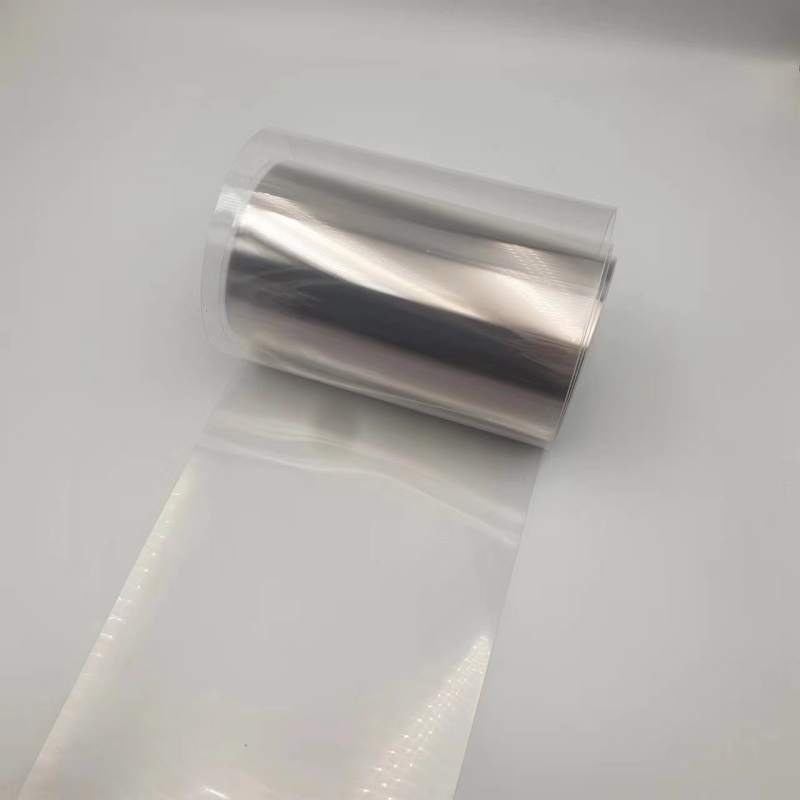

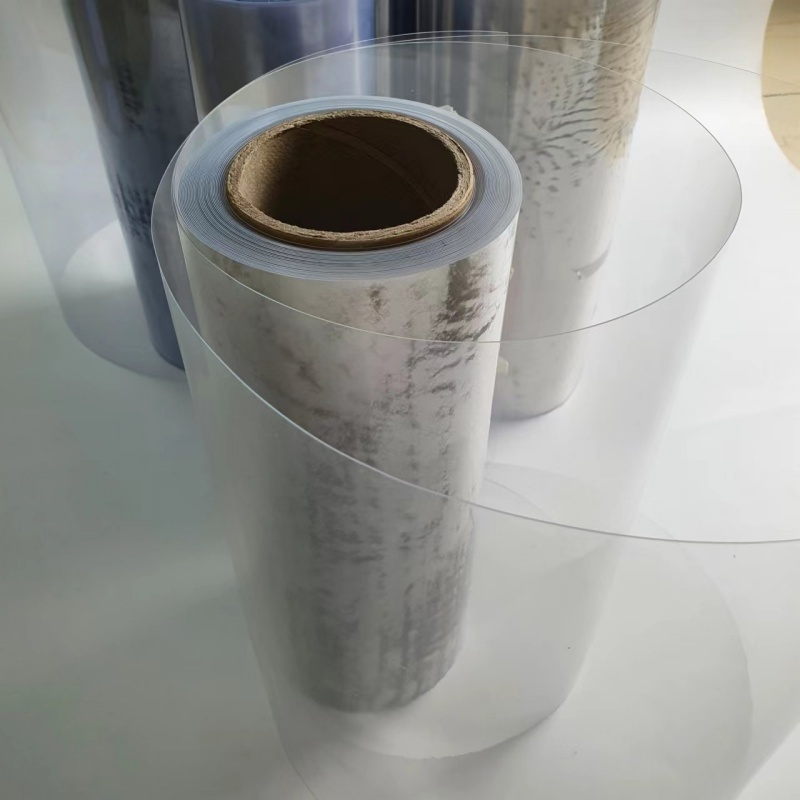

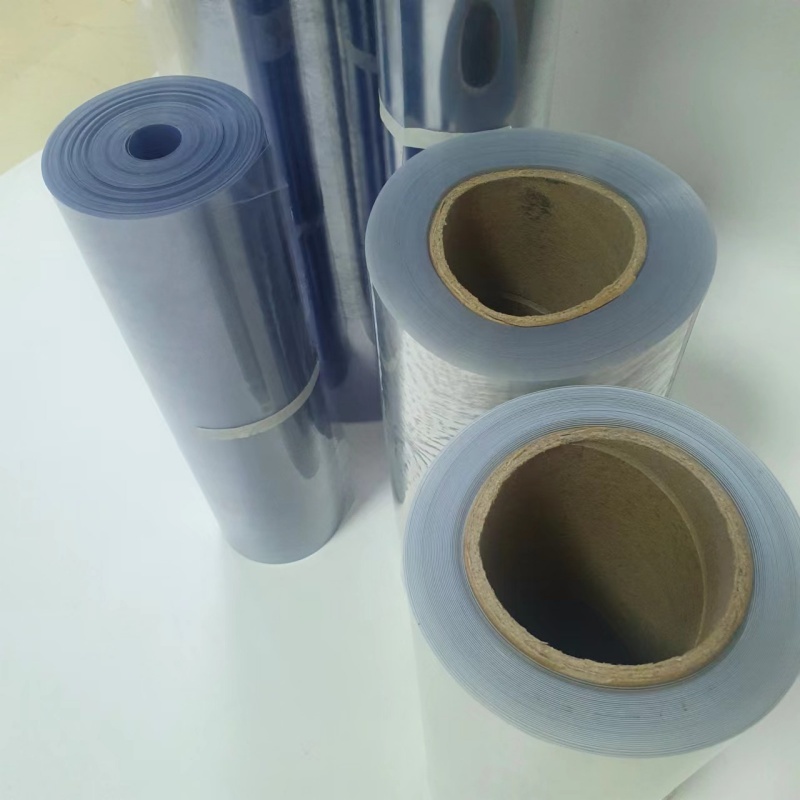

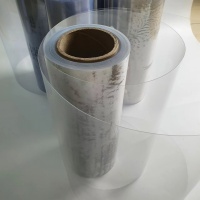

pvc film primary packaging glass clear

Transparent PVC medicinal hard sheet for PTP aluminum foil composite

Good transparency: can clearly display the appearance, shape, color, etc. of the drug, which is convenient for patients and medical staff to identify the drug, and is also conducive to the quality inspection and supervision of the drug.

- top leader plastic

- China

- 15 business days

- 1500 tons/month

- Information

Transparent PVC medicinal hard sheet for PTP aluminum foil composite

Good transparency: can clearly display the appearance, shape, color, etc. of the drug, which is convenient for patients and medical staff to identify the drug, and is also conducive to the quality inspection and supervision of the drug.

Suitable mechanical properties: It has certain strength and toughness. During packaging, transportation, storage and use, it can withstand certain pressure and impact force to protect the drug from damage, and at the same time it is convenient for patients to press the blister to take out the drug.

Excellent heat sealing performance: It can be well heat-sealed with PTP aluminum foil under certain temperature, pressure and time conditions to form a sealed packaging space, effectively blocking the outside air, moisture, light, etc., to prevent the drug from getting damp, oxidized, and deteriorating, and extend the shelf life of the drug.

