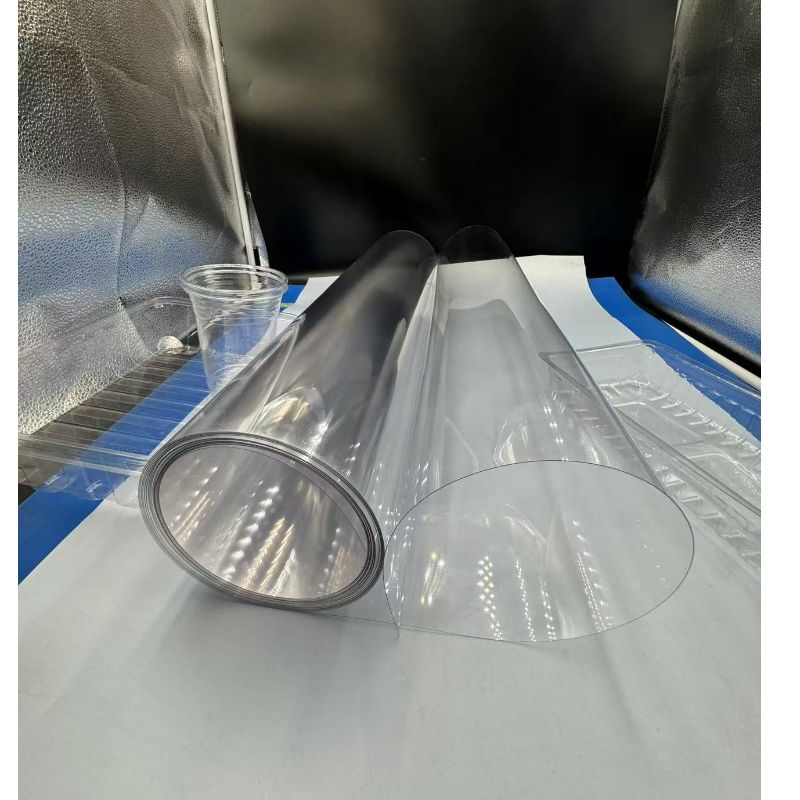

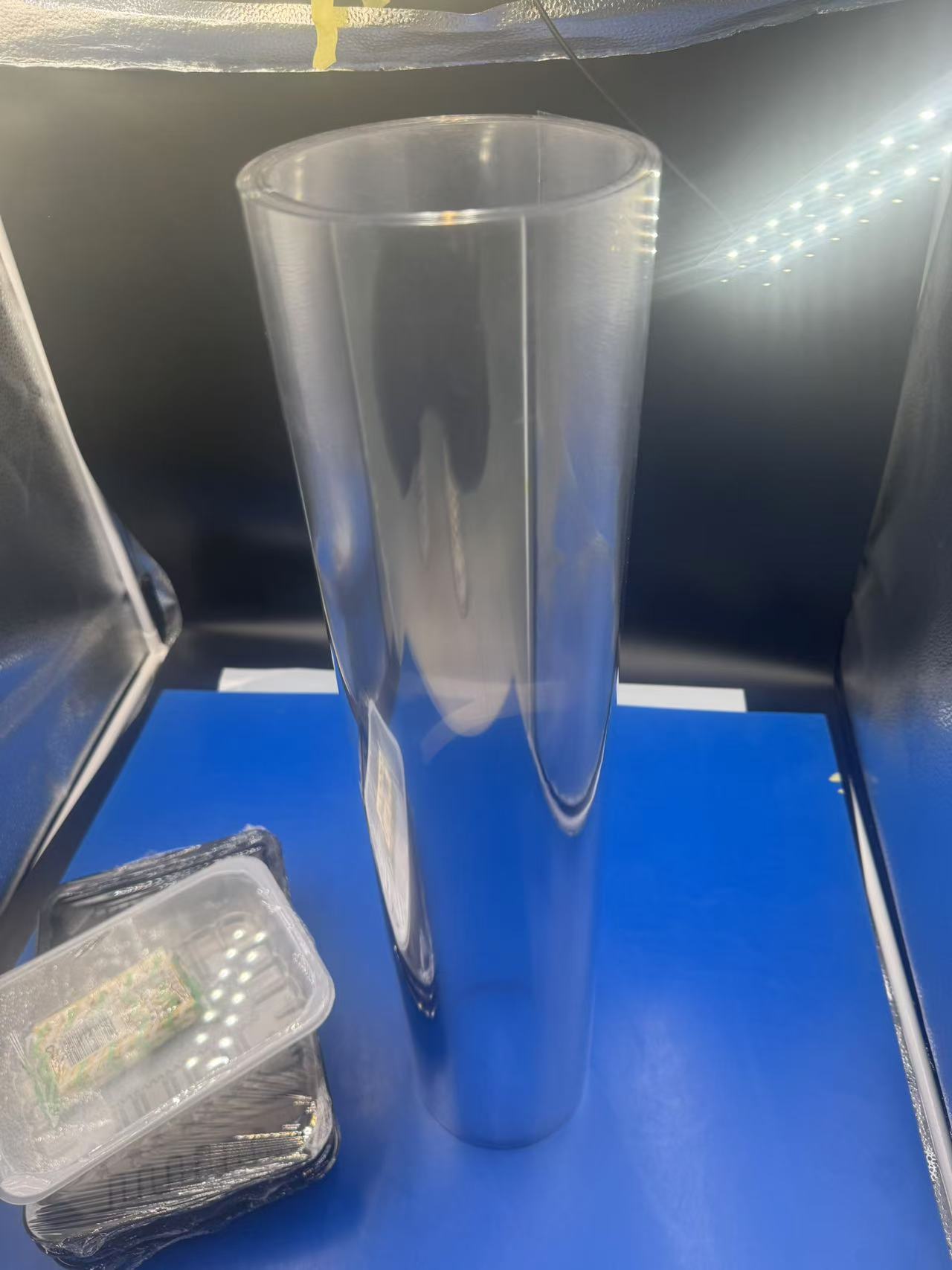

Unveiling the Clarity: Ultra-Transparent PET Film in Tableware Blister Packaging

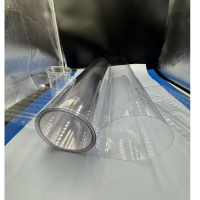

Material: PET Printable sheet

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

usage :for food tray plant tray

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

In the world of packaging, where functionality meets aesthetics, ultra-transparent polyethylene terephthalate (PET) film has carved a niche as a standout material. Known for its exceptional clarity, this versatile thermoplastic is revolutionizing blister packaging for tableware—think forks, spoons, knives, and plates elegantly encased in a crystal-clear shell. This article explores the defining characteristics of ultra-transparent PET film—its transparency, strength, recyclability, and heat stability—and how these properties make it a go-to choice for protecting and presenting tableware. Through concrete examples and solid reasoning, we’ll dive into why PET film shines in this specialized application.

Section 1: The Essence of Ultra-Transparent PET Film

PET film is derived from polyethylene terephthalate, a polyester formed by polymerizing ethylene glycol and terephthalic acid. The "ultra-transparent" variant is a highly refined form, optimized for optical clarity and performance. Its molecular structure, featuring a rigid backbone and crystalline regions, underpins its unique attributes, setting it apart from competitors like PVC or PP films.

