715PVC/PE Composite Film: Characteristics and Practical Applications

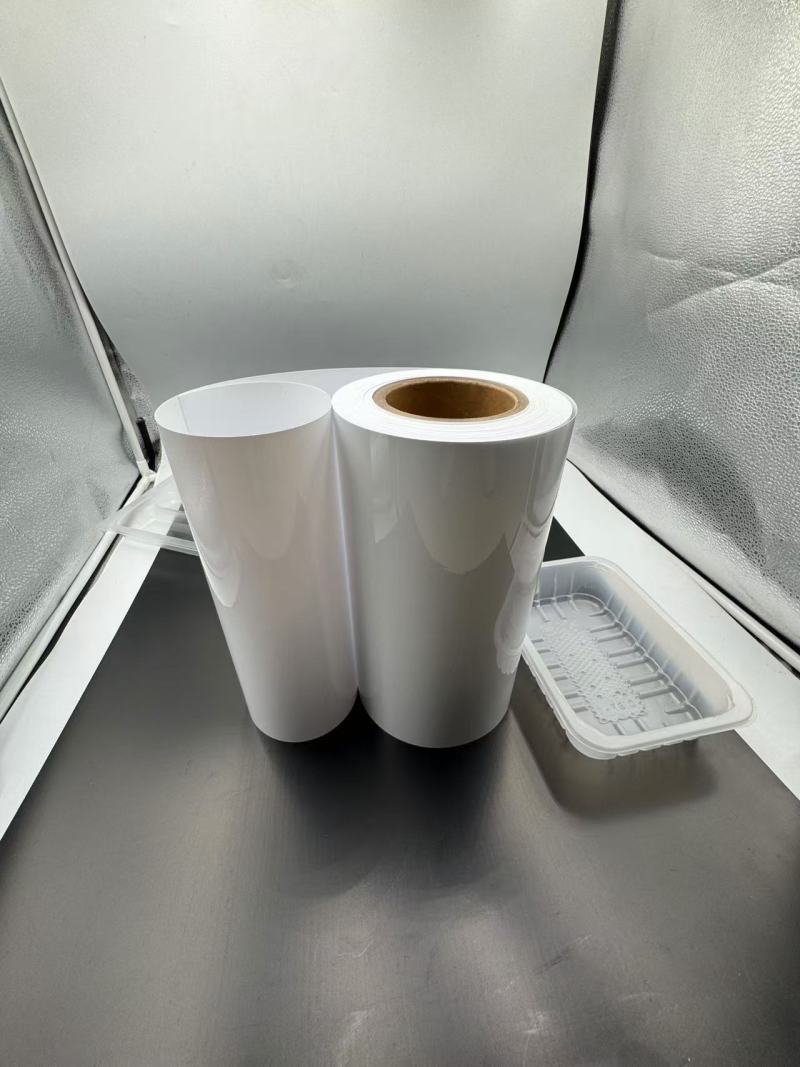

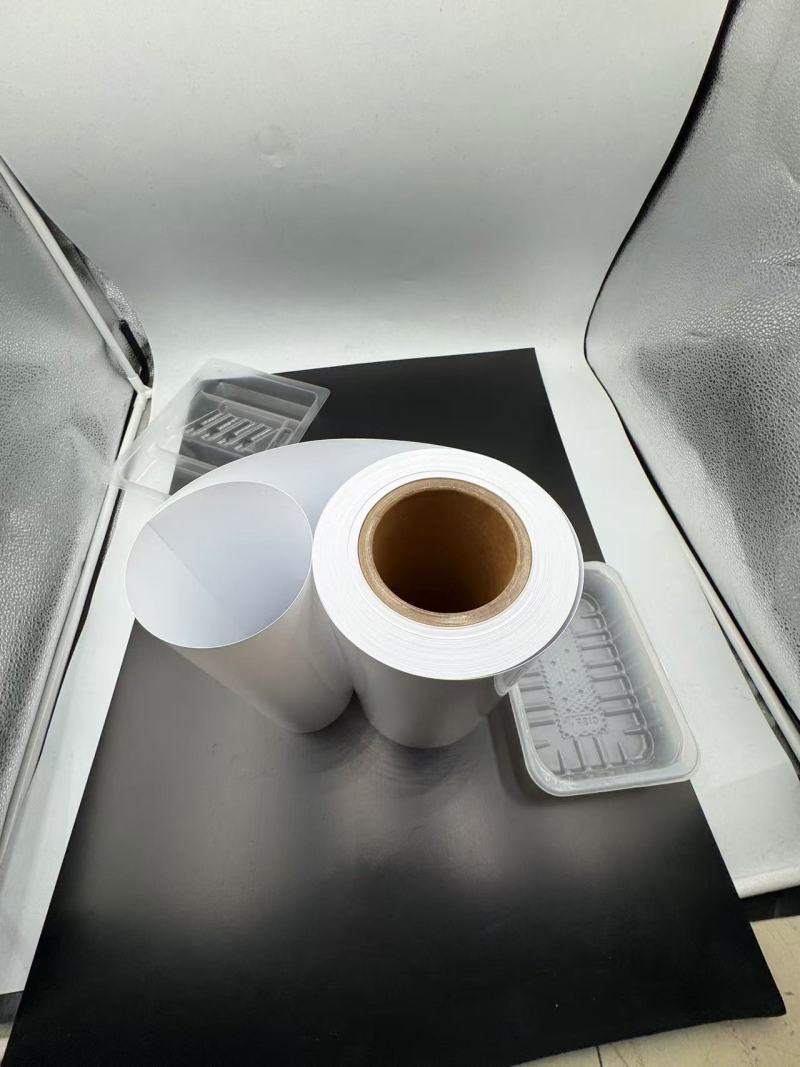

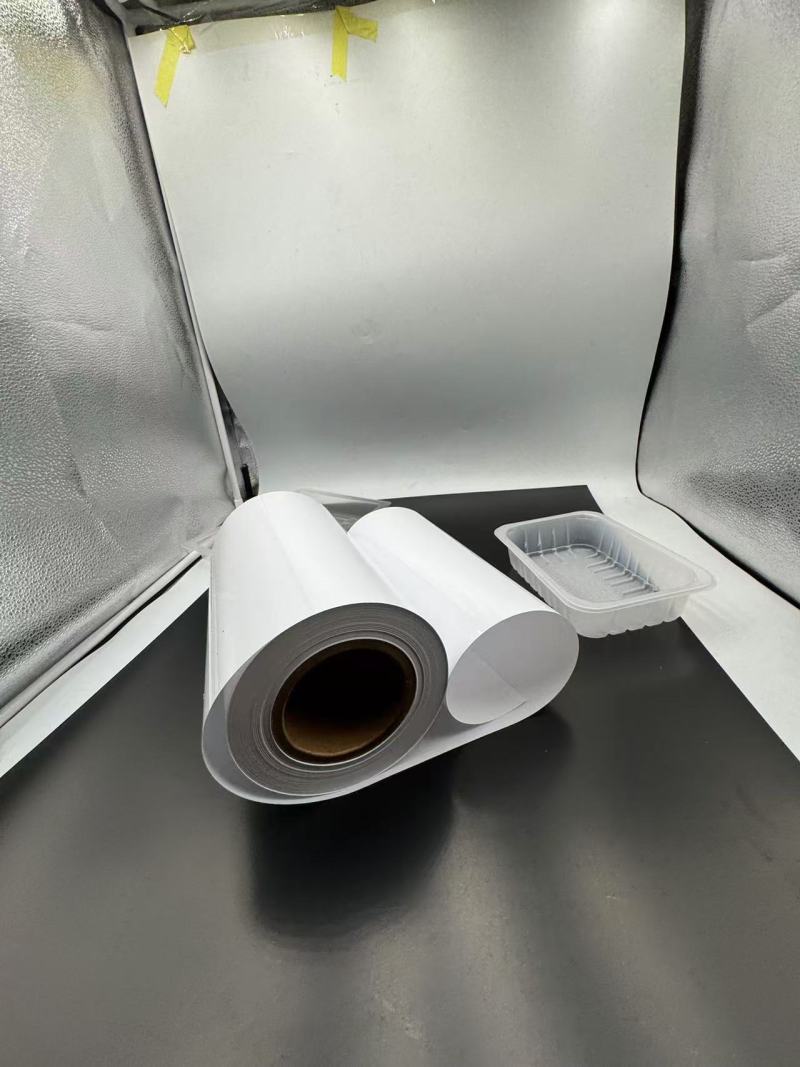

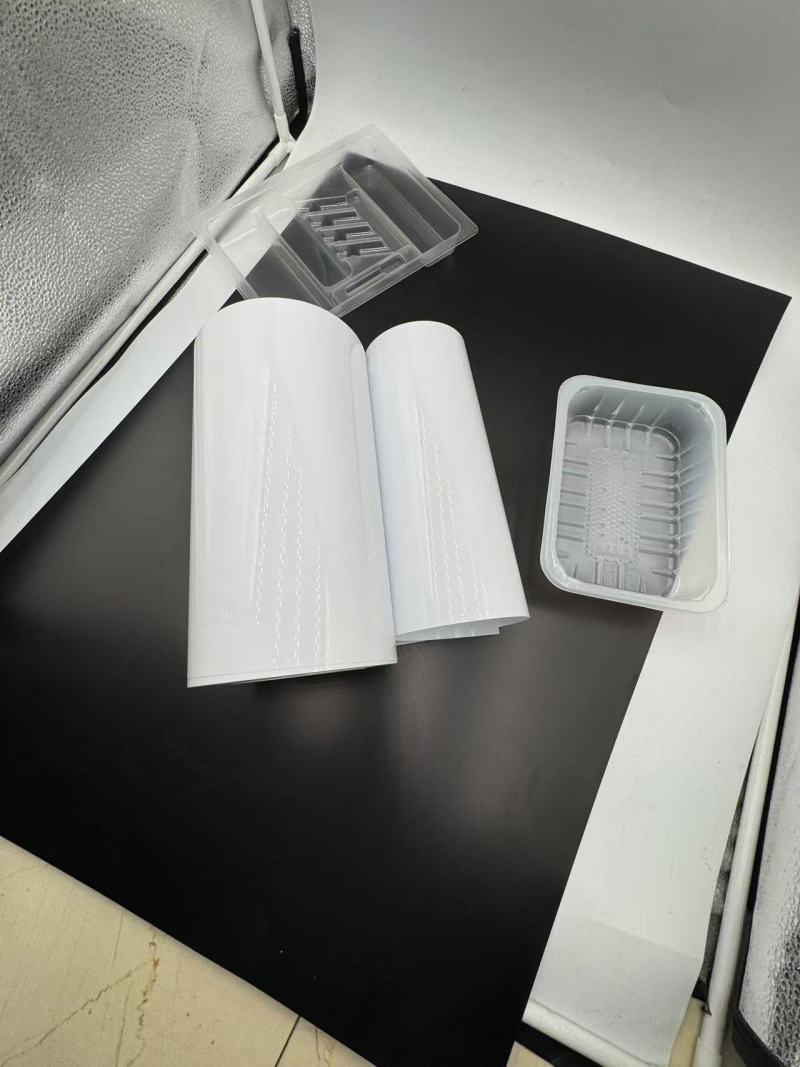

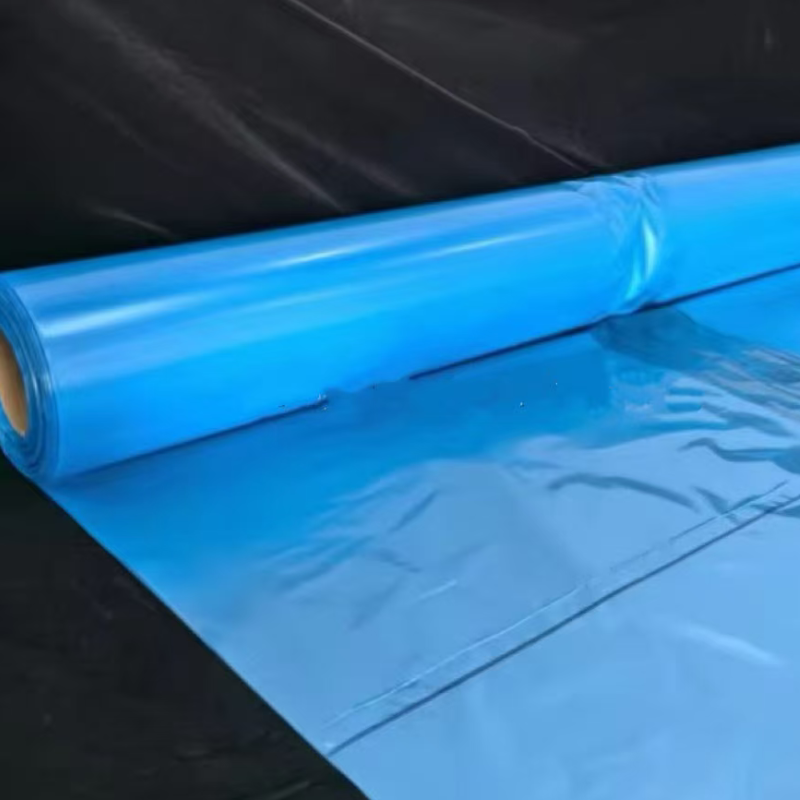

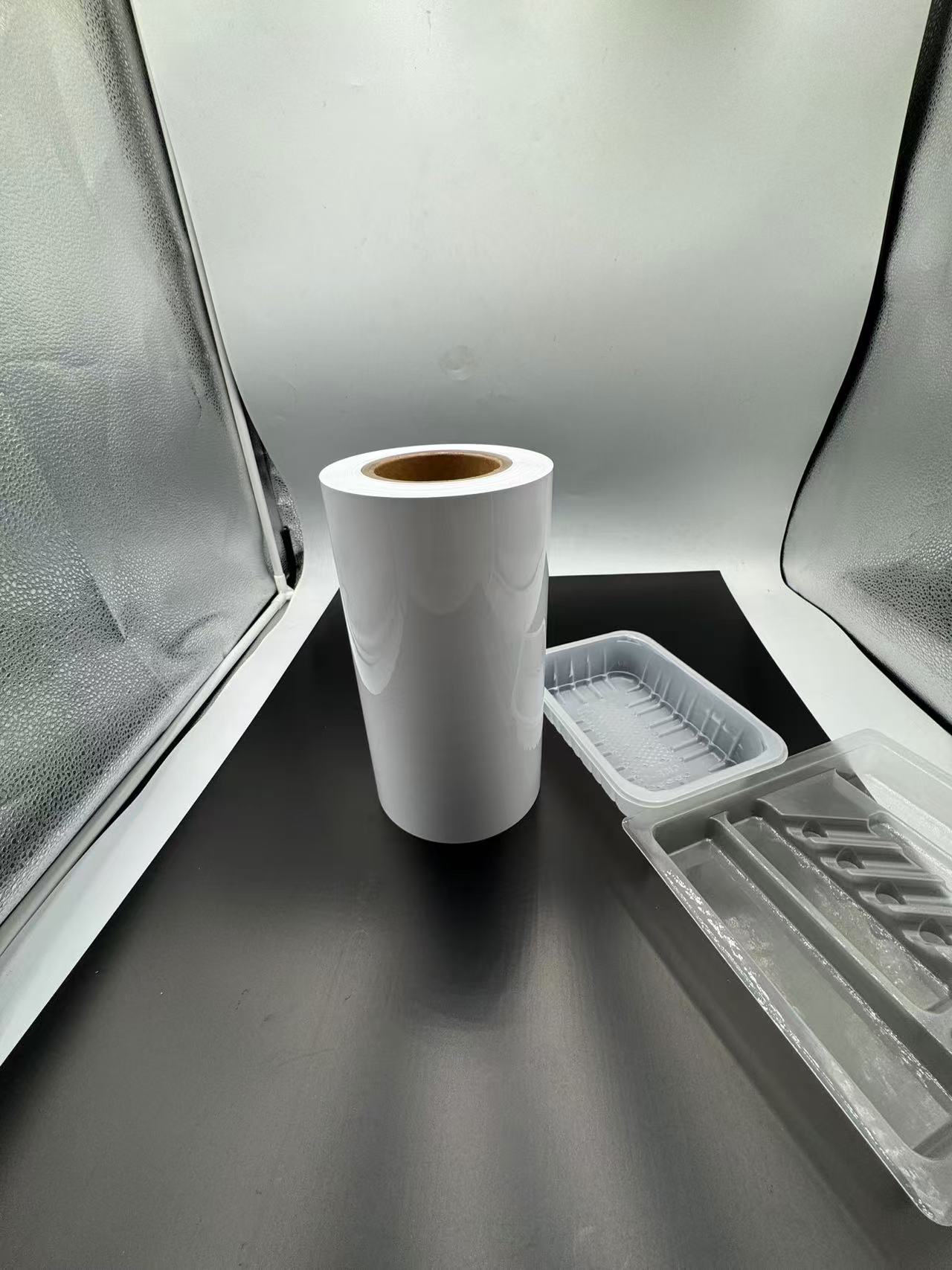

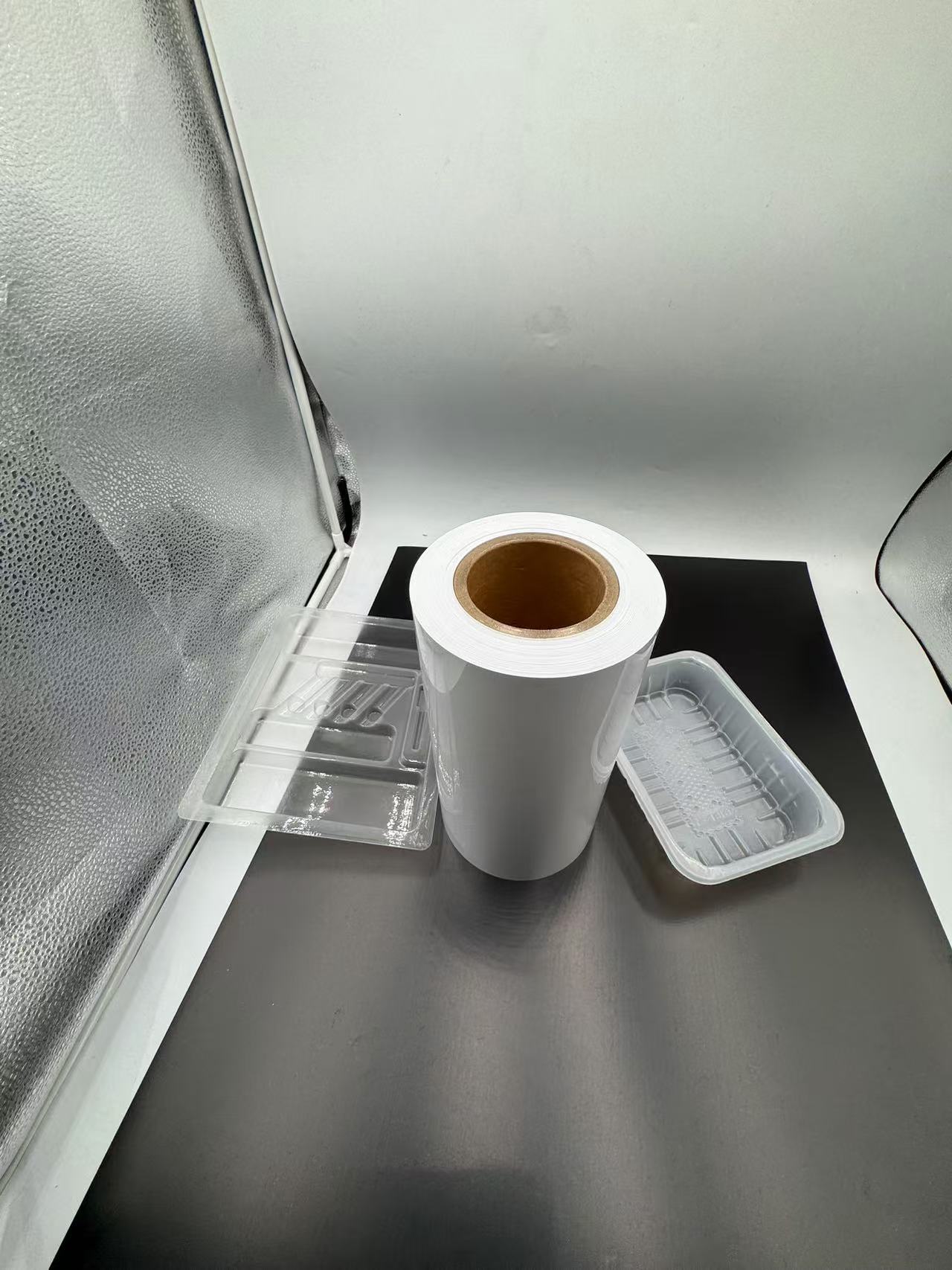

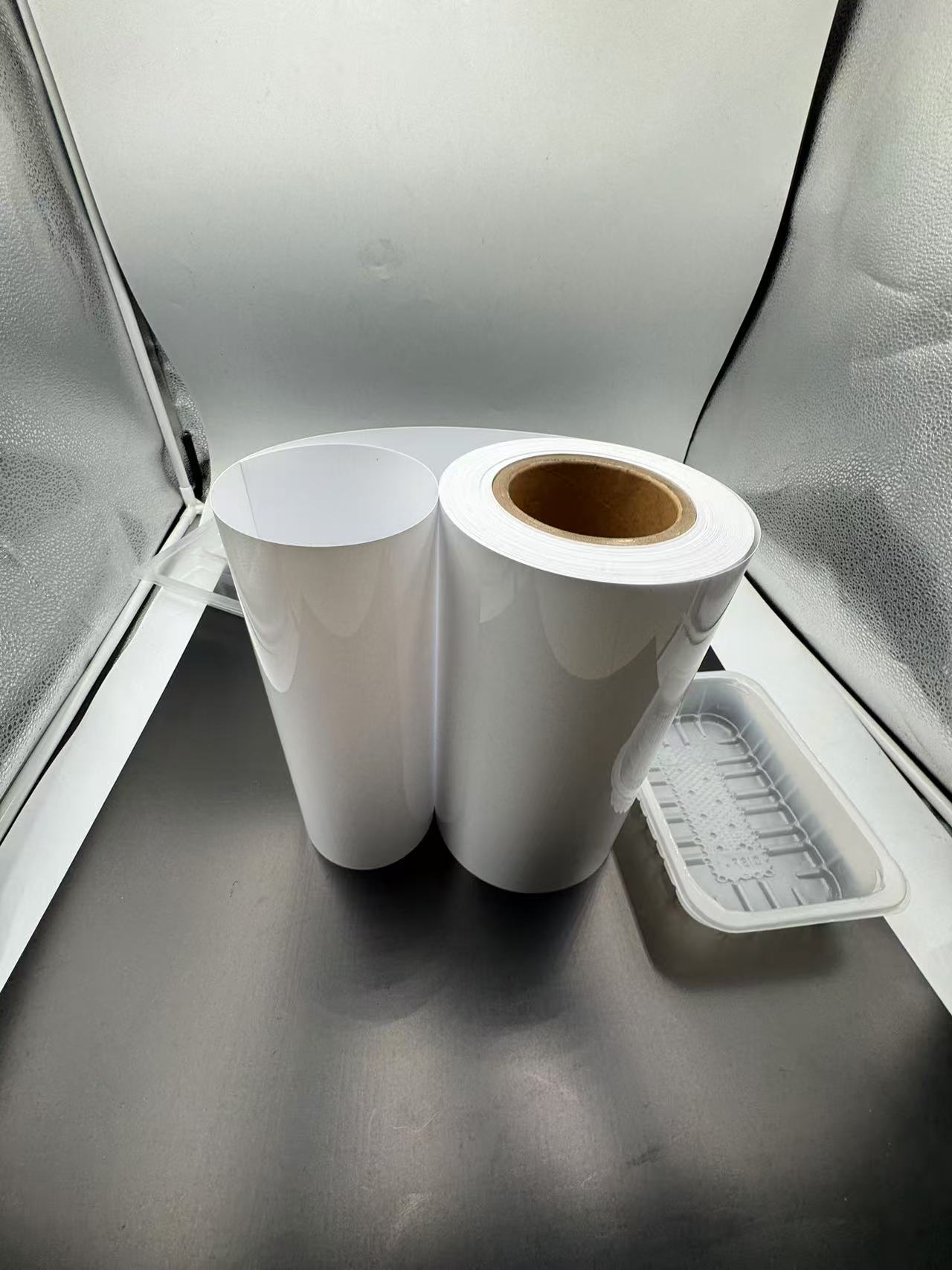

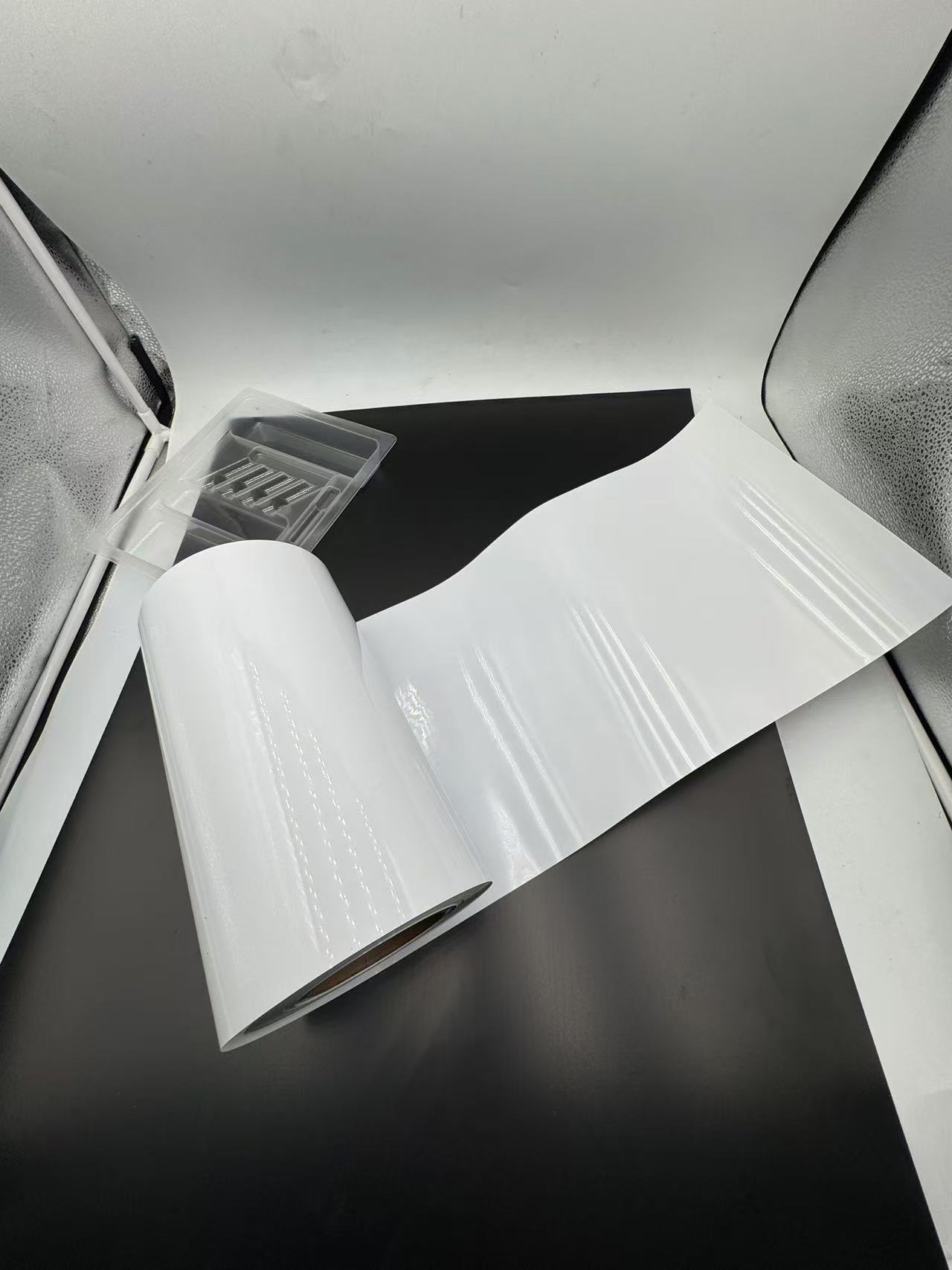

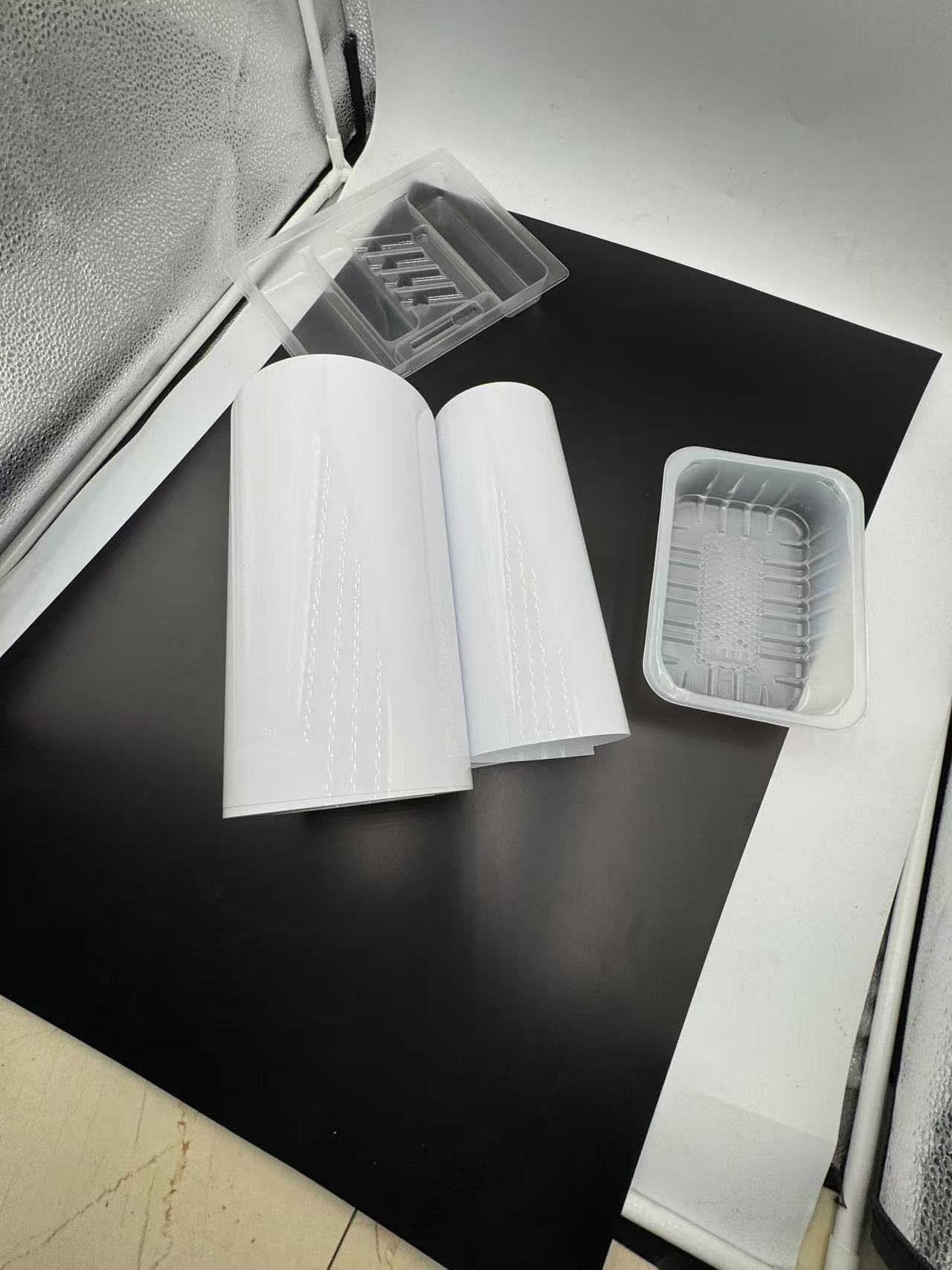

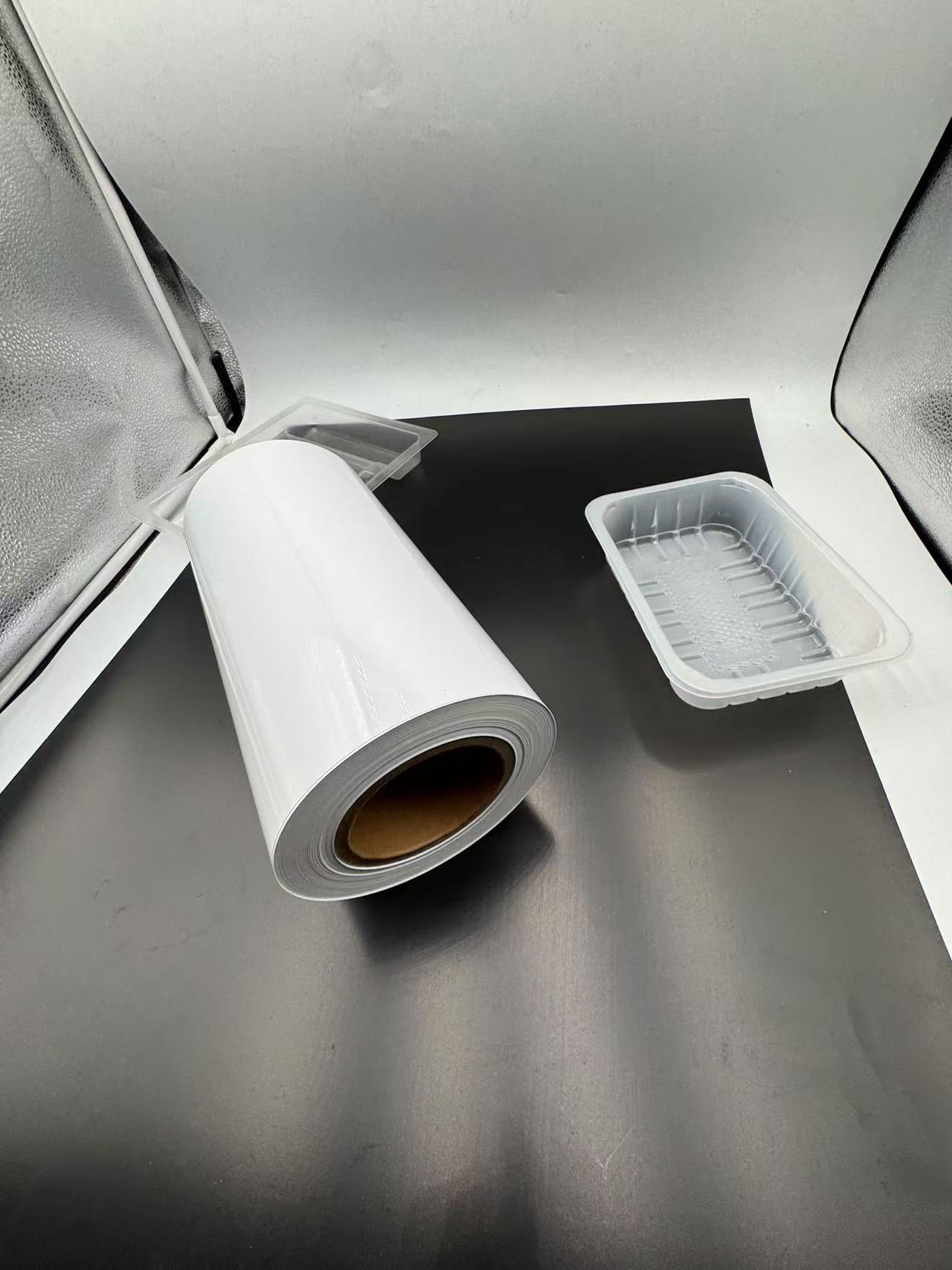

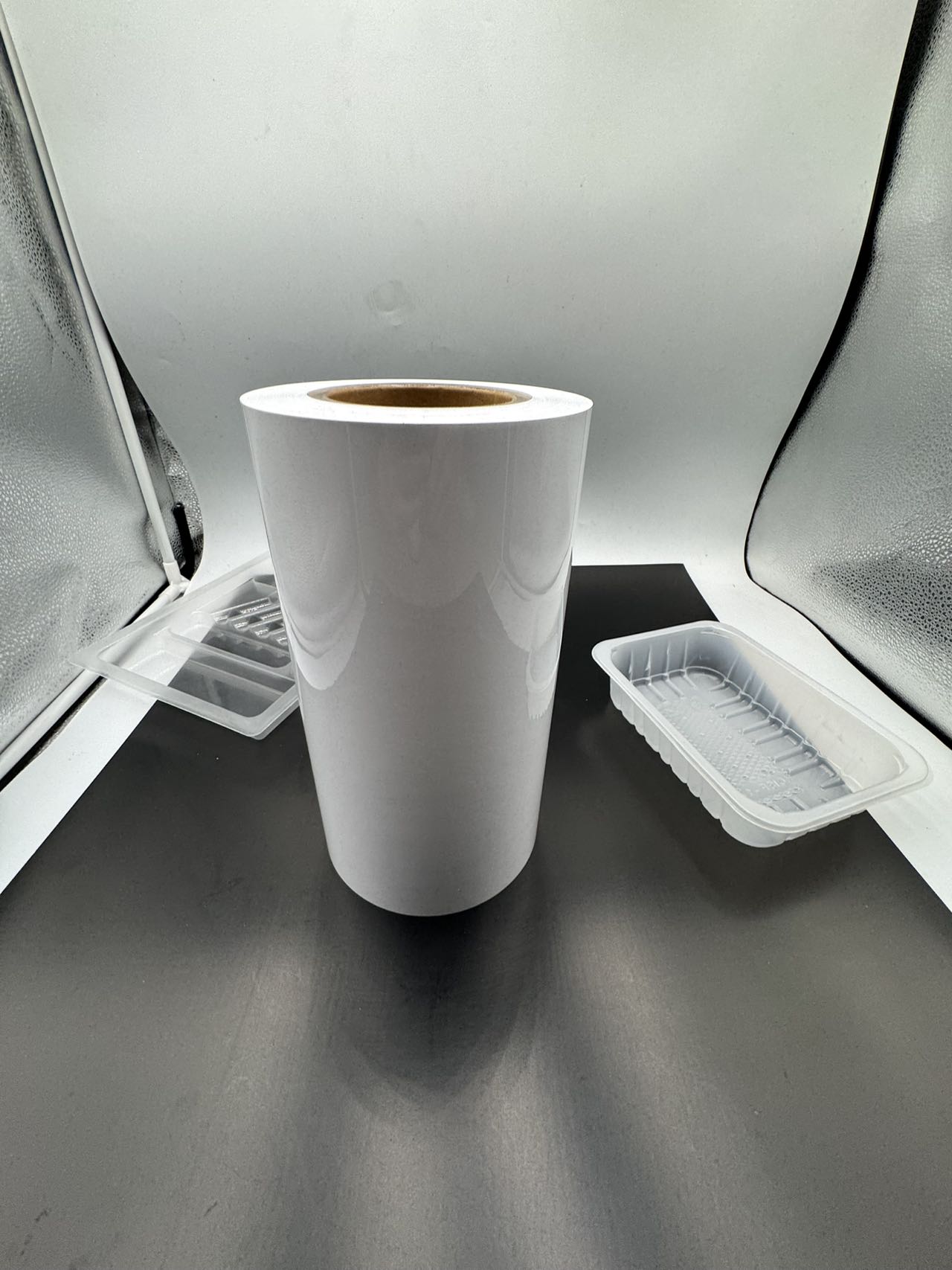

Material: PVC/PE ROLL

Thickness 0.14+0.03mm-customization

Size: 80MM/130MM/Customization

GRADE: food/pharma grade film

color: white/ customization

location: china

Usage: Pharmaceutical, dried food

