CPP354 CPP film protects against moisture and oxygen degradation of the active ingredient, ensuring tablet remains effective up to the expiration

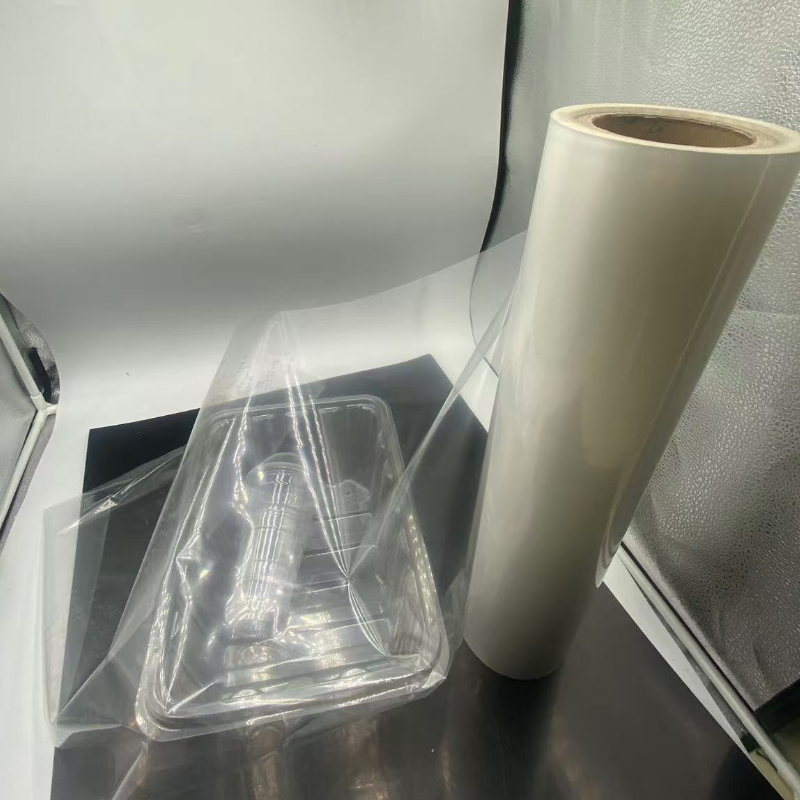

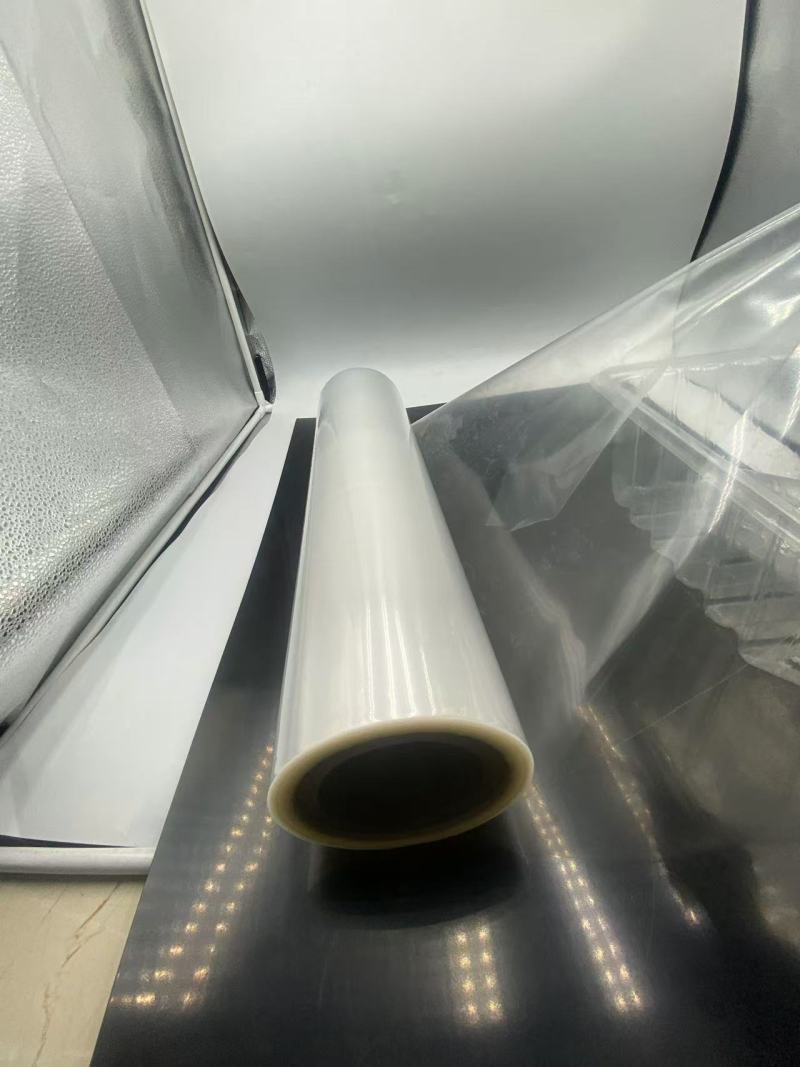

