The Versatile Shield: White PVDC Film in Liquid Nutrition, Medical Pharmaceuticals, and Packaging

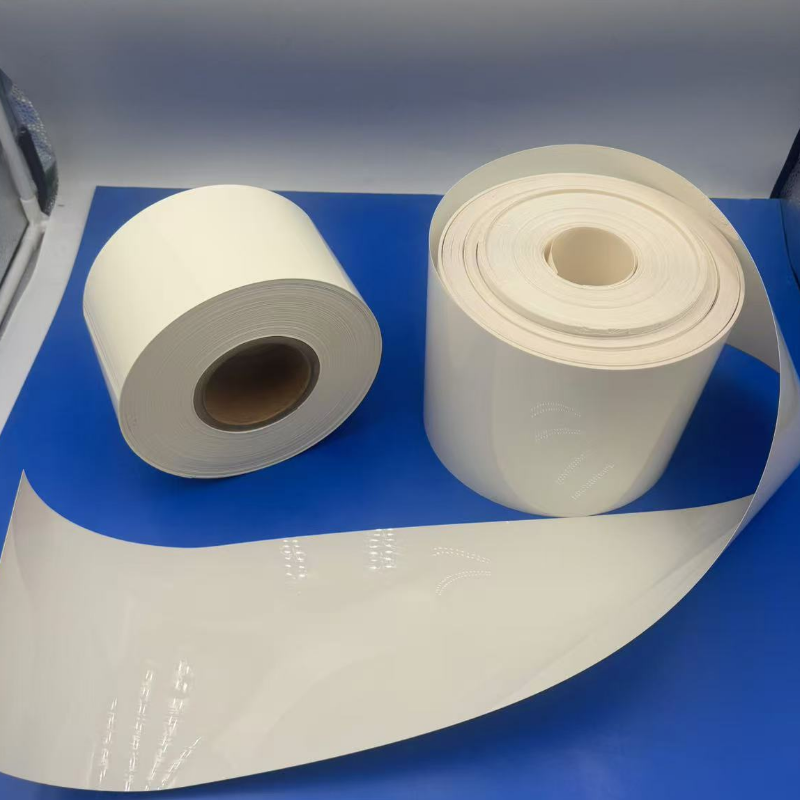

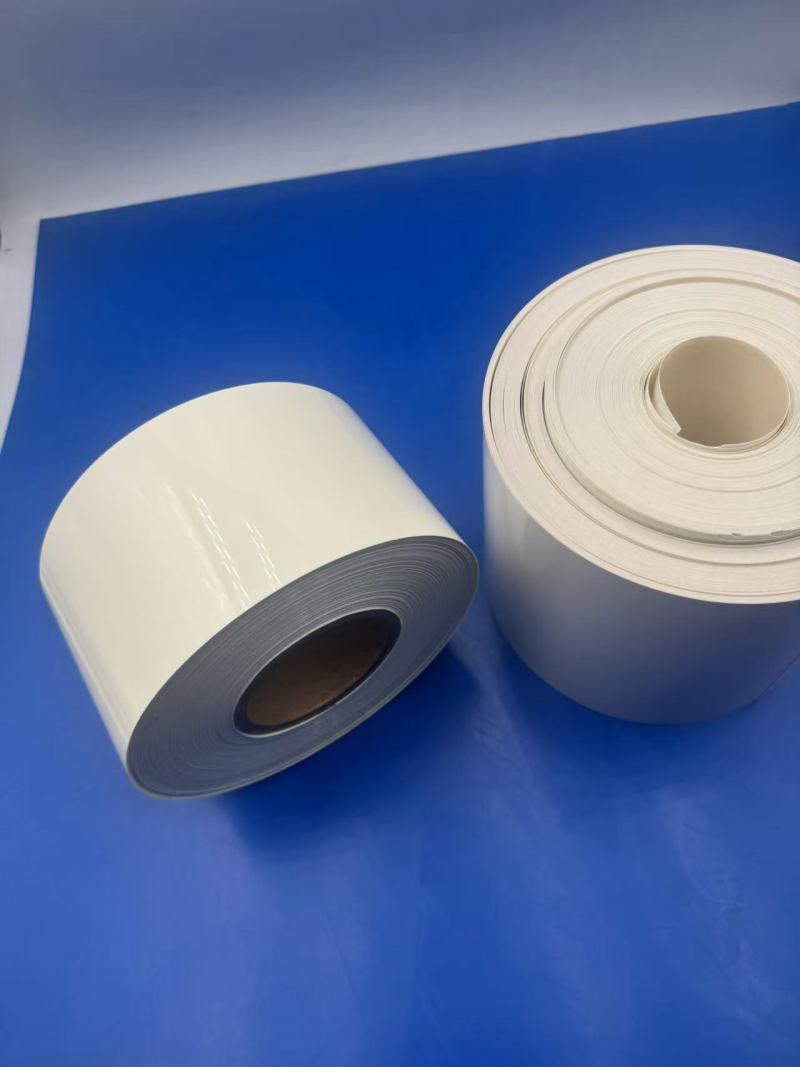

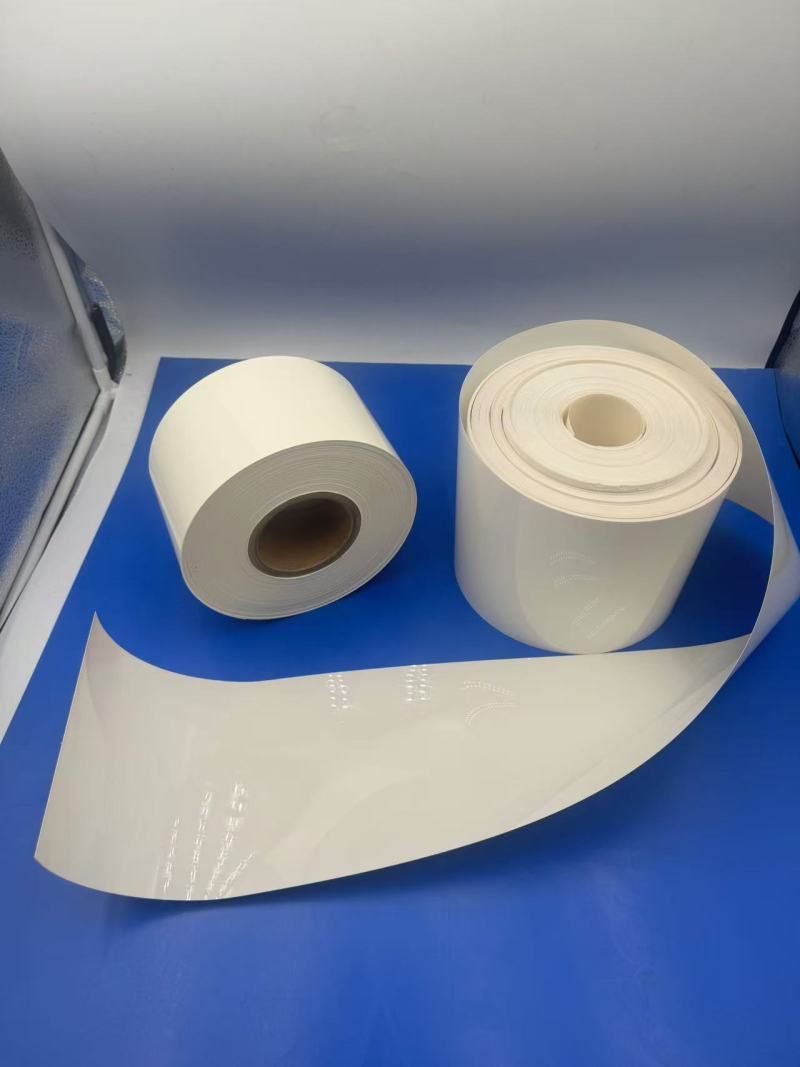

