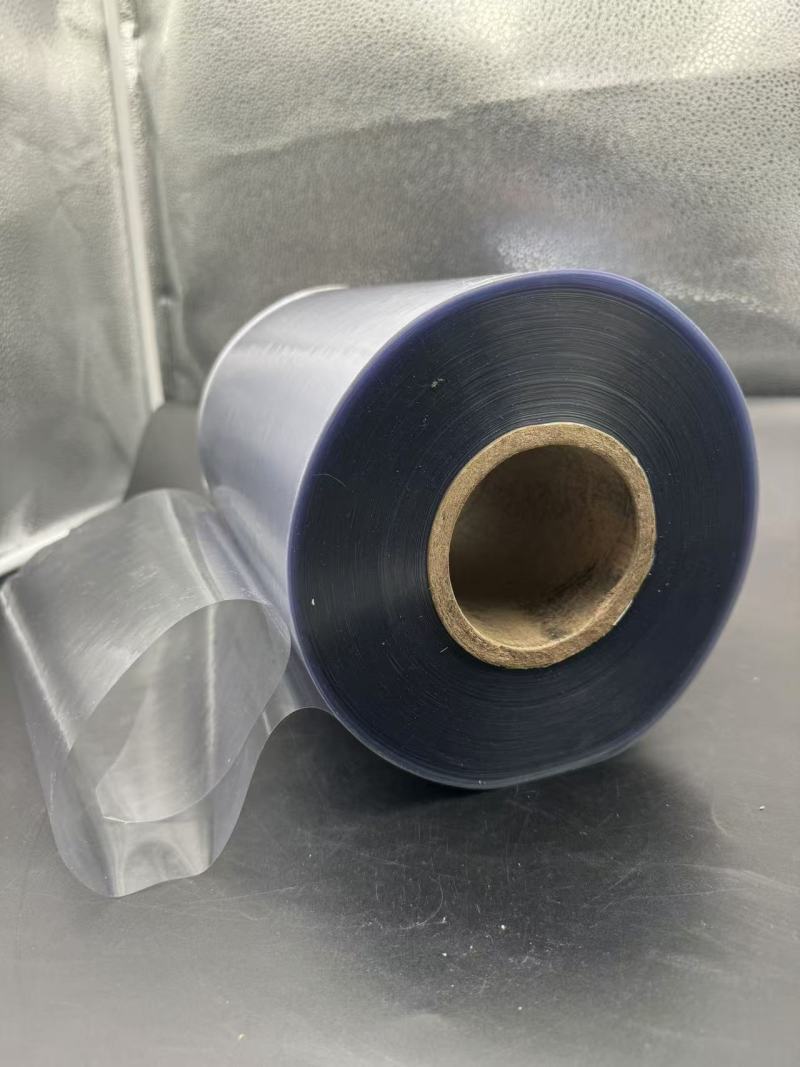

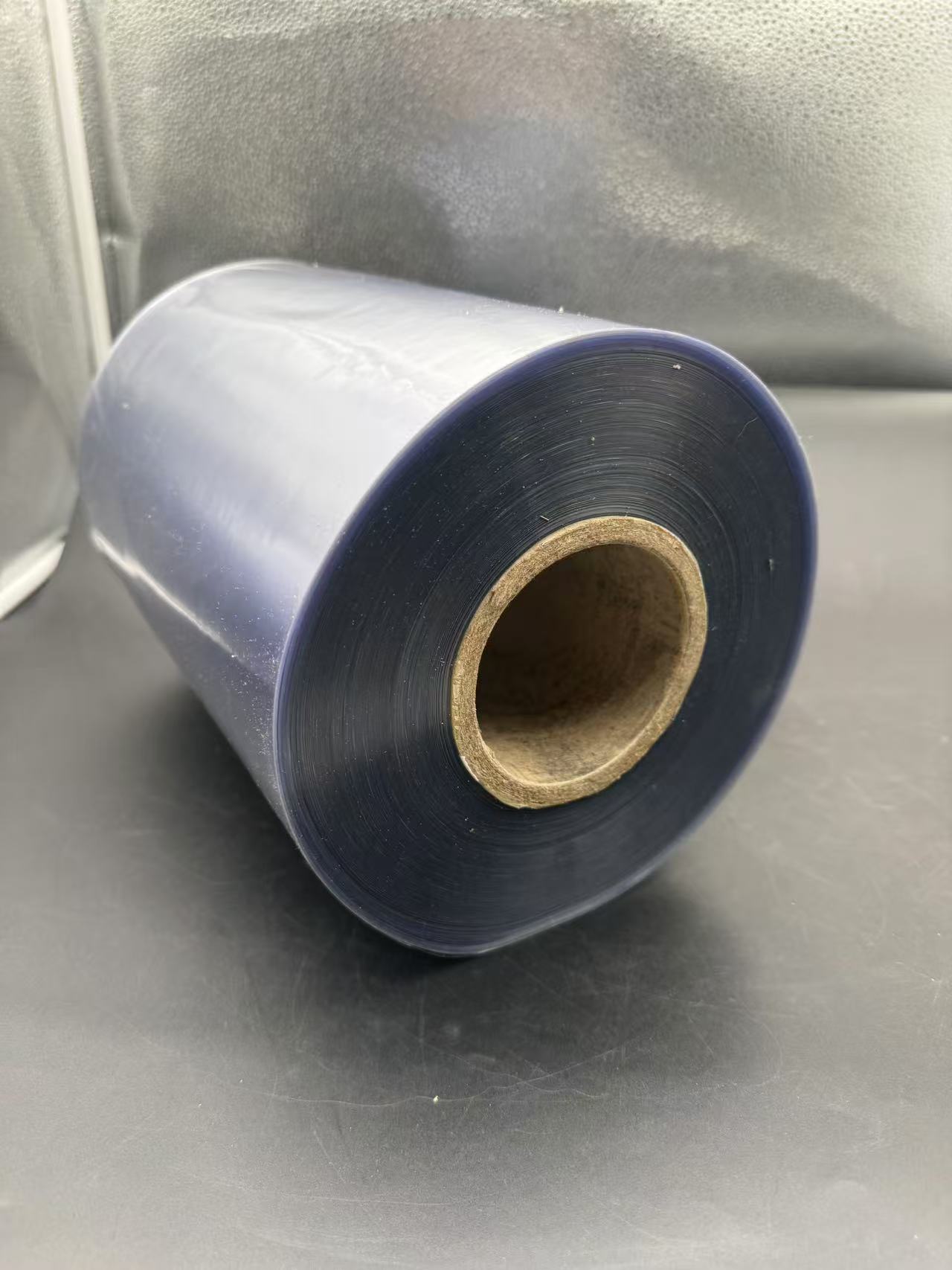

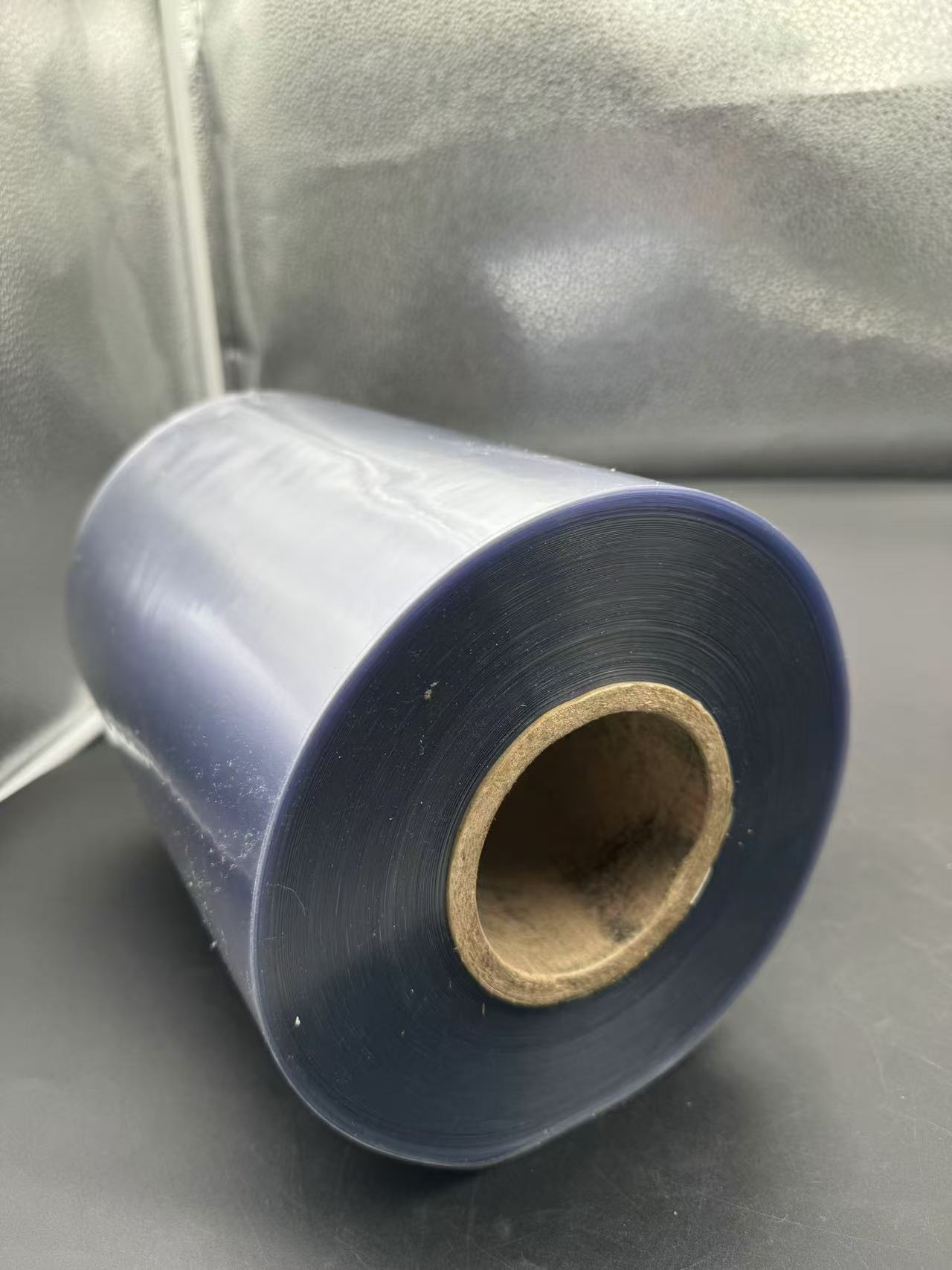

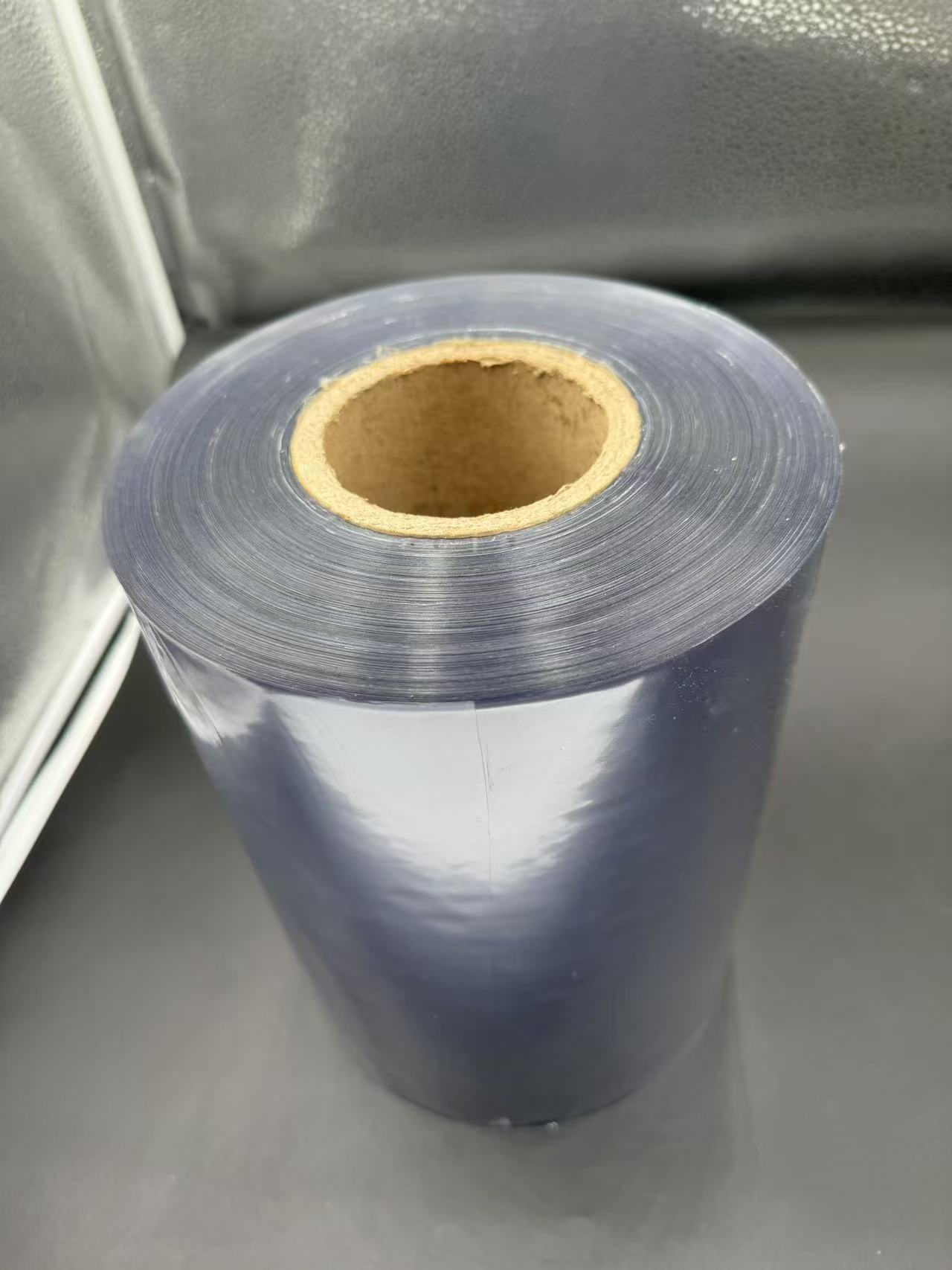

0071 PVC clear film for PVC - Alu - Alu Composite Cold Aluminum Film

Material: PVC ROLL

Thickness 0.45-0.018mm-customization

Size: 80MM/130MM/Customization

GRADE: pharma grade film

color: white/ customization

location: china

Usage: Pharmaceutical, dried food

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Download

The Application of Transparent PVC Film in PVC - Alu - Alu Composite Cold Aluminum Film

Introduction

In the packaging industry, the development of advanced composite materials has been crucial in meeting the diverse needs of product protection, preservation, and presentation. The PVC - Alu - Alu composite cold aluminum film, with the incorporation of transparent PVC film, has emerged as a significant innovation. This article will explore the various aspects of using transparent PVC film in the PVC - Alu - Alu composite cold aluminum film, including its material properties, manufacturing process, applications, advantages, and challenges.

Material Properties of Transparent PVC Film

Chemical Composition and Structure

Transparent PVC film is composed of polyvinyl chloride polymers. The molecular structure of PVC consists of long chains of carbon, hydrogen, and chlorine atoms. The chlorine atoms in the structure contribute to its unique properties, such as chemical resistance and flame retardancy. The polymerization process of PVC can be adjusted to control the molecular weight and degree of polymerization, which in turn affects the physical and chemical properties of the film. The transparency of the PVC film is achieved through careful manufacturing processes that minimize the presence of impurities and ensure uniform molecular alignment.

