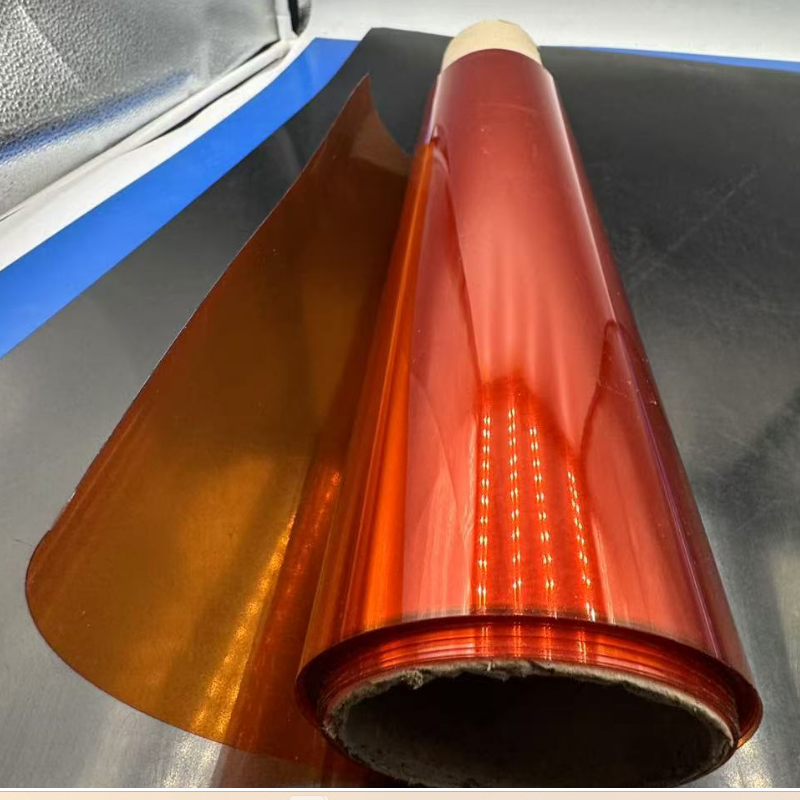

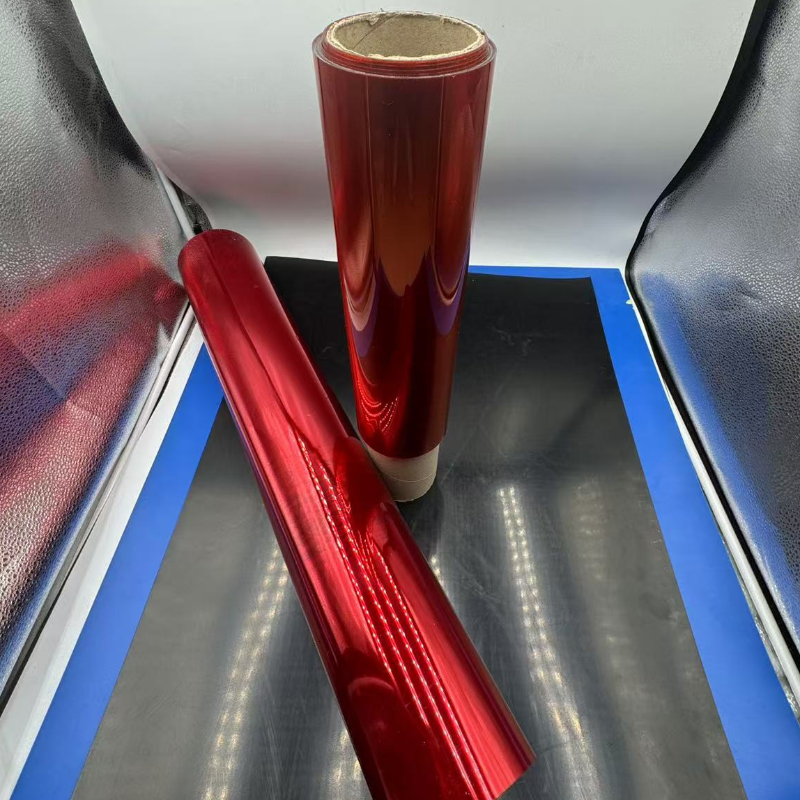

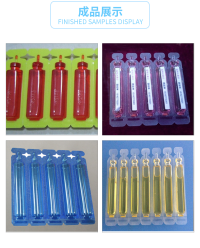

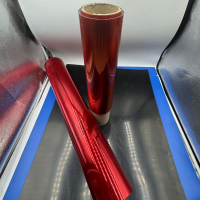