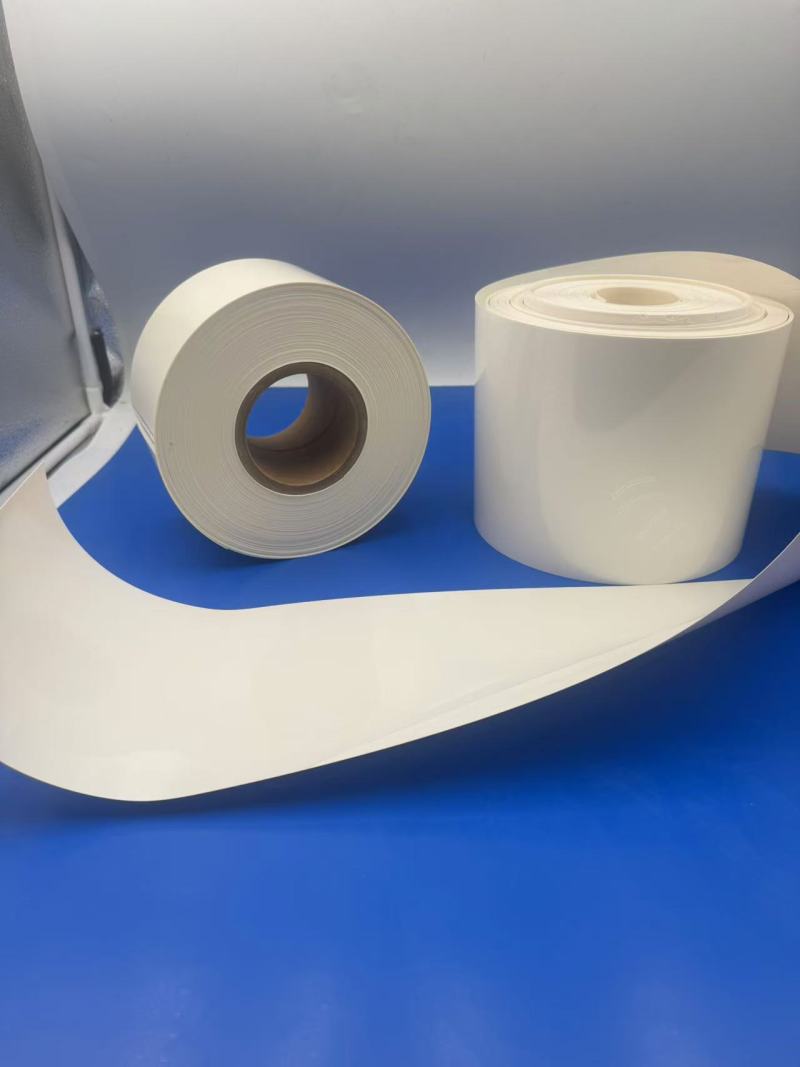

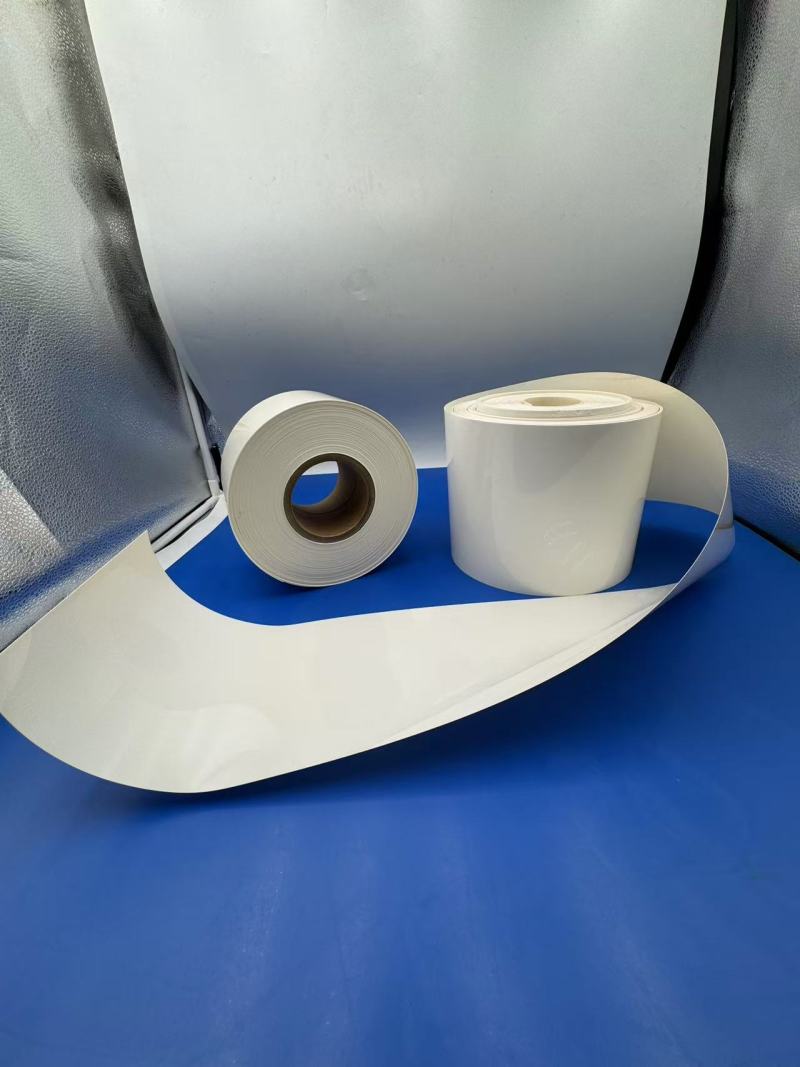

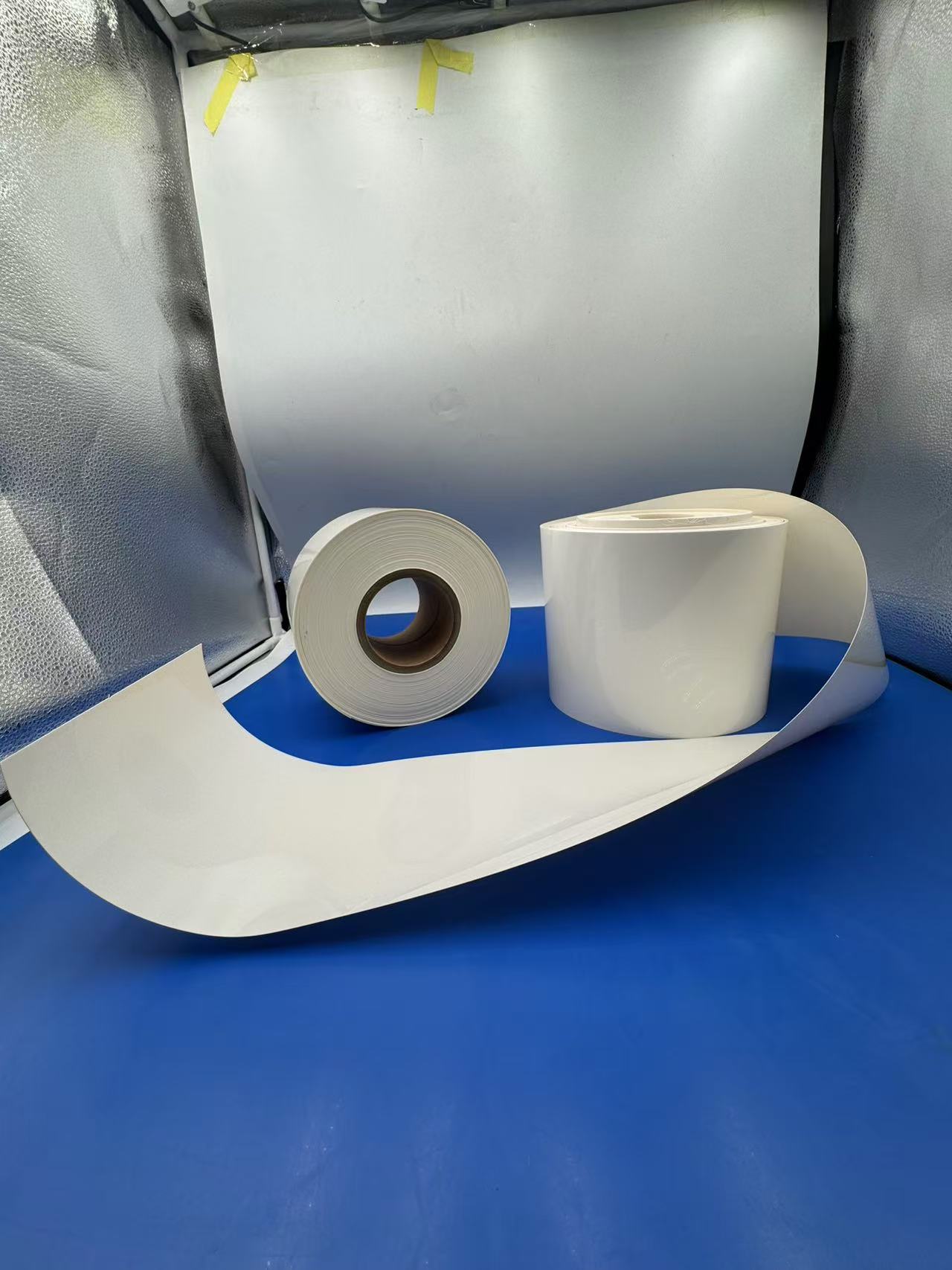

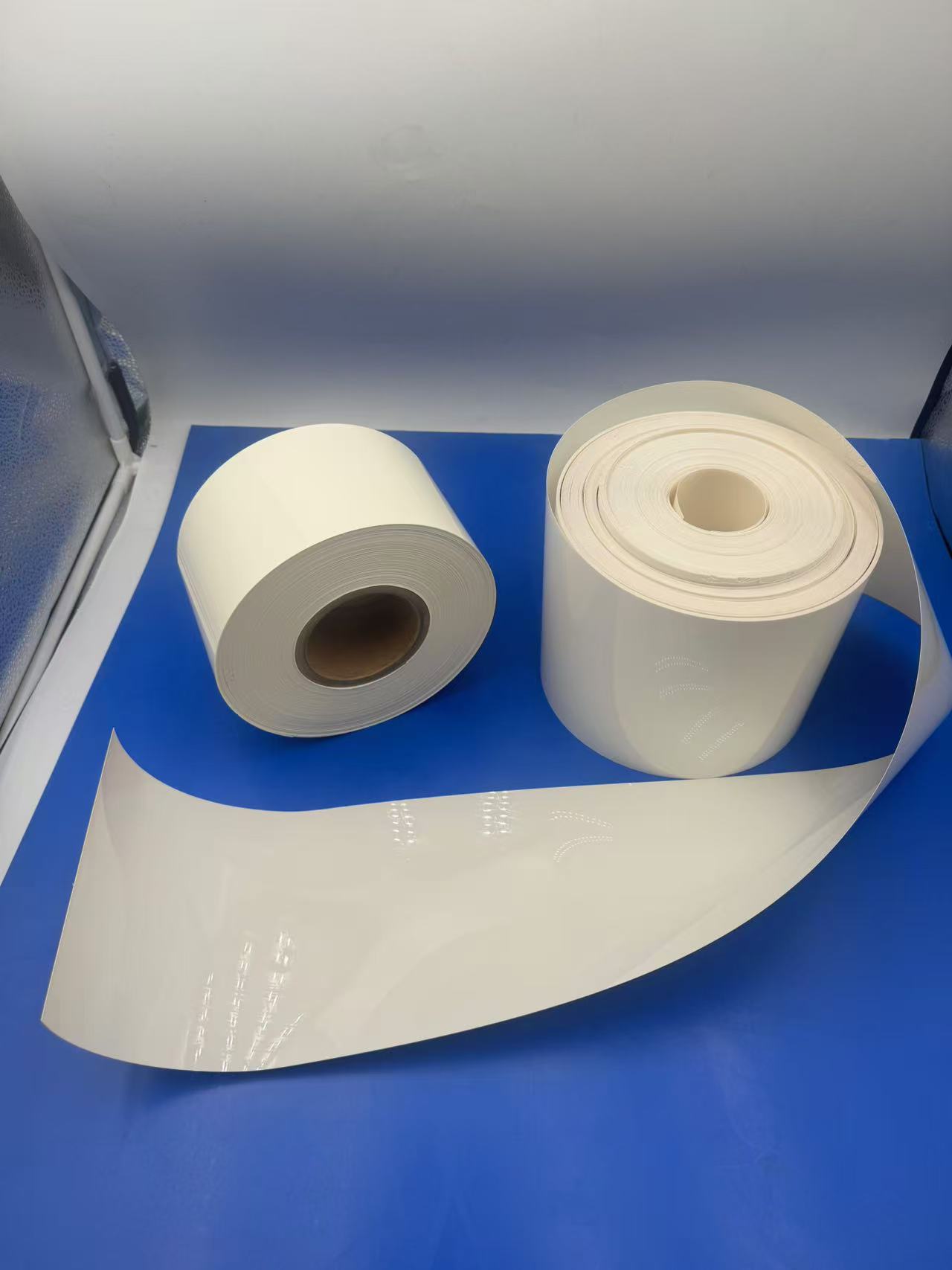

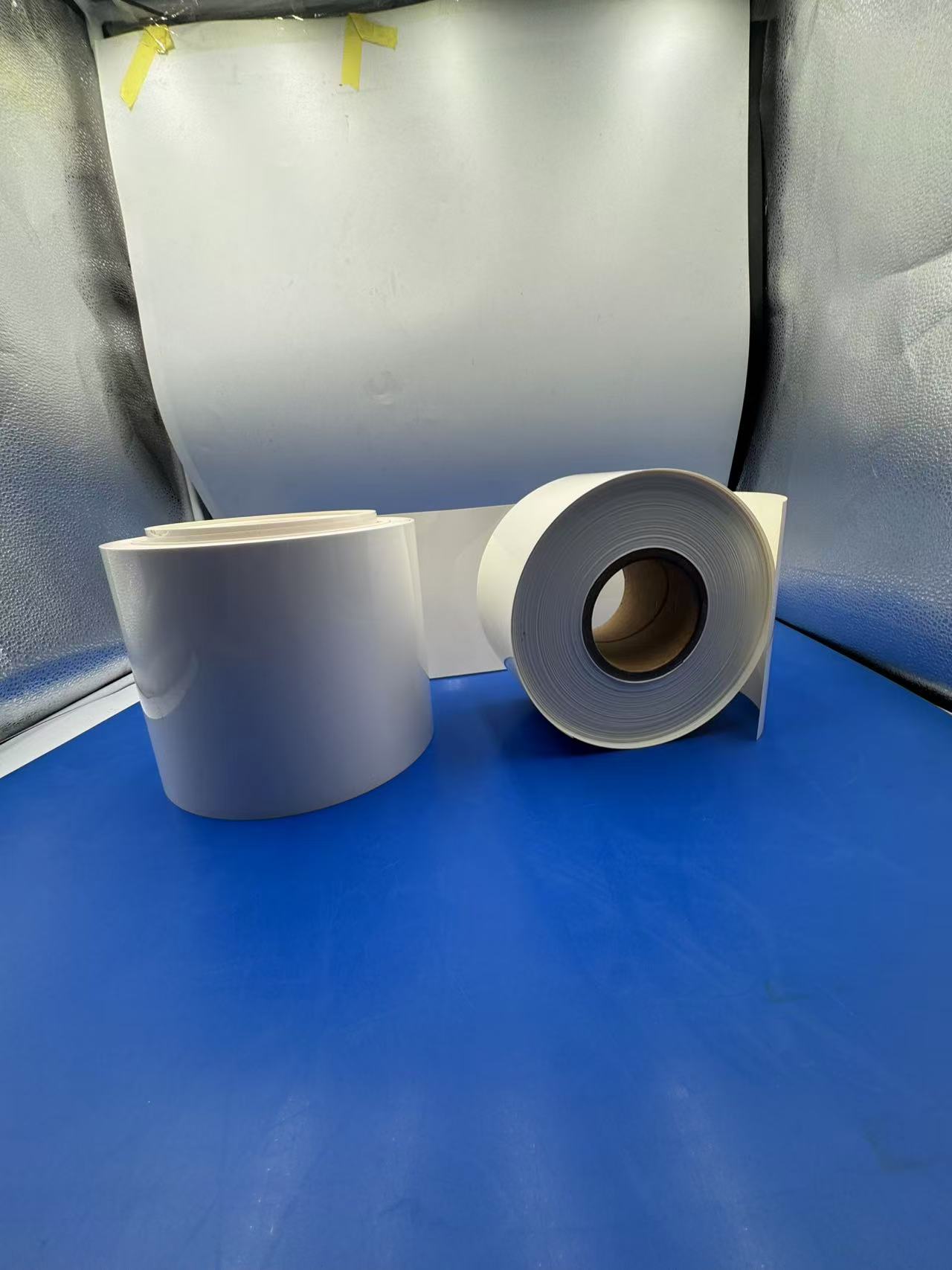

