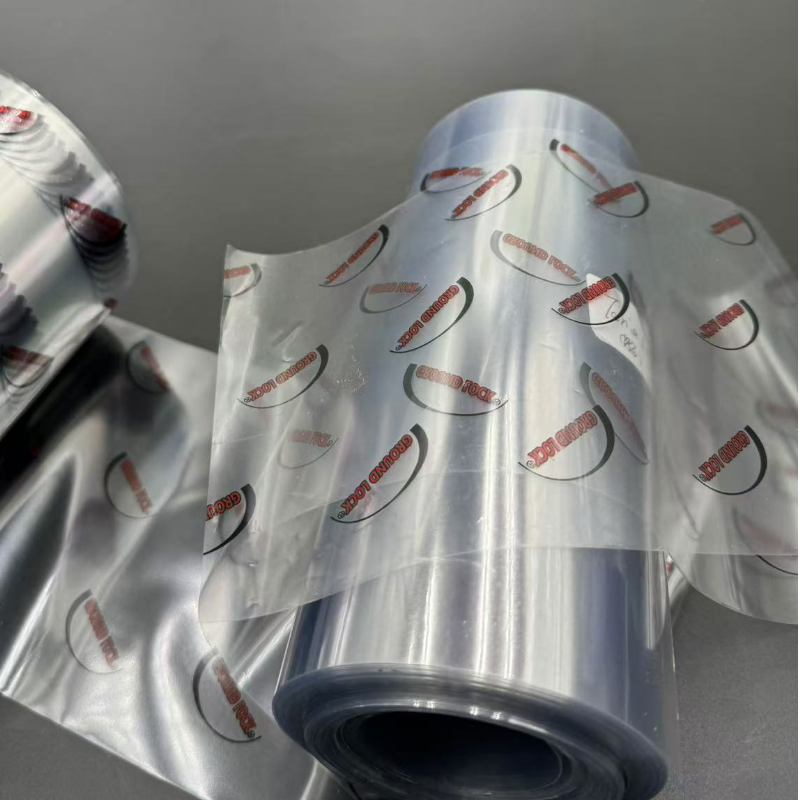

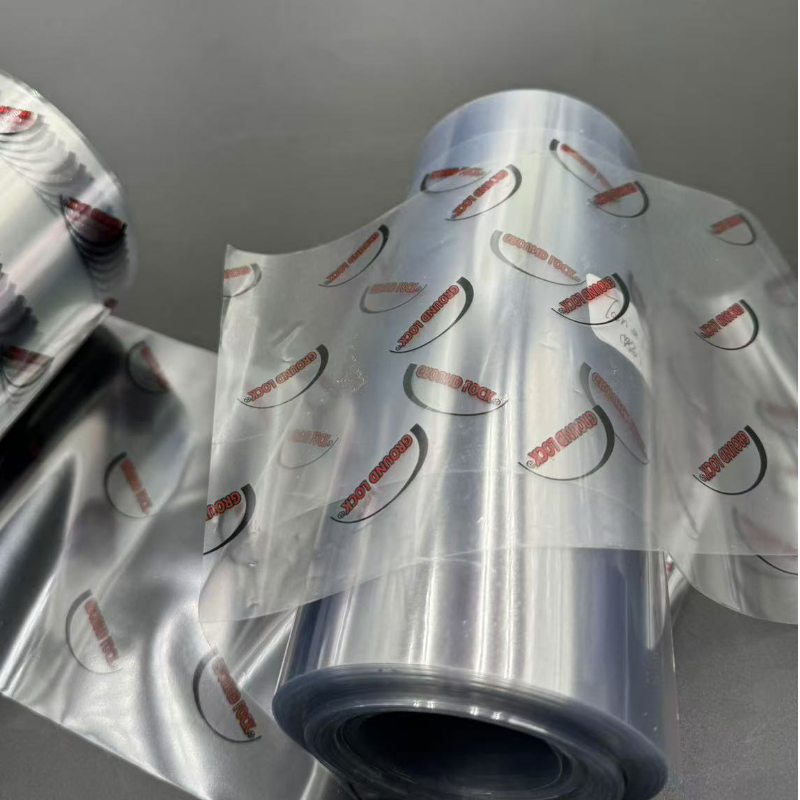

TL-PET-181 Pringtable PET film for transfer film and printable packaging

Material: PET Printable sheet

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

usage :for food tray plant tray

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

The Application of Transparent Soft PET Film in Printable Packaging

Introduction

In the modern packaging industry, the demand for high - quality, versatile, and visually appealing packaging materials has been constantly increasing. Transparent soft PET film has emerged as a remarkable choice for printable packaging, revolutionizing the way products are presented and protected. This article delves into the various aspects of the use of transparent soft PET film in printable packaging, exploring its properties, printing techniques, advantages, and applications.