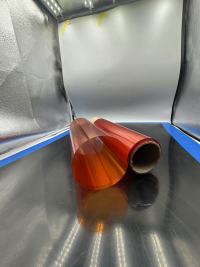

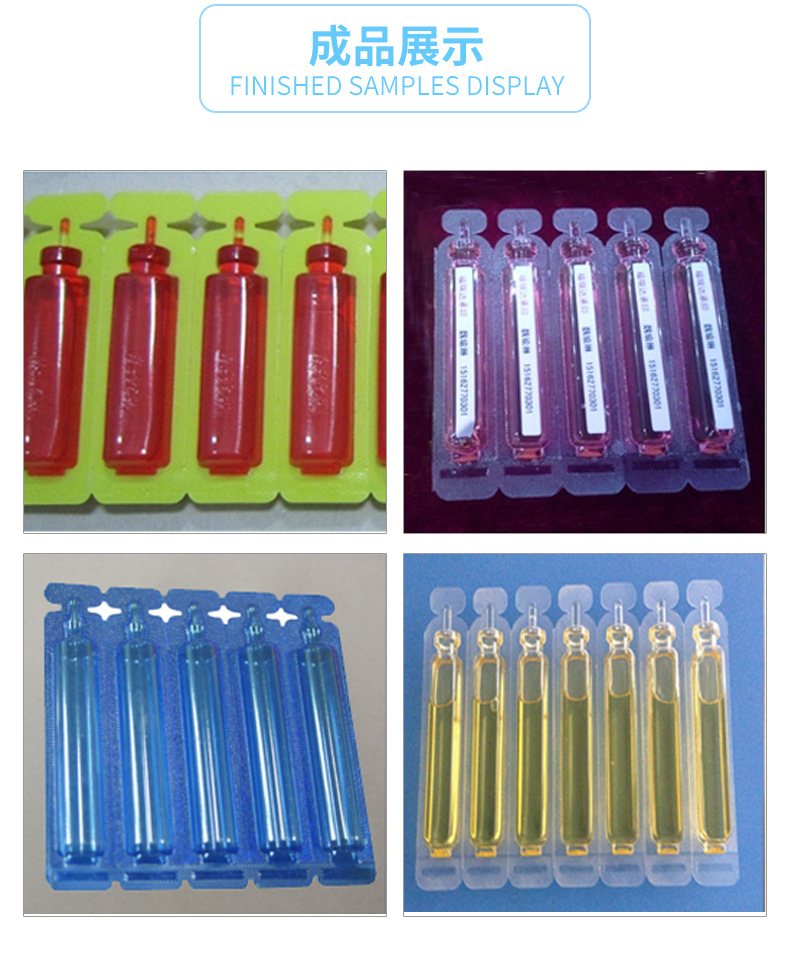

pvc/pe film Applications of Orange - Red Drug Blister Packaging and Battery Insulation Materials