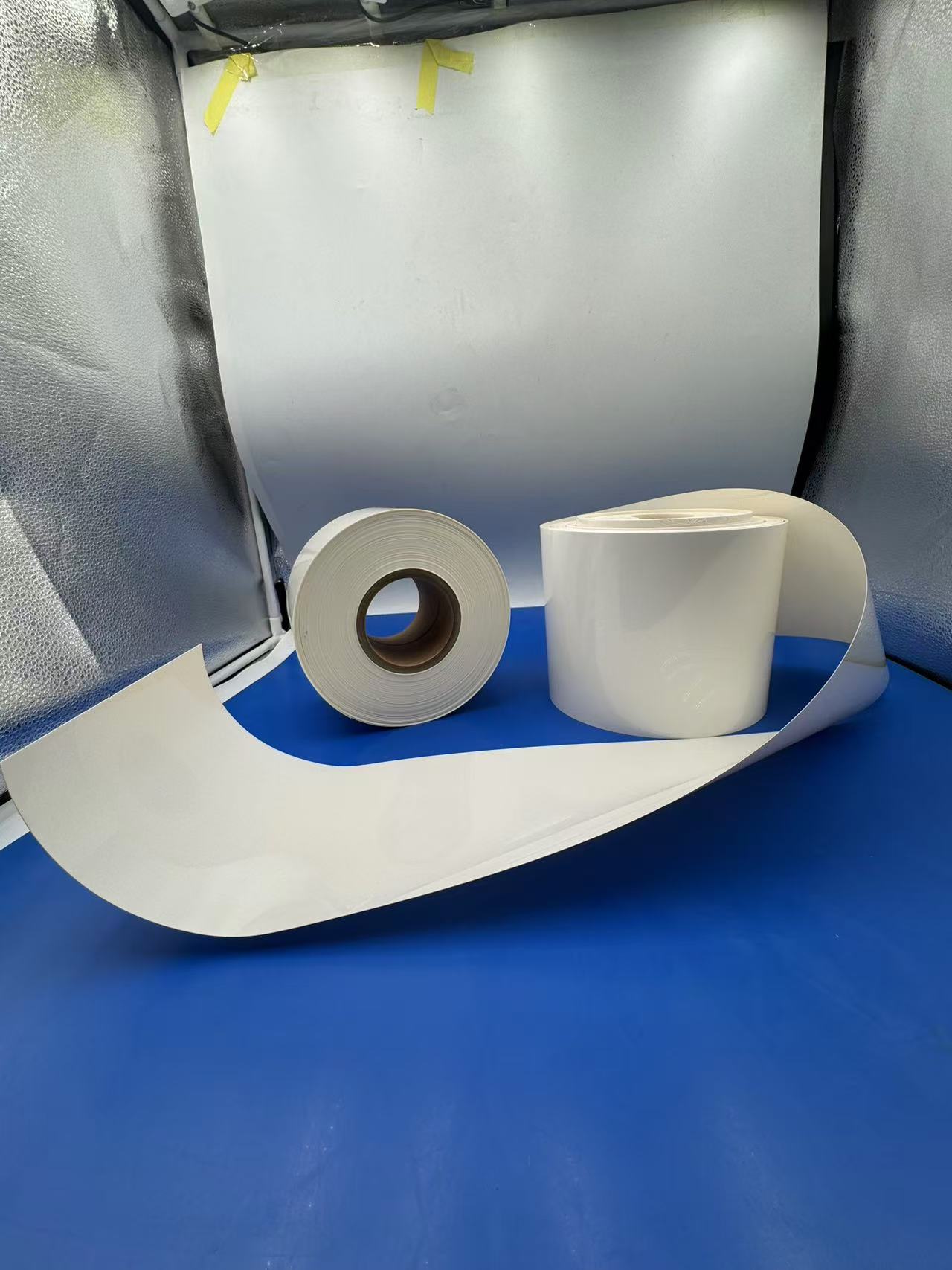

Material: PVC ROLL

Thickness 0.45-0.018mm-customization

Size: 80MM/130MM/Customization

GRADE: pharma grade film

color: white/ customization

location: china

Usage: Pharmaceutical, dried food container

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Introduction

In the world of pharmaceuticals, nutrition, and packaging, the preservation of product quality and safety is paramount. Among the myriad of materials available, white Polyvinylidene Chloride (PVDC) film stands out for its exceptional barrier properties, providing protection against moisture, oxygen,

Understanding PVDC

PVDC, or polyvinylidene chloride, is a synthetic polymer known for its unique molecular structure that allows it to form a dense, impermeable barrier. Unlike other plastics, white PVDC film excels in environments where maintaining product integrity is crucial. It's particularly noted for:

Moisture Resistance: PVDC has one of the lowest water vapor transmission rates (WVTR) among packaging materials, making it ideal for moisture-sensitive products.

