Transparent PET Heat-Seal Film: Characteristics and Applications in Food Packaging

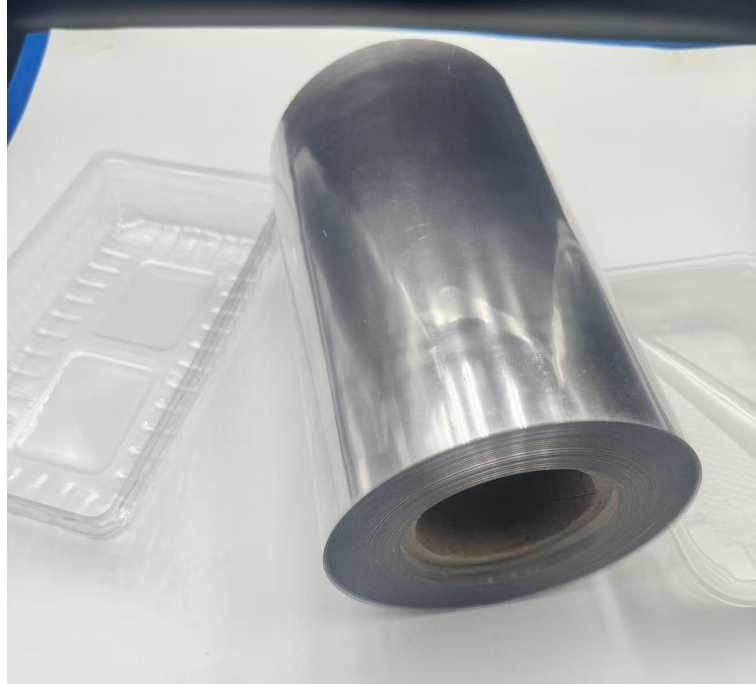

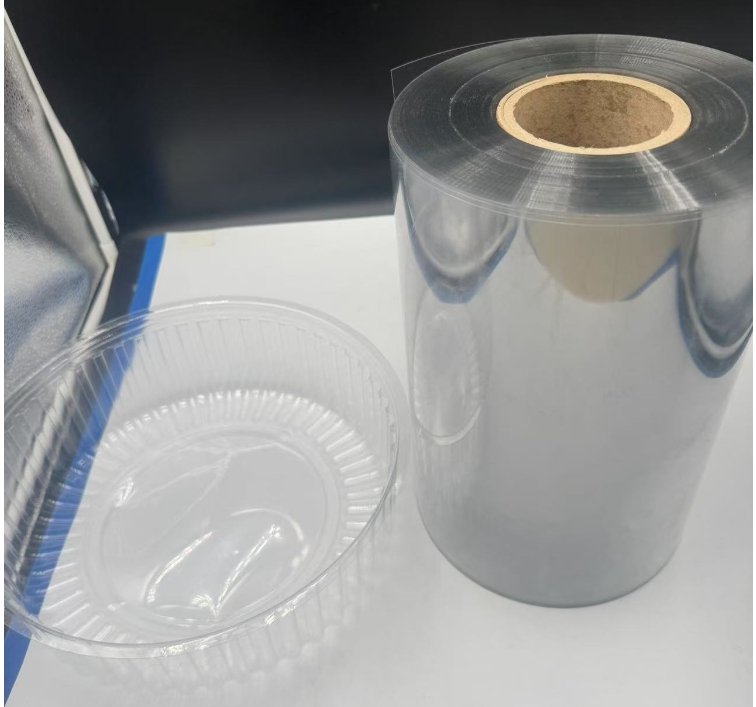

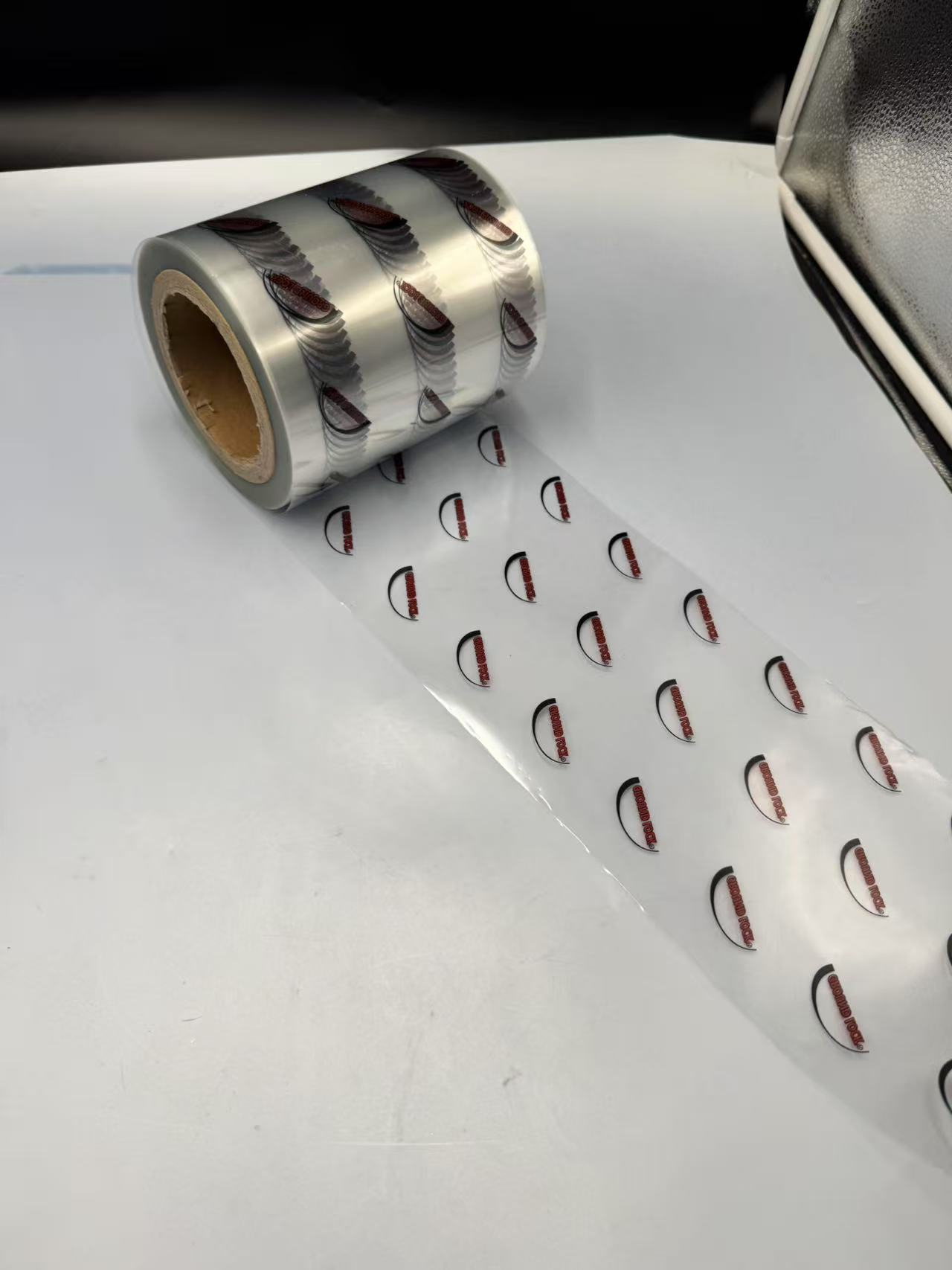

NamePETG film roll

SizeTk:0.012-0.023mm, h100-1200mm

MaterialPETG/Customized

Color/printingTransparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

UsageVegetable/Fruit/Meat

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

Introduction

In the fast-paced world of food packaging, where safety, freshness, and sustainability are paramount, transparent Polyethylene Terephthalate (PET) heat-seal film has emerged as a cornerstone technology.  Renowned for its clarity, strength, and sealing capabilities, this versatile material ensures that food products remain protected while appealing to consumers through visually stunning packaging. From ready-to-eat meals to perishable snacks, transparent PET heat-seal film plays a critical role in modern food preservation. This article explores the key characteristics of transparent PET heat-seal film and its transformative applications in food heat-seal packaging, highlighting why it is a preferred choice for manufacturers and consumers alike.

Renowned for its clarity, strength, and sealing capabilities, this versatile material ensures that food products remain protected while appealing to consumers through visually stunning packaging. From ready-to-eat meals to perishable snacks, transparent PET heat-seal film plays a critical role in modern food preservation. This article explores the key characteristics of transparent PET heat-seal film and its transformative applications in food heat-seal packaging, highlighting why it is a preferred choice for manufacturers and consumers alike.

Characteristics of Transparent PET Heat-Seal Film

1. Exceptional Clarity and Aesthetic Appeal

Transparent PET heat-seal film offers crystal-clear visibility, allowing consumers to view the packaged food in vivid detail. This optical clarity enhances product presentation, making it ideal for items like fresh produce, deli meats, or baked goods, where visual appeal drives purchasing decisions. The film’s glossy finish further elevates the premium look of packaged goods, aligning with modern consumer preferences for attractive, transparent packaging.