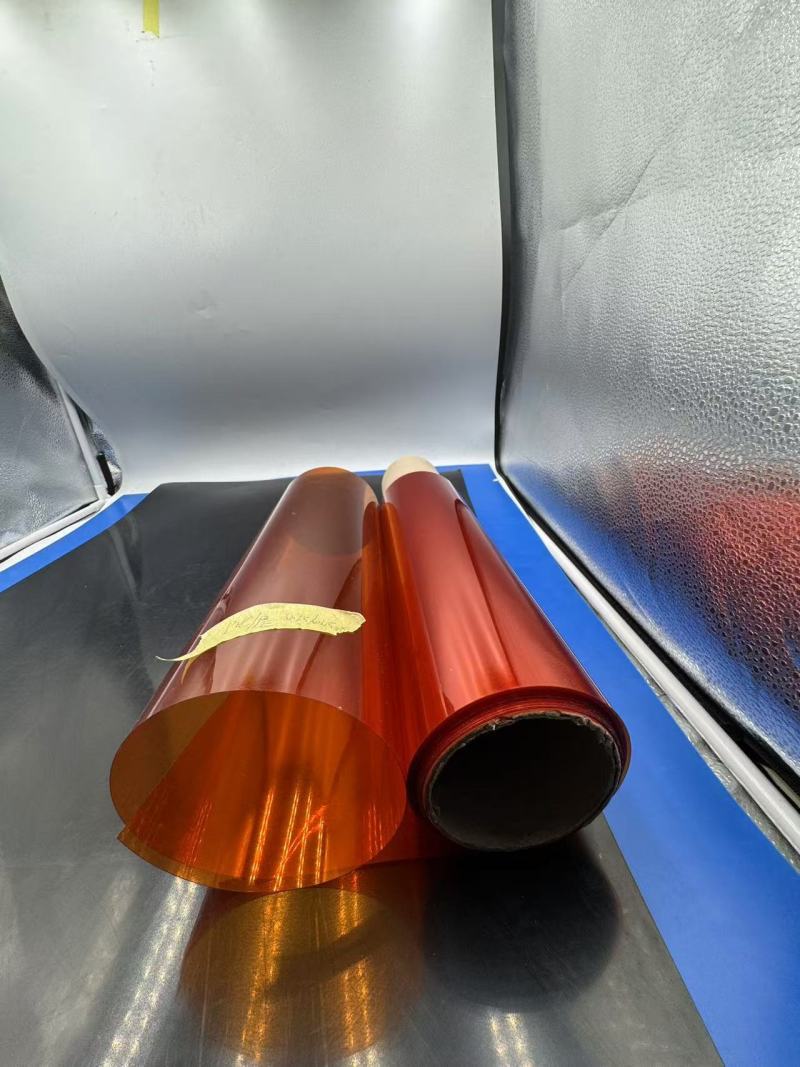

Material: PVC ROLL

Thickness 0.45-0.018mm-customization

Size: 80MM/130MM/Customization

GRADE: pharma grade film

color: white/ customization

location: china

Usage: Pharmaceutical, dried food curtain

- TOPLEADER

- 中国

- 15WORKING DAYS

- 500000T/M

- Information

- Video

- Download

Applications of Orange - Red Drug Blister Packaging and Battery Insulation Materials

I. Introduction

Material selection and application have become a critical factor in modern industry and daily life, as it directly influences the performance, safety, and user experience of products.

Two kinds of materials, which may seem irrelevant to each other, are orange-red drug blister packaging and battery insulation material. It is apparent that orange-red drug blister packaging not only relates to the process of drug storage but also transportation, drug sales,

