0097The Multifaceted Applications of PVC Shrink Calendered Film

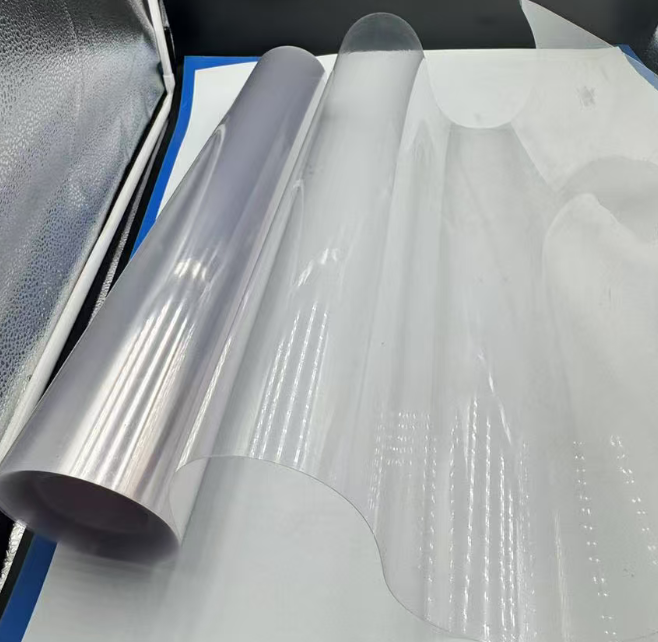

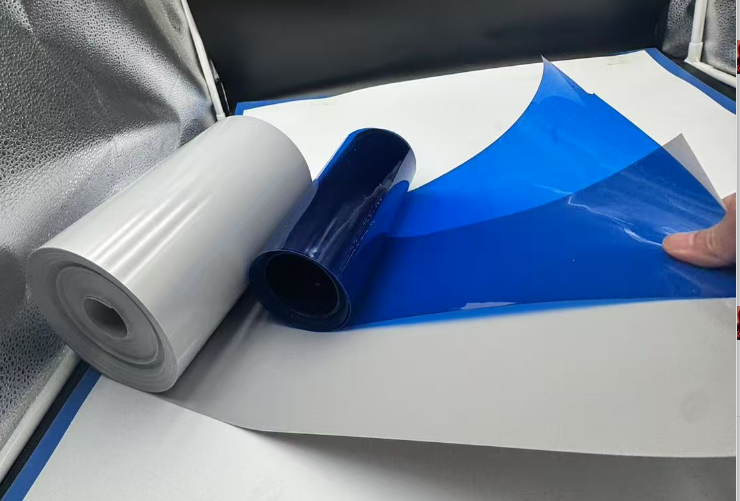

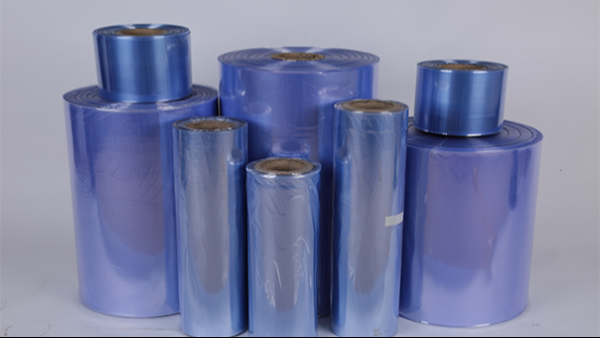

Material: PVC ROLL

Thickness 0.45-0.018mm-customization

Size: 80MM/130MM/Customization

GRADE:High impact grade film

color: white/ customization

location: china

Usage: for wall ,floor protection, wall paper printing ,engineering film

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

The Multifaceted Applications of PVC Shrink Calendered Film

Introduction

In the world of packaging, few materials have reached such a level of versatility and utility as that of PVC, or Polyvinyl Chloride, shrink calendered films. Owing to their tight conformance to products when heat is applied, these films have gained a leading position in many industries on account of their cost-effectiveness, durability, and aesthetic appeal. This article covers broad usages, ranging from a deep explanation of the benefits and manufacturing process to the myriad ways it enhances presentation, protection, and sustainability for a wide array of products.

