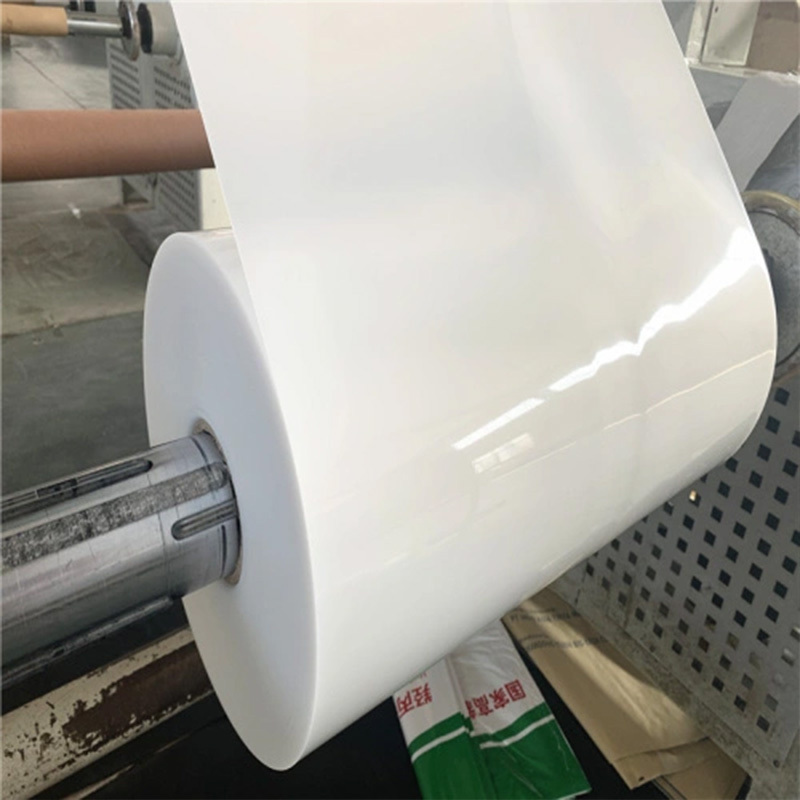

Milky white PP coil for blister, brand new polypropylene sheet for thermoforming

Milky white PP coil for blister, brand new polypropylene sheet for thermoforming, can add high barrier for yogurt cups, dog food boxes, etc.

- top leader plastic

- China

- 15 business days

- 1500 tons/month

- Information

- Video

In the field of food packaging, such as yogurt cups and dog food boxes, it is necessary to prevent the entry of oxygen, water vapor and odor to maintain the freshness and quality of food.

High barrier materials can effectively prevent the invasion of these adverse factors. For example, some high barrier additives can form a tight barrier to prevent the penetration of oxygen molecules and water molecules. Common high barrier materials include ethylene-vinyl alcohol copolymer (EVOH), polyvinylidene chloride (PVDC), etc., which can be used in combination with PP materials.

Processing adaptability of PP coils and sheets

Advantages of blister and thermoforming processes: PP material itself has good thermoforming properties, and its heat deformation temperature is generally around 100-120℃, which makes it well adapted to the shape of the mold during blister and thermoforming. When adding high barrier materials, the compatibility of the two needs to be considered during processing. Generally, multi-layer co-extrusion technology is used to combine the PP layer with the high barrier layer. For example, in a multi-layer co-extrusion device, different materials are extruded from different extruders and then composited in a mold.

Adjustment of processing parameters: During blistering and thermoforming, parameters such as processing temperature, pressure and time may need to be adjusted appropriately due to the addition of high barrier materials. Taking thermoforming as an example, the heating temperature may need to be slightly increased after adding high barrier materials to ensure good fusion and molding quality between the layers of materials. At the same time, the molding pressure may also need to be optimized according to the composite structure of the material to avoid stratification or uneven local thickness.

Product performance and application characteristics

Application of yogurt cups: For yogurt cups, the use of PP materials with high barrier can extend the shelf life of yogurt. From the appearance, the milky white PP material can provide a soft visual effect, and the smooth surface of the PP material is conducive to printing exquisite patterns and brand logos. The high barrier performance ensures that the yogurt maintains its rich taste and rich nutrition during storage and sales.