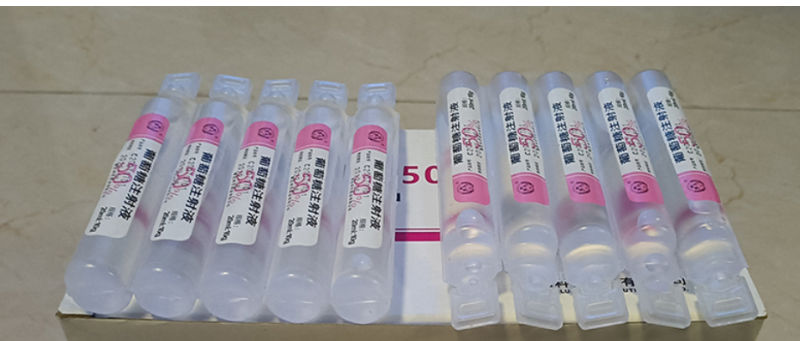

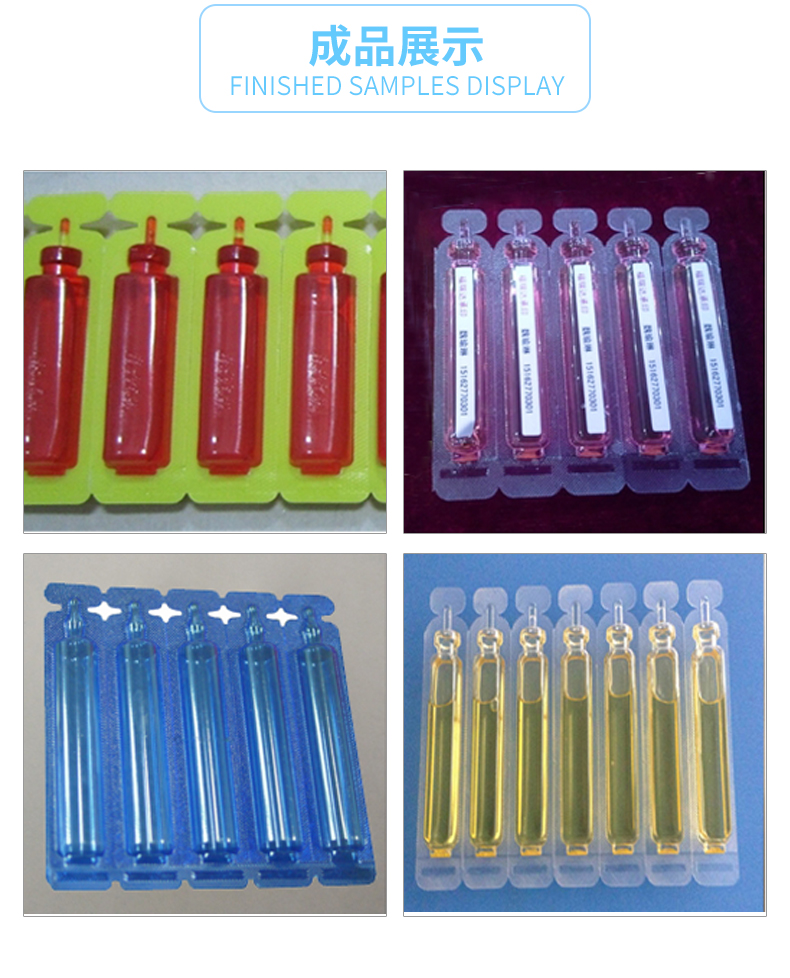

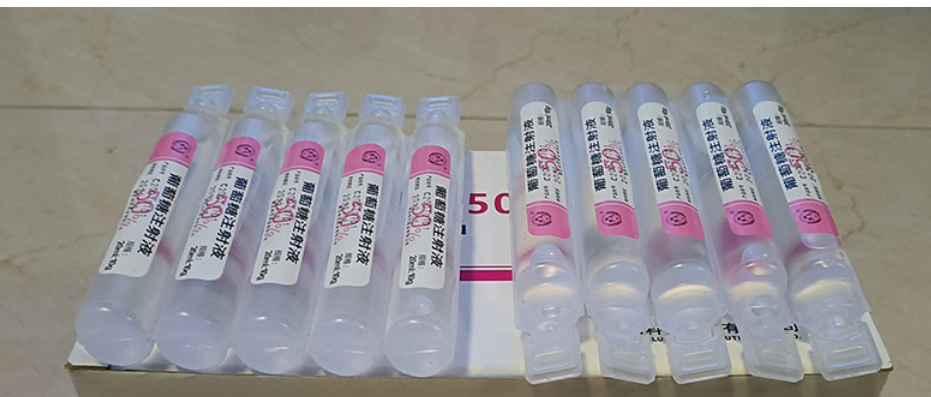

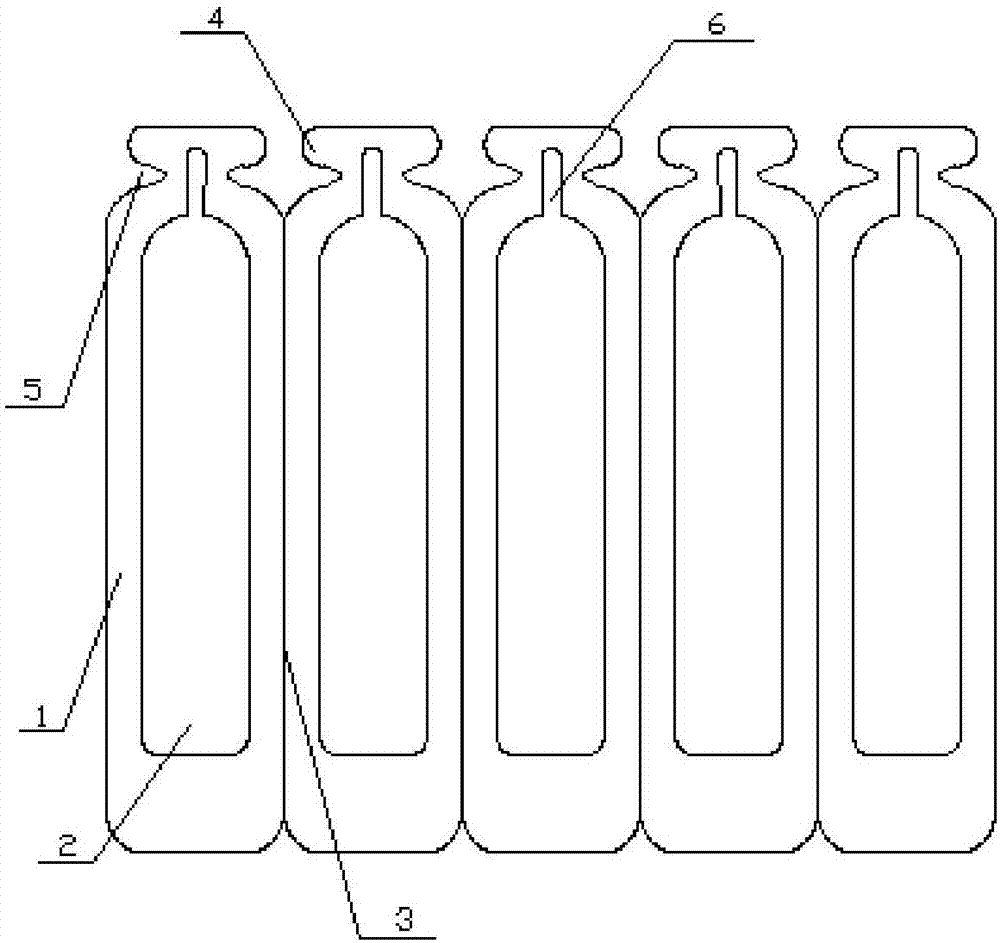

II. Blister Packaging of Drug in Orange - Red

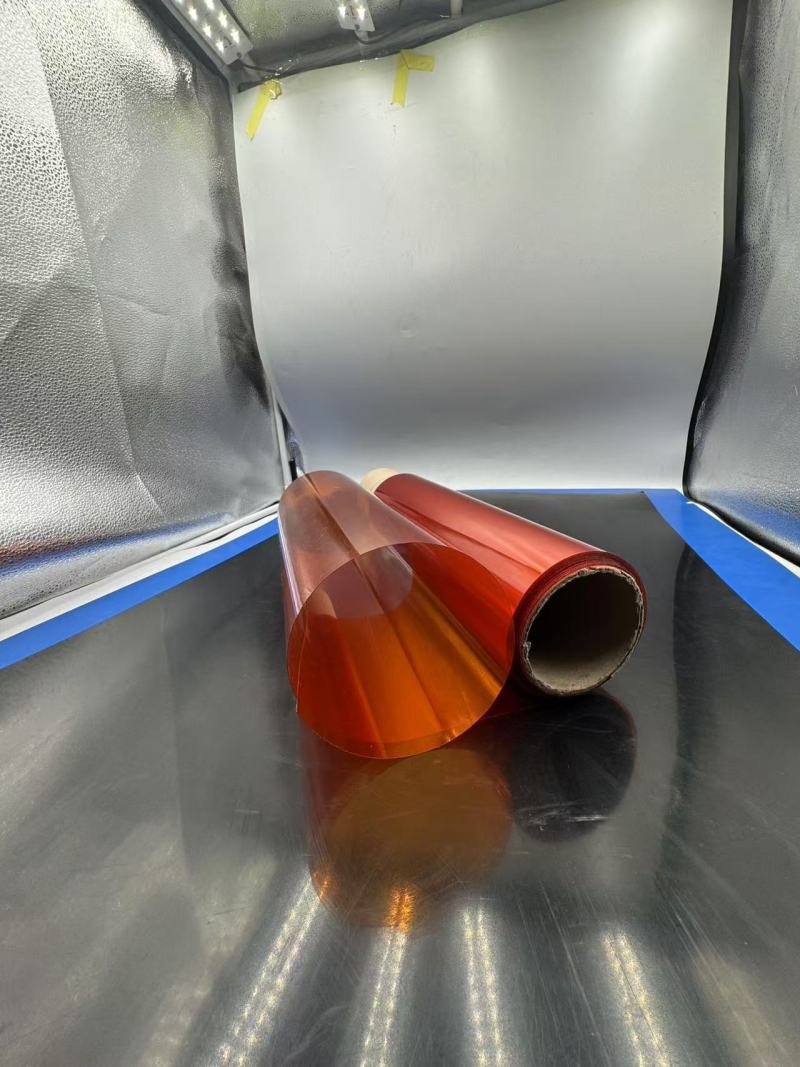

(I) Visual Characteristics and Brand Identity

Orange - red is a color with a high degree of visual impact. Application in the drug blister packaging, among the great number of drugs, can make it outstanding. Its recognition degree is very high; therefore, by consumers, the target drug could be found very quickly on the shelf in a pharmacy. For example, some children's antipyretics use orange - red for packaging. The bright color can attract the attention of parents and facilitate quick retrieval in case of emergency.

