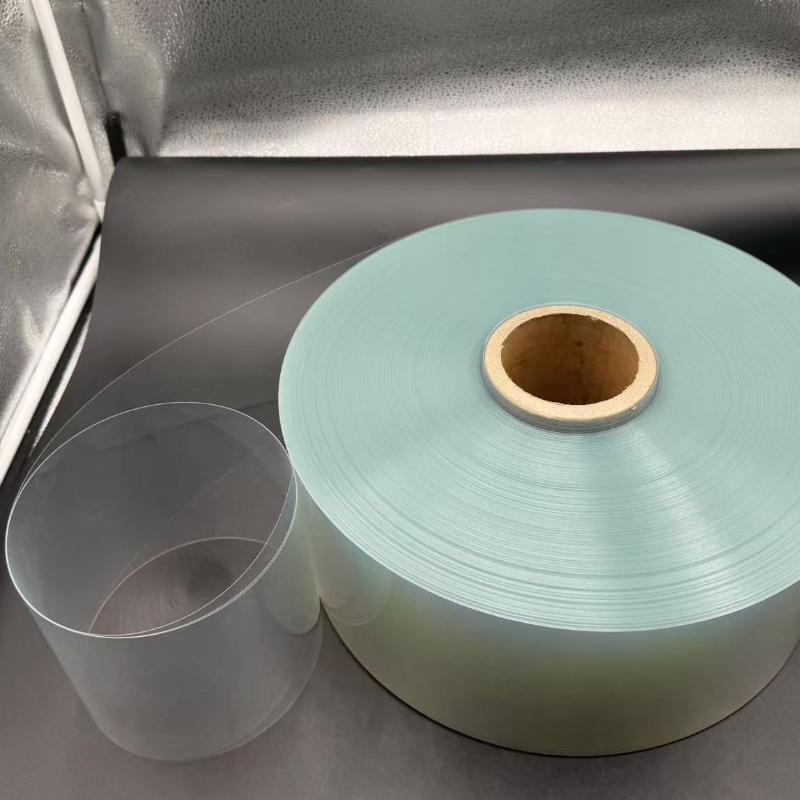

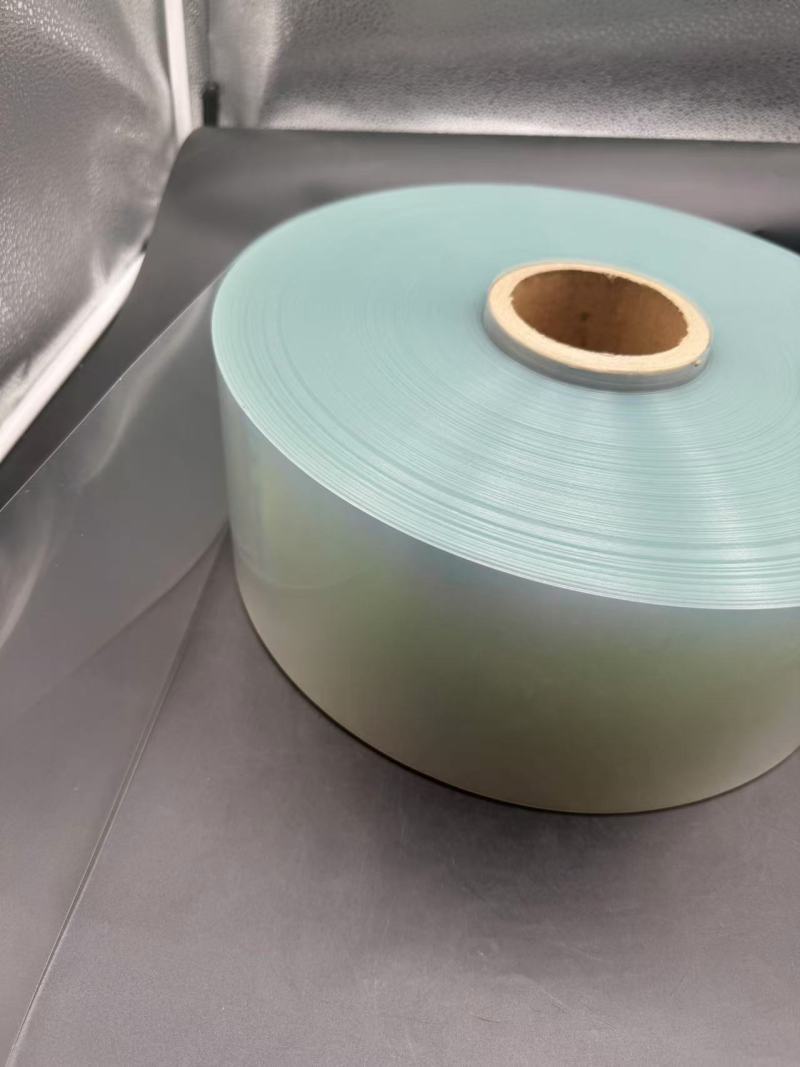

