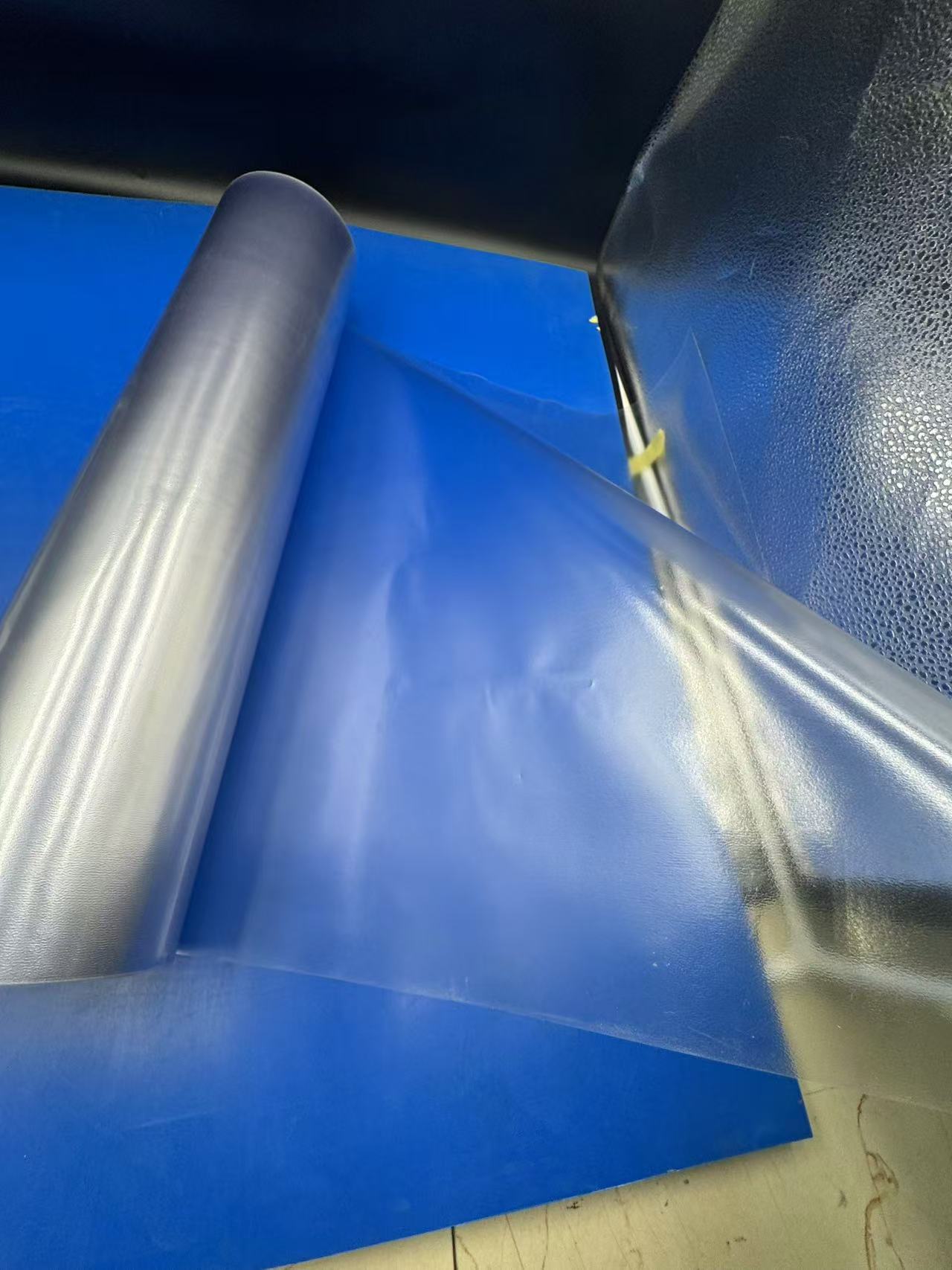

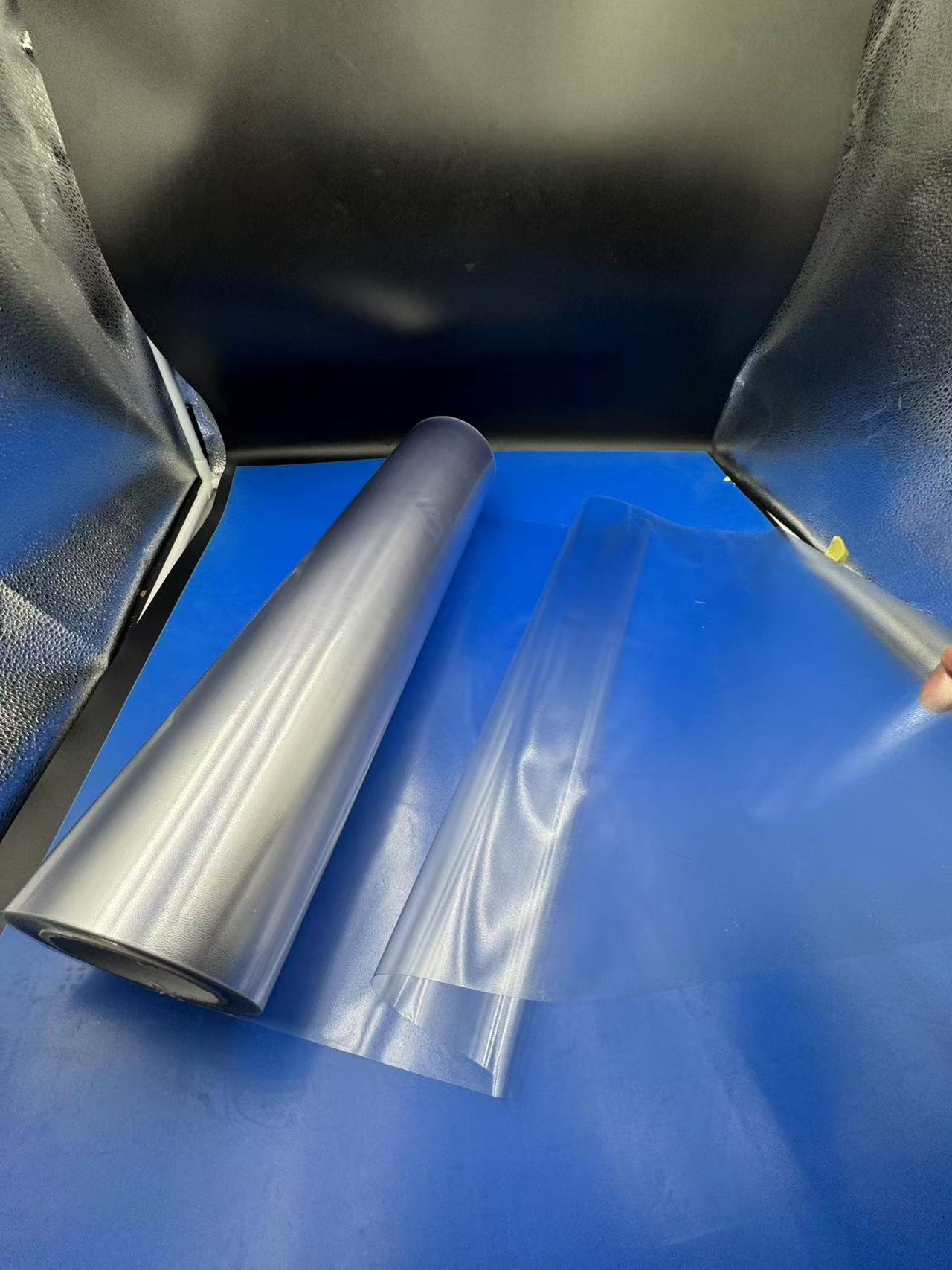

Exploring PVC Grain Skin Film: Properties and Versatility in Composite Films, Pharmaceutical, and Apparel Packaging

