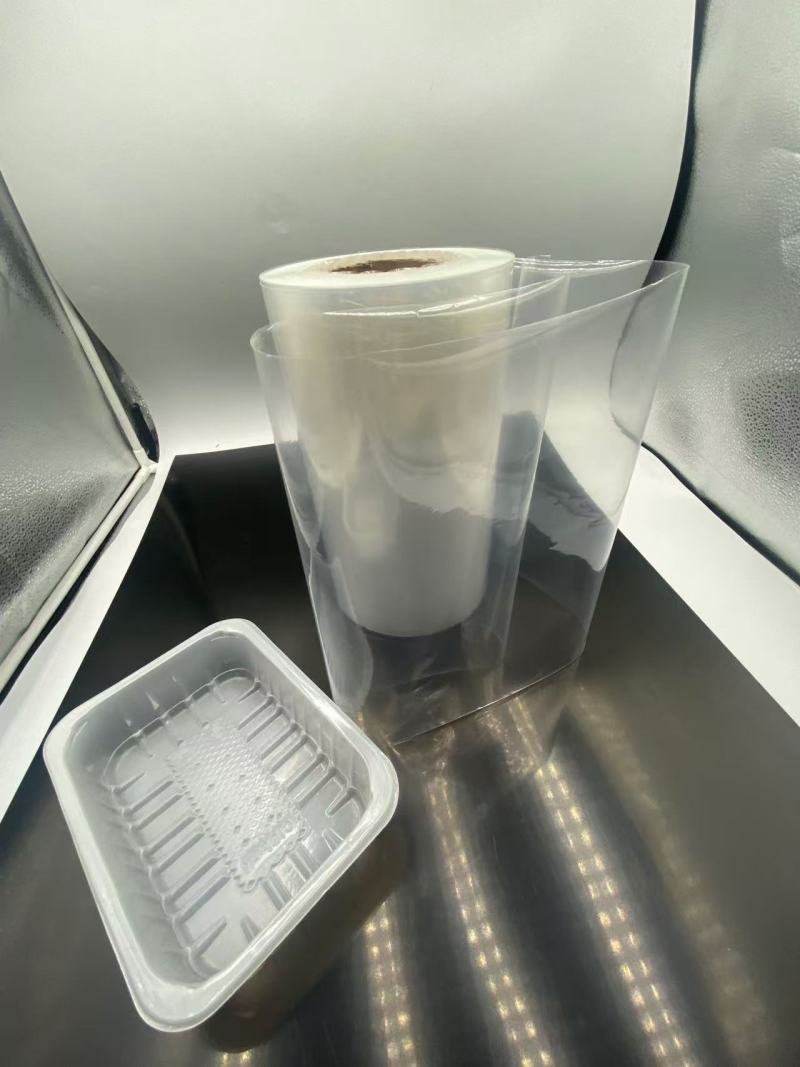

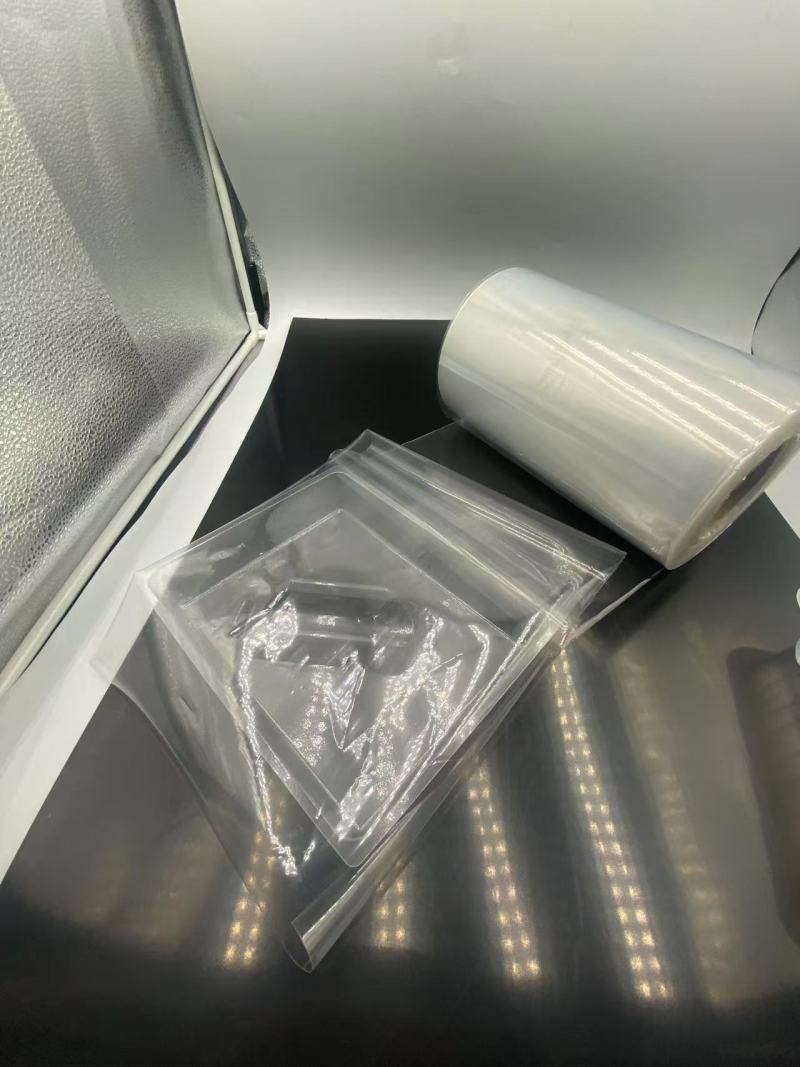

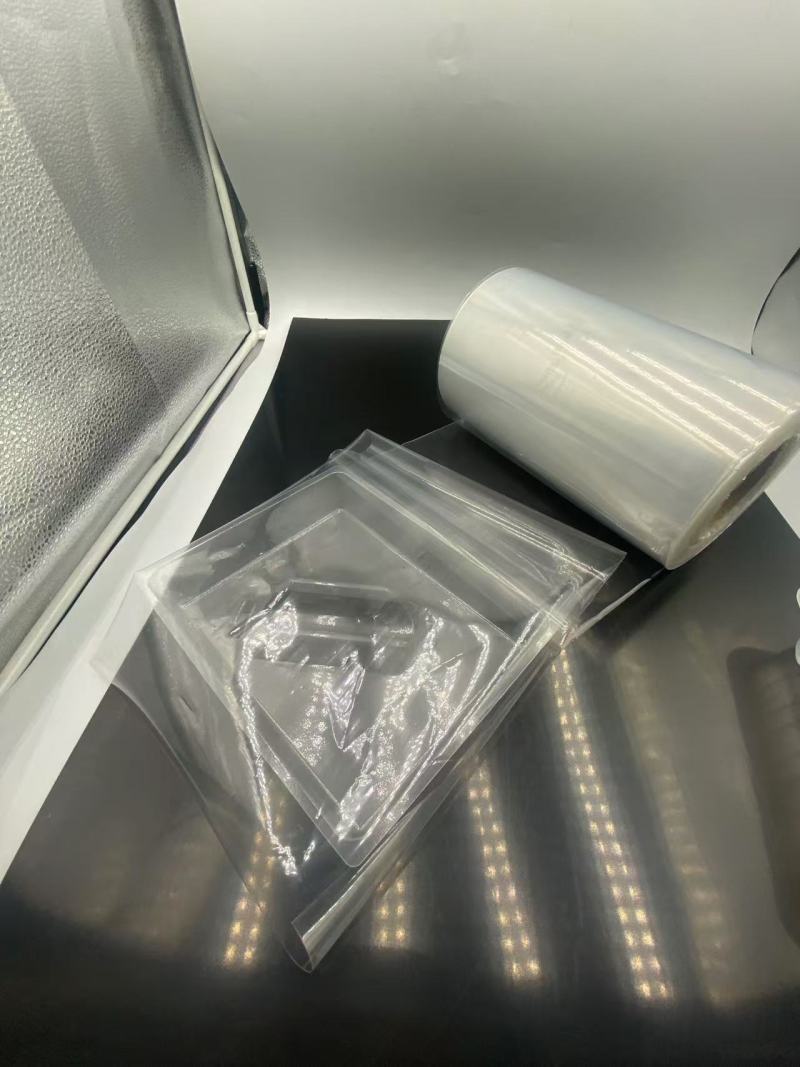

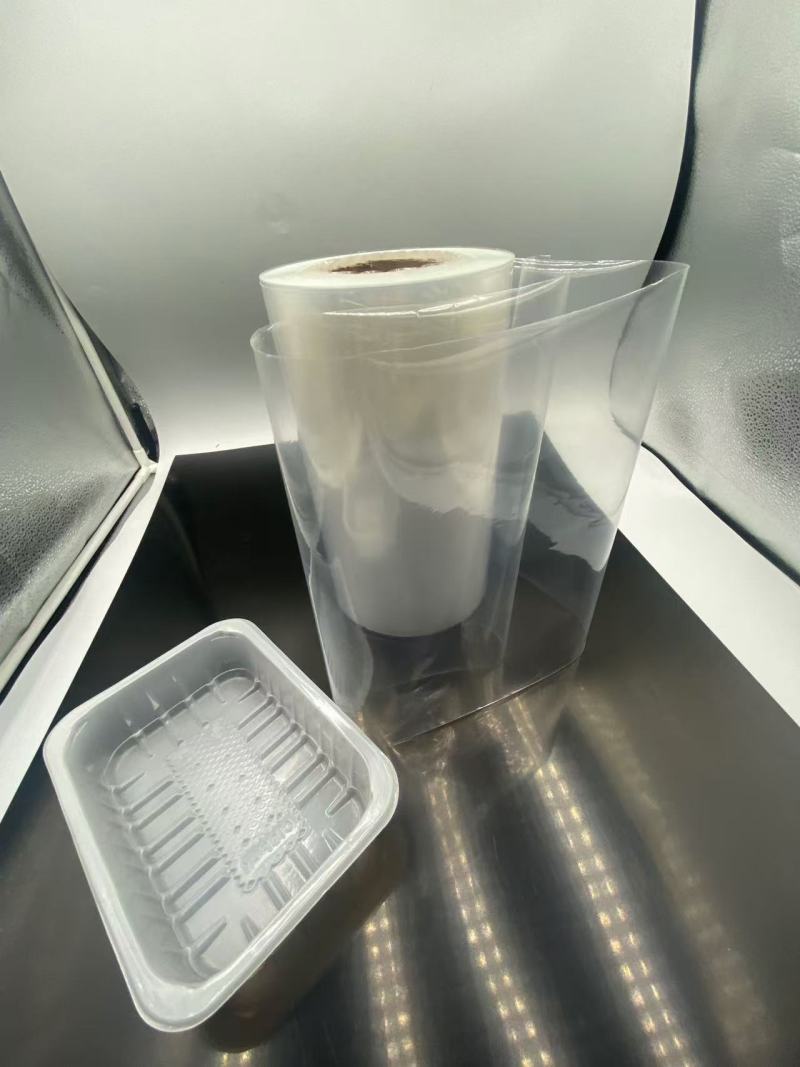

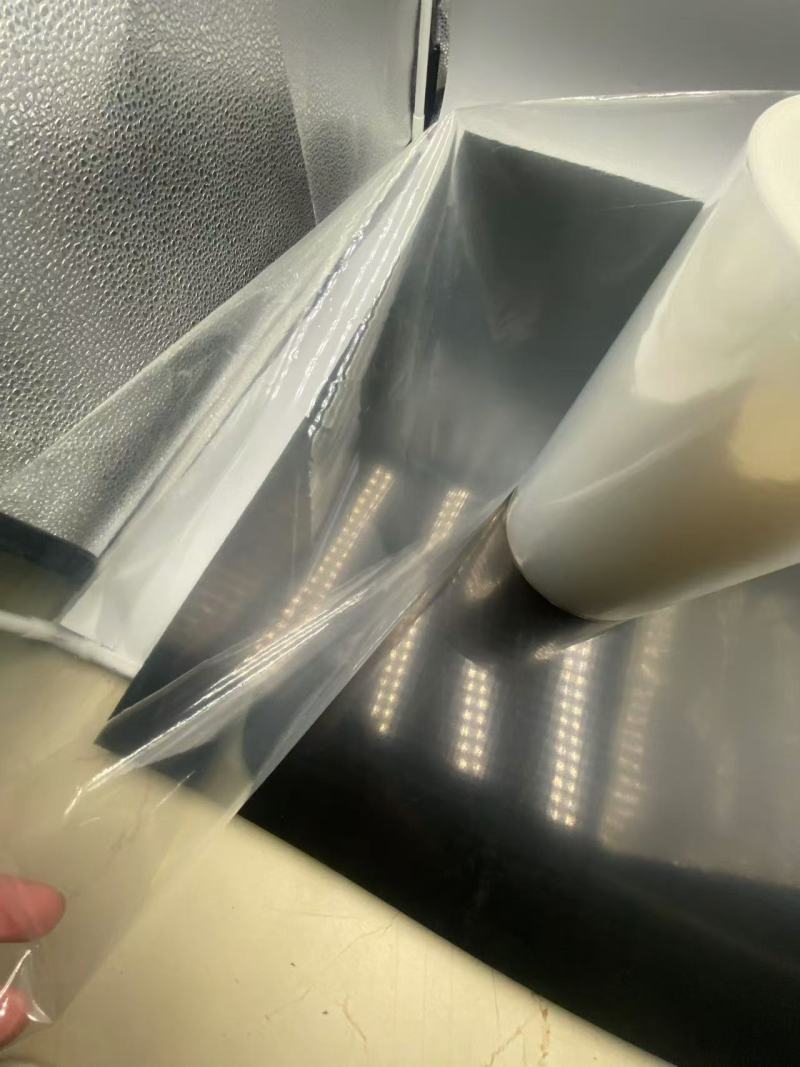

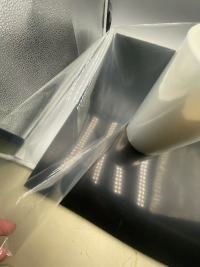

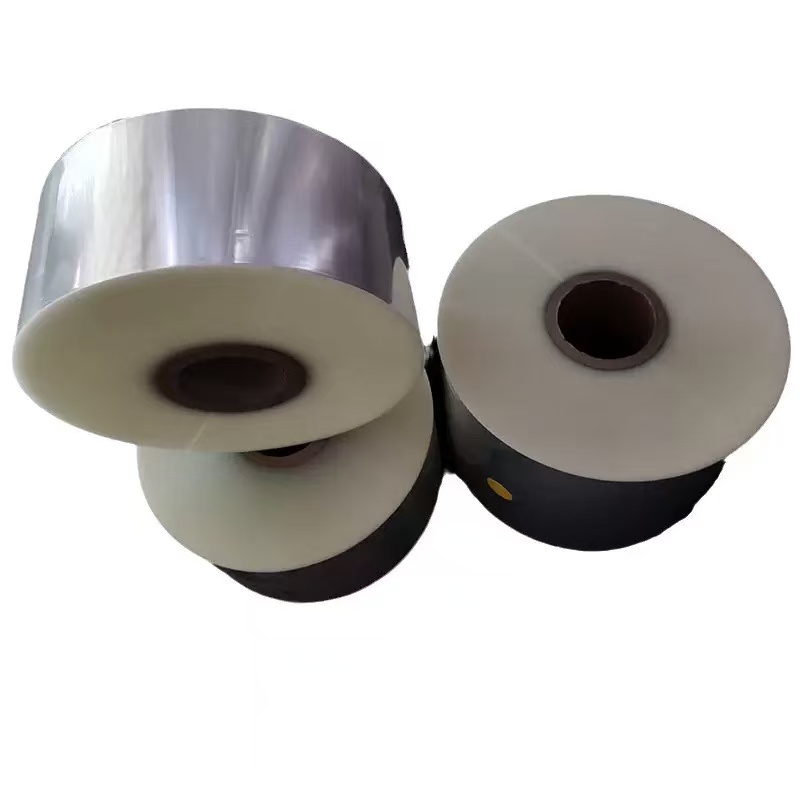

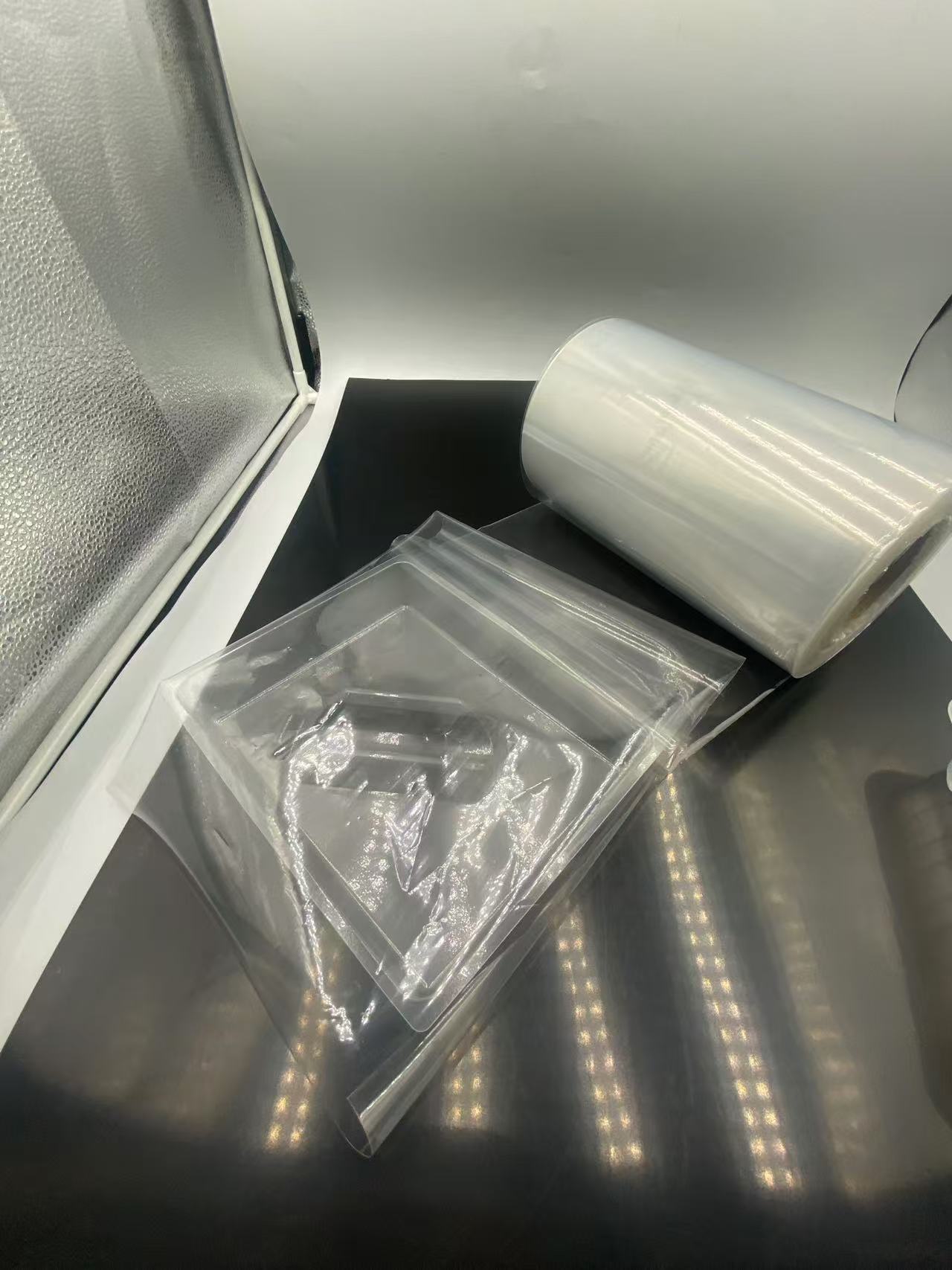

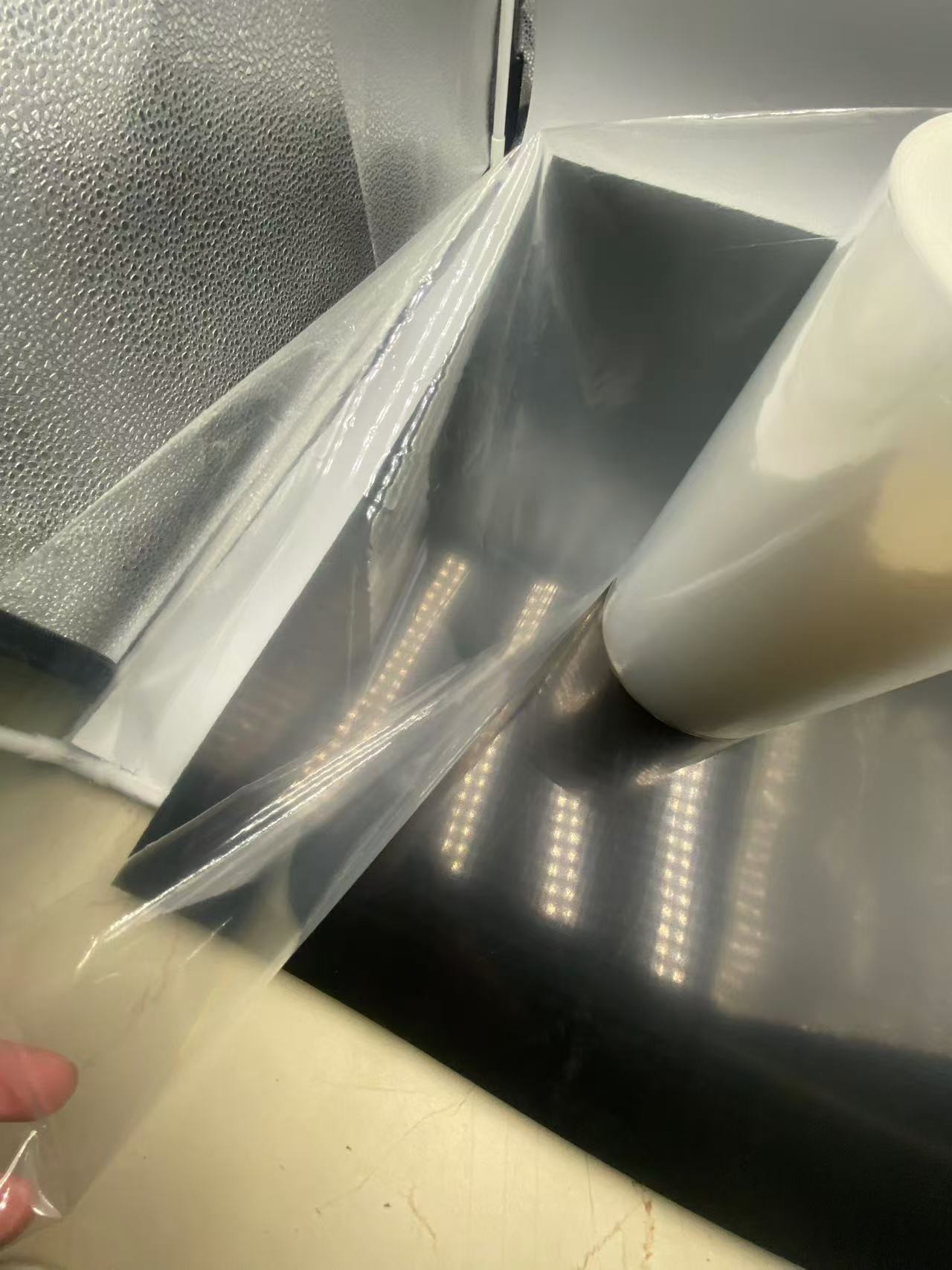

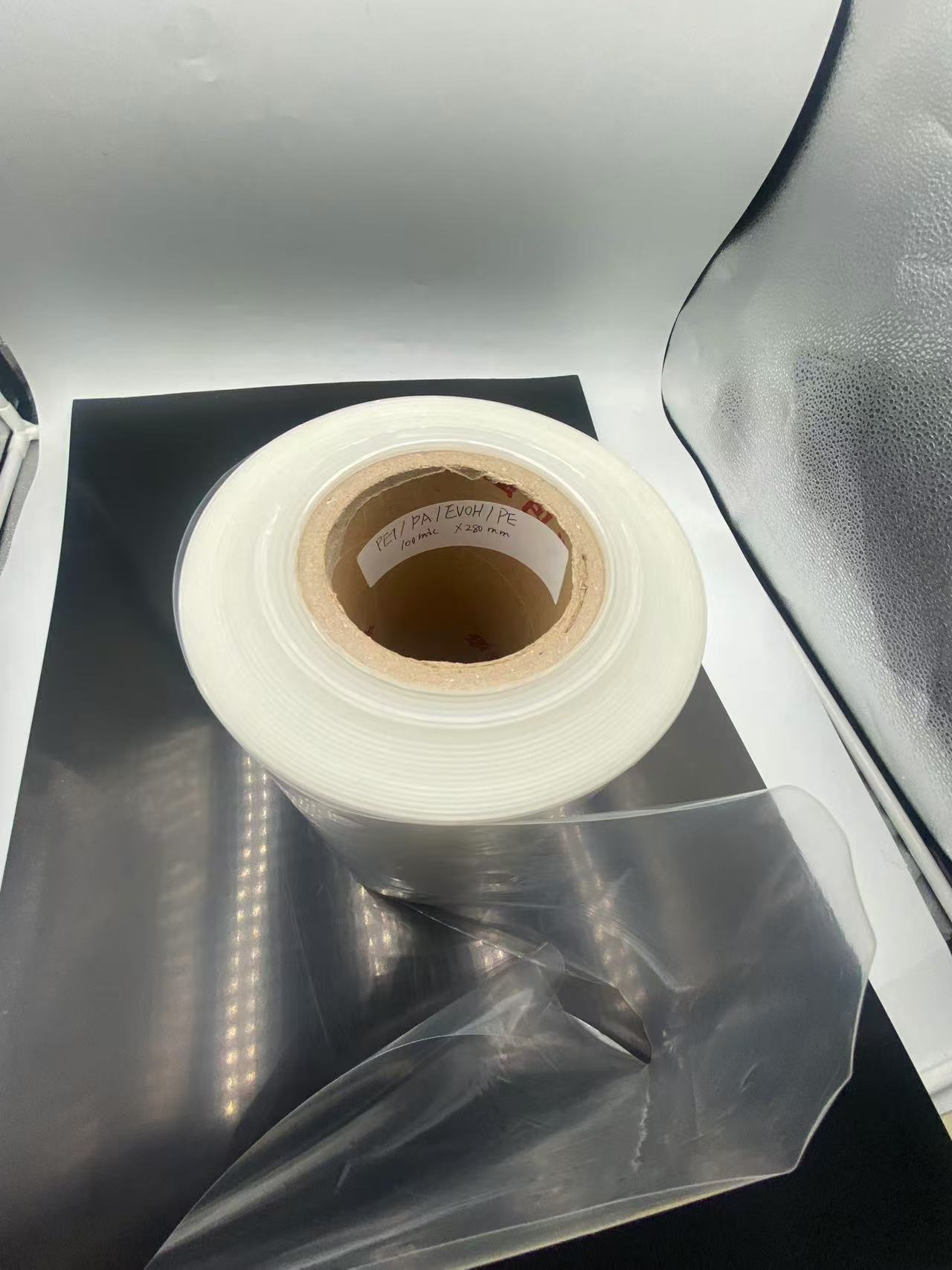

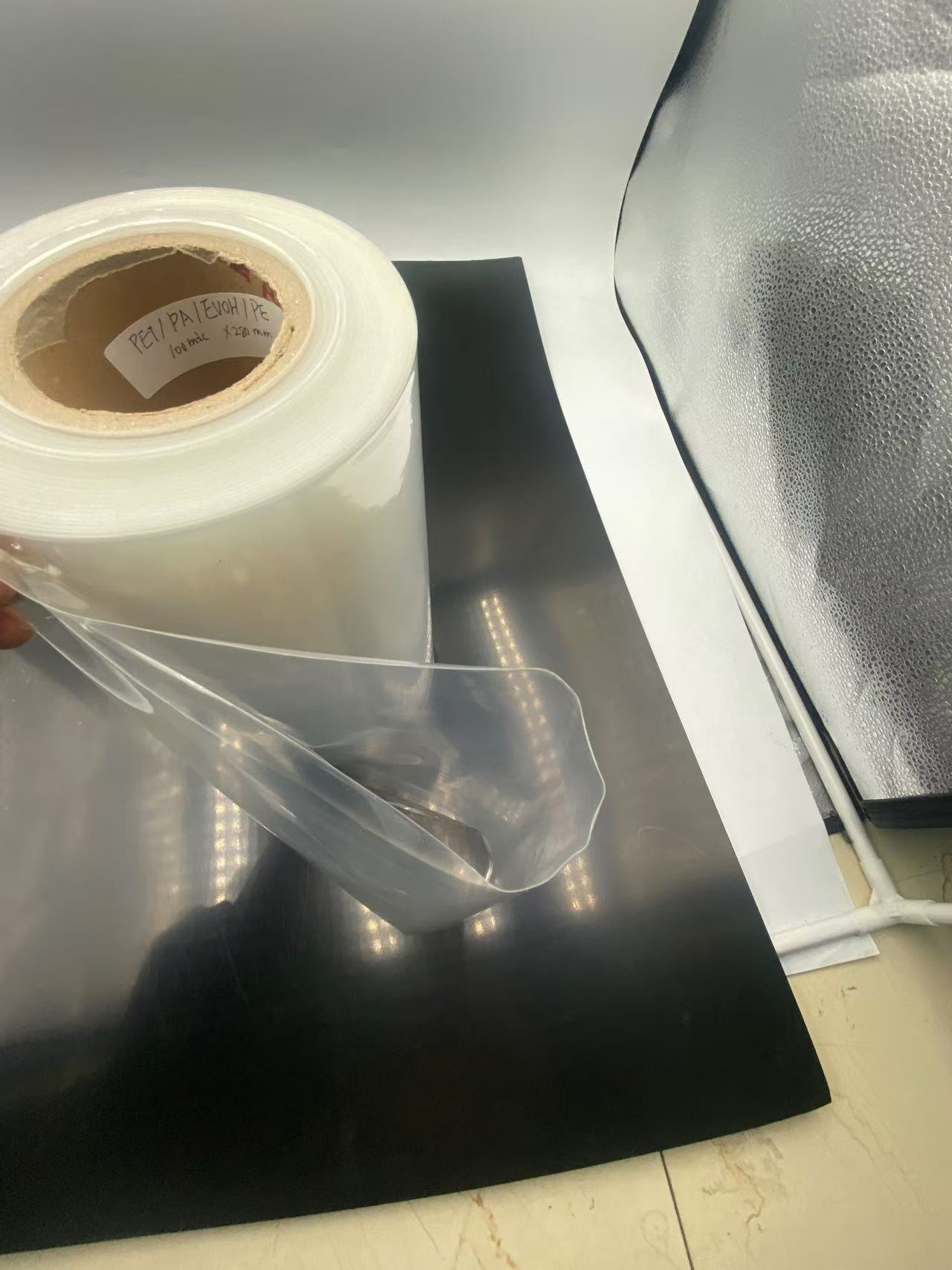

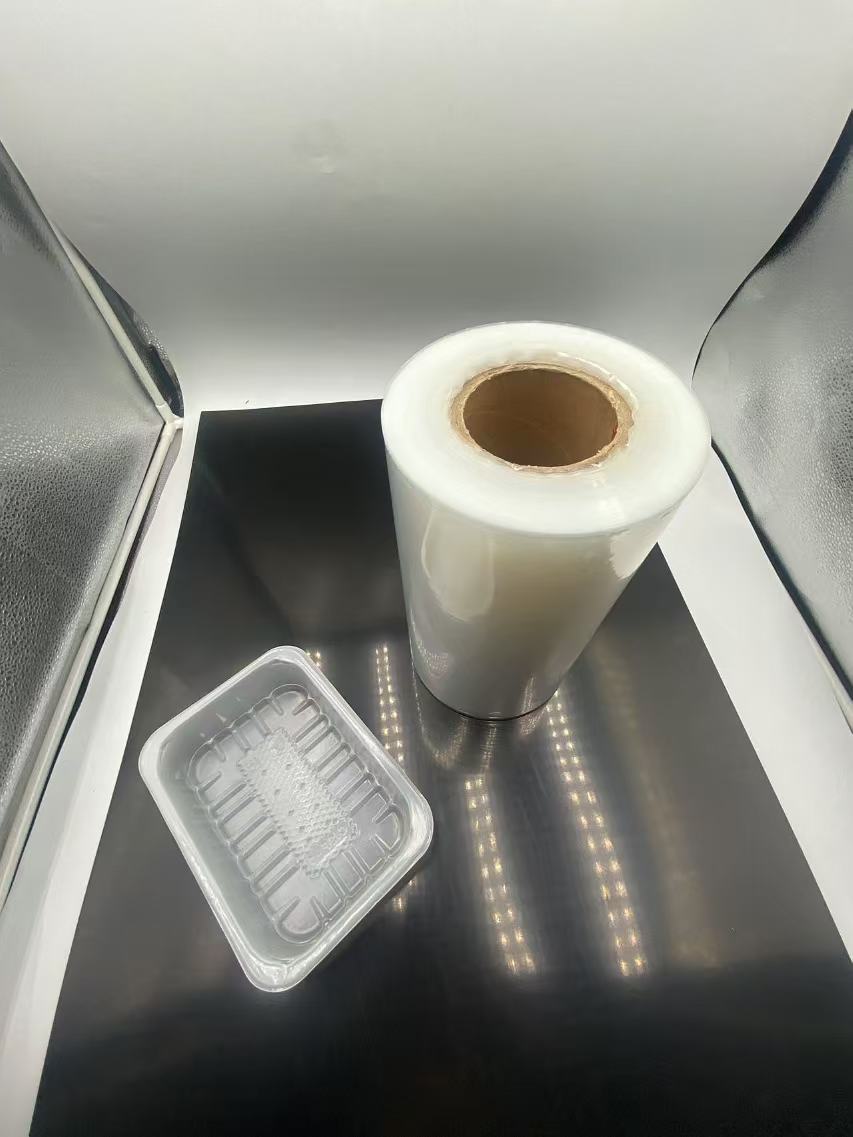

Material: PET/PA/EVOH/PE composite film

Thickness 0.1mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

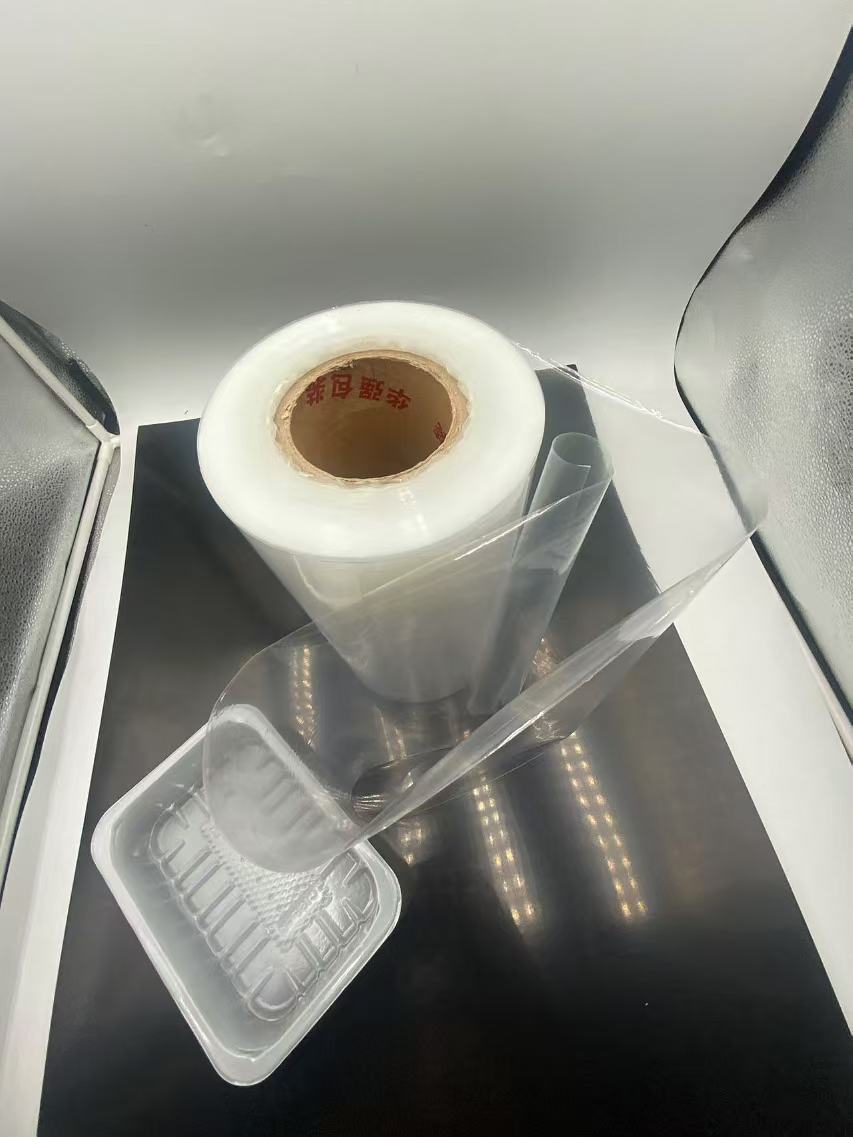

usage :for food and high barrier film bags ,heat sealing film

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

The characteristics and application of PET/PA/EVOH/PE transparent film.