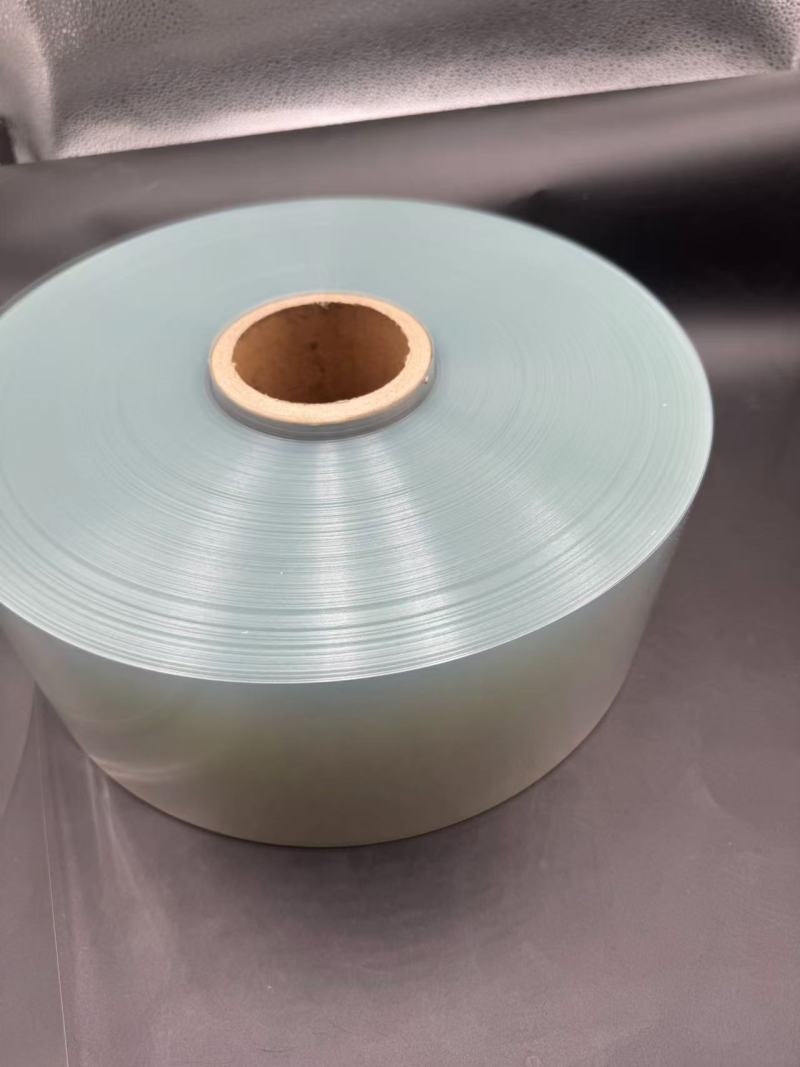

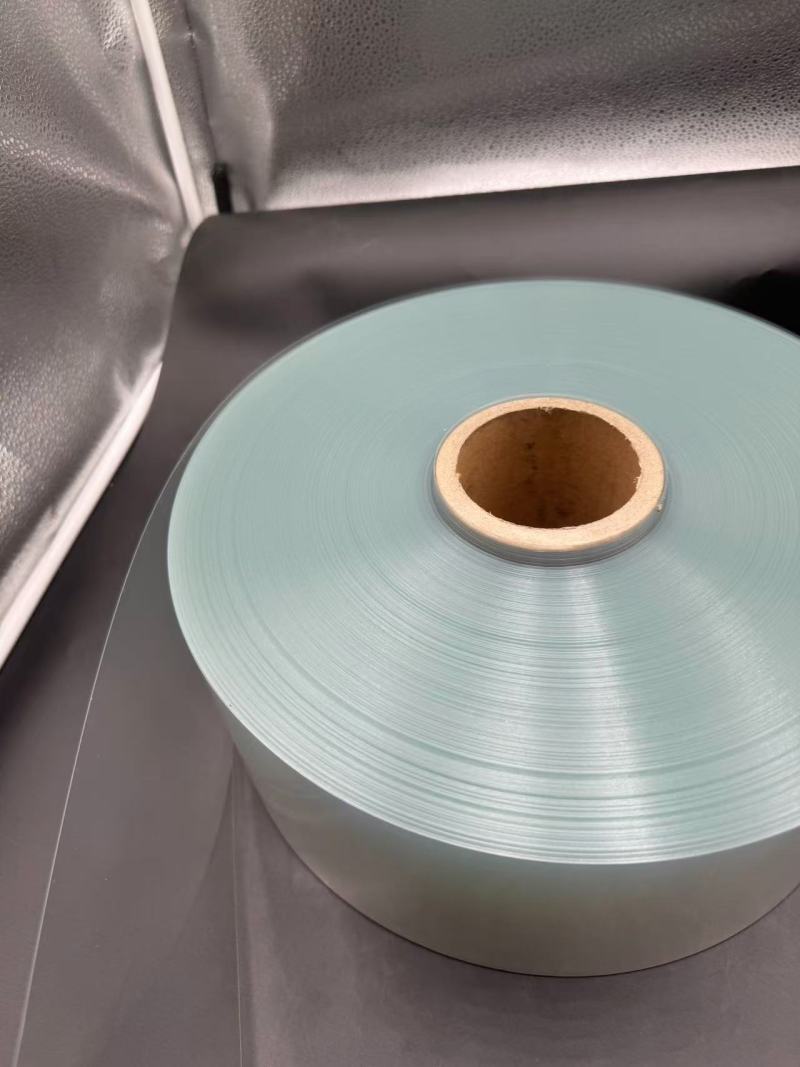

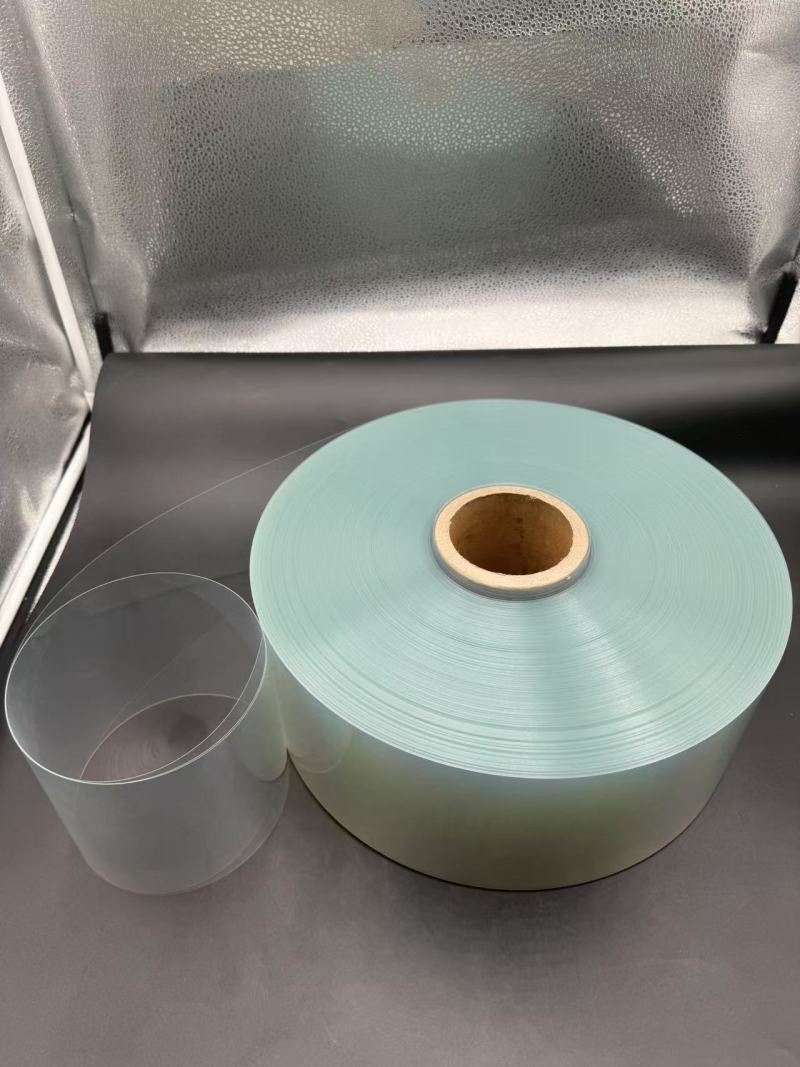