2. Robust Heat-Sealing Performance

The heat-seal layer of PET film, typically a co-extruded or coated amorphous PET (APET) or polyethylene (PE), enables strong, airtight seals when subjected to heat and pressure. This layer activates at precise temperatures (typically 120–180°C), forming a hermetic seal that prevents leaks and ensures product integrity. The film’s ability to bond with various substrates, such as PET trays, aluminum foils, or other plastics, makes it versatile for diverse packaging formats, including trays, pouches, and lidding films.

3. Superior Barrier Properties

Transparent PET heat-seal film provides excellent barrier protection against oxygen, moisture, and contaminants, which are critical for extending the shelf life of perishable foods. While standard PET films offer moderate oxygen and water vapor barrier properties (e.g., oxygen transmission rate of ~100 cm³/m²/day at 23°C), advanced versions incorporate coatings or co-extrusions, such as ethylene vinyl alcohol (EVOH) or silicon oxide, to achieve enhanced barriers (e.g., <10 cm³/m²/day). These properties safeguard food freshness and prevent spoilage, making the film suitable for sensitive products like dairy, meats, and snacks.

4. High Mechanical Strength and Durability

PET heat-seal film is renowned for its tensile strength and puncture resistance, ensuring that packaging remains intact during handling, transportation, and storage. With a tensile strength of approximately 200–250 MPa, the film withstands external pressures without tearing or deforming. This durability is particularly valuable for vacuum-sealed or modified atmosphere packaging (MAP), where the film must endure tight seals and internal pressure changes.

5. Thermal Stability and Processability

The PET substrate in heat-seal film exhibits excellent thermal stability, resisting deformation at sealing temperatures and maintaining structural integrity during processes like pasteurization or hot-filling (up to 85–95°C). This makes it compatible with a range of food processing techniques, from chilled to ambient storage. Additionally, the film’s smooth surface ensures consistent performance in high-speed sealing equipment, boosting production efficiency.

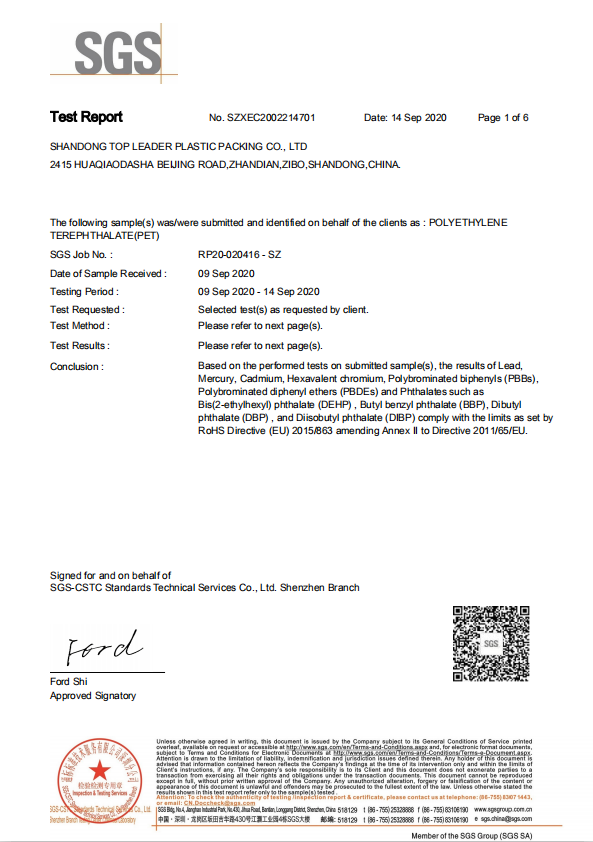

6. Food-Safe and Regulatory Compliance

Transparent PET heat-seal film is manufactured to comply with global food safety standards, such as those set by the U.S. Food and Drug Administration (FDA), European Food Safety Authority (EFSA), and China’s GB 9685 standards. The film is free from harmful substances like bisphenol A (BPA) and is certified for direct food contact. Its non-toxic nature and resistance to chemical migration ensure that packaged food remains safe for consumption.

7. Sustainability and Recyclability

As environmental concerns grow, transparent PET heat-seal film offers eco-friendly advantages. PET is one of the most recyclable plastics, with established recycling streams in many regions. Mono-material PET films, designed without complex laminates, enhance recyclability, aligning with circular economy goals. Additionally, lightweight PET films reduce material usage compared to traditional packaging, lowering the carbon footprint.

