Unveiling the Wonders of PVC Wear Layers: Revolutionizing Wallpaper, Floor Protection, and Flooring

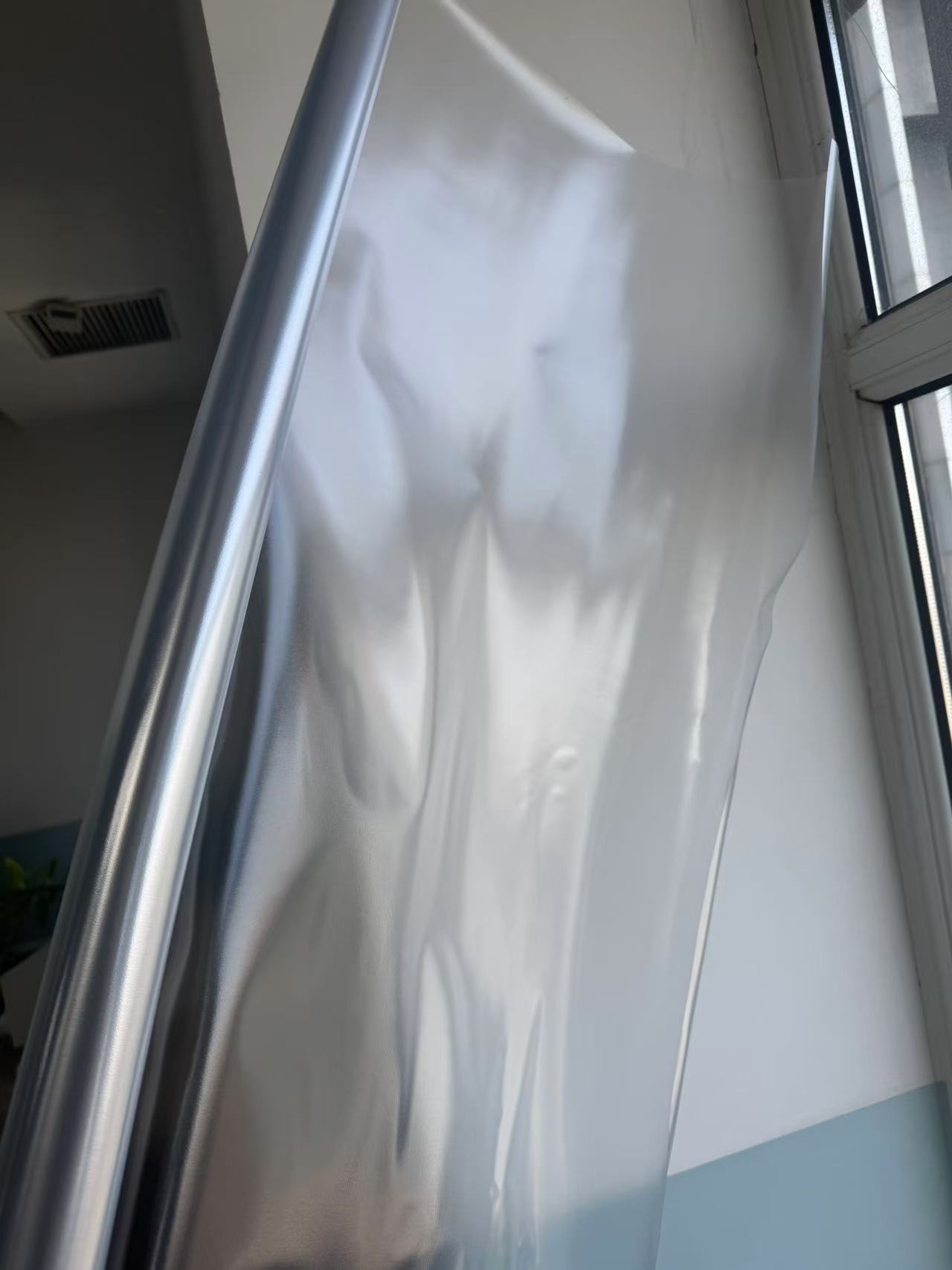

PVC ROLL

Thickness 0.45-0.018mm-customization

Size: 80MM/130MM/Customization

GRADE: pharma grade film

color: white/ customization

location: china

Usage:enhancing the longevity and aesthetic appeal of wallpapers, protecting floors during and after construction, and in the manufacturing of various flooring types. This extensive article delves into the intrinsic qualities of PVC wear layers and their multifaceted applications.