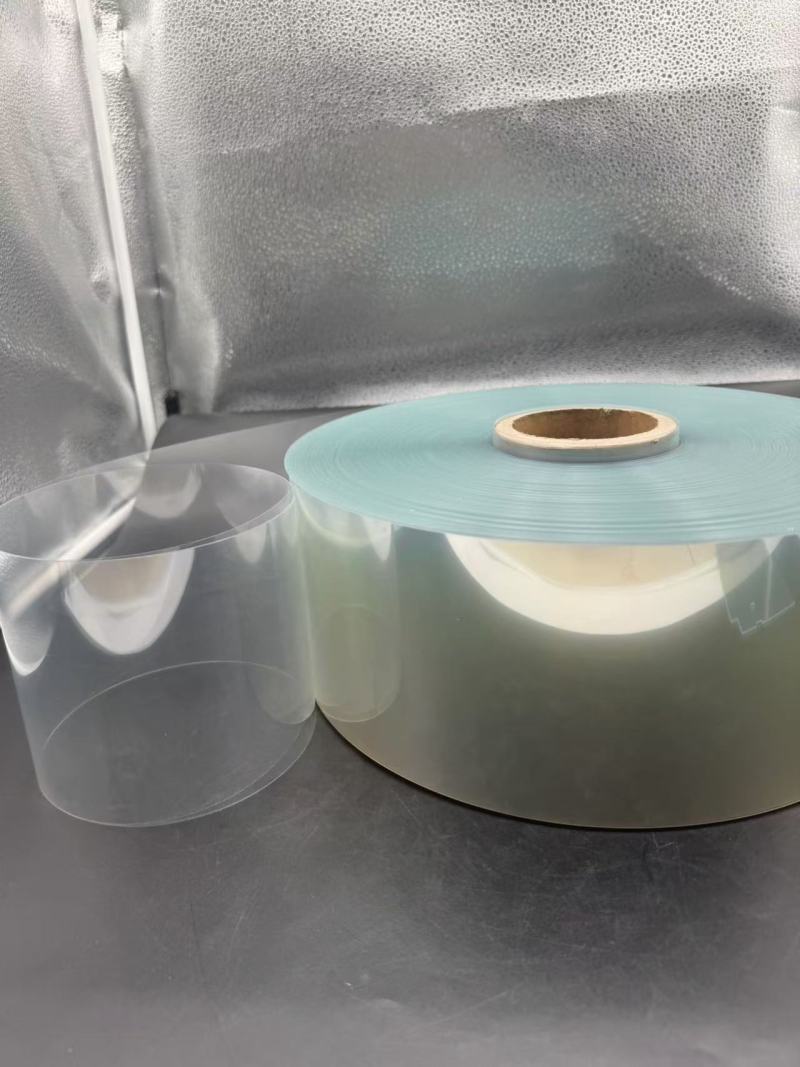

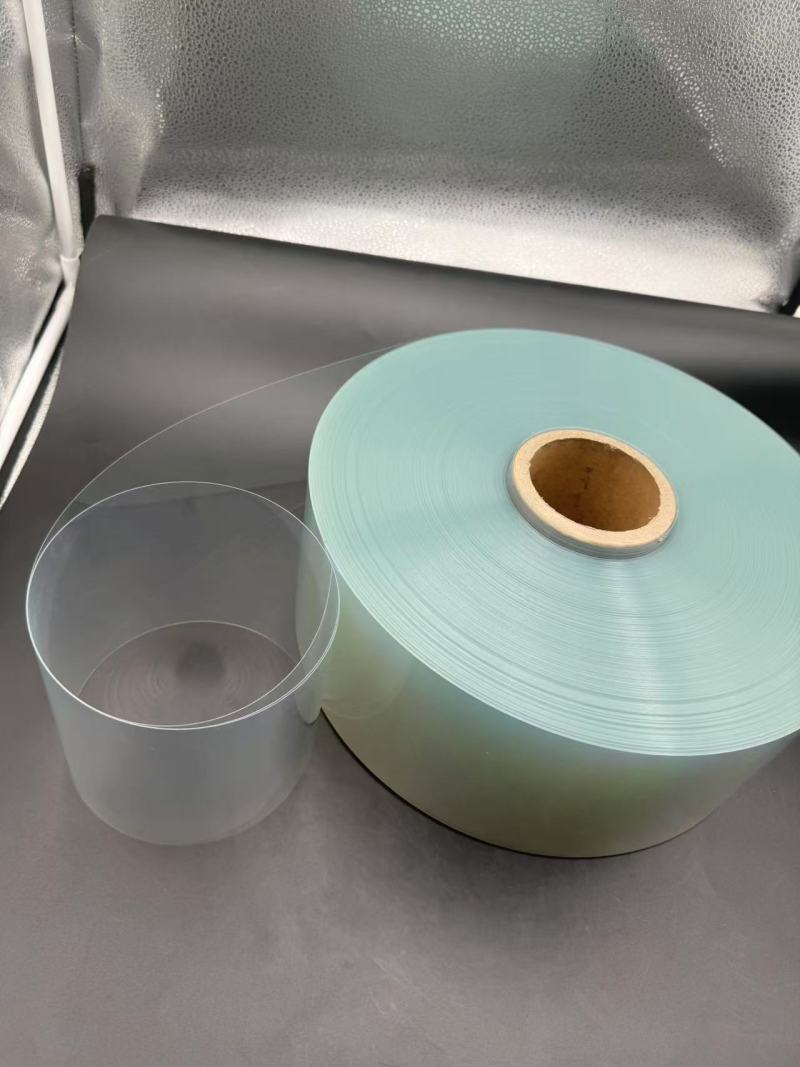