1. Properties of Transparent Soft PET Film

1.1 Chemical and Physical Characteristics

PET (Polyethylene Terephthalate) is a thermoplastic polymer resin of the polyester family. Transparent soft PET film has excellent chemical stability, being resistant to most common chemicals such as acids, alkalis, and oils. This property ensures that the packaging remains intact and unaffected by the contents within, even in harsh environments.

Physically, PET film has a relatively high tensile strength and good tear resistance. The soft variety of PET film retains these mechanical properties while also offering flexibility. This flexibility allows the film to conform to the shape of the product, providing a snug and protective fit. For example, in packaging delicate objects like electronics components or cosmetics, the soft PET film can cushion and protect against mechanical shocks during transportation.

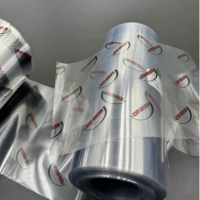

1.2 Optical Properties

The transparency of PET film is one of its most significant features. With a high - clarity appearance, it allows consumers to clearly see the product inside the packaging. This transparency not only enhances the visual appeal of the product but also provides important information about the product's quality, color, and texture. The light transmission properties of PET film are carefully controlled during the manufacturing process to ensure consistent and excellent optical performance.

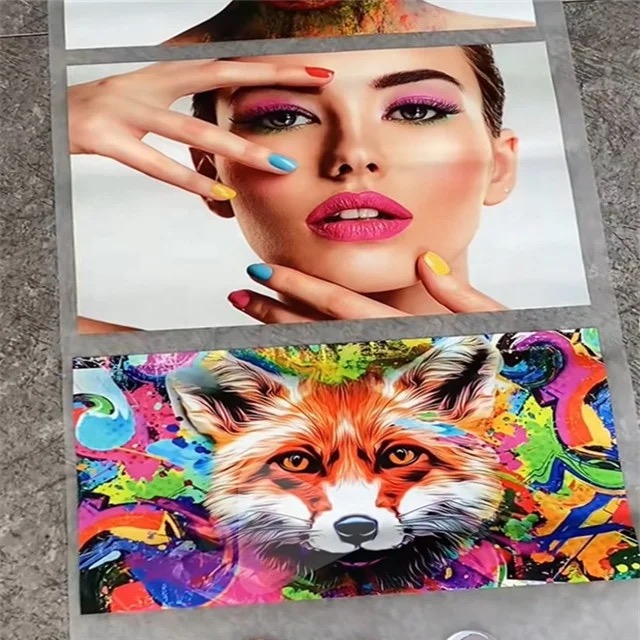

Moreover, the film has a relatively low haze value, which means that there is minimal scattering of light as it passes through the film. This results in a sharp and clear image when printed on, making it ideal for high - quality graphics and product information display.

1.3 Barrier Properties

PET film also offers good barrier properties against moisture, oxygen, and other gases. This is crucial in maintaining the freshness and quality of the packaged product. For food products, the ability of PET film to prevent the ingress of oxygen and moisture helps to extend the shelf life by reducing spoilage caused by oxidation and moisture - induced degradation. In the case of pharmaceuticals, the barrier properties ensure the stability of the active ingredients by protecting them from environmental factors.

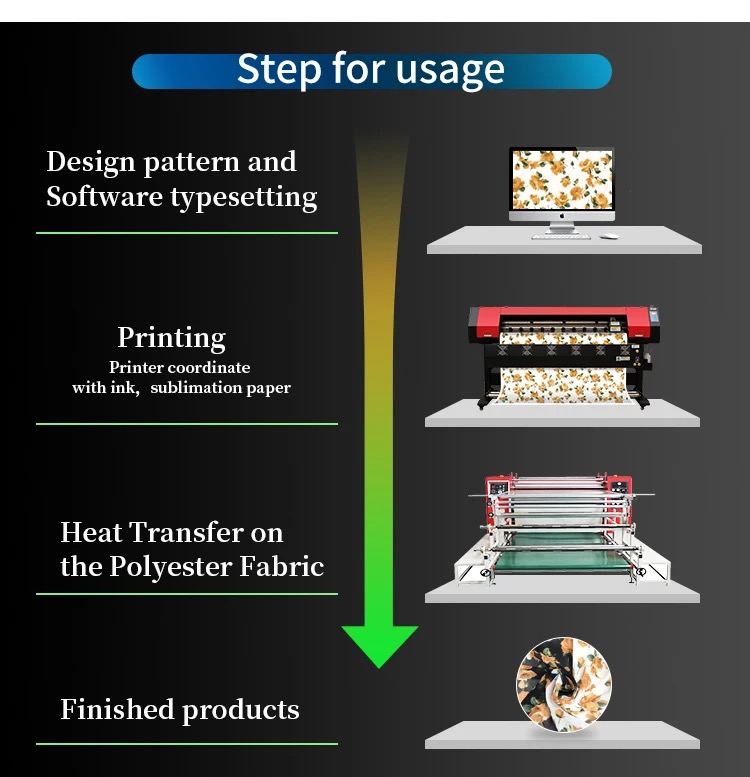

2. Printing Techniques for Transparent Soft PET Film

2.1 Flexographic Printing

Flexographic printing is a popular method for printing on PET film. It uses a flexible relief plate, which is inked and then transfers the ink onto the film. This technique is suitable for high - speed printing and can handle a wide range of ink types, including water - based, solvent - based, and UV - curable inks.

