TL-PVC-0066 Versatile Applications of Transparent Printable Rigid PVC Film in Packaging and decorative

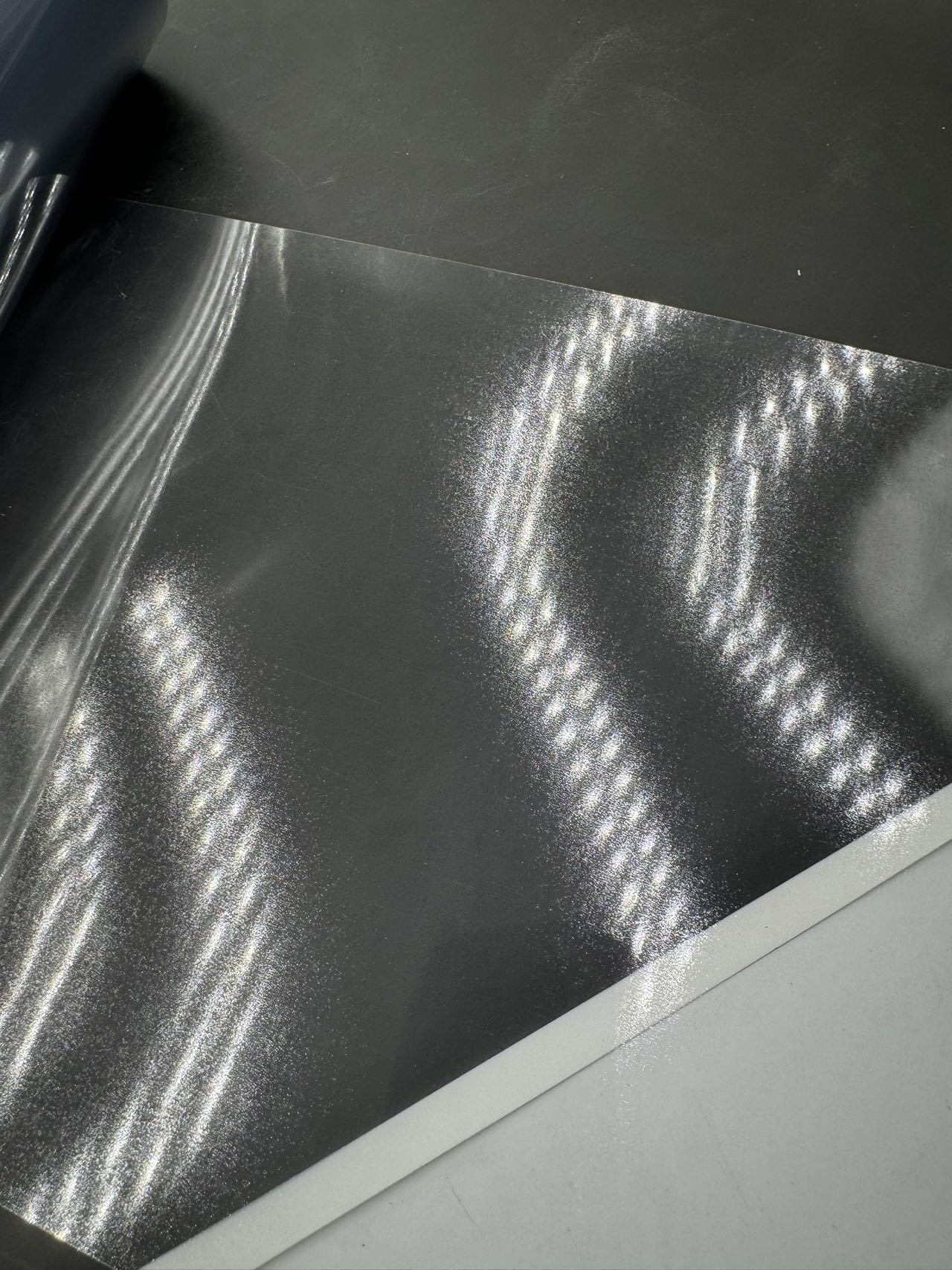

Material: PVC ROLL

Thickness 0.45-0.018mm-customization

Size: 80MM/1380MM/Customization

GRADE: PRintable

color:white/ transparent white/ customization

location: china

Usage: printable, decoration

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Title: The Versatile Applications of Transparent Printable Rigid PVC Film in Packaging and Beyond

Introduction

In today's world, packaging plays a crucial role in protecting and presenting products. Transparent printable rigid PVC film has emerged as a versatile material with a wide range of applications in various industries. From heat-forming packaging to printable decorations, glass composite films, and sample packaging, PVC film offers unique properties that make it an attractive choice for many applications. This article will explore the diverse uses of transparent printable rigid PVC film and highlight its advantages in different fields.

I. Understanding Rigid PVC Film

Polyvinyl chloride (PVC) is a synthetic polymer that is widely used in various applications due to its durability, flexibility, and chemical resistance. Rigid PVC film is a type of PVC material that is characterized by its high stiffness and strength. It is available in different thicknesses and can be easily printed on using various printing techniques.

The transparency of rigid PVC film allows for clear visibility of the contents inside, making it ideal for packaging applications. It can be printed with high-resolution images, text, and designs, enabling companies to create eye-catching packaging that stands out on the shelves. Additionally, PVC film is resistant to moisture, chemicals, and UV radiation, ensuring the longevity and integrity of the packaged products.

II. Heat-Forming Packaging Applications

A. Function and Mechanism

Heat-forming is a process in which a flat sheet of plastic is heated and molded into a specific shape. Rigid PVC film is well-suited for heat-forming packaging due to its ability to maintain its shape and strength during the molding process. When heated, the PVC film softens and can be easily shaped into trays, blisters, and other packaging forms.