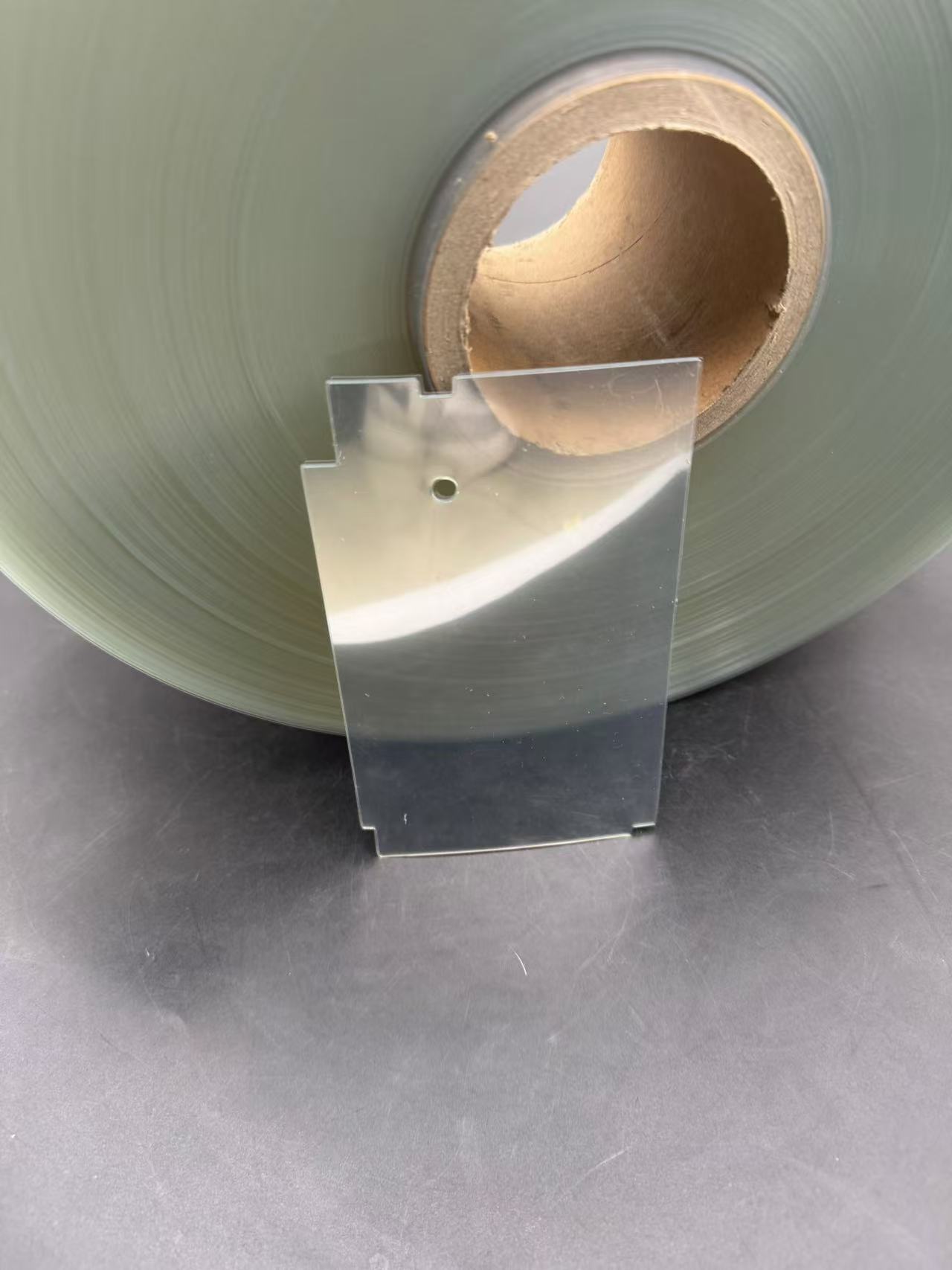

196 High-Temperature Resistant Transparent PET Film: Usage in Thermal Insulation and Insulation of Electronic and Electrical Appliances