1.1 PET***Film Transparency

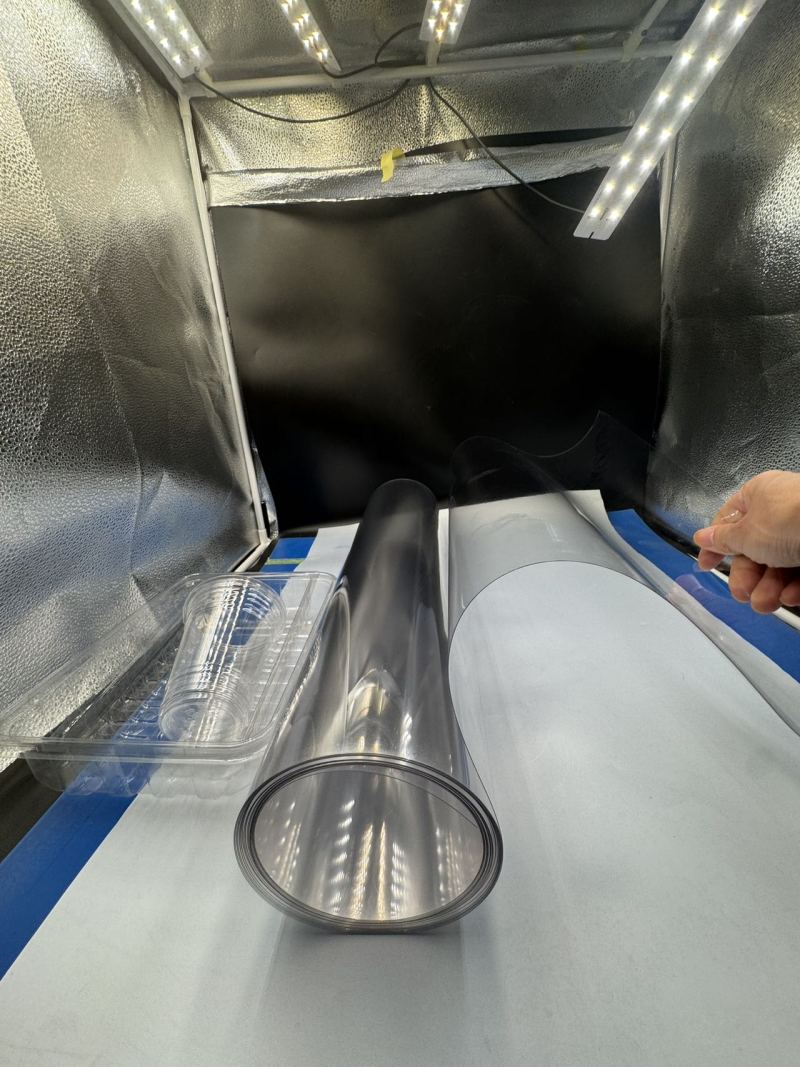

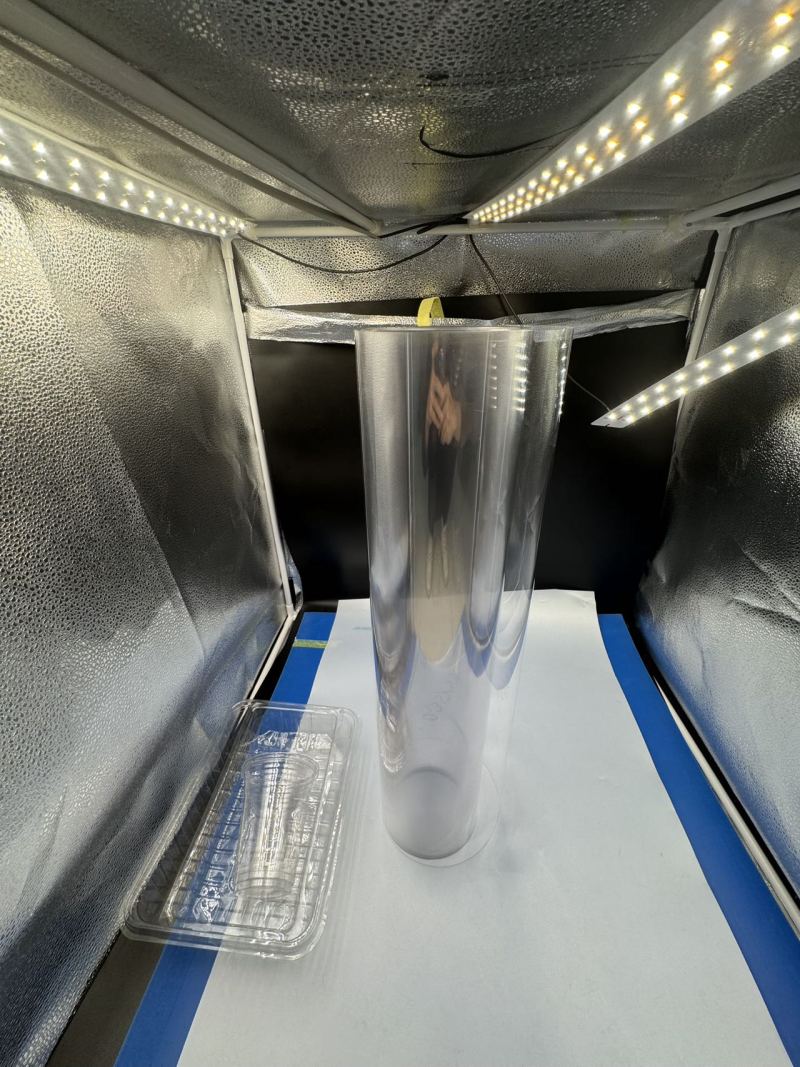

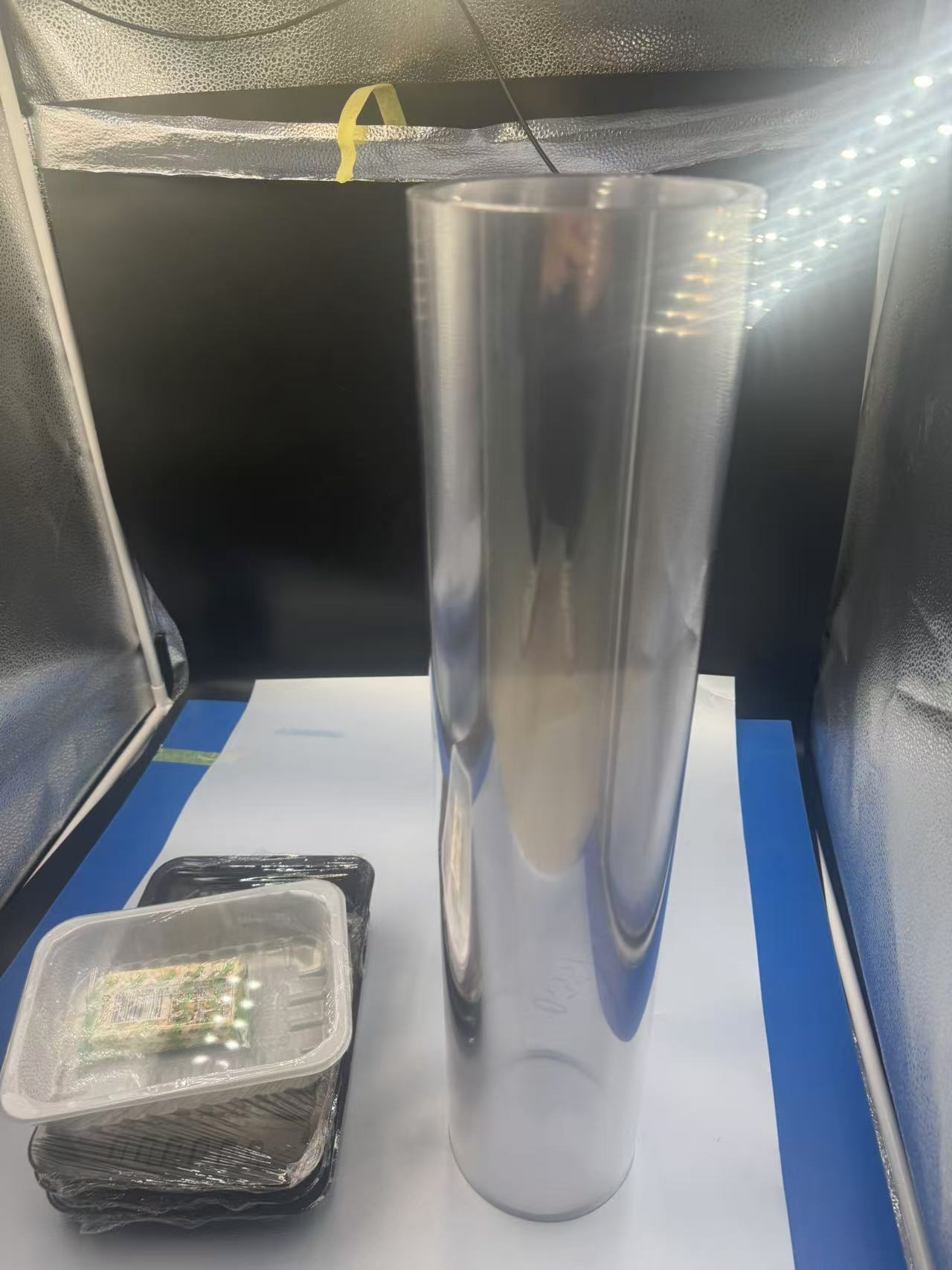

The hallmark of ultra-transparent PET film is its stunning clarity. With light transmission rates often exceeding 92% and haze levels below 1%, this material rivals glass in visual appeal. This transparency isn’t just cosmetic—it’s functional. Imagine a set of sleek, reusable plastic cutlery displayed on a store shelf: the PET film wrapping reveals every detail—the smooth curves of a spoon, the sharp edge of a knife—inviting customers to pick it up. This clarity stems from advanced manufacturing techniques, such as biaxial orientation, which aligns polymer chains to minimize light scattering. A 2022 study by the Society of Plastics Engineers noted that PET film’s optical properties enhance product visibility by up to 30% compared to less transparent alternatives.