Applications of Transparent PET Heat-Seal Film in Food Packaging

The unique properties of transparent PET heat-seal film make it a versatile solution for a wide range of food packaging applications. Its ability to balance functionality, safety, and aesthetics has cemented its role in the food industry. Below are key applications in heat-seal food packaging:

1. Lidding Films for Ready-to-Eat Meals

Transparent PET heat-seal film is widely used as a lidding material for pre-prepared meals, such as microwaveable trays or oven-ready dishes. The film’s clarity showcases the meal’s contents, while its strong heat-seal properties ensure an airtight seal that preserves freshness. For example, a PET lidding film with an EVOH barrier layer can extend the shelf life of a pasta dish by preventing oxygen ingress, while its peelable seal allows for easy opening. The film’s thermal stability also supports microwave or oven heating, enhancing consumer convenience.

2. Vacuum and Modified Atmosphere Packaging

For perishable products like fresh meats, seafood, or cheeses, transparent PET heat-seal film is used in vacuum or MAP applications. The film’s high barrier properties maintain low oxygen levels, slowing microbial growth and oxidation. Its puncture resistance ensures that vacuum-sealed packages remain intact, even for sharp-edged products like bone-in meats. A retailer might use PET heat-seal film to package sliced deli meats, offering consumers a clear view of the product while ensuring a shelf life of up to 30–45 days under refrigeration.

3. Flexible Pouches for Snacks and Dry Goods

Transparent PET heat-seal film is a popular choice for stand-up pouches used in snacks, dried fruits, nuts, and cereals. The film’s clarity highlights the product’s texture and color, while its heat-seal layer ensures secure closure to prevent moisture ingress. For instance, a brand might use a PET/PE laminate film to package granola, combining PET’s strength and clarity with PE’s sealing properties. The film’s lightweight nature also reduces shipping costs, making it cost-effective for global distribution.

4. Fresh Produce Packaging

Transparent PET heat-seal film is ideal for packaging fresh fruits, vegetables, and salads, where visibility and breathability are critical. Perforated or anti-fog PET films prevent condensation, keeping produce visible and appealing. The film’s heat-seal properties allow for secure sealing of trays or bags, protecting delicate items like berries or leafy greens during transport. For example, a supermarket might use PET heat-seal film to package pre-washed salad mixes, ensuring freshness and hygiene while showcasing vibrant greens.

5. Dairy and Dessert Packaging

In dairy applications, such as yogurt, cheese, or desserts, transparent PET heat-seal film serves as a lidding material for cups and trays. Its clarity enhances the visual appeal of creamy yogurts or layered desserts, while its barrier properties protect against spoilage. The film’s peelable seals cater to consumer convenience, allowing easy access without compromising safety. A dessert brand might use PET heat-seal film to package tiramisu, ensuring a premium presentation and extended shelf life.

6. Sustainable Packaging Solutions

As brands prioritize sustainability, transparent PET heat-seal film supports eco-friendly packaging initiatives. Mono-material PET films, which eliminate the need for multi-layer laminates, are fully recyclable and compatible with existing PET recycling streams. For example, a snack brand might adopt a recyclable PET heat-seal film for its pouches, reducing environmental impact while maintaining product protection. Additionally, the film’s lightweight design minimizes material usage, aligning with zero-waste goals.

Practical Considerations for Using Transparent PET Heat-Seal Film

To fully leverage transparent PET heat-seal film in food packaging, manufacturers must address several practical considerations:

1. Selecting the Right Film Structure

The choice of PET heat-seal film depends on the food product, packaging format, and shelf-life requirements. For high-barrier needs, such as meat packaging, a PET/EVOH/PE laminate is ideal. For breathable produce packaging, perforated PET films are preferred. Manufacturers should consult with suppliers to select films with appropriate sealing layers and barrier properties.

2. Optimizing Heat-Sealing Parameters

Effective heat sealing requires precise control of temperature, pressure, and dwell time. Typical settings include 120–180°C, medium pressure, and 0.5–2 seconds, depending on the film and substrate. Testing on pilot equipment ensures optimal seal strength and peelability. Anti-fog coatings should be verified to prevent condensation in humid conditions.

3. Ensuring Food Safety Compliance

Manufacturers must verify that PET heat-seal films meet regulatory standards for food contact. Certificates of compliance, migration test reports, and supplier declarations should be obtained. Films should be stored in clean, dry conditions (15–25°C, 40–60% RH) to prevent contamination or degradation.

Within 15-20 days after received payment...more