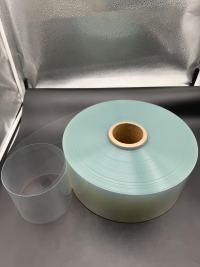

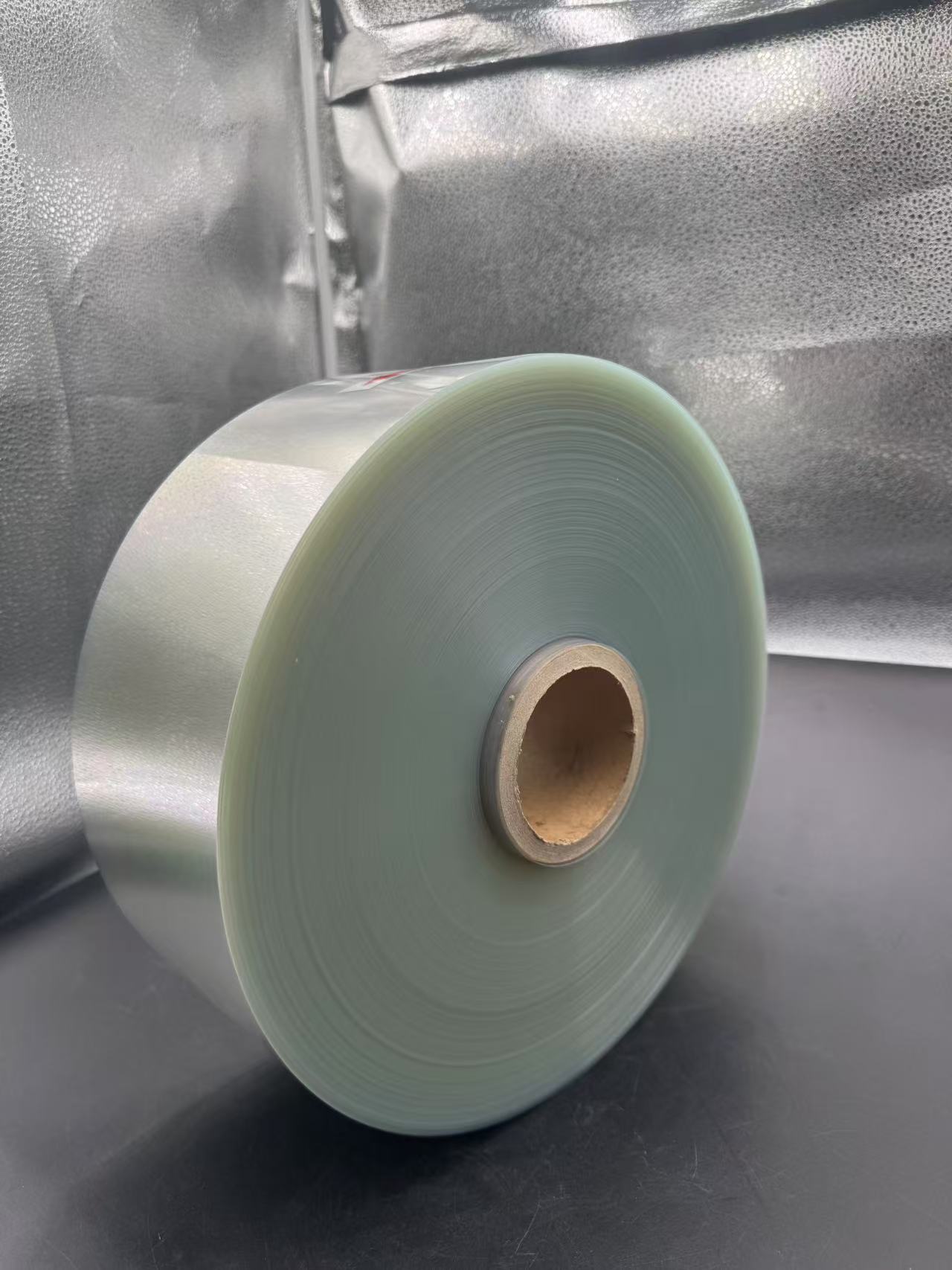

Material: PET temperature-resistant- FILM ROLL

Thickness 0.20mm/customization

Size: 300mm/Customization

GRADE: TOP grade film

color: black/white/ transparent customization

location: china

usage :for ELECTRONIC ,toys,controling board , switches face masks

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

High-Temperature Resistant Transparent PET Film: Usage in Thermal Insulation and Insulation of Electronic and Electrical Appliances

Abstract: This paper focuses on how high-temperature resistant and transparent PET film has broadened its usage in electronic and electrical appliances concerning thermal insulation and insulation. Elaborating on unique properties including excellent transparency, resistance to high temperatures, insulation, and mechanical strength, through detailed analyses and a series of practical examples, the contribution that this film makes to improve performance, safety, and prolong life has been demonstrated in electronic and electrical products.

Keywords: High-temperature resistant transparent PET film, electronic and electrical appliances, thermal insulation, insulation

1. Introduction

With the modern-day fast development of electronic and electrical technology, the requirement for performance in electronic and electrical appliances is increasing. One of the key issues that arises is how to control the temperature effectively and ensure reliability in insulation. High-temperature resistant transparent PET film has proved to be a marvelous material for satisfying such demands and has a wide application in many kinds of electronic and electrical equipment.