The heat-forming process typically involves the use of a thermoforming machine, which applies heat and pressure to the PVC film to create the desired shape. The film is then cooled and trimmed to size, resulting in a custom-made packaging solution. Heat-formed PVC packaging offers several advantages over traditional packaging methods, including better protection, enhanced product visibility, and cost-effectiveness.

B. Benefits of Heat-Formed PVC Packaging

1. Customization

Heat-formed PVC packaging can be customized to fit the specific dimensions and requirements of different products. This allows for a perfect fit, reducing the risk of damage during transportation and storage. Additionally, the packaging can be designed with unique shapes and features to attract consumer attention and enhance brand recognition.

2. Protection

The rigid nature of PVC film provides excellent protection for fragile and sensitive products. It can withstand impacts, vibrations, and pressure, ensuring that the contents remain safe and intact. Moreover, PVC film is resistant to moisture and chemicals, protecting the products from environmental factors that could cause spoilage or degradation.

3. Product Visibility

The transparency of PVC film allows consumers to see the contents of the packaging clearly. This can be a significant advantage for products that rely on visual appeal, such as cosmetics, electronics, and food items. The clear packaging also enables easy inspection of the product, increasing consumer confidence in the quality and authenticity of the goods.

4. Cost-Effective

Heat-formed PVC packaging is a cost-effective solution compared to other packaging materials. The material is relatively inexpensive, and the heat-forming process is efficient and can be automated, reducing labor costs. Additionally, PVC film is lightweight, which can result in savings on shipping and storage costs.

III. Printable Decorations

A. Wall Decals and Stickers

Transparent printable rigid PVC film can be used to create wall decals and stickers that add a decorative touch to homes, offices, and commercial spaces. The film can be printed with various designs, patterns, and images, allowing for endless customization options. Wall decals and stickers made from PVC film are easy to apply and remove, making them a popular choice for temporary decorations.

B. Window Graphics

PVC film can also be used to create window graphics for advertising, branding, and decoration. The transparent film can be printed with logos, slogans, and images, providing a unique way to showcase a business or product. Window graphics made from PVC film are durable and weather-resistant, ensuring long-lasting visibility.

C. Floor Graphics

For promotional events and trade shows, printable rigid PVC film can be used to create floor graphics that attract attention and guide visitors. The film can be printed with directional arrows, logos, and messages, providing a practical and eye-catching wayfinding solution. Floor graphics made from PVC film are slip-resistant and durable, ensuring safety and longevity.

IV. Glass Composite Films

A. Safety and Security

Rigid PVC film can be laminated to glass to create composite films that offer enhanced safety and security. The film acts as a barrier, preventing glass from shattering in the event of an impact or breakage. This can be particularly important in commercial buildings, schools, and hospitals where safety is a top priority.

B. Solar Control

Glass composite films made from PVC film can also provide solar control benefits. The film can block harmful UV rays and reduce heat transfer, helping to keep interiors cool and comfortable. This can result in energy savings and reduced cooling costs.

C. Privacy and Decorative Effects

PVC film can be printed with various patterns and designs to create privacy and decorative effects on glass. This can be useful in offices, conference rooms, and residential settings where privacy is desired. Additionally, the printed film can add a decorative touch to glass surfaces, enhancing the overall aesthetic of a space.

V. Printable Sample Packaging

A. Product Sampling

Transparent printable rigid PVC film is an ideal material for sample packaging. It allows for clear visibility of the sample product, while also providing protection and durability. The film can be printed with product information, instructions, and branding, making it an effective marketing tool for product sampling campaigns.

B. Cosmetic and Beauty Samples

In the cosmetic and beauty industry, sample packaging is essential for promoting new products and attracting customers. PVC film can be used to create sample packets, sachets, and tubes that are both attractive and functional. The transparent film allows consumers to see the product inside, while the printable surface can be used to display product details and benefits.

C. Food and Beverage Samples

For food and beverage companies, sample packaging can be a powerful marketing tool. PVC film can be used to create sample pouches, cups, and containers that are safe, hygienic, and visually appealing. The transparent film allows consumers to see the product inside, while the printable surface can be used to display nutritional information, ingredients, and branding.

VI. Advantages of Rigid PVC Film in Various Applications

A. Durability

Rigid PVC film is highly durable and can withstand harsh environmental conditions. It is resistant to scratches, abrasions, and impacts, ensuring that the printed images and designs remain intact for a long time.

B. Chemical Resistance

PVC film is resistant to chemicals, oils, and solvents, making it suitable for packaging applications that involve contact with various substances. This resistance helps to protect the packaged products from contamination and degradation.

C. Printability

The surface of rigid PVC film can be easily printed using various printing techniques, including digital printing, screen printing, and offset printing. This allows for high-quality, vibrant prints that can enhance the visual appeal of the packaging and decorations.

D. Cost-Effectiveness

PVC film is a cost-effective material compared to other packaging and decoration materials. It is available in large quantities at a relatively low cost, making it accessible to businesses of all sizes. Additionally, the printing and heat-forming processes are efficient and cost-effective, reducing production costs.

VII. Conclusion

In conclusion, transparent printable rigid PVC film is a versatile material with a wide range of applications in packaging, decorations, glass composites, and sample packaging. Its unique properties, such as transparency, durability, chemical resistance, and printability, make it an attractive choice for many industries. Whether it's creating custom packaging solutions, adding decorative touches to spaces, or promoting products through sample packaging, PVC film offers endless possibilities. As technology continues to advance, we can expect to see even more innovative applications of this versatile material in the future.

Within 15-20 days after received payment...more