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Introduction

Polyvinyl Chloride (PVC) wear layers have revolutionized the way we think about durability in interior design and construction. Known for their robustness, these layers are pivotal in enhancing the longevity and aesthetic appeal of wallpapers, protecting floors during and after construction, and in the manufacturing of various flooring types. This extensive article delves into the intrinsic qualities of PVC wear layers and their multifaceted applications.

Characteristics of PVC Wear Layers

1. Exceptional Durability:

Scratch Resistance: PVC films are engineered to resist scratches, crucial for high traffic areas where abrasion from shoes, furniture, or pets is common.

Impact Resistance: They possess a high degree of resilience against impacts, protecting the underlying material from damage caused by dropped objects or heavy use.

2. Chemical and Stain Resistance:

PVC layers are resistant to a broad spectrum of chemicals, making them ideal for spaces where cleaning chemicals or spills are frequent. This resistance extends the life of the product, keeping it looking new for longer.

3. Water Resistance:

Being inherently waterproof, PVC wear layers are perfect for environments prone to moisture, like kitchens, bathrooms, or outdoor areas, preventing water damage to the base materials.

4. UV Stability:

Many PVC wear layers are treated to resist UV degradation, ensuring that colors and patterns do not fade when exposed to sunlight, which is essential for both indoor and outdoor applications.

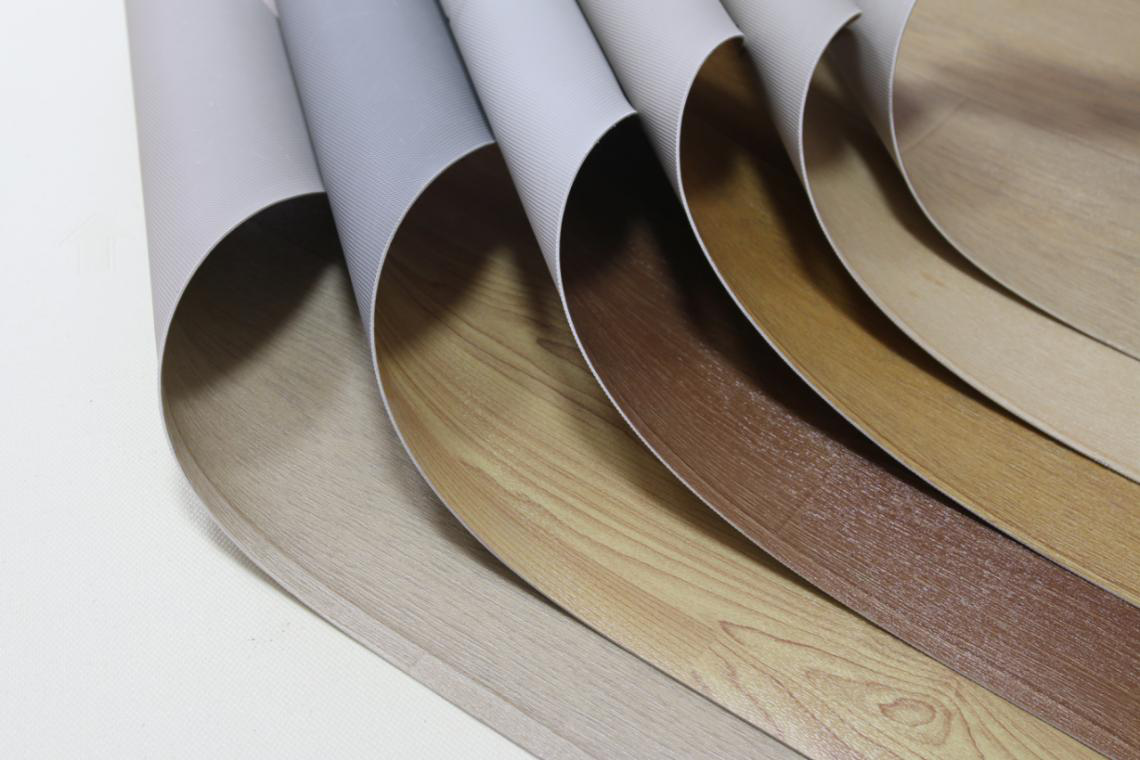

5. Flexibility and Conformability:

PVC films can adapt to various shapes and textures, providing a seamless appearance over complex surfaces, enhancing both functionality and aesthetics.