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

PVC/PE Composite Film: Characteristics and Practical Applications

In the modern packaging industry, the PVC/PE composite film has turned to be multifunctional, and it became a material which could not be dispensed with in various fields. This composite film combines properties of polyvinyl chloride and polyethylene, yielding a package solution for all kinds of requirements.

I. Characteristics of PVC/PE Composite Film

A. Transparency and Printability

The PVC layer in the composite film is very transparent. This provides crystal-clear visibility of the merchandise packaged, being more pleasingly attractive on the shelf, this transparency is for merchandising appeal not alone, but also to a very relevant purpose. This also means consumers can view the contents easily without opening the package, which is important for categories of products in which part of the purchase decision may include a visual examination. This may be very relevant in categories such as cosmetics, food items enclosed in clear glass or transparent containers, and electronic accessories.

Additionally, the PVC layer displays very good printability. The smooth surface it provides enables various printing options such as gravure, flexography, and digital printing. It enables manufacturers to produce vivid, accurate, and striking designs on the packaging. Be it some colorful logo, some information about the product, or some promotional graphics, they can all be faithfully reproduced with the use of PVC/PE composite film. For example, in the cosmetic industry, detailed images of models using certain products or stylish floral motives attract consumers and speak of luxuriance and quality. The combination of transparency and printability is such that it allows brands to narrate their story, hence differentiating their products within an active marketplace.

B. Heat-sealing Performance and Flexibility

On the other hand, the PE layer also has its own value-added characteristics. First, its excellent heat-sealing properties create airtight, secure seals in the packaging process. This is important for maintaining freshness, integrity, and quality in packaged goods. Food and beverage items, if heat sealed appropriately, can avoid air, moisture, and spoilage by contaminants. For example, during the