- Home

- >

- Products

- >

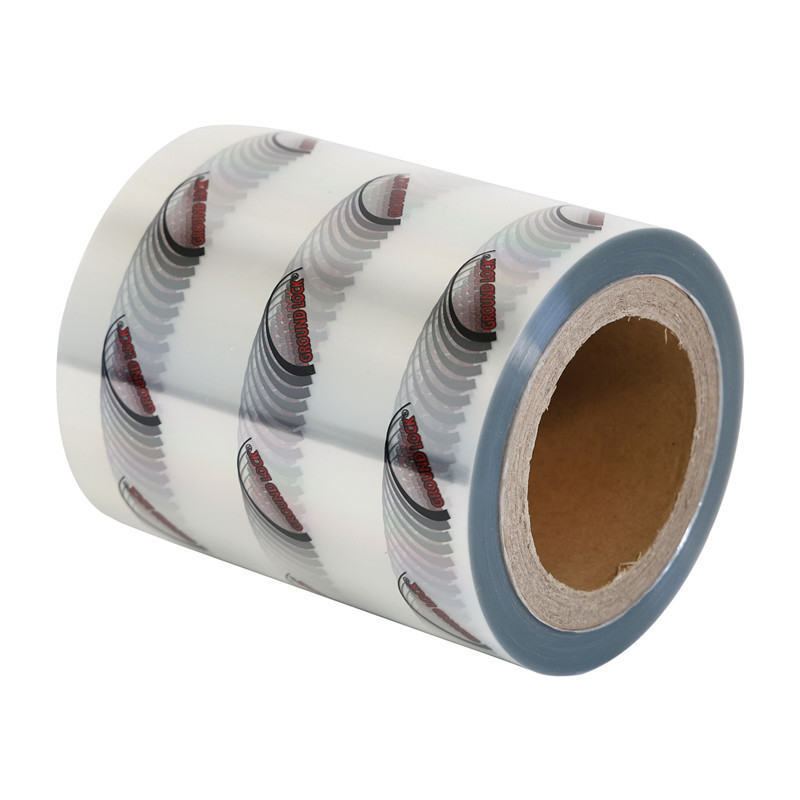

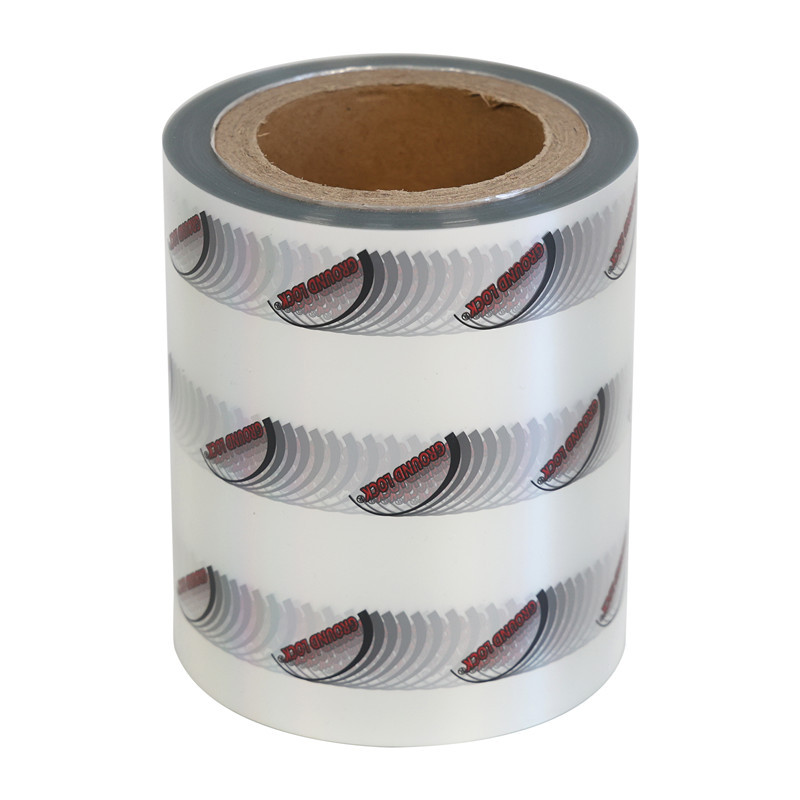

- PET/PE sealing film

- >

PET/PE sealing film

Heat Sealability:

- The film should be able to withstand the heat sealing process without losing its integrity or allowing leaks.

