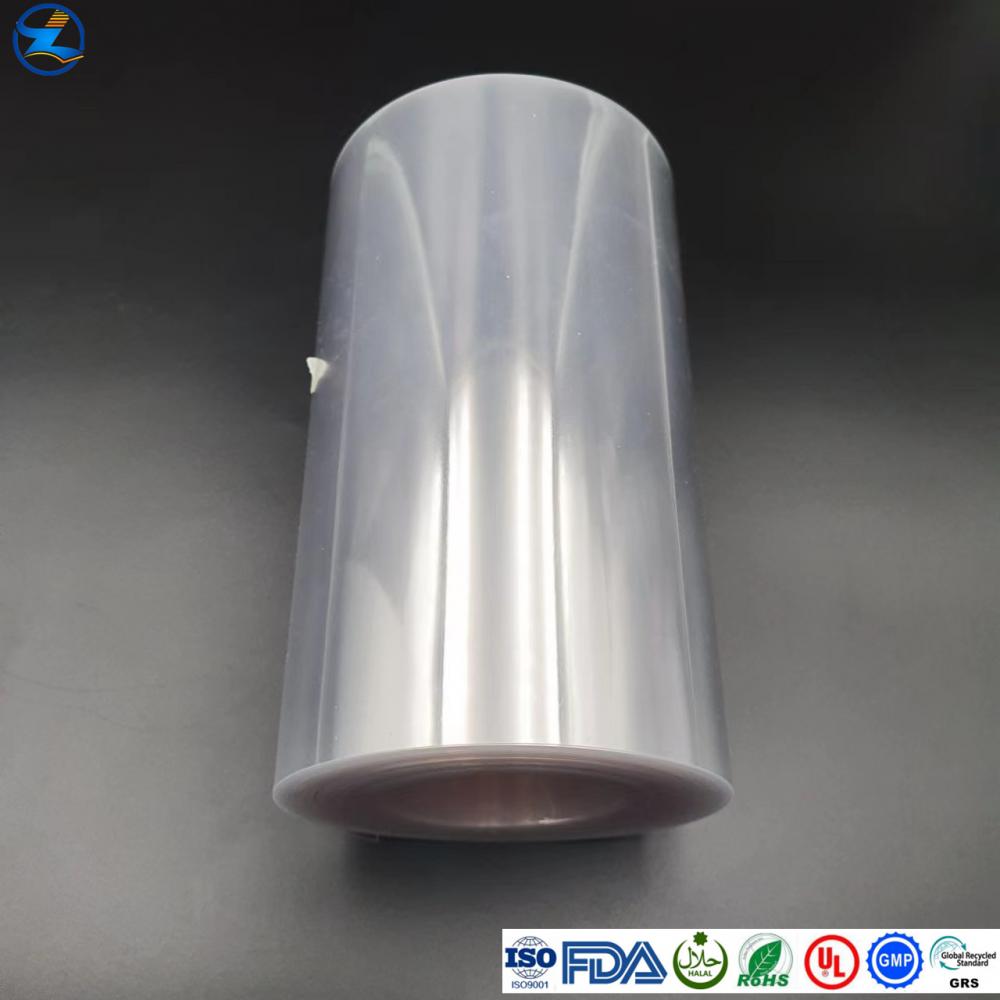

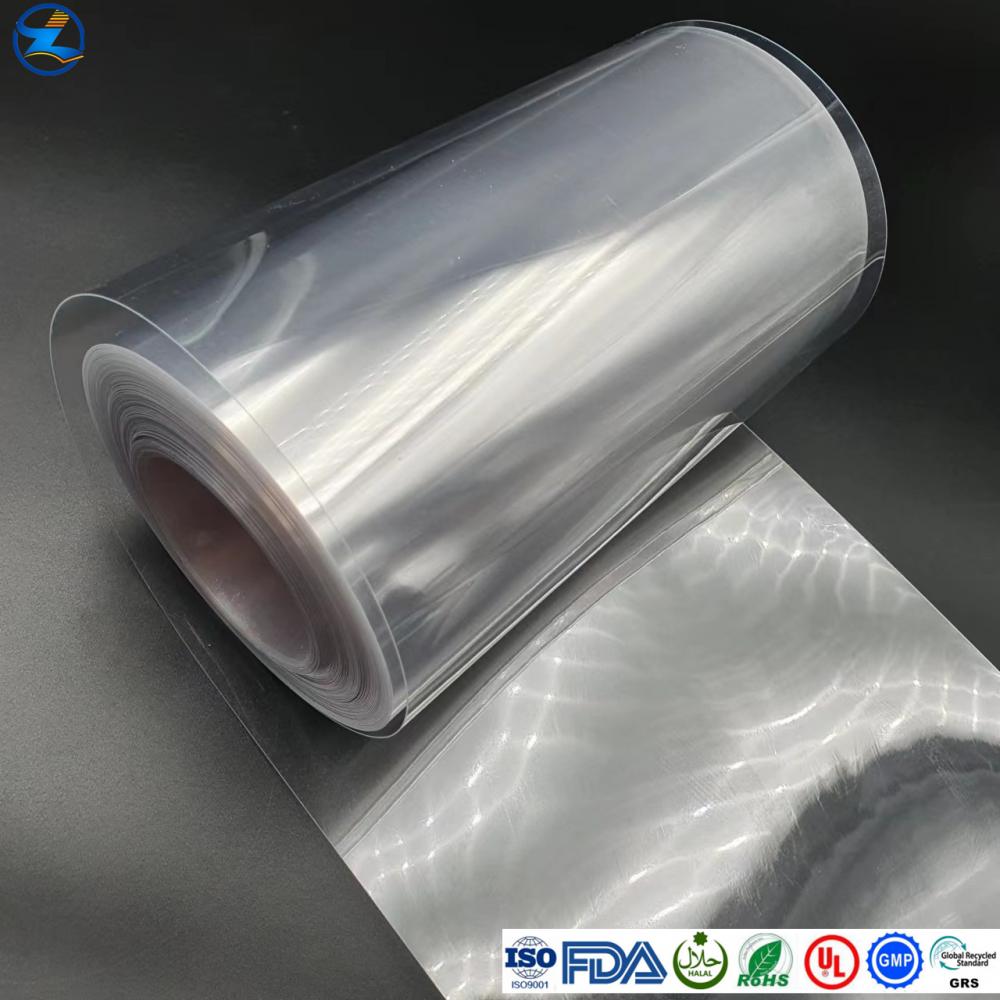

PVC plastic medical blister film

High transparency is essential for medical applications where visual inspection is necessary. PVC films can be made highly transparent through specific formulations.

