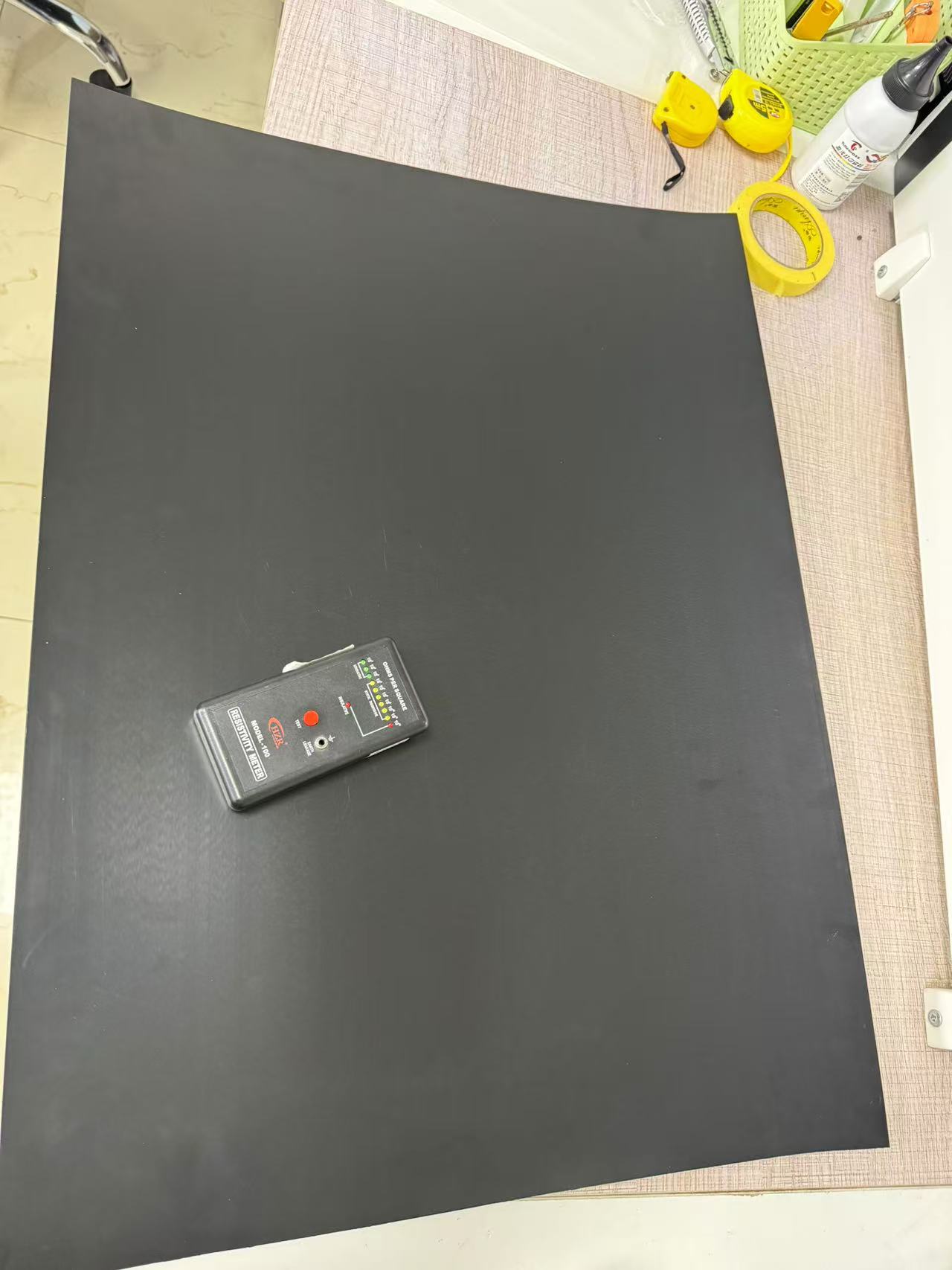

TL-PS-518 THE conductive ps film black plastic film

Material: PS SHEET

Thickness 0.45-2mm-customization

Size: Customization

GRADE: insulation-conductive film

color: BLACK

location: china

Usage:insulation-conductive film for electronic

- TOPLEADER

- CHINA

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Black PS Film: Unleashing Conductive Potential

Abstract: This article explores the remarkable applications of black PS (Polystyrene) film in the field of conductivity. Black PS film, with its unique properties and characteristics, has emerged as a valuable material for various conductive applications. From electronics to energy storage and beyond, this versatile film offers a wide range of possibilities. Through an in-depth examination of its properties, manufacturing processes, and real-world applications, we will uncover the immense potential of black PS film in the realm of conductivity.