From the perspective of brand marketing, orange-red can become a brand's iconic color. Take, for example, one well-known brand of vitamin supplements. Its persistent use of orange-red blister packaging makes consumers associate the brand with this color when they see it and enhances brand recognition and loyalty. This helps the brand take root in the highly competitive pharmaceutical market due to visual reinforcement.

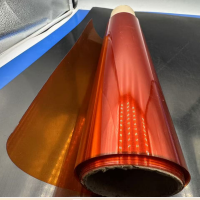

(II) Material Characteristics and Drug Protection

Barrier Properties

The barrier properties of drug blister packaging should be good to avoid the effects that oxygen, moisture, and microorganisms in the environment have on drugs.

(III) Application Scenarios and User Experience

Hospital Pharmacies

The orange-red packaging of drug blisters can let medical workers identify and distribute drugs rapidly in the hospital pharmacy.

Retail Pharmacies

In retail pharmacies, orange - red drug blister packaging attracts the attention of consumers and increases drug sales.

(IV) Environmental Protection and Sustainable Development

As environmental awareness gets enhanced, attention is paid to environmental friendliness concerning drug packaging. Orange - red drug blister packing is also being improved unceasingly in environmental protection. On the one hand, some companies have started making orange-red transparent blister packing from some biodegradable packing materials to promote environmental friendliness, such as the biodegradable plastics. These materials can be degraded slowly in nature and decrease the pollution of the environment. Besides, by optimizing packaging design, an enterprise can minimize the usage of materials in packaging and further improve the recycle rate. For example, by improving the structure of blister packaging, it can be made more compact to avoid waste of materials.