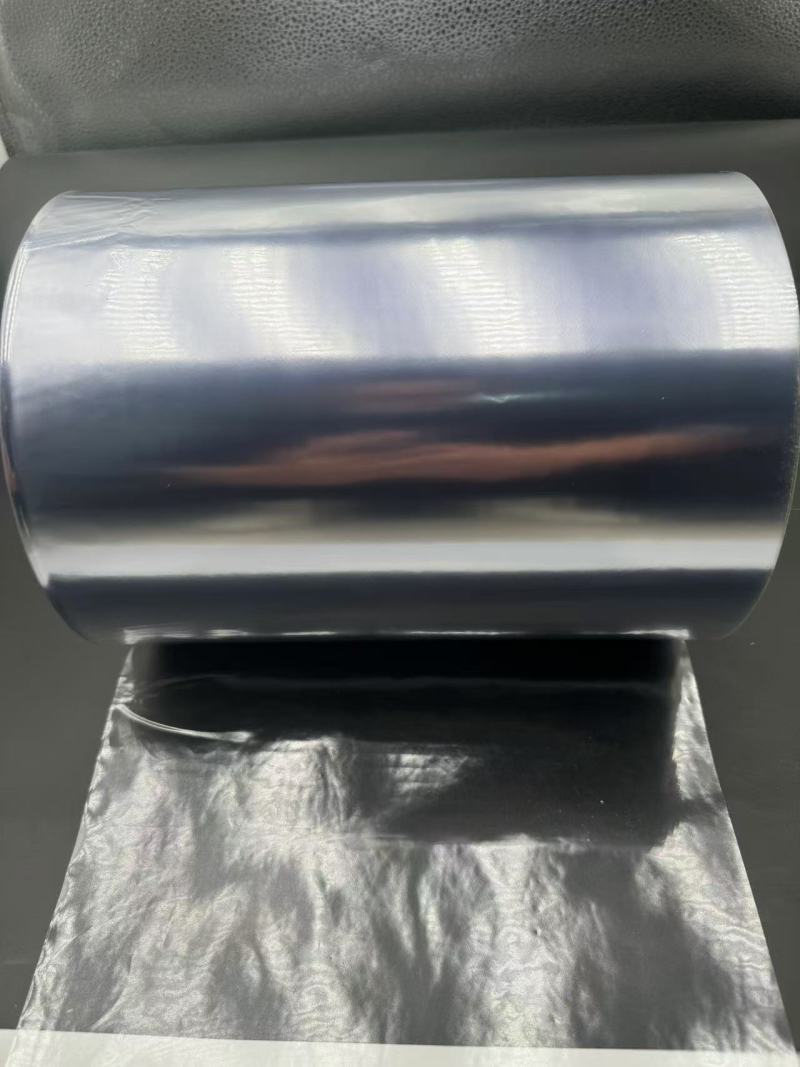

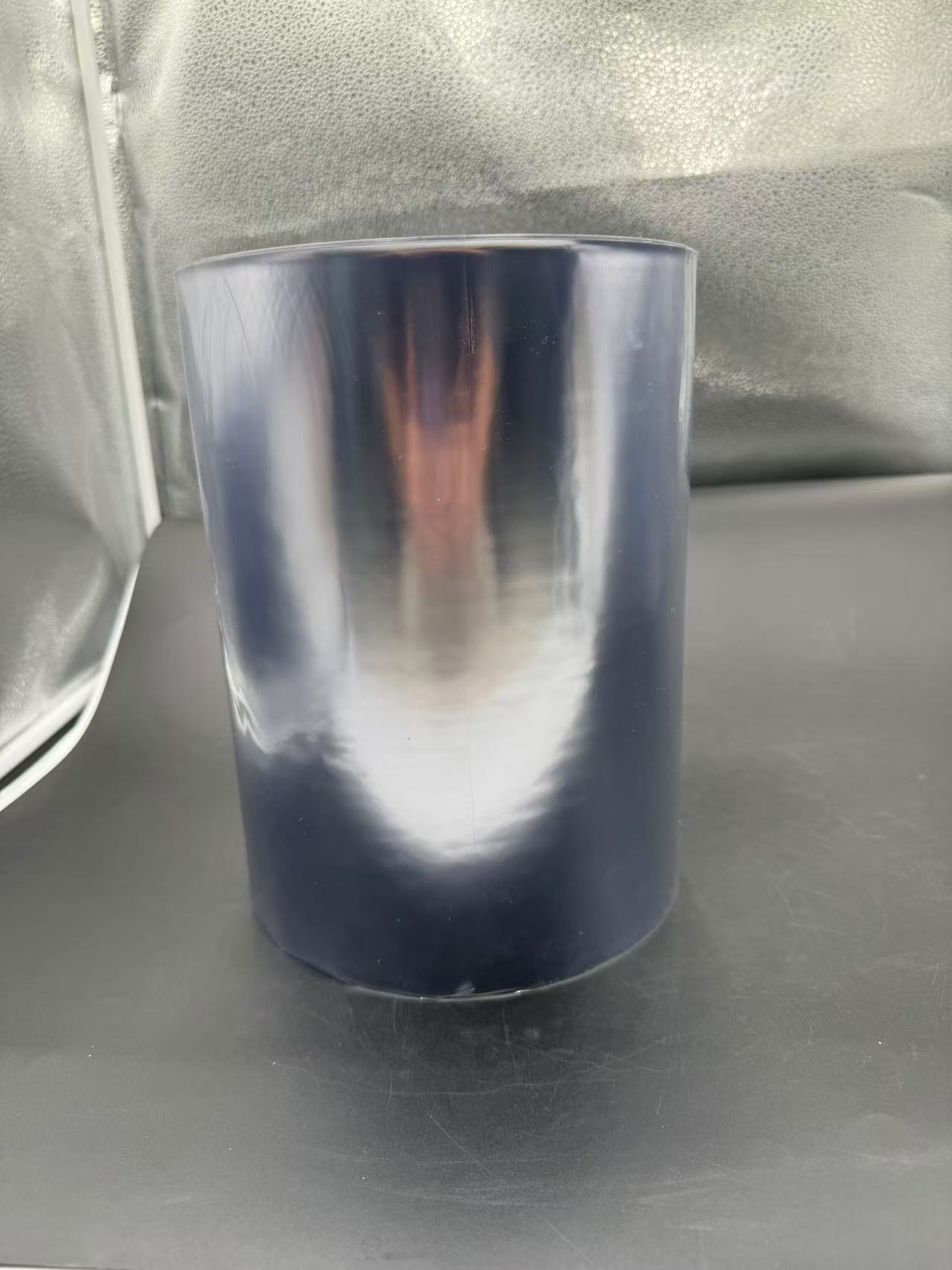

Transparency

The transparency of PVC film is one of its most notable features. It allows for clear visibility of the contents packaged within the PVC - Alu - Alu composite cold aluminum film. This is particularly important in applications where the product needs to be showcased, such as in the packaging of cosmetics, pharmaceuticals, and luxury goods. The high - level transparency is maintained over time and under different environmental conditions, providing a reliable window for consumers to view the product.

Mechanical Properties

PVC film exhibits good mechanical strength. It has a certain tensile strength that enables it to withstand stretching and pulling forces during the manufacturing process and in use. The film also has flexibility, which allows it to conform to the shape of the aluminum layers and other components in the composite. This flexibility is beneficial in preventing cracks and breaks during handling and transportation. Additionally, the film has a degree of puncture resistance, protecting the integrity of the composite structure from accidental damage.