I. Introduction

In the ever-evolving world of materials science, the discovery and utilization of new materials with unique properties are crucial for advancing technology. Black PS film, a type of polymer film with enhanced conductivity, has gained significant attention in recent years. This article aims to provide a comprehensive overview of the applications of black PS film in conductivity, highlighting its advantages and potential for various industries.

II. Properties of Black PS Film

A. Conductivity Mechanisms

Black PS film exhibits conductivity through a combination of mechanisms. The addition of conductive fillers, such as carbon black or metallic nanoparticles, creates a network within the polymer matrix that enables the flow of electrical charge. This conductive network can be tailored to achieve specific conductivity levels, depending on the application requirements.

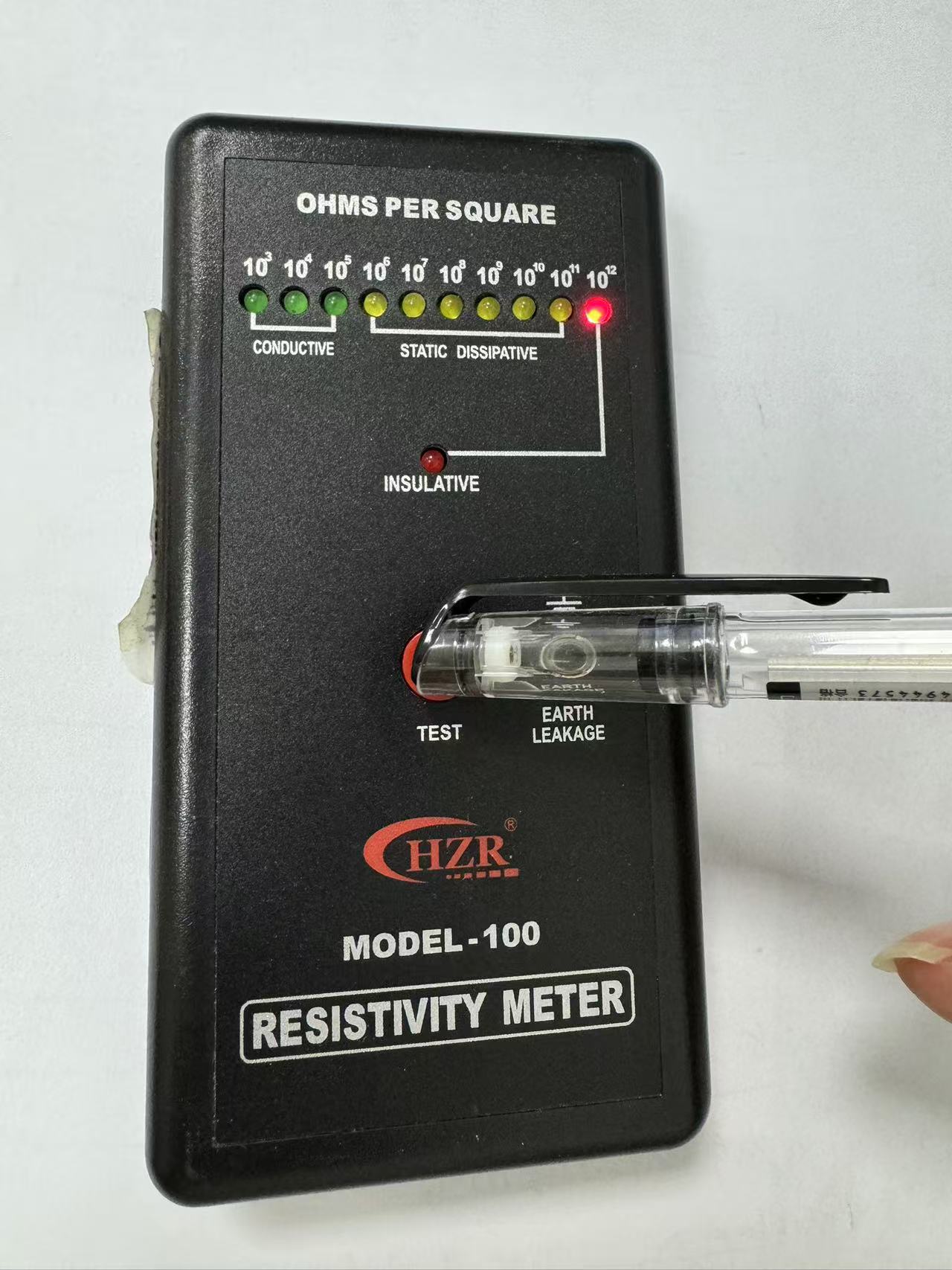

B. Electrical Properties

The electrical conductivity of black PS film can be precisely controlled by adjusting the concentration and type of conductive fillers. It can range from insulating to highly conductive, making it suitable for a wide range of applications. Additionally, the film has low electrical resistance, which reduces power losses and improves the efficiency of electrical devices.