Application of dog food boxes: The use of this material in dog food boxes can effectively prevent moisture and oxidation. Moreover, PP material has certain strength and toughness, which can bear the weight of dog food and prevent the box from breaking during transportation and storage. The shape of the box can be made into various convenient and practical designs through blister or thermoforming process, such as structures with easy-tear openings or sealed lids, which are convenient for consumers to use.

Product Description

Shape | roll |

Thickness | 0.03MM-1.8MM/ Customized |

Width | 10-1100mm,can be customized. |

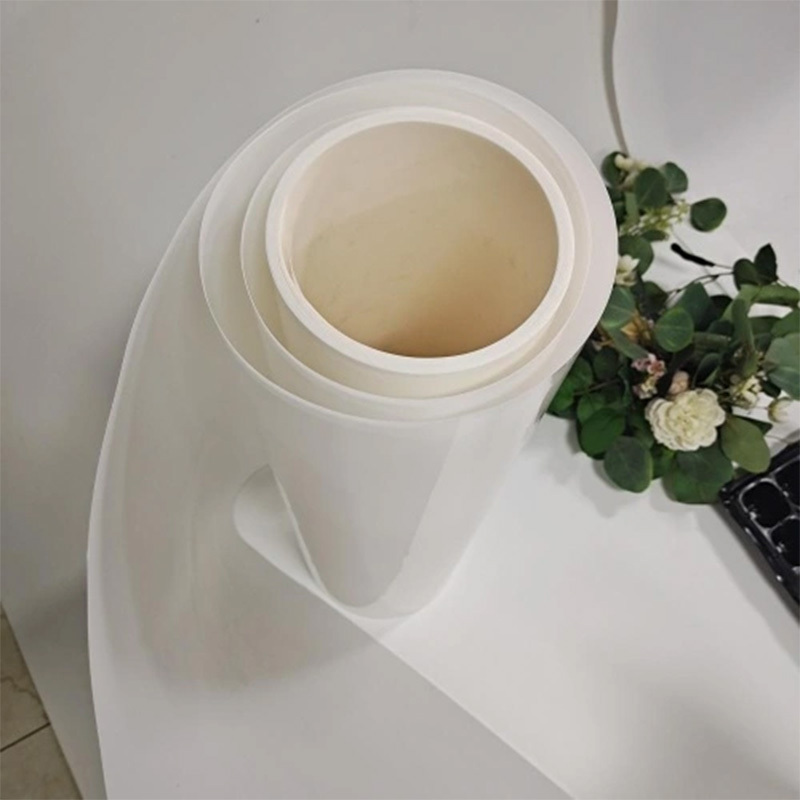

color | High transparency, ordinary transparency, translucent, color (can be customized color) |

Technics/Processing Type | Multiple Extrusion |

Material | 100%PP(polypropylene) |

Hardness: | Soft/ Rigid |

Density | 0.91g/cm2 |

texture/Surface | Smooth/frosted |

Certificate | RoSH, REACH |

Name | PP Sheet, PP plastic sheet, plastic sheet, pp solid sheet, plastic extruding sheet | |||

Material | Polypropylene raw material | |||

Length | Customized. | |||

Width | Customized. 0-1m | |||

Thickness | 0.15-2mm | |||

Density(g/cm3) | 0.91 | |||

Color | Costomized. Blue, green, black, white, red,and etc. | |||

Other Main Product

Extrusion PVC sheet,PVC sheet with one side or both sides protective film,PVC sheet for offset printing,Glossy PVC sheet,Matt PVC sheet for screen printing.

ECO-Friendly Material PET Film and PET Sheet.

PVC film for pharmaceutical and food packing.

Aluminium Foil for pharmaceutical Blister Package.

Packaging & Shipping for Plastic Sheet:

1. Sample packaging by covered by film or Craft paper.

2. LCL & FCL packaging by wooden pallet outside and plastic bag inside ,or according to the customers' requirement.

Within 15-20 days after received payment...more