When printing on transparent soft PET film using flexography, careful attention must be paid to factors such as plate selection, ink viscosity, and drying conditions. The soft nature of the film requires plates with good flexibility to ensure proper ink transfer without damaging the film. Additionally, the choice of ink is crucial to achieve good adhesion and durability of the printed image. Water - based inks are often preferred for their environmental friendliness and ability to provide good print quality on PET film.

2.2 Gravure Printing

Gravure printing is another commonly used technique for PET film printing. In this process, a metal cylinder with engraved cells of varying depths is used. Ink is filled into these cells, and excess ink is wiped off. The film then passes over the cylinder, and the ink is transferred onto the film under pressure.

Gravure printing offers high - quality and precise printing with excellent color reproduction. It is particularly suitable for printing detailed and complex graphics on transparent soft PET film. However, the setup cost for gravure printing can be relatively high, and it requires skilled operators. The choice of engraving depth and ink formulation needs to be carefully optimized based on the specific requirements of the PET film and the printed design.

2.3 Digital Printing

.

3. Advantages of Using Transparent Soft PET Film in Printable Packaging

Moreover, the ability to print on both sides of the film provides more design possibilities. Brands can use the front and back of the packaging to tell a story, communicate product benefits, or provide additional marketing messages. This multi - faceted approach to packaging design helps to differentiate the product on the store shelf and attract consumers.

3.2 Product Protection

As mentioned earlier, the physical and barrier properties of PET film contribute to excellent product protection. The soft nature of the film provides a cushioning effect, reducing the risk of damage during handling and transportation. The moisture and oxygen barrier properties keep the product in optimal condition, maintaining its quality and integrity. In the case of food packaging, this means that the flavor, texture, and nutritional value of the food are preserved. For non - food products like electronics or medical devices, the film protects against dust, moisture, and mechanical impacts.

3.3 Sustainability

4. Applications of Transparent Soft PET Film in Printable Packaging

4.1 Food Packaging

4.2 Cosmetics Packaging

Cosmetics companies rely on the aesthetic appeal of transparent soft PET film for their packaging. From lipsticks to creams and perfumes, the clear film allows consumers to see the product's color, texture, and quantity. High - quality printing on the film can create a luxurious and elegant look, enhancing the brand image of the cosmetics. The softness of the film also provides a comfortable feel when consumers handle the packaging, adding to the overall user experience.

Moreover, PET film can be shaped and molded to fit the unique contours of cosmetic products. For example, the packaging for a curved lipstick tube or a uniquely shaped perfume bottle can be custom - designed using PET film to provide a perfect fit and maximum protection.

4.3 Electronics Packaging

In the electronics industry, protecting sensitive components from environmental factors is of utmost importance. Transparent soft PET film is used to package items such as mobile phone screens, computer chips, and other delicate parts. The film's flexibility allows it to conform to the shape of the components, providing a snug fit and protection against dust, moisture, and mechanical shocks.

Printing on the PET film in electronics packaging can include product specifications, serial numbers, and branding information. The transparency of the film allows technicians to quickly identify the components without having to open the packaging, saving time during assembly and quality control processes.

4.4 Pharmaceutical Packaging

PET film is prone to static charge build - up during the printing process. Static electricity can attract dust particles, causing defects in the printed image. To address this problem, anti - static agents can be added to the film during manufacturing or anti - static equipment can be used in the printing environment. This helps to dissipate the static charge and maintain a clean printing surface.

5.3 Print Registration

Accurate print registration, especially in multi - color printing, can be a challenge on soft PET film. The flexibility of the film can cause slight movements during the printing process, resulting in misaligned prints. To solve this, advanced printing presses with precise registration systems are used. Additionally, using adhesives or laminating techniques to stabilize the film during printing can improve print registration accuracy.

6. Future Trends in Transparent Soft PET Film for Printable Packaging

6.1 Smart Packaging

The integration of smart technologies into packaging is an emerging trend. Transparent soft PET film can be used as a substrate for incorporating features such as RFID (Radio - Frequency Identification) tags, NFC (Near Field Communication) chips, or sensors. These technologies can provide information such as product authenticity, temperature history, and freshness indicators. For example, a temperature - sensitive sensor printed on the PET film of food packaging can alert consumers if the product has been exposed to improper storage conditions.

6.2 Sustainable Innovations

In conclusion, transparent soft PET film has become an indispensable material in the printable packaging industry. Its unique combination of properties, along with the availability of various printing techniques, offers numerous advantages for packaging a wide range of products. Despite some challenges, continuous innovation in materials science and printing technology will further expand the applications and capabilities of transparent soft PET film in the future, meeting the evolving needs of the packaging market.

Within 15-20 days after received payment...more