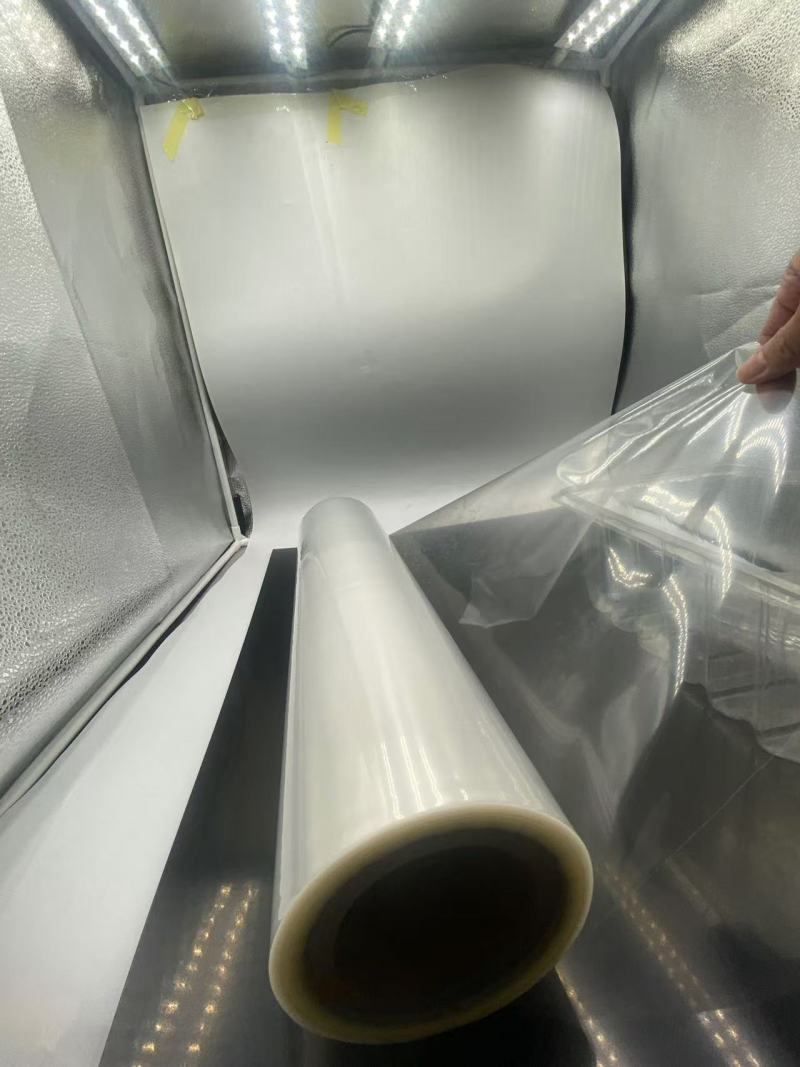

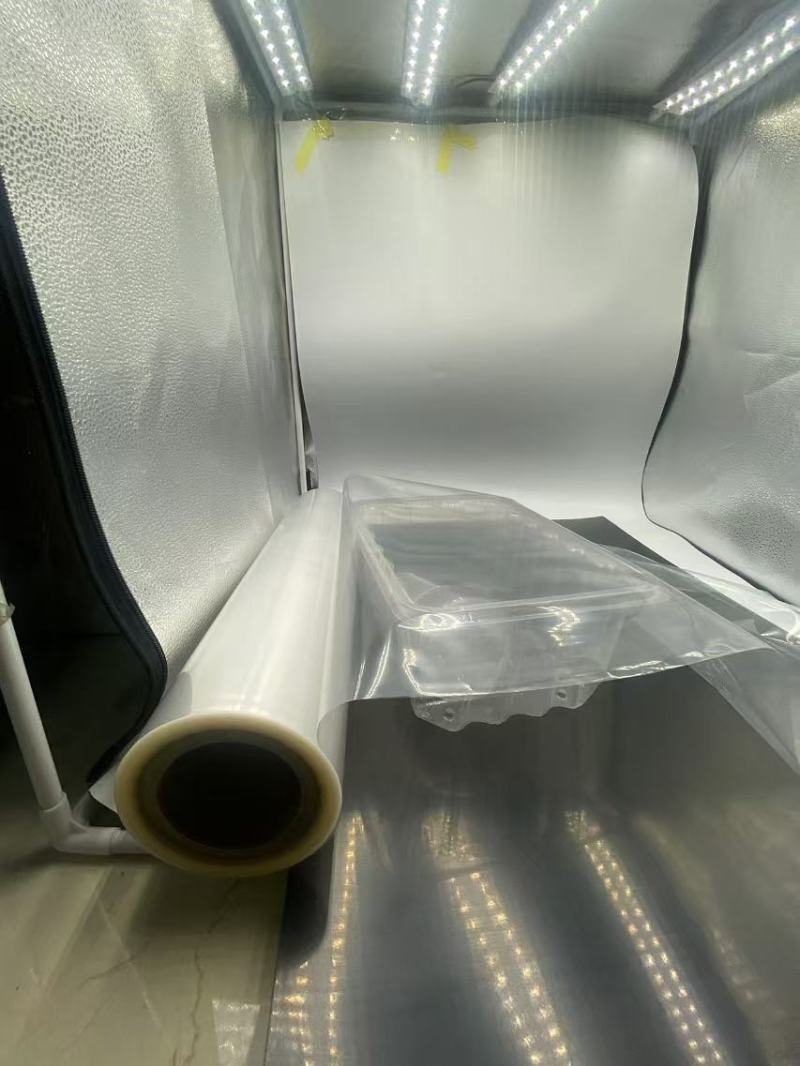

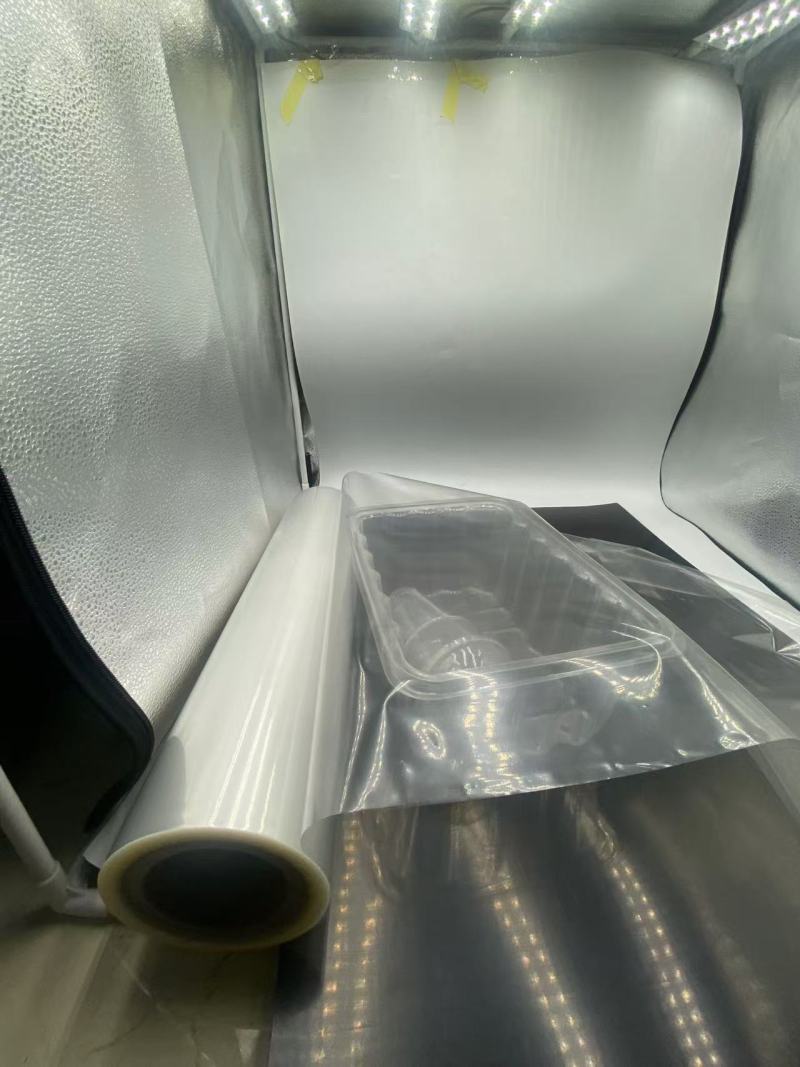