Abstract: This paper reviews in detail the properties and various applications of transparent film PET/PA/EVOH/PE. The specific properties of each layer within the film are discussed, as well as how these combine to give a product with very good barrier, mechanical, optical, and thermal properties. Applications in food packaging, pharmaceuticals, and electronics, among others, are also discussed in fair detail, showing the importance of this multi-layer film in modern manufacturing and product protection.

Keywords: PET/PA/EVOH/PE transparent film, film characteristics, packaging applications, barrier properties

1. Introduction

Within today's industrial framework, packaging materials have great importance for protecting the products, extending their shelf life, and enhancing their appeal in the market. Such is the development of PET/PA/EVOH/PE transparent film that is outstanding in its function and can fulfill very high demands of different industries through a synergistic effect. Each of the polymers in this composite film adds to specific characteristics: PET or polyethylene terephthalate, PA or polyamide, EVOH or ethylene-vinyl alcohol copolymer, and PE or polyethylene make this film versatile and highly functional.

PET is characterized by excellent mechanical strength, dimensional stability, and transparency. PA features toughness, abrasion resistance, and barrier properties against gases and moisture. EVOH is well-known for its excellent gas barrier properties, especially against oxygen, which is critical in maintaining the quality and freshness of many products. PE offers flexibility, heat sealability, and moisture resistance. The combination of these polymers in a multilayer structure creates a film that can withstand a wide range of environmental conditions and protect the contents from physical, chemical, and biological degradation.

2. Characteristics of PET/PA/EVOH/PE Transparent Film

2.1 Barrier Properties