1.2 PET***Film Strength

Strength is another pillar of PET film’s appeal. With a tensile strength of 50–70 MPa, it resists tearing, puncturing, and deformation under stress. This robustness is vital for tableware blister packaging, where items must endure handling, stacking, and shipping. Picture a pallet of PET-packaged plates jostling in a truck across a bumpy road: the film holds firm, preventing cracks or breaches that could compromise hygiene. Unlike flimsier materials, PET film’s durability ensures that a fork doesn’t pierce its packaging, keeping the contents pristine from factory to table.

1.3 PET***Film Recyclability

In today’s eco-conscious market, PET***film recyclability is a major draw. PET is one of the most recycled plastics globally, with established systems converting used film into new products like fibers or bottles. Its chemical stability allows it to be melted and reformed without significant degradation, supporting a circular economy. For tableware manufacturers, this means PET film aligns with sustainability goals, appealing to environmentally savvy consumers.

A real-world example: a European retailer switched to PET film for its disposable cutlery packs and saw a 15% uptick in sales, partly due to the “recyclable” label resonating with buyers.

1.4 PET***Film Heat Stability

Heat stability rounds out PET film’s impressive profile. With a glass transition temperature of about 70–80°C and a melting point nearing 250°C, it withstands moderate heat without warping or losing clarity. This makes it suitable for tableware that might face warm storage conditions or brief sterilization processes. Consider a stack of PET-packaged trays in a warehouse near a heating vent: while lesser films might soften or haze, PET film retains its shape and transparency, ensuring the product inside remains both protected and presentable.