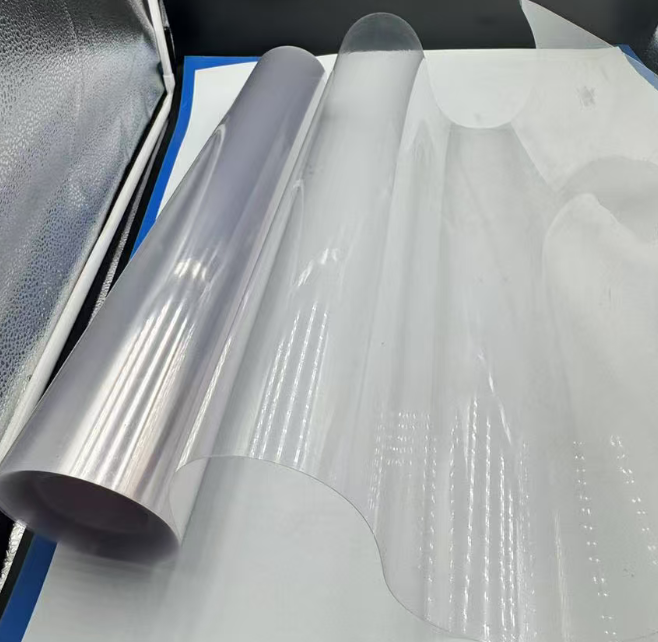

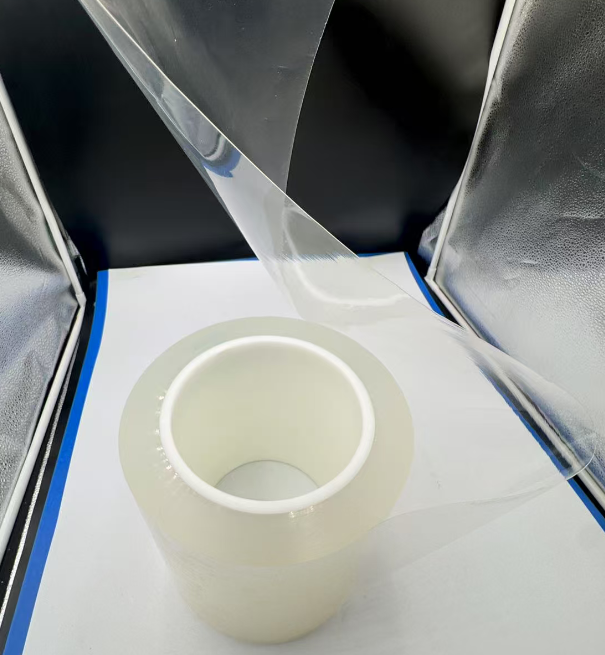

Material: PVC Grain film

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: phama Food grade film

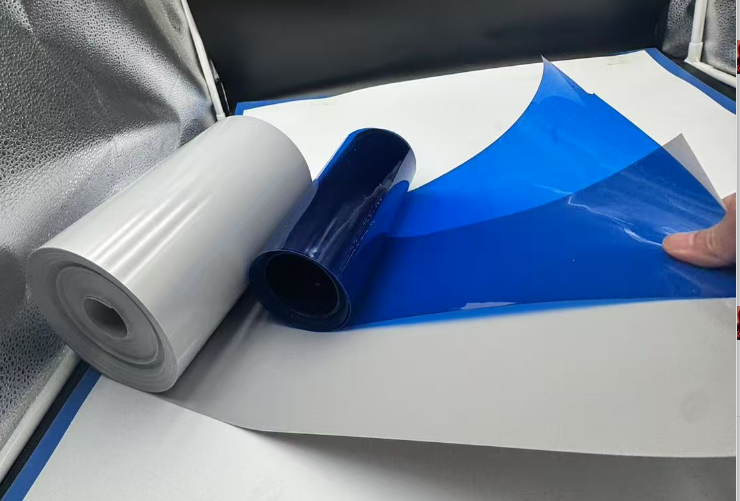

color: transparent/pearl white/ customization

location: china

usage :for lamination, phama packaging

Material: Flexible PVC ROLL

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

Introduction

With their unique properties, Polyvinyl Chloride grain skin films have found wide applicability across different industries. This paper examines the properties of PVC grain skin film, considering its various uses in composite films, pharmaceutical packaging, and packaging for apparel. We look into the physical and chemical properties that make PVC the ideal material for use in such applications and provide a critical review of its practical applications.

Properties of PVC Grain Skin Film

Physical Characteristics:

• Flexibility and Durability: The inherent flexibility of PVC, upon plasticization, provides for grain skin films capable of fitting into irregular shapes and sizes, an important feature in packaging where adaptability is a prime factor. Its durability ensures the packaging can resist handling, transport, and storage stresses.