The EVOH layer in the PET/PA/EVOH/PE film is the key contributor to its exceptional gas barrier properties. It forms an impermeable barrier against oxygen, carbon dioxide, and other gases. This is very important in food packaging, where the ingression of oxygen may cause oxidation of fats, spoilage of food, and loss of flavor and nutritional value. For instance, in fresh meat packaging, the low oxygen permeability of the film maintains the red color and freshness of the meat for a longer period. The PA layer also helps to improve the barrier performance by acting as an additional physical obstacle to gas and moisture migration. The oxygen transmission rates for the PET/PA/EVOH/PE film can be reduced in several orders of magnitude compared with single-layer films, enabling it to maintain the integrity and quality of the packaged product. 2.2 Mechanical Properties

The PET layer gives the film high tensile strength and stiffness, which enables it to bear mechanical stresses during handling, transportation, and storage. It provides a rigid structure that protects the contents from physical damage. The PA layer further contributes to the toughness of the film, making it resistant to punctures and abrasions. This is particularly beneficial in packaging applications where the products may have sharp edges or need to endure rough handling. For example, when packaging hardware tools or irregularly shaped electronic components, the PET/PA/EVOH/PE film prevents items from tearing through the packaging and getting damaged. The combination of PET and PA also gives the film good dimensional stability, ensuring that it retains its shape and size even under varying environmental conditions.

2.3 Optical Properties