Section 2: PET Film in Blister Packaging – A Seamless Fit

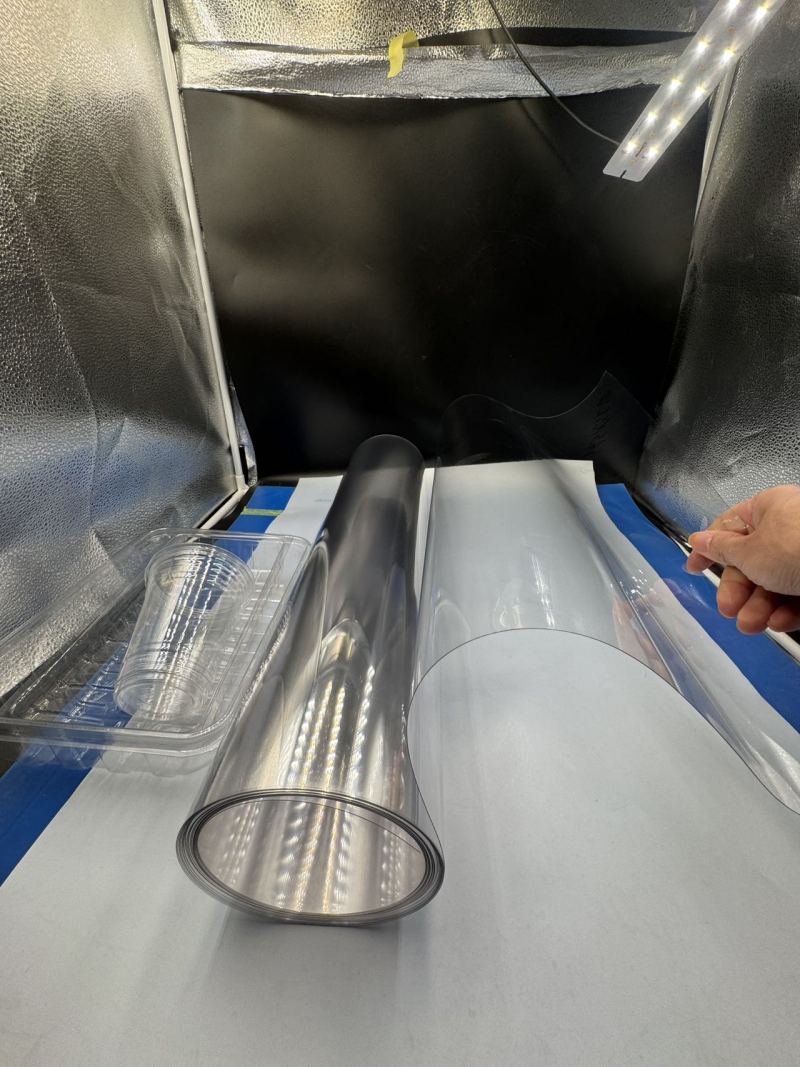

Blister packaging involves molding a plastic film into a cavity that encases a product, often sealed with a backing like foil or cardstock. For tableware, this method ensures hygiene, portability, and retail-ready display. Ultra-transparent PET film’s properties align perfectly with these demands, as detailed below.

2.1 Exceptional Formability

PET film’s thermoforming capability is a key advantage. When heated to its softening point (around 80–100°C), it becomes pliable, allowing it to mold tightly around tableware shapes—whether the slender handle of a spoon or the broad surface of a plate. This precision fit minimizes movement within the package, reducing scratches or damage. For instance, a set of picnic knives packaged in PET film stays securely in place, even when tossed into a bag, thanks to the film’s ability to conform like a second skin.

2.2 Protective Barrier

While not as moisture-impermeable as multilayer films, PET film offers solid protection against dust, dirt, and light contamination—critical for tableware meant for food contact. Its surface resists scratches and scuffs, maintaining clarity through handling. Imagine a shipment of plastic cups crossing a dusty region: PET film keeps them spotless, ensuring they’re ready for immediate use upon arrival. Its chemical inertness also prevents reactions with the packaged items, preserving their quality.

2.3 Aesthetic and Marketing Edge

The ultra-transparency of PET film doubles as a marketing tool. Retailers and brands leverage its glass-like finish to elevate product perception. A set of disposable forks in a PET blister pack looks premium, not cheap, encouraging impulse buys. A 2023 Packaging Digest report found that transparent PET packaging boosted tableware sales by 12% in test markets, as consumers associated clarity with quality. The film’s ability to be printed or labeled further enhances branding without sacrificing visibility.

Section 3: Practical Applications in Tableware Packaging

PET film’s versatility shines in real-world uses, from everyday disposables to specialized kits.

3.1 Disposable Cutlery for Takeout

In the fast-paced takeout industry, disposable cutlery must be hygienic and easy to distribute. PET film blister packs encasing a fork, spoon, and napkin are a staple in meal kits. The film’s strength ensures the pack survives being stuffed into a crowded delivery bag, while its transparency lets customers verify contents at a glance. A chain of restaurants reported fewer customer complaints about missing utensils after adopting PET film packaging, attributing it to the clear visibility.

3.2 Reusable Tableware for Retail

For reusable items like lightweight plates or camping cutlery, PET film offers a polished presentation. Its heat stability allows packages to sit under store lights without distorting, and its recyclability appeals to eco-minded shoppers. A retailer noted that PET-packaged reusable spoons outsold competitors in opaque packaging by 18%, as customers valued the ability to inspect the product’s color and finish.

3.3 Travel and Outdoor Kits

Outdoor enthusiasts rely on compact, durable tableware kits. PET film blister packs containing a knife, fork, and spoon are lightweight (density of 1.38 g/cm³) and tough enough for rugged use. A camping gear supplier found that PET film reduced packaging failures—like cracked covers—by 20% compared to previous materials, ensuring kits stayed intact during hikes.

Section 4: Challenges and Future Directions

PET film isn’t flawless. Its moderate barrier properties limit its use for oxygen-sensitive goods, though this rarely affects tableware. Its higher cost compared to PP film can also deter budget-focused manufacturers. However, innovations like recycled PET (rPET) are lowering costs and boosting sustainability. Advances in co-extrusion—layering PET with barrier films—promise to expand its capabilities, keeping it competitive in the packaging landscape.

Conclusion

Ultra-transparent PET film brings a rare blend of transparency, strength, recyclability, and heat stability to tableware blister packaging. From safeguarding disposable forks in takeout bags to showcasing reusable plates on retail shelves, it excels in both form and function. As sustainability and aesthetics grow in importance, PET film stands poised to lead, offering manufacturers and consumers a clear, durable, and eco-friendly solution. In a crowded market, its brilliance is impossible to overlook.

Within 15-20 days after received payment...more