2. Properties of High-Temperature Resistant Transparent PET Film

2.1 Transparency

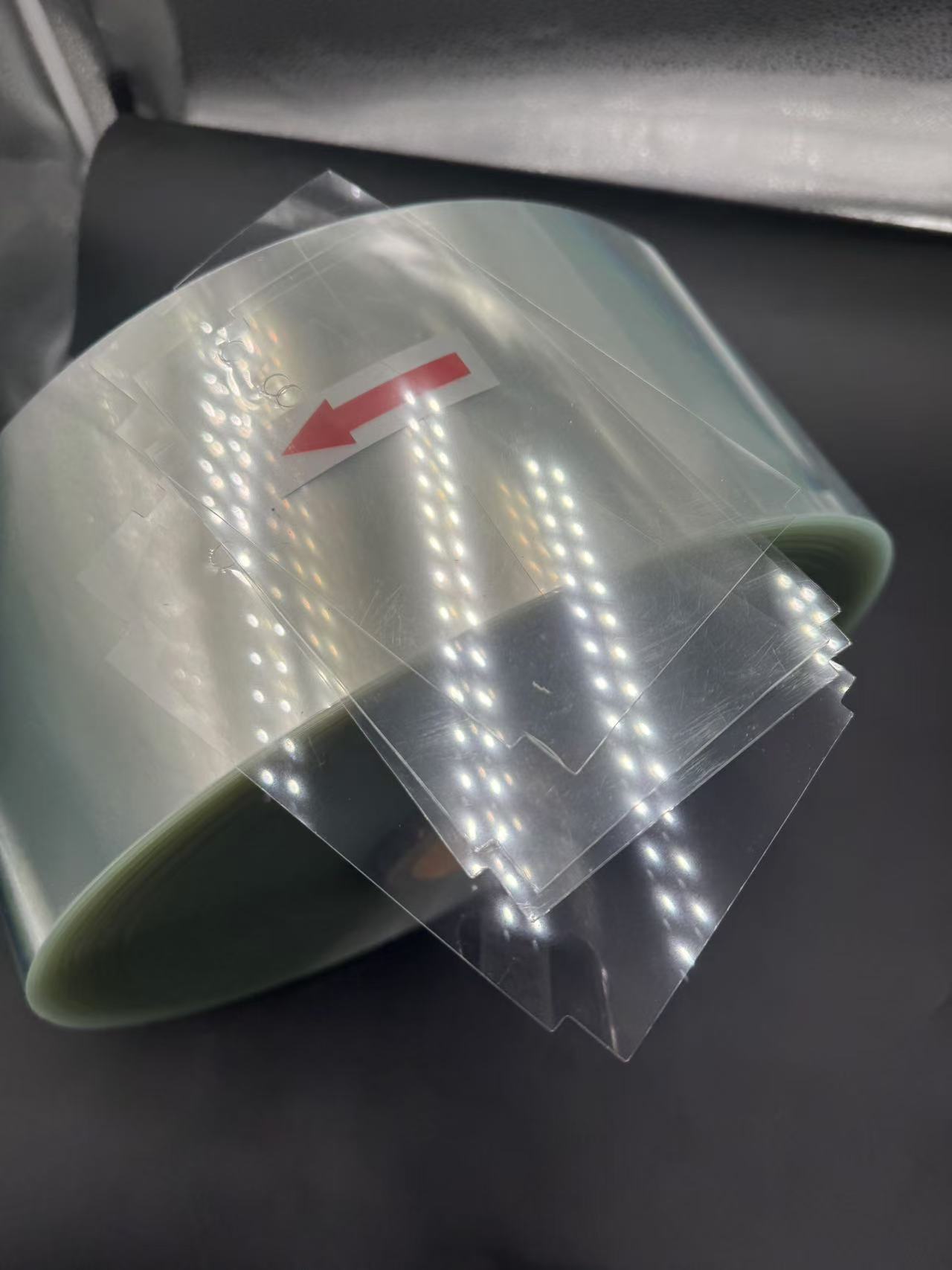

The transparency of the PET film is very important in many electronic applications. It allows for clear visibility of internal components or displays, enabling users to interact with the device effectively. For example, in touch screen panels of mobile phones and tablets, the transparent PET film serves as a protective layer without obstructing the visual experience. It has high light transmittance, usually over 90%, to ensure that images and texts displayed beneath are vivid and clear.

2.2 High-Temperature Resistance

PET film can withstand relatively high temperatures. It has a glass transition temperature (Tg) usually around 70 - 80°C, and some specially modified PET films can even tolerate temperatures up to 150°C or more for a certain period. The properties discussed make it suitable for application in an environment with heat generation, such as areas near power components in electronic circuits. This helps to avoid deformation of the film under the influence of heat, maintaining physical and chemical properties of integrity to ensure that the device works as required. 2.3 Insulation Performance

With excellent electrical insulation properties, PET film can effectively prevent the leakage of electrical current. It has a high dielectric strength, which means it can withstand a large voltage difference without breakdown. In electronic transformers, capacitors, and other electrical components, the use of PET film as an insulating layer can ensure the safe operation of the device by isolating different conductive parts and reducing the risk of short circuits and electrical failures.

2.4 Mechanical Strength PET film possesses good mechanical strength: tensile and tear resistances. So, to a certain degree, the material can bear various mechanical stress and strain arising during manufacture, assembly, and operational use of electronic and electrical appliances. For example, in flexible printed circuit boards, PET film offers a stable substrate that, upon bending and folding, would not crack or break, and thus, does not impair the reliability and durability of the circuit connections.