Chapter 1: Understanding PVC Shrink Calendered Film

1.1 What is PVC Shrink Calendered Film?

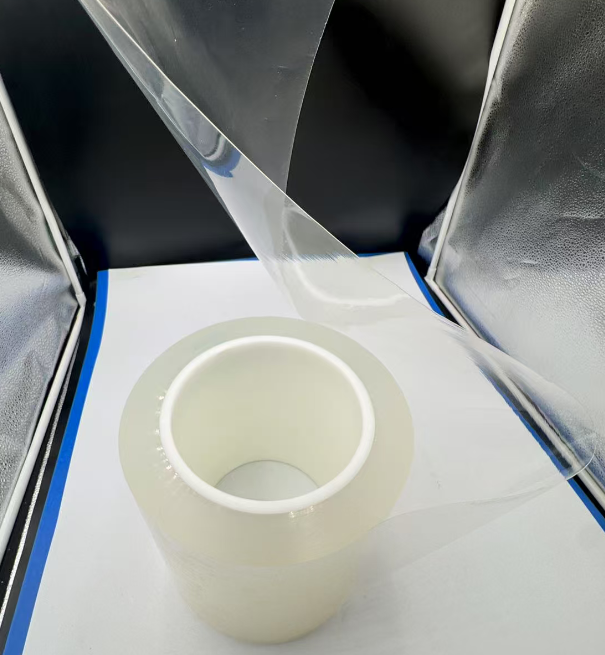

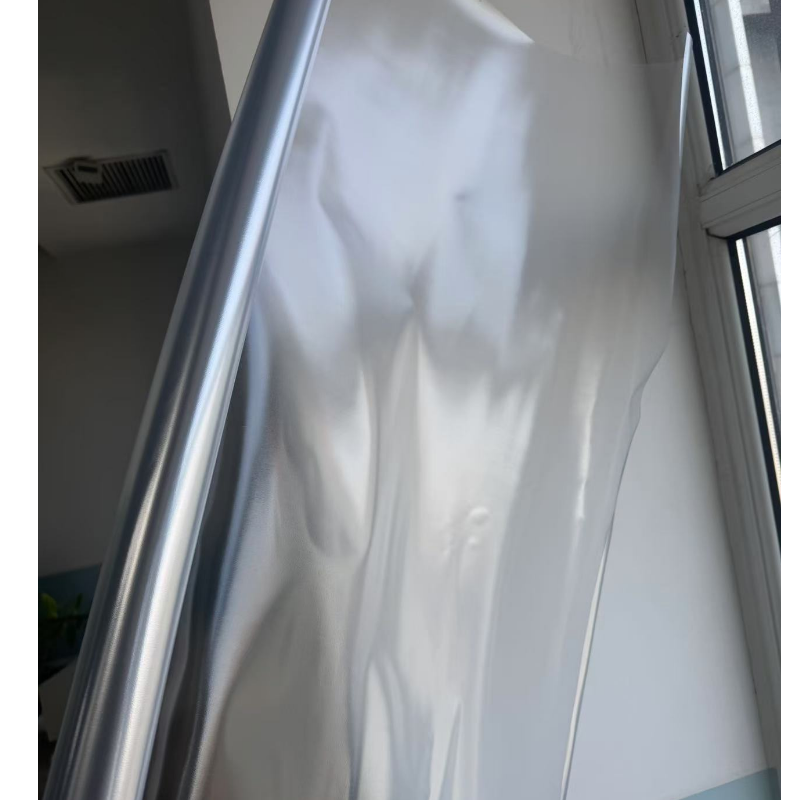

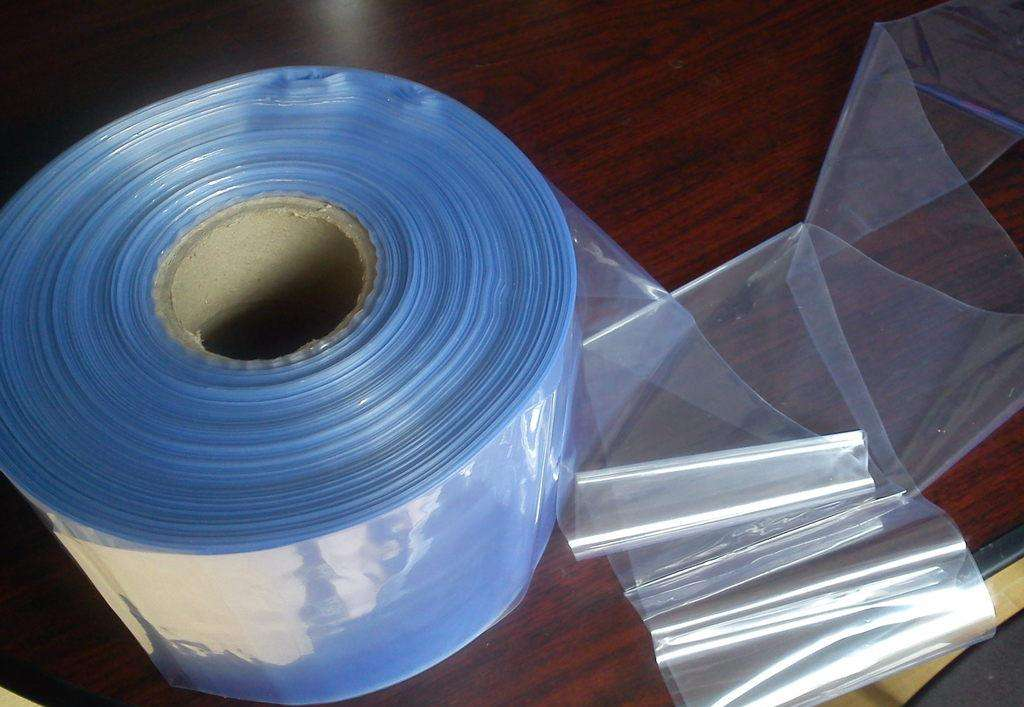

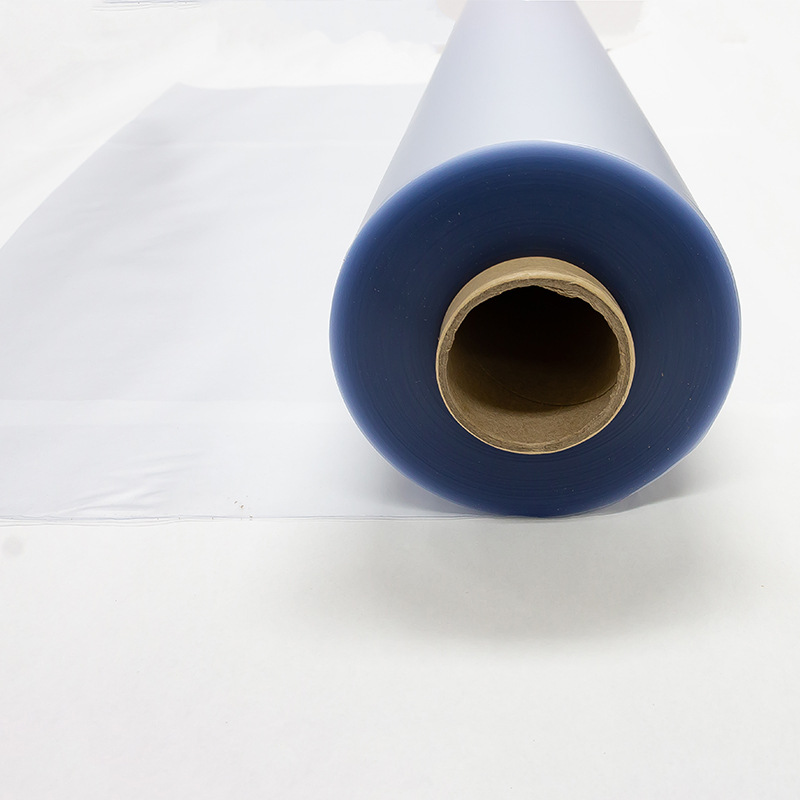

PVC shrink calendered film is a kind of plastic packaging material made from polyvinyl chloride and processed through a technique called calendering, where the PVC is melted and passed through a set of rollers to attain the required thickness and texture. When heated, the film shrinks tightly to wrap the product for protection in an appealing way. 1.2 Manufacturing Process

The production involves the following steps:

Compounding: a mixture of PVC resin with selected stabilizers, plasticizers, and other additives. Calendering: heating the mixture and then passing it through a series of heated rollers to achieve the desired thin, uniform sheet. Orientation: Stretching the film in one or both directions to provide the capability for the film to shrink back to its original dimensions when subsequently heated. Cooling and Winding: the film is cooled and then wound into rolls for distribution. 1.3 Key Properties

Shrinkability: It can shrink up to 50-60% in one or both directions; thus, it can keep products tightly wrapped.

Clarity: It allows excellent clarity, which is important for product visibility.

Tensile Strength: Resists tears, punctures, and environmental breakdown.

Printability: Can be printed on with branding and information.

Cost: It is cost-effective against other alternatives such as polyolefin.