Barrier Properties

In terms of barrier properties, transparent PVC film offers protection against moisture, gases, and other environmental factors. It can act as a barrier to prevent the ingress of moisture, which is crucial for products that are sensitive to humidity, such as food items and electronic components. The film also provides some resistance to gases like oxygen and carbon dioxide, helping to maintain the freshness and quality of the packaged product. However, its barrier properties may be enhanced when combined with the aluminum layers in the PVC - Alu - Alu composite.

Chemical Resistance

PVC film is known for its chemical resistance. It can withstand contact with a variety of substances, including oils, acids, and alkalis. This property makes it suitable for packaging products that may contain or come into contact with such chemicals. For example, in the pharmaceutical industry, where drugs may have different chemical compositions, the PVC film can provide a protective layer without reacting with the active ingredients.

Manufacturing Process of PVC - Alu - Alu Composite Cold Aluminum Film with Transparent PVC Film

Preparation of Transparent PVC Film

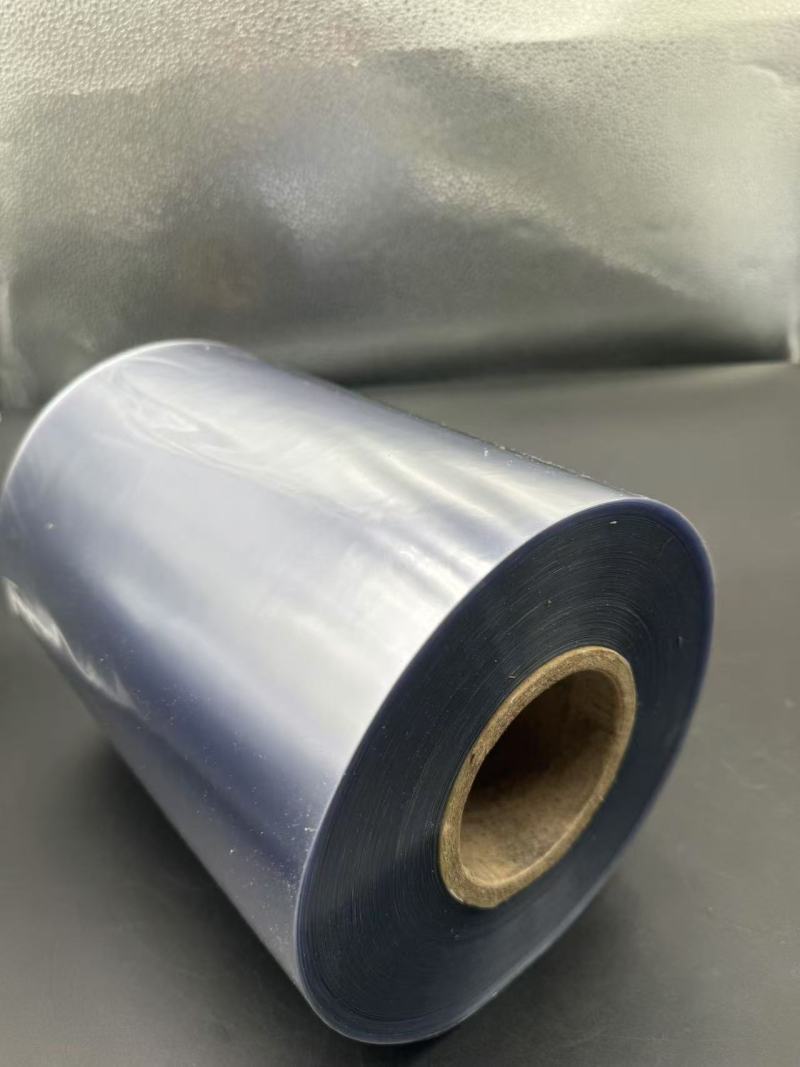

The production of transparent PVC film starts with the selection of high - quality PVC resin. The resin is mixed with various additives, such as plasticizers to improve flexibility, stabilizers to enhance thermal stability, and lubricants to facilitate the extrusion process. The mixture is then fed into an extruder, where it is heated and melted. The molten PVC is forced through a die to form a continuous sheet of film. The thickness of the film is precisely controlled, and it is cooled and wound onto rolls for further processing.

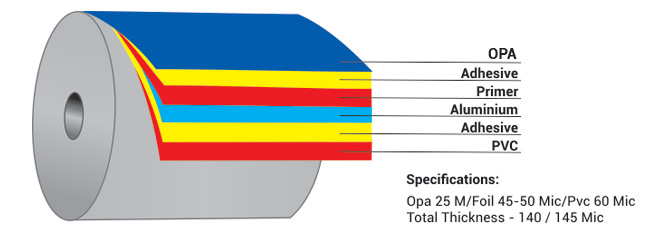

Aluminum Layer Preparation

The aluminum layers in the PVC - Alu - Alu composite are typically produced by aluminum foil manufacturing processes. High - purity aluminum is melted and then rolled into thin foils of specific thicknesses. These aluminum foils are further processed to ensure their surface quality and flatness. They are cleaned and treated to enhance their adhesion properties with the PVC film and other layers in the composite.