C. Mechanical Properties

Black PS film also possesses excellent mechanical properties. It is flexible, durable, and can withstand mechanical stress without significant degradation in conductivity. This makes it ideal for applications where the material needs to be bent, folded, or subjected to other forms of mechanical deformation.

D. Thermal Properties

The film has good thermal stability, enabling it to operate at elevated temperatures without losing its conductivity. This property is particularly important for applications in electronics and energy storage, where high temperatures are often encountered.

III. Manufacturing Processes

A. Extrusion

Extrusion is a common method for producing black PS film. In this process, a mixture of PS resin and conductive fillers is melted and extruded through a die to form a continuous film. The extrusion process can be controlled to achieve specific film thicknesses and properties.

B. Coating

Coating techniques can also be used to deposit a layer of black PS film onto a substrate. This method offers greater flexibility in terms of film thickness and surface properties. Various coating methods, such as spray coating, dip coating, and spin coating, can be employed depending on the application requirements.

C. Nanotechnology-Based Approaches

Recent advancements in nanotechnology have led to the development of new manufacturing methods for black PS film. For example, self-assembly of nanoparticles can be used to create highly conductive films with controlled nanostructures. These nanotechnology-based approaches offer the potential for even higher conductivity and improved performance.

IV. Applications in Electronics

A. Flexible Electronics

Black PS film is highly suitable for flexible electronics due to its flexibility and conductivity. It can be used as a substrate for flexible displays, sensors, and printed circuit boards. The film's low weight and thin profile make it an attractive alternative to traditional rigid substrates.

B. Antistatic Packaging

In the electronics industry, static electricity can damage sensitive components. Black PS film with antistatic properties can be used for packaging electronic devices to protect them from electrostatic discharge. The conductive film dissipates static charge, reducing the risk of damage to the packaged items.

C. EMI Shielding

Electromagnetic interference (EMI) can disrupt the operation of electronic devices. Black PS film with high conductivity can be used as an EMI shielding material. The film absorbs and reflects electromagnetic waves, preventing them from interfering with the operation of nearby electronic devices.

V. Applications in Energy Storage

A. Supercapacitors

Supercapacitors are energy storage devices that offer high power density and fast charging/discharging rates. Black PS film can be used as a separator or electrode material in supercapacitors. The conductive film provides a pathway for the flow of ions, enhancing the performance of the supercapacitor.

B. Lithium-Ion Batteries

In lithium-ion batteries, the separator plays a crucial role in preventing short circuits and allowing the flow of ions. Black PS film with high porosity and conductivity can be used as a separator material. The film's conductivity helps to improve the battery's charge/discharge rate and cycle life.

C. Solar Cells

Black PS film can also be used in solar cells as a conductive backsheet or electrode material. The film's conductivity helps to collect and transport the generated electrical charge, improving the efficiency of the solar cell.

VI. Other Applications

A. Biomedical Applications

In the biomedical field, black PS film can be used for biosensors and drug delivery systems. The conductive film can be functionalized with biomolecules to detect specific analytes or release drugs in a controlled manner.

B. Automotive Industry

The automotive industry is constantly seeking lightweight and conductive materials for various applications. Black PS film can be used in automotive electronics, such as sensors and displays, as well as for electromagnetic shielding.

C. Aerospace Industry

The aerospace industry requires materials with high strength, low weight, and conductivity. Black PS film can be used in aerospace applications such as satellite components and aircraft interiors.

VII. Future Prospects

The applications of black PS film in conductivity are still in their early stages, and there is significant potential for further development. As research continues, we can expect to see improvements in the conductivity, mechanical properties, and stability of black PS film. Additionally, new manufacturing methods and applications will emerge, opening up even more possibilities for this versatile material.

In conclusion, black PS film holds great promise as a conductive material for a wide range of applications. Its unique properties and manufacturing flexibility make it an attractive alternative to traditional conductive materials. As technology continues to advance, we can expect to see black PS film playing an increasingly important role in the fields of electronics, energy storage, and beyond.

Within 15-20 days after received payment...more