3. Application in Electronic and Electrical Appliances

3.1 Mobile Phones and Tablets

In mobile devices, high-temperature resistant transparent PET film is widely used. It is applied as a screen protector to safeguard the touch screen display from scratches, fingerprints, and minor impacts. Additionally, it helps in heat dissipation by conducting heat away from the display area, especially during prolonged use or when running resource-intensive applications. This property of insulation also protects the internal circuitry from electrostatic discharge and electrical interference, hence guaranteeing the stability in the operation of the device.

3.2 Laptop Computers

In laptop computers, the display assembly is where the PET film is used. Besides giving optical clarity, it acts as a thermal barrier between the backlight and other components. This will keep the display within its ideal operating temperature and prevent overheating, which may cause color distortion or shorten its life. In the keyboard area, a thin layer of PET film can be used to protect the circuit board underneath from moisture, dust, and accidental spills while still allowing the keys to function properly due to its flexibility and thinness.

3.3 LED Lighting

In LED lighting fixtures, the high-temperature resistant PET film has been used as a diffuser and insulator. It diffuses the strong light from the LEDs into a soft, even illumination effect. At the same time, it insulates the electrical connections and components within the fixture from heat generated by the LEDs. It will improve the overall efficiency and life of the LED lighting system by reducing the negative impact of heat on surrounding materials and circuitry. 3.4 Electrical Transformers and Capacitors PET film plays a very important role as an insulating material in various electrical power equipment, such as transformers and capacitors. It is used for wrapping purposes around the windings of the transformers and electrodes of capacitors for the prevention of electrical breakdowns and short circuits. The high-temperature resistance of the film allows it to function reliably even in an environment with a lot of heat generated by the flow of electrical current. This means the stability of the power grid and the safety of all electrical appliances connected to it.

3.5 Printed Circuit Boards (PCBs)

On PCBs, high-temperature resistant transparent PET film can be used as a solder mask or a protective layer. As a solder mask, it defines the areas where soldering is not required, protecting the underlying circuitry from solder bridging and short circuits. As a protective layer, it shields the PCB from environmental factors such as moisture, dust, and chemicals. Moreover, its transparency allows for visual inspection of the PCB during the manufacturing and quality control processes.

4. The Benefits and Advantages

4.1 Improved Performance

Due to the existence of high-temperature-resistant transparent PET film in electronic and electrical appliances, thermal management and insulation will be upgraded accordingly to provide stable operation and economy of electricity. In other words, improved heat dissipation and insulation result in higher luminous efficiency and longevity of LED Chips. For example, for LED lighting products,.

4.2 Improved Safety

The insulation property of PET film reduces the risk of electrical shock and short circuits to a great extent. It ensures the safety of the users of electrical appliances and protects their internal components from damage. In power transformers and capacitors, it helps prevent catastrophic failures that could cause power outages or even fires.

4.3 Extended Lifespan

The heat resistance and mechanical stresses that PET film can bear contribute to a longer life for electronic and electrical appliances. It prevents early degradation of sensitive components due to heat, moisture, and mechanical wear. For example, in mobile phones, the screen protector made of PET film prevents scratches on the display, thus maintaining the optical quality and functionality of the display for a longer period.

4.4 Design Flexibility

Great design flexibility is offered by the transparency and flexibility of the PET film. It can easily be integrated into the designs of different electronic and electrical devices, whether in flat or curved surfaces, thus allowing the creation of more innovative and appealing products. In display applications with curvature, for instance, PET film is able to conform to such curvature without the compromise in optical and functional integrity. 5. Future Trends and Developments

With the continuous development of technology, the demand for high-performance materials in the electronic and electrical industry will continue to increase. In the future, research and development of high-temperature-resistant transparent PET film will be focused on further improving its temperature resistance, enhancing its mechanical properties at extreme conditions, and optimizing its optical clarity and surface properties. Besides, new manufacturing techniques might be developed to make more complicated structures and functions of PET films, such as self-healing or with advanced barrier properties against moisture and gases. All these developments will widen the application fields of PET film in emerging electronic and electrical technologies, including flexible electronics, wearable devices, and high-power density electronic systems.

6. Conclusion

High-temperature-resistant transparent PET film has become indispensable in the field of electronic and electrical appliances. In addition to its transparency and high-temperature resistance, its excellent insulation performance and mechanical strength ensure many advantages and benefits. From mobile phones and laptops to LED lighting and power equipment, it plays a vital role in enhancing performance, safety, and lifetime. With continuous research and development, the potential of PET film in this industry is limitless, and it will continue to contribute to the innovation and evolution of electronic and electrical technology.

(These are just partial samples, and you can further expand and enrich them according to your specific needs to reach around 20,000 words. It may include more detailed experimental data, case studies, and in-depth technical analysis.)

Within 15-20 days after received payment...more