Chapter 2: Food and Beverage Applications

2.1 Bottled Beverages

PVC shrink films find wide applications in the bottling industry for labeling and bundling bottles, especially within the beverage segment. They provide perfect contour labels that improve branding and prevent tampering.

2.2 Food Packaging

From deli meats to cheeses, PVC shrink film is used to seal food items for extended shelf life by limiting exposure to air and bacteria. It's particularly popular in packaging multi-packs of items like sausages or cheese slices, where visibility and hygiene are paramount.

2.3 Case Study: Wine and Spirits

In the wine industry, PVC shrink film is wrapped around bottle necks for tamper evidence or over the whole bottle for promotion or to indicate special editions. Besides securing the seal, this adds a touch of luxury and class to the product presentation.

Chapter 3: Industrial and Commercial Applications

3.1 Electronics

The films are used in bundling cables, insulation of components, and packaging of small electronics such as remote controls and chargers. They provide protection against dust, moisture, and physical damage in shipment.

3.2 Construction

In construction, the films wrap materials such as pipes or hardware to protect them from weather elements and ensure they reach the site in good condition.

3.3 Stationery and Office Supplies

For everything from pens to notebooks, PVC shrink film can package either sets or singles, professionally and safely.

Chapter 4: Health and Pharmaceuticals

4.1 Medical Devices

For everything from syringes to catheters, PVC shrink films provide sterile, tamper-evident packaging. Their clarity is critical in ensuring visual inspections of the contents.

4.2 Pharmaceuticals

The application of PVC films in pharmaceutical products, mainly for unit-dose packaging, protects each dose and makes it identifiable, thereby improving patient safety and compliance.

Chapter 5: Consumer Goods and Retail

5.1 Cosmetics

Cosmetics use PVC shrink film for the packaging of several products together in a set or for holding an individual product such as lipsticks or mascara, creating an appealing professional appearance that prevents damage to the product.

5.2 Toys and Games

In the case of toys, especially those with several components, PVC shrink wrap keeps parts together to avoid loss or damage in transit or storage.

5.3 Retail Bundling

Retailers use PVC shrink film for product bundling in promotions such as buy-one-get-one-free, where visibility of the product is important for consumer appeal.

Chapter 6: Environmental and Sustainability Considerations

6.1 Recycling Challenges

While PVC is recyclable, the presence of additives such as plasticizers complicates the process. However, there are specialized facilities for the recycling of PVC that reduce landfill waste.

6.2 Regulatory Compliance

In many regions, regulations on the use of PVC in packaging are tightening due to environmental concerns. This has spurred innovation in the production of PVC film to make it greener, such as reducing harmful additives.

6.3 Alternatives and Future Directions

The industry is venturing into alternatives such as biodegradable plastics or switching to other materials like polyolefin for specific uses due to the environmental effects of PVC. Nevertheless, improvements in recycling technology may also continue to make PVC a very important component.

Chapter

7: Technical Developments and Innovations

7.1 Value Addition

Newer PVC shrink films could offer UV inhibitors for outdoor applications, anti-static properties for electronic components, or even antimicrobial surfaces for medical applications.

7.2 Intelligent Packaging

Incorporating technologies such as QR codes or NFC tags into the PVC shrink labels could provide customers with further information on the product and thus enhance the customer shopping experience.

Chapter 8: Market Dynamics and Future Outlook

8.1 Market Growth

The increasing need for efficient, attractive, and low-cost packaging solutions, such as PVC shrink films, has been driving the demand from consumer goods, pharmaceuticals, and food industries.

8.2 Packaging Trends

There is a trend towards bespoke packaging solutions where PVC films can be tailored in color, thickness, and shrink properties to meet specific branding or functional needs.

8.3 Global Expansion

As emerging markets develop their manufacturing sectors, the usage of PVC shrink film is set to expand particularly in regions that place a high value on cost-effective packaging solutions.

Conclusion

Due to its unique combination of functionality, aesthetics, and cost, PVC shrink calendered film remains a very important material in modern packaging. Applications range from securing food freshness to adding luxury appeal to wine bottles and providing tamper-proof packaging for pharmaceuticals. In the face of growing environmental concerns, however, the industry will have to adapt by focusing on recycling innovations and exploring biodegradable alternatives. It was a future that balanced the now-institutional uses of PVC shrink film with demands for sustainability at the door. Continuous satisfaction of consumers' and various industries' changing needs worldwide-what a demanding task.

Within 15-20 days after received payment...more