packaging of snacks like potato chips, the PE layer keeps the bag tightly closed, keeping the chips crispy and tasteful for a pretty long period of time.

Apart from the heat-sealing properties, the PE layer lends flexibility to the composite film. Due to this flexibility, the package takes the form of the product, much like a glove. This is highly advantageous in the case of packaging irregularly shaped products. Imagine the packaging of toys, which are available in diverse shapes and sizes. The PVC/PE composite film wraps the toys' contours and curves to protect it from scratches and damage that may occur in the transportation or storage processes. Such flexibility thus extends to customers in ensuring ease of handling and access to the package, as well as increasing the experience of users in the goods.

Practical Applications in Various Industries

A. Liquid Packaging

1. Pharmaceutical and Healthcare Products

The PVC/PE composite hard sheets are commonly used for blister packaging in the pharmaceutical realm. The packaging type will be suitable for several types of medicines, such as oral liquids, suppositories, and some topical creams. This composite film offers much more safety compared to the traditional glass ampoules. Glass ampoules are fragile and may break into pieces, leading to loss of product, contamination, and injury to patients and health workers. On the contrary, the PVC/PE composite film is unbreakable, and such cases are highly unlikely to happen.

For example, in the packaging of cough syrups or eye drops, the clear PVC layer will afford the patient or caregiver with a clear view of the remaining dosage, while the PE layer provides a tight seal to keep the medication sterile and potent. The resilience of the composite film also means that it can withstand the rigors of transportation and storage in pharmacies and hospitals.

2.

Consumer Health and Beauty Products

Other than pharmaceuticals, liquid health and cosmetic preparations also find their packaging in PVC/PE composite. Shampoos, conditioners, lotions, and perfumes are ordinarily packed in bottles or tubes made with this material. Transparency of the PVC layer reveals the color and texture of the product to tempt consumers, while printability enables inclusion of a detailed ingredient list, usage instructions, and branding elements.