Lamination Process

The lamination of the transparent PVC film with the aluminum layers is a crucial step. The PVC film is first coated with an adhesive layer. The adhesive is carefully chosen to ensure good bonding between the PVC and the aluminum. The aluminum foils are then placed on either side of the PVC film, and pressure and heat are applied to complete the lamination. The lamination process is carried out under controlled conditions to ensure uniform adhesion and to avoid air bubbles or wrinkles in the composite. In some cases, additional layers or coatings may be added to further enhance the properties of the composite, such as a protective varnish layer on the outer surface of the PVC film.

Quality Control and Finishing

After the lamination, the PVC - Alu - Alu composite cold aluminum film undergoes rigorous quality control. The thickness of the composite, the adhesion between the layers, and the transparency of the PVC film are all tested. Any defects or non - conformities are identified and corrected. The composite film is then cut into the desired sizes and shapes, and it may be further processed, such as by printing or adding perforations for easy opening.

Applications of PVC - Alu - Alu Composite Cold Aluminum Film with Transparent PVC Film

Pharmaceutical Packaging

Blister Packs

In the pharmaceutical industry, PVC - Alu - Alu composite cold aluminum film with transparent PVC film is widely used for blister packs. The transparent PVC film allows for easy identification of the tablets or capsules inside. The aluminum layers provide a high - level of protection against moisture, light, and oxygen, which are crucial for maintaining the potency and stability of the drugs. The composite film also offers good mechanical protection, preventing the blister pack from being damaged during handling and transportation.

Sachets

For powdered or liquid pharmaceutical formulations, sachets made from this composite film are used. The transparency of the PVC film enables the user to see the contents and check for any irregularities. The barrier properties of the composite ensure that the active ingredients are not affected by external factors. The sachets are also easy to open and use, providing convenience for patients.

Food Packaging

High - value Food Items

For high - value food products such as gourmet chocolates, specialty cheeses, and high - end confectionery, the PVC - Alu - Alu composite cold aluminum film is an excellent choice. The transparent PVC film showcases the product, making it more attractive to consumers. The aluminum layers protect the food from spoilage by preventing the ingress of moisture, oxygen, and odors. The composite film also helps in maintaining the texture and flavor of the food, extending its shelf life.

Ready - to - eat Meals

Ready - to - eat meals that require long - term preservation can benefit from this composite packaging. The barrier properties of the film keep the food fresh and safe to consume. The transparent PVC film allows for visual inspection of the meal components, and the mechanical strength of the composite ensures that the package can withstand the rigors of storage and transportation.

Cosmetics Packaging

Compact Powders and Creams

Cosmetics like compact powders and creams are often packaged in containers made with PVC - Alu - Alu composite cold aluminum film. The transparent PVC film gives a clear view of the product, which is important for marketing and consumer appeal. The aluminum layers protect the cosmetics from oxidation and contamination, maintaining their quality and efficacy. The packaging also gives a luxurious feel, enhancing the brand image of the cosmetics.

Perfume Boxes

Perfume boxes made with this composite film can have a window of transparent PVC film, allowing consumers to see the bottle inside. The aluminum layers help in preserving the fragrance by preventing the escape of volatile compounds. The mechanical strength of the composite ensures that the box can protect the perfume bottle during shipping and display.

Advantages of Using Transparent PVC Film in PVC - Alu - Alu Composite Cold Aluminum Film

Product Protection and Preservation

The combination of the transparent PVC film and the aluminum layers in the composite provides excellent protection and preservation for the packaged product. The PVC film contributes its barrier properties against moisture and gases, while the aluminum layers enhance the overall protection, especially against light and oxygen. This helps in maintaining the quality, potency, and freshness of products such as pharmaceuticals, food, and cosmetics, reducing the risk of spoilage and degradation.

Visual Appeal and Marketing

The transparency of the PVC film is a great asset for marketing purposes. It allows consumers to see the product inside the package, which can attract their attention and influence their purchasing decisions. Whether it's a beautiful piece of chocolate, a stylish cosmetic, or a well - designed pharmaceutical tablet, the clear view through the PVC film can enhance the product's visual appeal and make it stand out on the shelf.

Durability and Mechanical Strength

The PVC - Alu - Alu composite cold aluminum film has good durability and mechanical strength. The PVC film's flexibility and tensile strength, combined with the rigidity and strength of the aluminum layers, make the composite able to withstand various handling and transportation conditions. It can resist impacts, punctures, and crushing, ensuring that the product inside is well - protected throughout the supply chain.