- TOP LEADER

- CHINA

- 7-15 Working days

- 5000t/Month

- Information

Product description

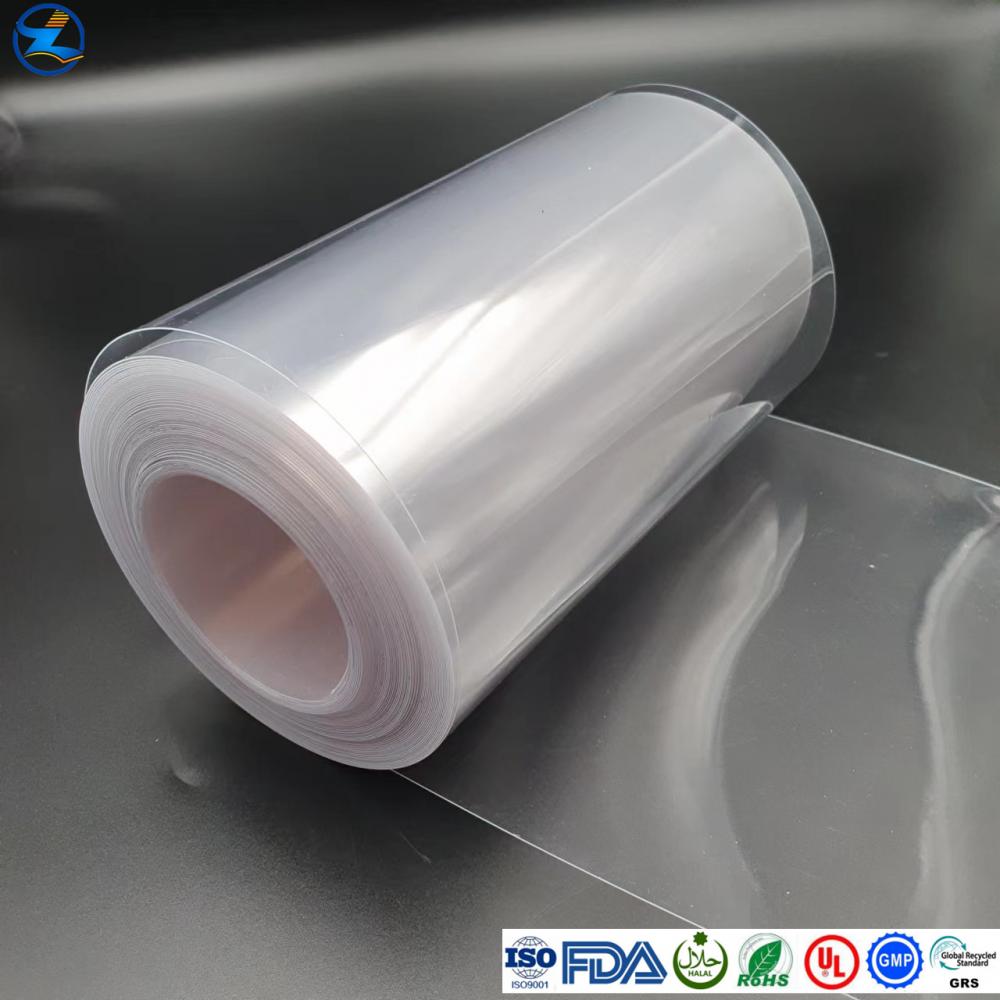

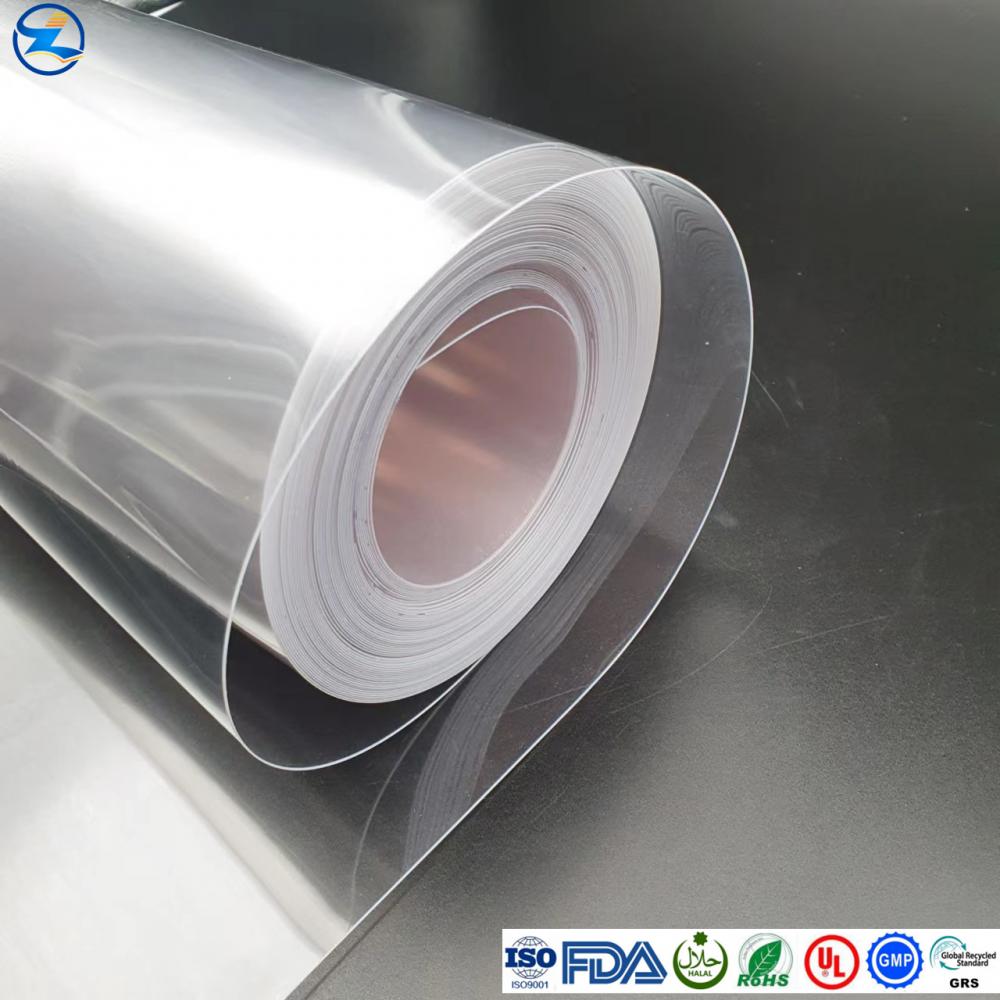

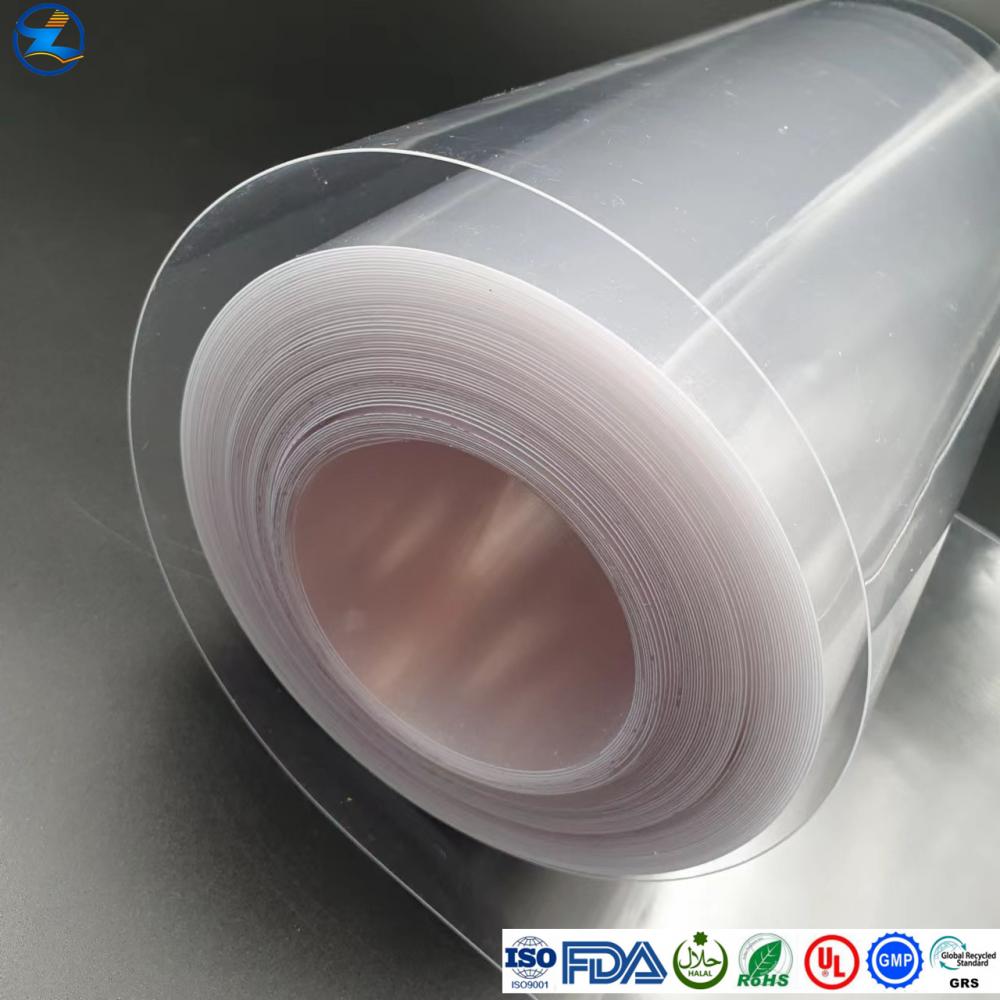

PVC (Polyvinyl Chloride) medical plastic films are widely used in various healthcare applications due to their unique properties, such as transparency, flexibility, and chemical resistance. These films play crucial roles in medical procedures, packaging, and devices. Here is an overview of the key specifications for PVC medical plastic films:

1. Material Composition

- Base Material: PVC, which is a thermoplastic polymer made from polyvinyl chloride.

2. Thickness

- The thickness can vary widely depending on the intended application, typically ranging from 0.01mm to 0.3mm or more.

3. Transparency

- High transparency is essential for medical applications where visual inspection is necessary. PVC films can be made highly transparent through specific formulations.

4. Strength and Durability

- Tensile Strength: Determines how much force the film can withstand before breaking.

- Elongation at Break: Measures the film's ability to stretch before breaking.

- Flexural Strength: Important for maintaining shape under bending forces.

5. Chemical Resistance

- PVC films are known for their good resistance to many chemicals, which is crucial in medical settings where they might come into contact with various substances.

6. Biocompatibility

- PVC films should meet biocompatibility standards to ensure they do not cause adverse reactions when in contact with human tissues or fluids.

7. Sterilization Compatibility

- Films must be able to withstand common sterilization processes, including ethylene oxide, gamma radiation, and steam autoclaving.

8. Printing and Lamination

- PVC films can be printed on one or both sides using various techniques to add identification, instructions, or other information. They can also be laminated with other materials for added strength or barrier properties.

9. Packaging and Sterilization Indicators

- Some PVC films include features that change color upon exposure to heat or radiation, indicating whether the packaging has been properly sterilized.

Get the latest price? We'll respond as soon as possible(within 12 hours)