One of the key benefits of the transparency of the PET/PA/EVOH/PE film is that it allows consumers to clearly see the product inside the package, which is very important for marketing purposes. For food and beverages, packaging that allows visibility can enhance the appeal of the products for customer consumption and choice. For instance, in the packaging of fresh fruits and vegetables, a clear film in the wrapping helps to bring into view the colors and freshness of the produce on the supermarket shelf for the consumer. Moreover, the film is of good gloss and clarity that further enhances its appearance and gives a premium look to the products packed in them.

2.4 Thermal Properties

The PET/PA/EVOH/PE film is a thermally stable film that can be subjected to a wide range of temperatures. It can be used for both hot and cold fill techniques. In hot-fill applications - packaging of hot beverages or pasteurized products - the film resists such high temperatures without deforming or losing its barrier properties. Conversely, in conditions of cold storage or freezing, the film remains flexible and does not become brittle. This ability to function in different thermal environments is what makes it suitable for a wide variety of products with diverse requirements for storage and handling.

2.5 Printability

The surface of the PET/PA/EVOH/PE film can be easily printed for product information, branding, and decoration. Printing of the film could be done to a high quality by means of several techniques, like gravure printing, flexography, and digital printing. With its smooth surface and evenness, film provides an excellent substrate for ink adhesion, resulting in sharp and vibrant printed images. This is very important to differentiate the product and effectively promote it. In applications related to cosmetics or luxury goods packaging, for instance, fancy and attractive printing of the film can help raise the brand image and give the product an edge in the market.