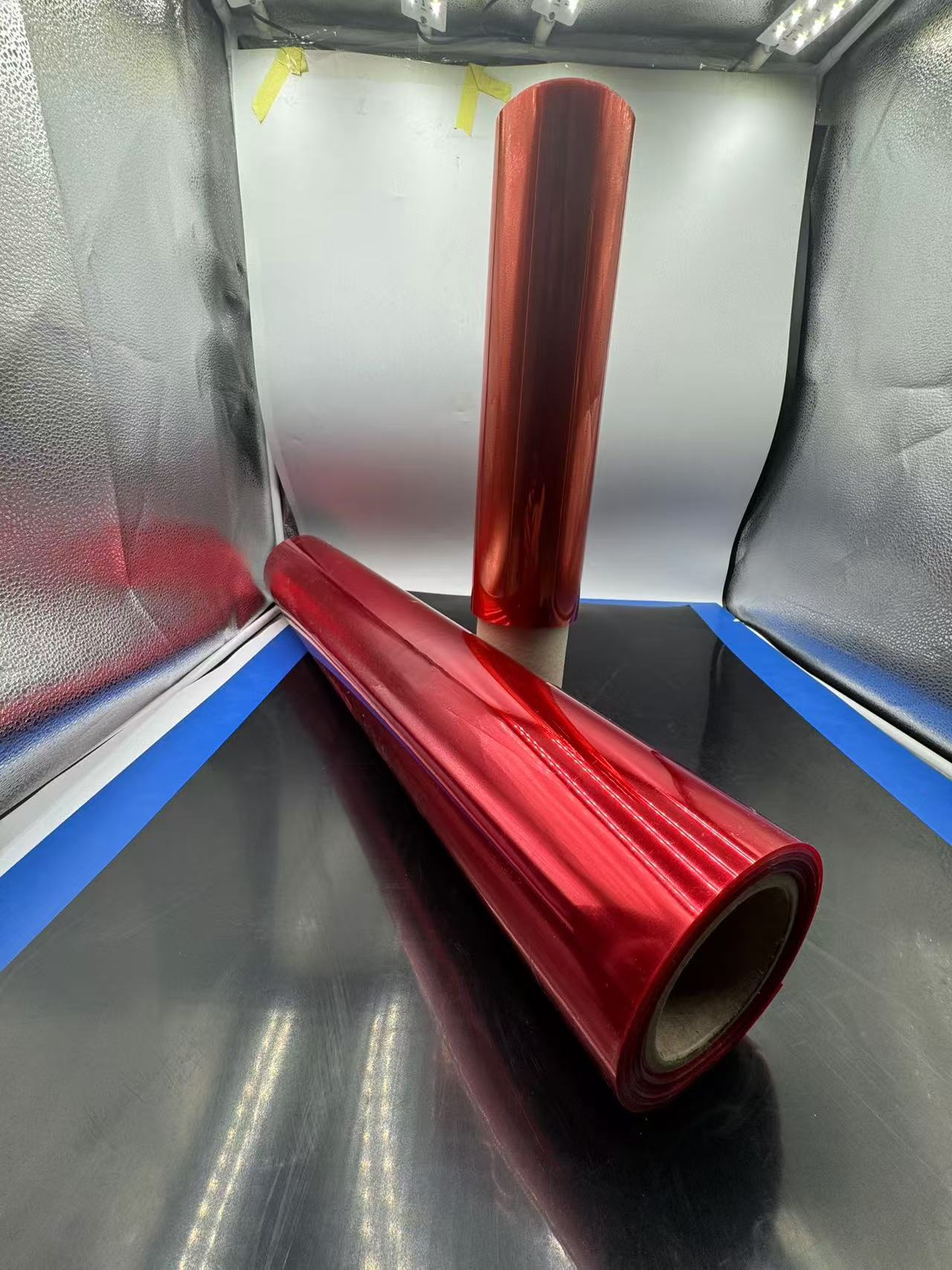

III. Battery Insulation Materials

(I) Electrical Insulation Performance

In other words, insulating material primarily performs good electrical insulation to hinder internal short circuits of the batteries. Commonly, a battery contains insulation isolation that separates both the positive and negative electrodes against each other, while current needs to travel a predesigned route. Most-applied materials nowadays as insulation diaphragms are polyethylene (PE) and polypropylene (PP) in lithium-ion batteries. These materials boast high resistance and can prevent the direct conduction of electrons, thus guaranteeing the normal operation of the battery. The electrical insulation performance of insulation materials directly influences the safety and stability of the battery. If the insulation performance is poor, it may lead to serious consequences such as overheating, fire, or even explosion of the battery.