Chemical stability: It is chemically inert to most drug ingredients and will not react chemically with the drug, ensuring the quality and safety of the drug.

High surface finish: The surface is flat and smooth, without defects such as bubbles, cracks, scratches, etc., easy to print and mark, and can clearly print the drug name, specifications, production date, expiration date and other information.

Cutting and slitting: According to the actual packaging needs, the cooled and shaped PVC hard sheet is cut and slid into suitable sizes and specifications for subsequent composite packaging with PTP aluminum foil.

Quality inspection: The transparent PVC medicinal hard sheet produced is subjected to comprehensive quality inspection, including appearance inspection, thickness measurement, tensile strength test, heat sealing performance test, transparency test, solvent residue test, etc., to ensure that the hard sheet meets the quality standards of medicinal packaging materials and relevant regulatory requirements.

Application in pharmaceutical packaging

Blister packaging: It is the main form of composite application of transparent PVC medicinal hard sheet and PTP aluminum foil. Through heating vacuum forming or cold stamping forming, the PVC hard sheet is made into a groove suitable for the shape of tablets, capsules and other drugs. After filling the drug, it is heat-sealed with PTP aluminum foil to form an independent sealed blister, which is convenient for the storage, transportation and use of drugs, and has good display effect and anti-counterfeiting performance.

Within 15-20 days after received payment...more