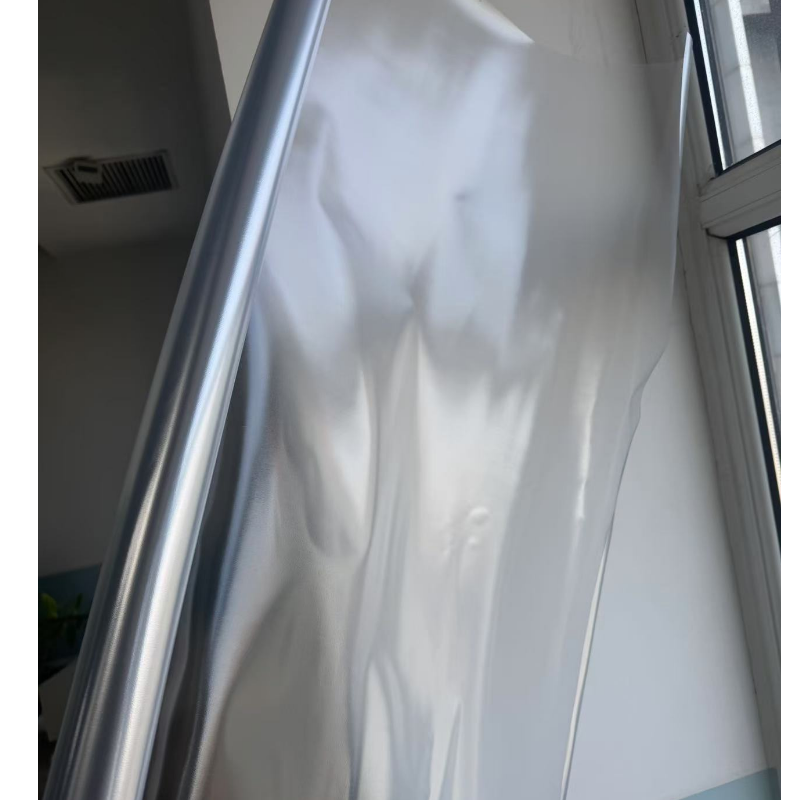

• Optical Clarity: Since the surface texture in PVC films is usually a grain texture, it can still have great clarity notwithstanding. Though not as clear as PET, good visibility of the packaged goods is achieved, which becomes beneficial, especially for retail purposes.

• Texture and Aesthetic Appeal: The grained skin texture helps increase grip and handling and adds aesthetic appeal to mimic other, more premium materials, like leather or fabric, for packages regarding apparel.

Chemical Properties:

• Barrier Properties: PVC has a moderate barrier to oxygen, moisture, and certain gases. These properties, when combined with other materials in composite films, become significantly enhanced to make the product suitable for sensitive packaging.

• Chemical Resistance: It resists oils, fats, and many chemicals; this property of PVC is quite important because as a packaging material, it can come in contact with a lot of different things, especially in pharmaceutical applications.

• Heat Sealability: The heat sealability of PVC makes the material useful in packaging applications, providing hermetic seals that ensure safety and prolong life.

Manufacturing Process of PVC Grain Skin Films

• Polymerization: PVC is produced by polymerizing vinyl chloride into PVC resin.

• Plasticization: The rigid PVC is made flexible by the addition of plasticizers to obtain a film-like consistency that is applied to the skin of grains.

• Extrusion and Calendering: The compound is extruded into sheets and then calendered to give the desired texture of the grain skin.

• Finishing: The film can undergo lamination or coating to impart added value to certain characteristics like barrier or printability

Application in Packaging

Composite Films :

• Enhanced Barrier: This film combines PVC grain skin with other base materials such as polyethylene or polyamide for better barrier properties against moisture, oxygen, and UV light in the packaging of food or pharmaceutical products.

• Multi-Layer Structures: The ability of PVC to be incorporated into complex multi-layer films in which each layer may have a specific function to play-from structural integrity to barrier protection-enhances the overall performance of the pack. Pharmaceutical Packaging:

• Blister Packs: PVC possesses properties that are ideal for the blister packaging of tablets, capsules, and other solid medical formulations. Its heat sealability provides tight sealing to the content by preventing external environmental factors.

• Medical Device Packaging: The toughness and chemical resistance of PVC come in good application for the packaging of medical devices to safe sterilization and integrity during transport and storage.

• Regulations Compliances: PVC used in pharmaceutical packaging is strictly tested to ensure safety and does not interfere with the content of the drugs; this assures patient safety.

Apparel Packaging:

• Protection and Presentation: A range of PVC grain skin films lends a tactile protection and thereby enriches the appearance of the apparel product-be it shoes, belts, or garments of high-end designer wear. The film protects components from dust, moisture, and minor physical damages.

• Branding: Printing on PVC, or even using it in clear or colored variants, helps in branding for product differentiation within competitive retail.

• Sustainability Considerations: While there is an environmental concern related to the disposal of PVC, development is moving toward the use of recyclable or biodegradable additives for PVC.

• Environmental Impact: The presence of plasticizers and other additives complicates the recycling process for PVC. In developing PVC formulations, more sustainable or "green" PVC is showing promise.

• Health Concerns: A number of concerns about the migration of plasticizers into products have been expressed, mainly for applications involving food and pharmaceuticals. Alternatives include phthalate-free PVC or using different polymers.

• Material Science Innovation: Future directions could be the improvement of PVC biodegradability or the formulation of composites where the negative attributes of PVC are minimized due to synergistic effects with other materials.

Conclusion

PVC grain skin film, due to its versatile properties, is being used in various modern packaging applications in different industries. From the improvement of barrier properties in composite films for pharmaceuticals to adding an aesthetic touch to apparel packaging, PVC shows a wide utility. However, the road to sustainability and health safety is ongoing, shaping its development and application. Going forward, the balance between functional advantages of PVC and considerations related to the environment and health will be important in order to keep this material relevant and responsible in the packaging landscape.

Within 15-20 days after received payment...more