3. Applications of PET/PA/EVOH/PE Transparent Film

3.1 Food Packaging

3.1.1 Fresh Produce

In the packaging of fresh fruits and vegetables, the PET/PA/EVOH/PE film offers an ideal solution. These are excellent gas barrier properties that prevent the loss of moisture and ingress of oxygen, maintaining freshness and crispiness of the produce. The transparency of the film will allow consumers to view the quality of the fruits and vegetables before purchase. For example, in strawberry packaging, the film maintains plump and juicy berries by limiting water loss and slowing the process of ripening. Mechanical strength imparts strength to the film, saving delicate fruits from bruising during transportation and handling.

3.1.2 Meat and Poultry

The control of oxygen and moisture levels in the films is very important for the preservation of meat and poultry products. It helps to inhibit the growth of spoilage bacteria and maintains the color and texture of the meat. Low oxygen permeability of the EVOH layer inhibits fat oxidation, which can lead to rancidity. For vacuum-packed meat, the film tightly seals the product, excluding air, which extends shelf life. Another important factor is the puncture resistance of the PA layer, which withstands the sharp edges of the bones to avoid any leakage. 3.1.3 Dairy Products Dairy products, such as cheese and yogurt, need protection from light, oxygen, and moisture. The film of PET/PA/EVOH/PE provides a very good barrier against all these factors. Because it is a transparent film, consumer can see the product from outside which is very significant for cheese since appearance and texture is an important component of customer preference. It has the PE layer at the end which can form a very strong seal; this would not allow even a drop to leak through and helps to keep the freshness of the dairy products.

3.2 Packaging in Pharmaceutical

In Pharmaceuticals it packs tablet capsules of medication or other type of. Excellent barrier properties against moisture and oxygen serve to preserve the potency and stability of the drugs. The transparency of the film enables the identification and inspection of the contents with ease. The mechanical strength and puncture resistance of the film protect the medications from damage during handling and transportation. The film acts as a barrier in the packaging of blister packs and protects the individual tablets or capsules until consumption. It can also be printed with key information like dosage instructions, expiry dates, and batch numbers on the film, which is important for patient safety and regulatory compliance.

3.3 Electronics Packaging

The packaging materials used in the electronics industry must protect sensitive components from ESD, moisture, and physical damage. To that effect, the property of antistatic PET/PA/EVOH/PE film modification can fit for packaging electronic components such as integrated circuits, printed circuit boards, and displays, among others. The barrier properties of the film keep away moisture that may cause corrosion and short circuits. The mechanical strength and puncture resistance protect the components from mechanical stresses during shipping and handling. The transparency of the film also allows for visual inspection of the components without opening the package, which is quite convenient for quality control/inventory management.

3.4 Cosmetics Packaging

Many cosmetics products require packaging that can be both attractive and serviceable. The PET/PA/EVOH/PE film meets these requirements. Transparence and printability are excellent features for making interesting, informative, and aesthetic packagings. It can protect the cosmetics from oxidation, moisture, or light that might degrade quality through its barrier properties. The film plays a huge role in keeping the perfume smell in place by avoiding the escape of volatile compounds into space in perfume packaging. The mechanical strength of the film will keep the packaging intact during storage and transportation and hence protect the delicate bottles and containers of cosmetics.

4. Advantages and Significance of Using PET/PA/EVOH/PE Transparent Film

4.1 Product Protection

The excellent barrier, mechanical, and thermal properties of the PET/PA/EVOH/PE film ensure all-round protection for a wide variety of products. This helps in maintaining the quality, freshness, and integrity of the contents, reducing the risk of spoilage, damage, and degradation. This is especially true for perishable commodities like food and pharmaceuticals, where any loss of quality will have very serious consequences on the health and satisfaction of consumers.

4.2 Extended Shelf Life

Due to effective gas, moisture, and light ingress control, the film will be able to extend the shelf life of packaged products very significantly. It reduces food waste and extends the time a manufacturer can distribute their product over a larger geographical region for a longer period of time. For instance, regarding packaged snacks, the extended shelf life that the film allows will have the stores stocking those products for a longer time, hence reducing the number of times to restock the product, improving the efficiency in the supply chain.

4.3 Marketing and Branding

This is a great opportunity for marketing and branding, considering the transparency and printability of the film. The packaging design could be made very attractive and communicative, catching the eye of consumers and adding value to the product. The clear view of the product through the film may enhance its desirability and influence purchasing decisions. In a competitive market, effective packaging can make a big difference in product sales and brand recognition.

4.4 Sustainability

The PET/PA/EVOH/PE film may offer relevant contributions to sustainable packaging. For this purpose, the multilayer structure allows the employment of thinner films while guaranteeing performance levels. With the usage of thinner films, the material consumption decreases and therefore the generation of less waste. Besides that, such a film might be recyclable, although recycling processes will be more difficult compared with single-layered film packaging. However, several works try to improve the process in order to make this package more ecologically friendly.

5. Future Trends and Developments

In the near future, this PET/PA/EVOH/PE transparent film will continue to be researched and improved upon due to constant development in technologies and a change in consumer needs. It is expected that there are still many chances for developing better barrier properties against contaminants and gases. In particular, there is growing interest in films with enhanced biodegradability or compostability due to ecological issues. In the field of smart packaging, the film can be integrated with sensors or indicators which can give real-time information about the quality and freshness of the packaged product. For instance, a sensor could detect changes in temperature or gas concentration inside the package and alert consumers or supply chain managers if the product is at risk of spoilage. Further, there could also be newer methods of manufacturing this film to produce it more economically and thus make it even more viable for use in many industries.

In the final analysis, this transparent film made of PET/PA/EVOH/PE is a fantastic modern packaging material with a wide profile of characteristics and applications. The special combination of its properties makes this material vital in modern packaging for protecting products, enhancing their storage life, and allowing effective marketing. With continuous research and development, this film is likely to continue changing and playing an even more vital role in various industries in times to come.