Oxygen Barrier: Its ability to block oxygen ingress extends the shelf life of oxygen-sensitive pharmaceuticals and nutritional products.

Chemical Resistance: PVDC resists a wide range of chemicals, from acids to solvents, ensuring product purity.

Aroma Retention: It retains the original flavors and odors of packaged goods, which is vital for both medicines and nutritional supplements.

Applications in Liquid Nutritional Supplements

Liquid nutritional supplements often require packaging that not only preserves their nutritional content but also maintains their taste and aroma. Here's how white PVDC film is utilized:

Barrier Packaging: White PVDC film, often used as a coating on other films like PET or as a standalone layer, prevents the degradation of vitamins and minerals by blocking oxygen and moisture. This is especially critical for products like omega-3 supplements, where oxidation can lead to rancidity.

Aesthetic Appeal: The white color of the PVDC adds an element of cleanliness and purity, enhancing consumer trust. This visual cue is particularly effective in the health-conscious market where appearance can influence purchase decisions.

Sustainability: With advancements, manufacturers are focusing on reducing the thickness of PVDC coatings to minimize environmental impact while retaining barrier properties.

Medical Pharmaceuticals

The pharmaceutical sector leverages white PVDC for its protective capabilities:

Blister Packaging: PVDC is a key component in blister packs, especially for tablets and capsules. Its use ensures that medications are protected from environmental factors that could compromise their efficacy. The clarity of PVDC allows visual inspection of the product while offering high barrier properties.

Sterility: For injectables and other sterile products, PVDC film helps maintain sterility until the point of use, crucial for patient safety.

Pharmaceutical Grade: The film complies with stringent pharmacopoeia standards, ensuring no interaction with active ingredients, which is vital for sensitive drugs like anti-cancer medications.

Pharmaceutical Packaging

In broader pharmaceutical packaging, white PVDC plays several roles:

Primary Packaging: As a primary packaging material, PVDC provides a first line of defense against environmental degradation. It's commonly used in pouches, sachets, and bottles where product integrity is paramount.

Secondary Packaging: In multi-layer packaging systems, PVDC enhances the overall barrier performance, often combined with materials like aluminum to provide light protection as well.

Customization: The film can be tailored for specific needs, from different thicknesses to varying barrier levels, making it adaptable to a wide range of pharmaceutical products.

Case Studies

Case Study 1: Vitamin C Supplements: A manufacturer switched to packaging their vitamin C in white PVDC-coated blisters, resulting in a shelf life extension from 12 to 24 months due to superior moisture and oxygen barriers.

Case Study 2: Liquid Pain Relievers: A well-known brand utilized PVDC laminated film for their liquid pain relievers, ensuring the product's active ingredients remained potent and the taste was preserved, enhancing consumer satisfaction.

Challenges and Innovations

While PVDC offers numerous benefits, it's not without challenges:

Environmental Concerns: The recycling of PVDC is complex due to its nature, though efforts are underway to develop more sustainable solutions.

Cost: Historically, PVDC has been more expensive than alternatives, though its high performance often justifies the cost in critical applications.

Innovation: Recent innovations include super barrier PVDC grades that offer enhanced protection with less material, aiming at both performance and sustainability.

Conclusion

White PVDC film is a cornerstone in the packaging of liquid nutritional supplements, medical pharmaceuticals, and general pharmaceutical packaging. Its ability to provide an almost impenetrable barrier against environmental threats ensures that products reach consumers in optimal condition. As technology progresses, the use of PVDC is likely to become even more refined, balancing performance with environmental considerations. This material not only preserves the quality and efficacy of products but also upholds the integrity of brands in the eyes of consumers, making it an invaluable asset in the health and wellness industry.

This article, while aimed at an extensive discussion, has covered the essentials of white PVDC film's application across vital sectors, offering both a broad overview and specific insights into its practical use.

Within 15-20 days after received payment...more