PP/EVOH/PP high barrier sheet for cheese packaging

Oxygen Barrier: Oxygen Transmission Rate (OTR) ≤ 0.1 cc/m²·day (at 23°C, 50% RH)—100x lower than single-layer PP sheets, preventing food oxidation, discoloration, and spoilage.

- TOP LEADER

- CHINA

- 7-15 Working days

- 5000t/Month

- Information

Oxygen Barrier: Oxygen Transmission Rate (OTR) ≤ 0.1 cc/m²·day (at 23°C, 50% RH)—100x lower than single-layer PP sheets, preventing food oxidation, discoloration, and spoilage.

Moisture Barrier: Water Vapor Transmission Rate (WVTR) ≤ 3 g/m²·day (at 38°C, 90% RH), keeping foods like baked goods crisp and frozen items free from freezer burn.

Odor Resistance: EVOH core blocks odor permeation, ensuring no cross-contamination between flavored foods (e.g., spicy meals, cheese) and packaging.

Meets strict food-contact standards: FDA 21 CFR 177.1520 (PP) & 177.1330 (EVOH) (US), EU 10/2011 (EU), and GB 4806.7-2023 (PP) & 4806.11-2024 (EVOH) (China).

100% BPA-free, phthalate-free, and non-toxic—no harmful substances migrate into food, even under refrigerated or frozen conditions.

Provides complete compliance documentation: Certificates of Analysis (CoA), Declaration of Conformity (DoC), and third-party test reports (SGS/TUV).

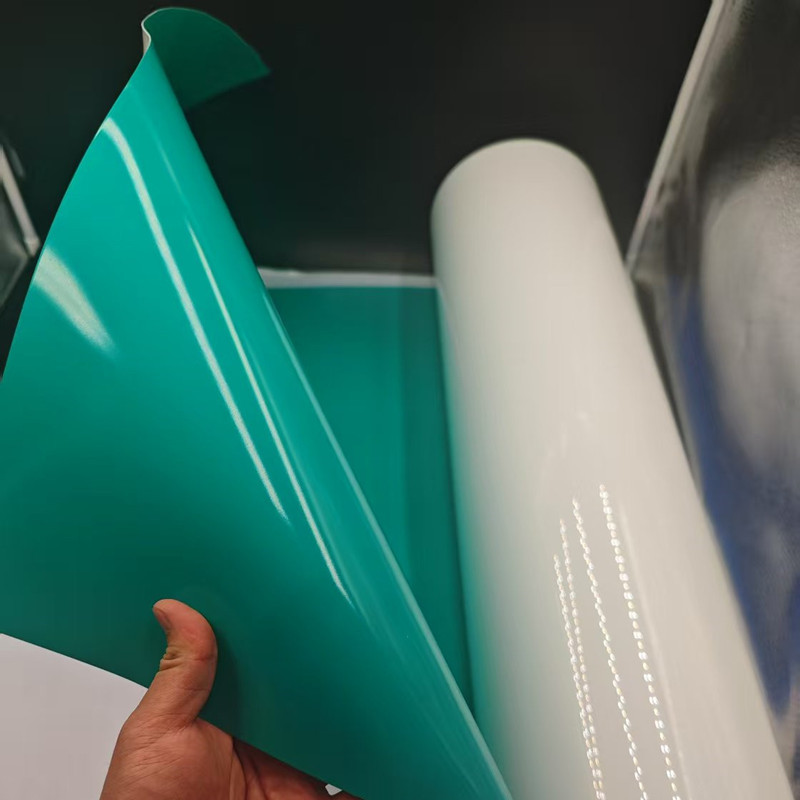

Layer Adhesion: Advanced co-extrusion technology ensures strong bonding between PP and EVOH layers—no delamination during thermoforming, trimming, or transportation.

Consistent Thickness: Total thickness tolerance ±0.03mm (layer ratio customizable: e.g., 30% PP / 40% EVOH / 30% PP), reducing production waste and ensuring uniform packaging.

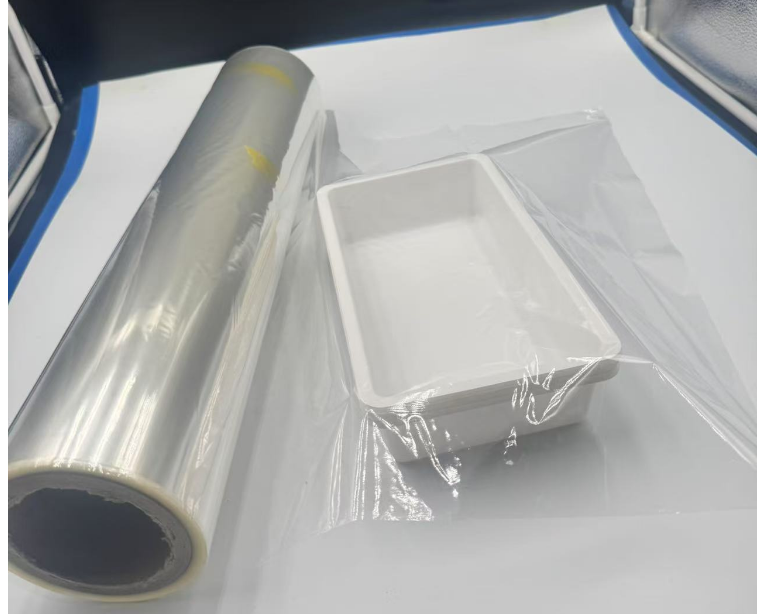

Machine Compatibility: Works with automatic/manual thermoforming machines (cycle speed up to 30 cycles/min) and supports deep-draw forming for complex packaging shapes.

Withstands extreme temperatures: -40°C (freezer-safe) to 120°C (hot-fill compatible)—suitable for frozen foods, microwaveable meals, and hot-fill beverages (e.g., soup, sauce).

No brittleness at low temps or warping at high temps, maintaining packaging integrity throughout the supply chain.

Custom Options: Total thickness (0.3mm–2.0mm), width (300mm–1400mm), surface finishes (glossy/matte/anti-fog), and colors (transparent, white, custom RGB).

Recyclability: PP outer layers are fully recyclable (recycling code #5); EVOH can be separated via industrial recycling processes, aligning with eco-friendly packaging trends.