In the case of perfumes, for example, the value addition in the eyes of the consumer may be effected by the classy appearance which printability of the composite film allows. The heat-sealability and flexibility of the PE layer also ensure that caps and dispensers will not fall off, thereby preventing leakage and spillage-a very important feature to preserve product integrity and prevent contamination of the immediate environment.

B. Medical and Pharmaceutical Packaging (Solid Dosage Forms)

1. Tablets and Capsules

In the packaging of both tablets and capsules, PVC/PE composite film is an important material used by the pharmaceutical industry. Blister packs from this material allow for dosing in each compartment, at the same time protecting the medication against moisture, light, and mechanical damages. Transparency of the PVC layer lets the patient clearly see a tablet or capsule inside, thus limiting dosing errors.

Speaking of prescription drugs, direct printing onto a blister pack containing medication name, dosage strength, and expiration date is an option that becomes invaluable. This allows the pharmacist to distribute the correct medication much quicker and more accurately and the patient to easily obtain all necessary information right there at their fingertips. The heat-sealing properties of the PE layer ensure the blister pack is sealed right up until it's time for the patient to take the dose, keeping the medicine potent and safe. 2. Medical Devices and Supplies

Apart from medicines, PVC/PE composite packaging is also employed in medical devices and consumables. Pouches made of this material generally hold surgical gloves, syringes, and even bandages. The transparency allows for visual inspection of the content regarding sterility and correctness in assembly. The heat-seal capability prevents contamination of any kind and ensures the maintenance of product integrity during storage or transit.

For example, surgical gloves packaged in PVC/PE composite pouches can easily be inspected for defects or any other type of damage before use. In fact, the film is sufficiently flexible that health professionals will have little problem opening up such packages in a sterile manner as quickly and efficiently as possible.

C. Food Packaging

1. Indirect Food Contact Applications

Although in many parts of the world, PVC usage is restricted when it comes into direct contact with food because of concerns about potential migration of certain additives, applications do exist involving food contact, albeit indirect. Examples might include a composite film of PVC/PE for the outer wrapper of food items such as chocolate bars or cereal boxes. The layer of PVC provides a very nice gloss and excellent printability for branding and marketing, while the PE layer gives some resistance to moisture to help protect the inner food packaging.

The application of the composite film in packaging bakeries is achieved whereby it could be utilized as an outer sleeve for boxes of cakes and wrapping pastry trays. This would be helpful in maintaining products clean and presentable and acts as a barrier to dust and minor physical damage.

2.

Non-food Contents Packaging

Other times, the PVC/PE composite film is applied for nonfood components enclosed in packaged foods. Such merchandise could be applied for wrapping sachets of coffee stirrers, sugar packets, or condiment flavorings in a way that it makes clear what is inside; yet through heat sealing, sachets are sealed until usage, with any instance of physical tears or puncture at an absolute minimum.

D. Packaging of Daily Essentials

1.

Cleaning Products

PVC/PE composite film is normally used for the packaging of cleaning agents, such as detergents, window cleaners, and disinfectants. It comes in bottle or container forms. Because of the transparency of the PVC layer, it allows seeing the level of the remaining product inside, which would be helpful to schedule the next purchase. Printability can show product characteristics, usage methods, and safety precautions.

The heat-sealability and flexibility of the PE layer ensure that the caps and triggers on spray bottles fit snugly and function as they should, thus preventing leaking and possible spills that in the case of cleaning chemicals could be dangerous.

2.

Cosmetics

Cosmetics packaging requires aesthetics and functionality, both of which are delivered by the PVC/PE composite film. Containers for lipsticks, compacts, and skincare products are usually made with this material. Transparency shows the color and texture of the product while printability allows creativity in branding, making it look luxurious.

For example, a luxury lipstick is packaged in a prestigious-feeling tube with a clear PVC window to display the lipstick shade. It is by the help of the PE layer cap could fit tightly to seal up the cap hence preventing drying-out or possible deterioration of lipstick. Further more, the ease of films enable consumers' opening/closing of a package readily easy.

E. Industrial Product Packaging

1. Chemicals

In the industrial field, there are a lot of chemical substances that are packed with PVC/PE composite films. The PVC layer prevents corrosive goods from chemical attack, while the PE layer provides excellent sealing to prevent leaks. This is important in ensuring safety to workers and the environment.

For instance, the composite film can be used to package hydrochloric acid or sulfuric acid in small laboratory quantities by making safe pouches or bottles. Transparency of the PVC layer allows for a visual check of color and clarity of the chemical which may indicate purity. Heat sealing properties of the PE layer prevent accidental spills during handling and transportation.

2.

Electronics Components

The composite film of PVC/PE, while being used in the packaging of electronic components, imparts ESD protection. This is extremely important to prevent any form of damage to sensitive electronics. It can be formulated with additives for the dissipation of static electricity, hence securing microchips, circuit boards, and other components.

The clarity of the PVC layer will give clear visibility of the enclosed components in the package, flexibility and heat-sealing will give it a good fit, protects the components from physical damage, especially during the manufacture and assembly of electronic components

F. Hotel Supplies Packaging

1. Toiletries

In the hospitality industry, most hotels normally give some basic free toiletries, like shampoo, conditioner, body lotion, and soap, to guests. Normally, all of them come in small bottles or sachets made from composite films like PVC/PE. Transparency of the PVC layer allows these products to offer an upmarket appeal to a consumer, and on account of printability, the hotel is able to brand its packaging with a logo and personal message.

In essence, the PE layer ensures leakage-proof bottles and sachets; moreover, it allows easy tearing. This will contribute to a convenient and agreeable experience for guests while positively changing their perception of the hotel service performance.

2. Amenities

Other hotel products, such as toothbrushes, combs, and razors, are also packaged in this PVC/PE composite film. The quality of the product can be perceived through the transparent layer of PVC, although printability is possible for instructions or other promotional messages. Its resistance ensures that during storage or transportation, the film will be firm enough to keep the items inside in perfect condition at the time it dispenses to the guests.

The transparency, printability, and flexibility, along with heat sealing performance, made PVC/PE composite film indispensable for the packing industries. Unique performances ultimately led it to stand against different specific requirements of varied industries. From protecting medicines or preserving food to making cosmetic preparations more attractive or conveniently packaging hotel toiletries, this film composite continues to play its role in the everyday life of a human being. The evolution of the PVC/PE composite film for packaging continues to rise with the continuous rise of technological development and changing consumer perceptions, finding its own place in the packaging world.

Within 15-20 days after received payment...more