- TOP LEADER

- CHINA

- 7-15 Working days

- 5000t/Month

- Information

Product description

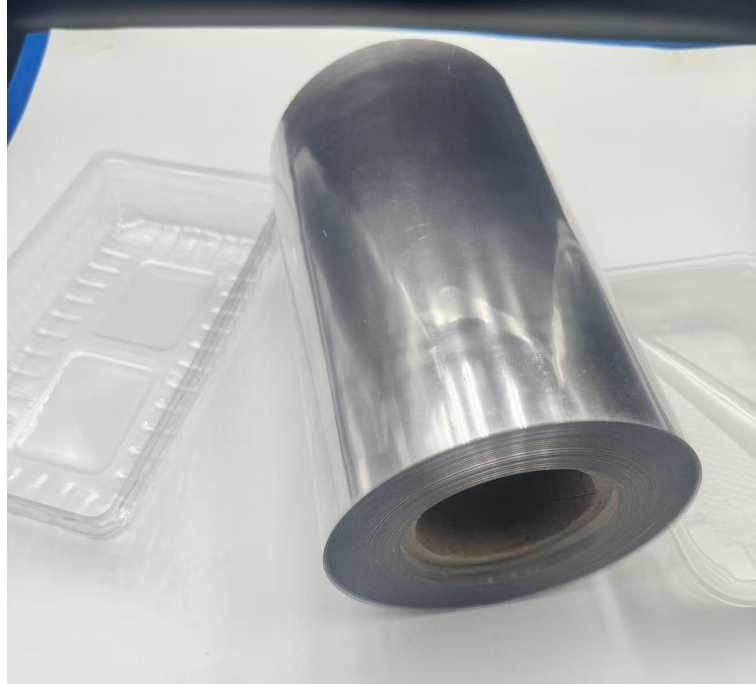

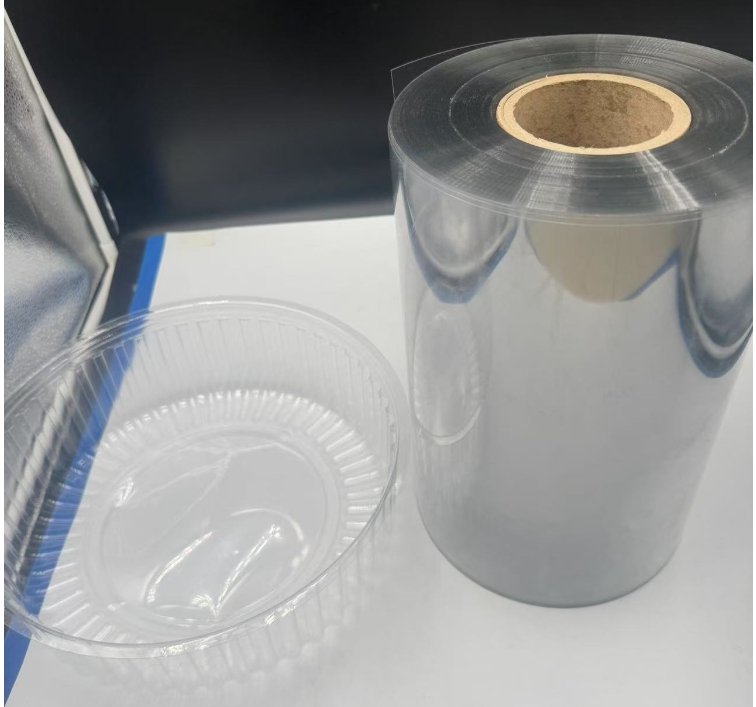

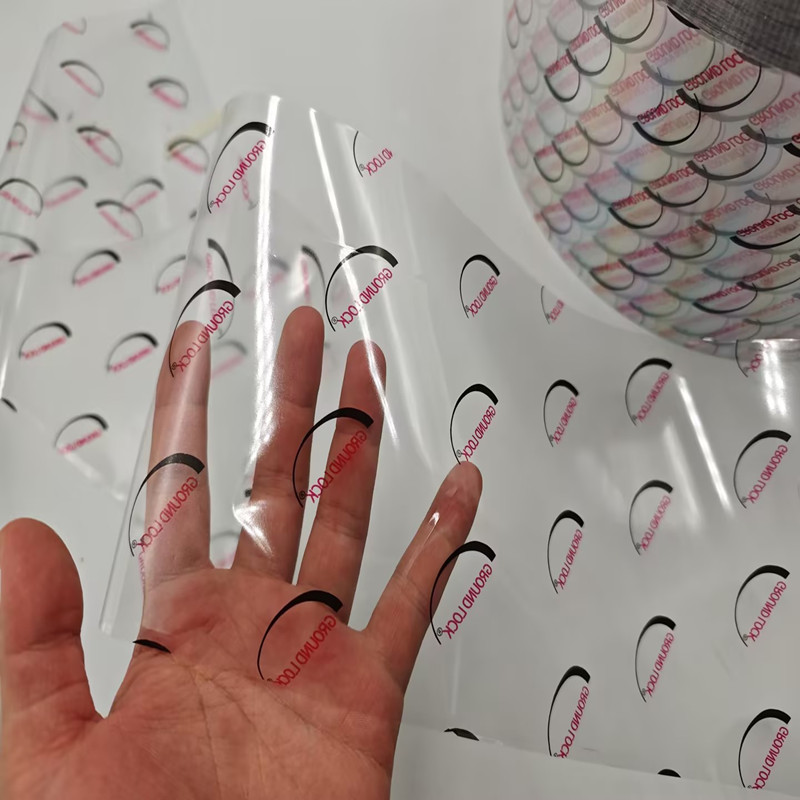

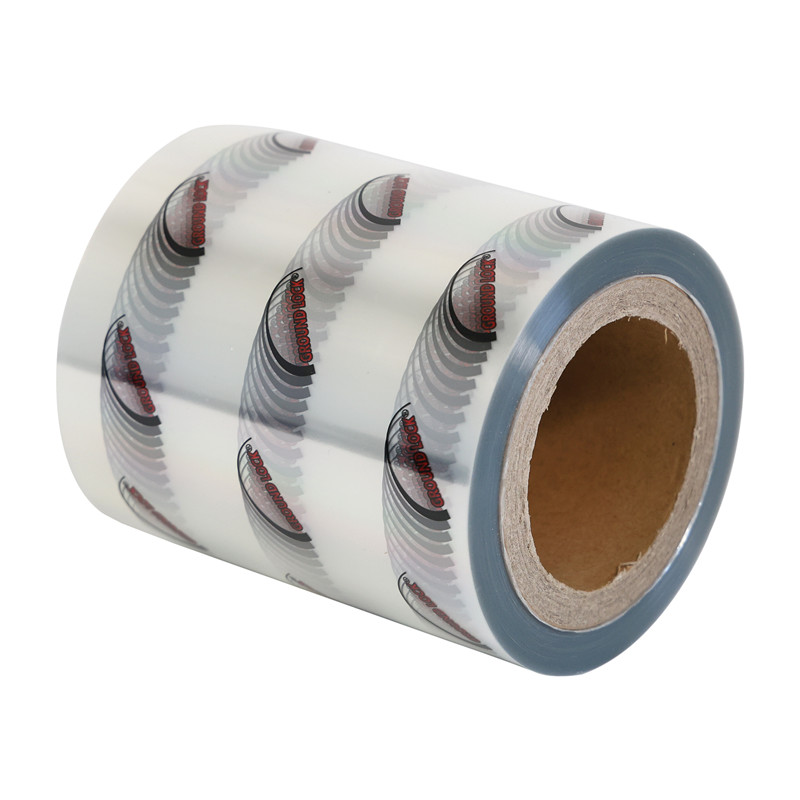

| Product name: | PET/PE Customized printing plastic tray sealing film |

| Printing: | offset printing or flexo printing , Digital printing |

| Size & Thickness: | As clients' requirement. |

| Application: | Home Appliance, Ecommerce Mailer, make-up box, wig box, cosmetic, perfume, Gift, retail, shipping, postal, |

| Style Options: | Rigid boxes, Corrugated boxes, Cardboard boxes |

| Features: | Clear Window, handles, magnet cover, sliding drawer, foldable etc. |

| Leading Time: | 1 day for stocked samples, 10 days for new samples, 25 days for mass production |

| Shipping: | 1). By Express (3-7 working days), suitable for Urgent Order or Small Quantity. To your door. |

| 2). By Sea (15-30 days), suitable for regular Mass Production. To your seaport. | |

| 3). By Air (4-5 days), from Airport to Airport. |

PET and PE are two of the most widely used plastics in food packaging due to their excellent properties, including durability, transparency, and barrier properties against gases and moisture.

Here are the basic facts about PET/PE customized printing plastic tray-sealing films:

1. Material Composition:

PET is used basically when one needs clarity and rigidity.

PE is incorporated usually for flexibility and proper sealability.

2. Custom Printing:

Can be printed with company logos, branding information, and nutritional facts that must be included.

3. Sealing Properties:

- It should be able to seal well so that the content inside is well-protected and tightly sealed.

4. Barrier Properties:

- Depending on the product being packaged, the film may need to provide protection against oxygen, moisture, or light to maintain the freshness and quality of the contents.

5. Heat Sealability:

- The film should be able to withstand the heat sealing process without losing its integrity or allowing leaks.

6. Thickness:

- The thickness of the film can be adjusted according to the needs in strength, flexibility, and cost.

7. Environmental Considerations:

- Some companies are looking for more sustainable options, so biodegradable or recyclable materials might be considered.

Get the latest price? We'll respond as soon as possible(within 12 hours)