Customizability

The composite film can be easily customized. The transparent PVC film can be printed with product information, branding, or decorative designs. The size, shape, and thickness of the composite can also be adjusted according to the specific requirements of the product. This allows manufacturers to create unique and tailored packaging solutions for different products and markets.

Barrier Property Enhancement

The presence of the aluminum layers in the composite significantly enhances the barrier properties of the overall structure. While the PVC film itself has some barrier capabilities, the addition of aluminum foils provides a much higher level of protection against moisture, gases, and light. This is especially important for products that are highly sensitive to environmental factors, such as some pharmaceuticals and luxury food items.

Case Studies of PVC - Alu - Alu Composite Cold Aluminum Film with Transparent PVC Film in Practice

Case Study 1: Pharmaceutical Company's Blister Pack Upgrade

A pharmaceutical company was facing issues with the stability of its drugs in traditional blister packs. They decided to switch to PVC - Alu - Alu composite cold aluminum film with transparent PVC film. After the switch, they noticed a significant improvement in the shelf life of their drugs. The transparency of the PVC film allowed for easy quality control and patient identification. The aluminum layers provided enhanced protection against moisture and light, ensuring that the drugs remained potent and effective for a longer period. The company also received positive feedback from patients and healthcare providers regarding the new packaging.

Case Study 2: Gourmet Chocolate Brand's Packaging Innovation

A gourmet chocolate brand wanted to improve the packaging of its products to enhance their visual appeal and extend their shelf life. They opted for PVC - Alu - Alu composite cold aluminum film. The transparent PVC film made the chocolates look more enticing on the shelf, and the aluminum layers kept the chocolates fresh and prevented them from developing a rancid taste. The brand saw an increase in sales and customer satisfaction, and the packaging also helped in positioning their products as high - quality and luxurious.

Case Study 3: Cosmetics Brand's Packaging Redesign

A cosmetics brand redesigned its packaging using PVC - Alu - Alu composite cold aluminum film for its compact powders and creams. The transparent PVC film allowed consumers to see the product's color and texture, which was a key selling point. The aluminum layers protected the cosmetics from oxidation and maintained their quality. The new packaging gave the brand a more upscale image, and they experienced a boost in sales, especially in high - end retail stores.

Challenges and Solutions in Using Transparent PVC Film in PVC - Alu - Alu Composite Cold Aluminum Film

Environmental Concerns

One of the main challenges is the environmental impact of PVC. PVC is not easily biodegradable, and its disposal can pose a problem. To address this, efforts can be made to recycle the PVC - Alu - Alu composite film. Some recycling programs are being developed to separate the PVC and aluminum layers and recycle them separately. Additionally, manufacturers can explore the use of more environmentally friendly alternatives to PVC or develop biodegradable versions of PVC film.

Adhesion and Lamination Issues

Ensuring proper adhesion between the transparent PVC film and the aluminum layers during the lamination process can be a challenge. If the adhesion is not strong enough, the layers may separate, compromising the integrity of the composite. To overcome this, careful selection of adhesives and optimization of the lamination process parameters, such as temperature, pressure, and curing time, are essential. Testing and quality control measures should be in place to ensure consistent adhesion quality.

Cost Considerations

The use of PVC - Alu - Alu composite cold aluminum film can be more expensive than some traditional packaging materials. The cost of the raw materials, the manufacturing process, and the quality control requirements all contribute to the higher cost. To make it more cost - effective, manufacturers can look for ways to optimize the production process, such as improving production efficiency and reducing waste. They can also consider the long - term benefits of the composite film, such as better product protection and increased sales, which may offset the initial cost.

Regulatory Compliance

In industries such as pharmaceuticals and food, there are strict regulatory requirements regarding packaging materials. The PVC - Alu - Alu composite cold aluminum film must comply with these regulations, which may include tests for migration of substances from the film into the product, barrier property standards, and safety requirements. Manufacturers need to ensure that their production processes and the final product meet all relevant regulatory standards through proper testing and documentation.

Conclusion

The use of transparent PVC film in PVC - Alu - Alu composite cold aluminum film has opened up new possibilities in packaging. It offers a combination of product protection, visual appeal, durability, and customizability that is highly valuable in industries such as pharmaceuticals, food, and cosmetics. Despite the challenges related to environmental concerns, adhesion, cost, and regulatory compliance, there are solutions and strategies available to address them. As technology and manufacturing processes continue to evolve, the PVC - Alu - Alu composite cold aluminum film is likely to remain an important packaging solution, providing high - quality and effective packaging for a wide range of products. Manufacturers, packaging designers, and industries will continue to explore and optimize the use of this composite film to meet the ever - changing demands of the market and consumers.

Within 15-20 days after received payment...more