(II) Chemical Stability

The inner chemical environment of the battery is relatively complex, and insulation materials must be resistant to erosion from inner chemical substances inside the battery. For instance, the electrolyte in a lead-acid battery is strongly acidic, and the insulation material should be able to maintain stability in such an acid environment without any possible chemical reaction. insulation materials commonly used in batteries, such as PTFE, possess superior chemical stability to withstand the corrosion of a wide variety of chemical substances so that the insulation performance of the battery will not be affected during long-term use. If insulation material has poor chemical stability, it may deteriorate internally in the battery, hence causing a decline in insulation performance and thus affecting the service life of the battery.

(III) Mechanical Properties

Moreover, other indispensable mechanical properties among battery insulation materials are those intended to make such materials stand mechanical stressors during the whole course of its manufacture and service. The resistance power to mechanical forces-stretch, squeeze, and perforation-is vital when insulating materials work during battery assembling. For example, when assembling the insulation diaphragm to the battery, the diaphragm should be flexible to a degree and fit all the components inside the battery in close contact but at the same time should show some strength sufficient to prevent rupture throughout the operation process. In the use of batteries, especially in some use scenarios with large vibrations, such as battery packs for electric vehicles, insulation materials need to bear stress brought about by such vibrations and maintain structural integrity to ensure that insulation performance is not affected.

(IV) Application Scenarios

Electric Vehicles

In electric vehicles, the performance of battery insulation materials is directly related to the safety and reliability of the vehicle. Generally, the battery packs of electric vehicles are made up of many modules, and there should be good insulation isolation between each module. For example, high-performance insulation materials are used in electric vehicles produced by Tesla to ensure safe operation of the battery pack under the condition of high voltage and great current. The quality and performance of the insulation materials play a very important role in avoiding internal short circuits in the battery pack, increasing the energy density of the battery, and prolonging its service life.

Portable Electronics Another important insulation material is used in batteries for portable electronic devices such as mobile phones and tablet computers. Most of these batteries are small in size, slender, yet high in energy density, and their requirements for insulation performance can also be very high. Advanced insulation materials are used in the iPhone, for example, to make sure that within this narrow space, the battery will work safely and stably. For portable electronic devices, miniaturization and multi-functionality require insulation materials with good electrical insulation performance and characteristics of light weight, thinness, and flexibility. Energy Storage Systems In the energy storage system for renewable energy sources such as solar and wind energy, insulation materials of batteries also have an important role. Normally, the energy storage system requires a huge amount of electrical energy for a very long time, while the safety and stability requirements would be very high for the battery. For example, in the energy storage battery packs of large-scale solar power plants, a multi-layer insulation structure is adopted, and high-performance insulation materials are used to prevent short-circuits and leakage during the charging and discharging process of the battery, ensuring the reliable operation of the energy storage system.

(V) Development Trends

Along with the continuous progress of science and technology, the battery insulation materials are also developing continuously. On one hand, researchers are developing new types of insulation materials to meet the increasingly demanding requirements for battery performance. For instance, some new nanocomposites have excellent electrical insulation performance, chemical stability, and mechanical properties, and are expected to become the mainstream of future battery insulation materials. On the contrary, with the development of battery technology, insulation materials' performance requires continuous improvement. For instance, when improving the cruising ranges of electric vehicles, the requirement for energy density is getting higher and higher. This requires insulation materials to provide better insulation performance at thinner thicknesses while possessing higher heat resistance and chemical corrosion resistance.

IV. Conclusion

Although the application fields of orange-red drug blister packaging and battery insulation materials are different, they are of equal importance in their respective fields. The orange-red drug blister packing provides powerful support for medication storage, transportation, and sales, with its unique appearance, good material properties, and attention to user experience. On the other hand, insulation materials for batteries guarantee safe and stable operations of batteries with excellent electrical insulation

performance, chemical stability, and mechanical properties, which promote the development of electric vehicle, portable electronic device, and energy storage system fields. While science and technology are constantly developing, and social needs are changing, these two materials will continue to innovate and develop for more convenience and safety guarantees in our lives and industrial production. They will continuously play a very important role in medicine and energy-related fields, contributing to the development of related industries

Within 15-20 days after received payment...more