Applications in Wallpaper Manufacturing

Enhancing Visual Appeal:

PVC wear layers add a protective barrier to wallpapers, preserving the vibrancy of colors and patterns. They can also impart different finishes (e.g., matte, gloss), which can dramatically alter the mood of a room.

Longevity and Maintenance:

In environments where walls are frequently touched or cleaned, such as in hotels or hospitals, PVC-enhanced wallpapers maintain their integrity, reducing the need for frequent replacements.

Design Flexibility:

The durable nature of PVC allows for more creative and complex designs in wallpapers, from embossed textures to digital prints, without worrying about wear.

Floor Protection Applications

During Construction or Renovation:

PVC films serve as an excellent temporary shield for floors, protecting them from paint, construction debris, or heavy tools. They are easily applied and removed without leaving residues.

Permanent Protection in Commercial and Residential Spaces:

In areas where floors are subject to intense use, like shopping centers or homes with pets, PVC wear layers extend the life of flooring materials, reducing maintenance costs and enhancing safety by providing slip resistance.

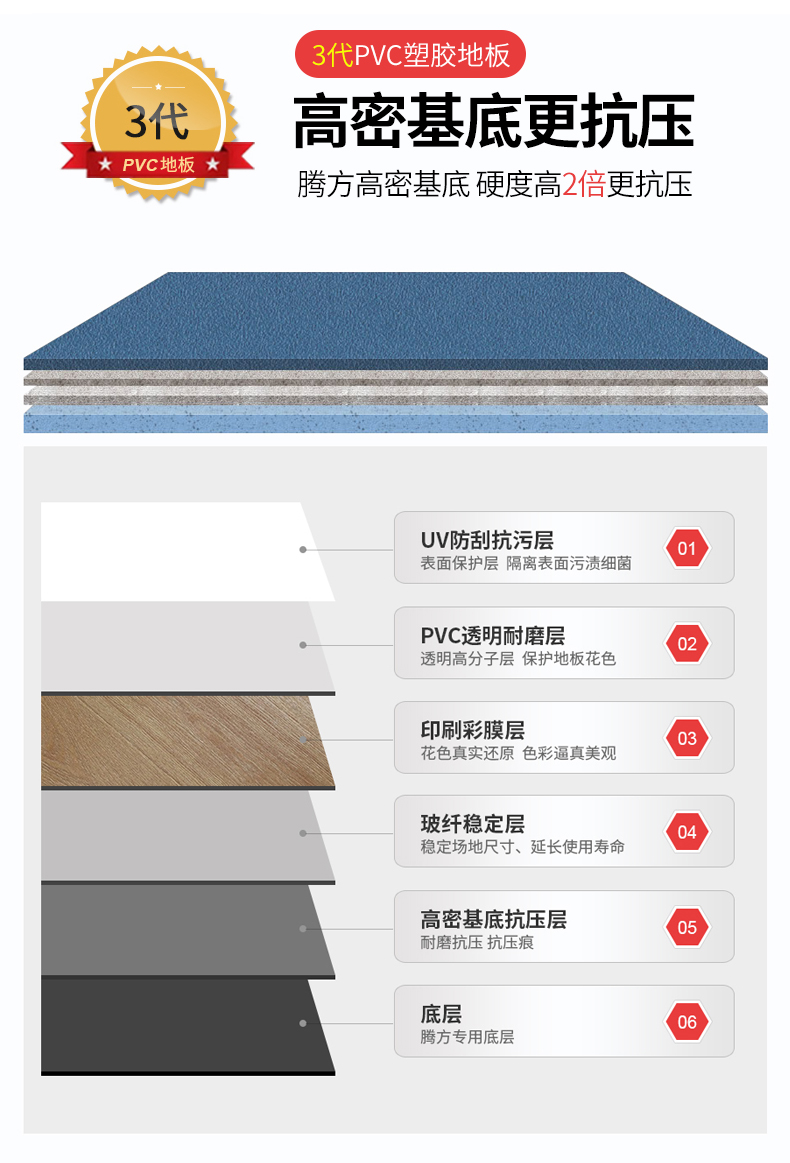

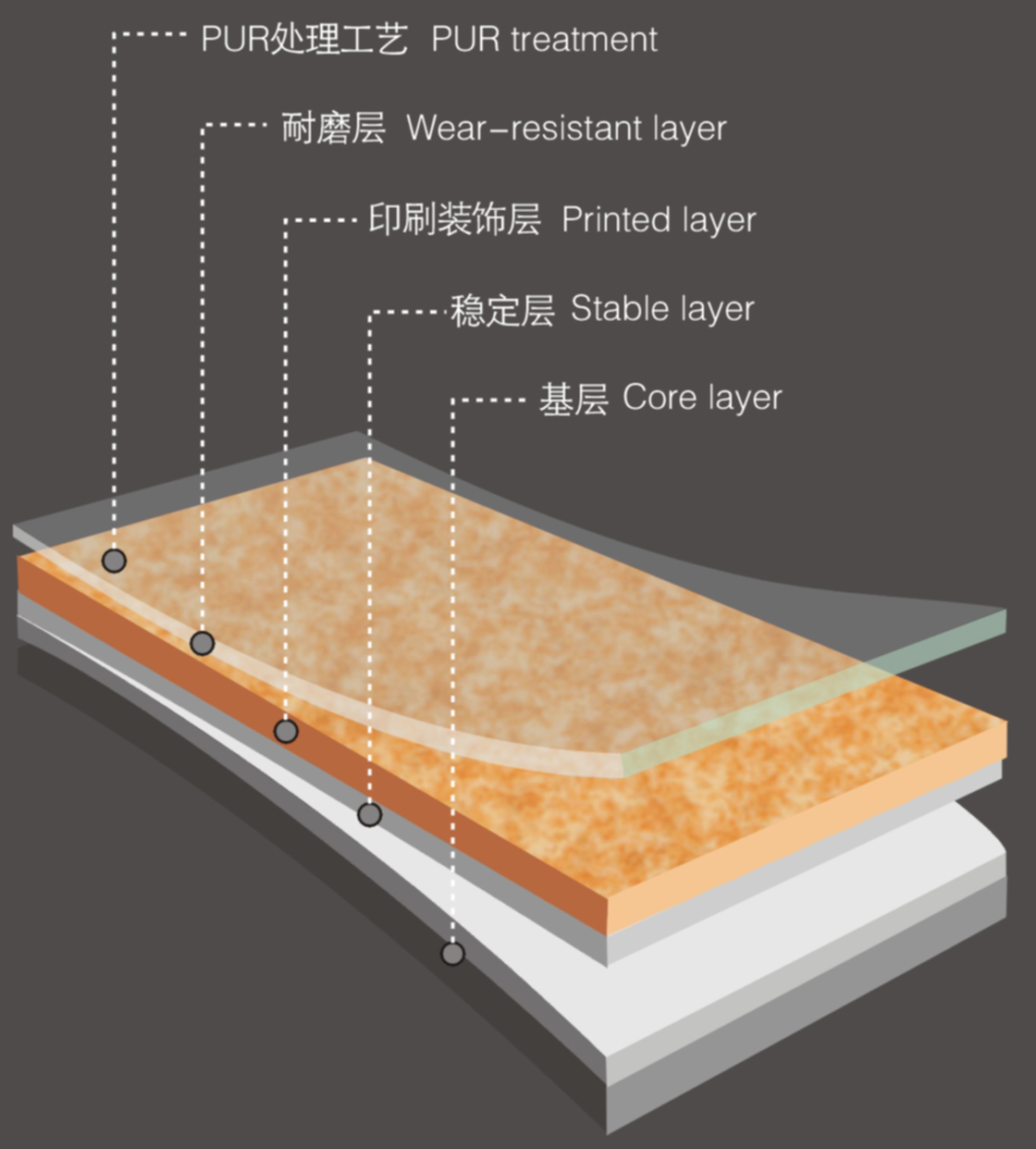

Flooring Manufacturing

Vinyl Flooring:

PVC wear layers are integral to vinyl flooring, where they provide the surface that faces daily wear. This layer ensures that the flooring looks good and functions well over time, even in high-traffic areas.

Laminate and Engineered Flooring:

Here, PVC layers not only offer protection but also contribute to the authenticity of the flooring's appearance by mimicking the texture of natural materials like wood or stone.

Sustainability Considerations:

While PVC has environmental concerns, advancements in manufacturing include recycled content and more eco-friendly production methods, aiming for sustainability without compromising on quality.

Conclusion

PVC wear layers have become a cornerstone in modern interior applications due to their versatility, durability, and aesthetic enhancement properties. From protecting delicate wallpapers to ensuring floors withstand the test of time, PVC films are indispensable in shaping environments that are not only visually pleasing but also practical and long-lasting. As technology evolves, we can anticipate even more innovative uses of PVC, further pushing the boundaries of what's possible in interior design and construction.

Within 15-20 days after received payment...more