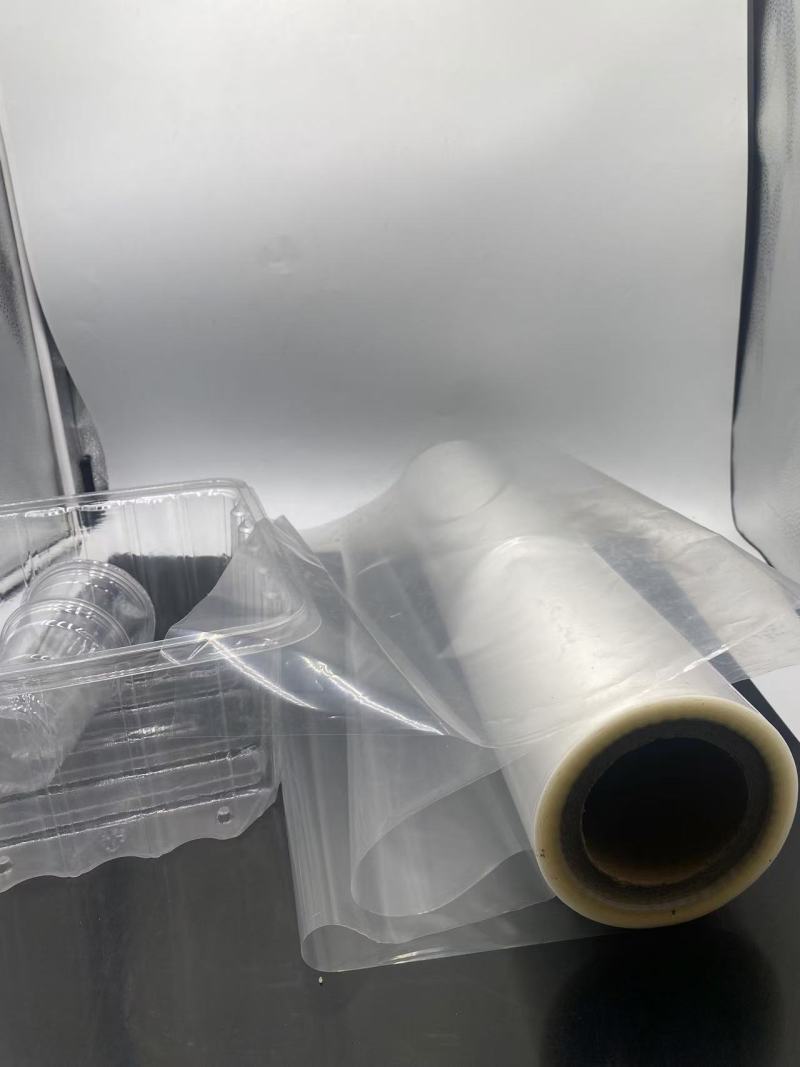

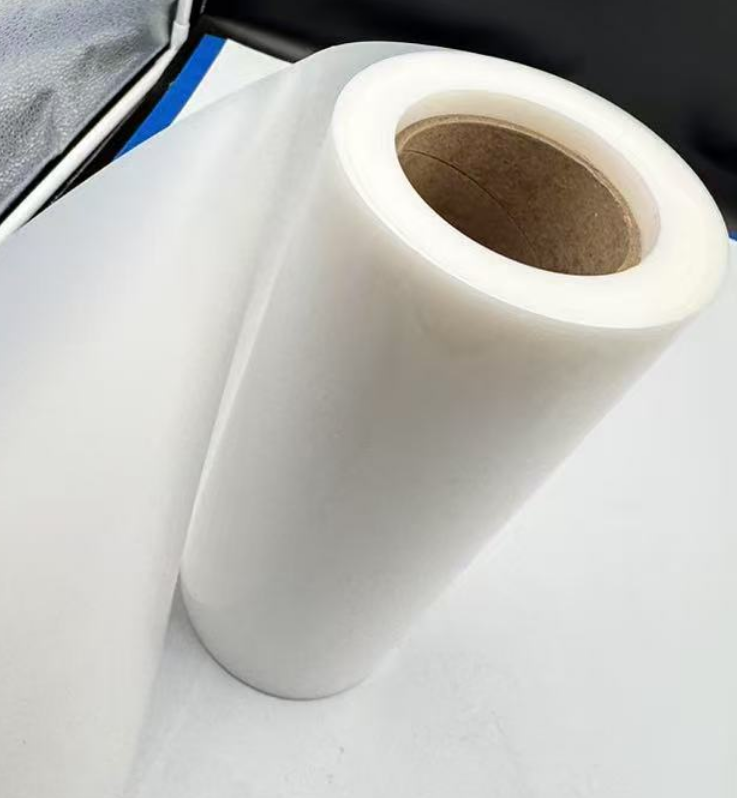

Material: cpp film roll

Thickness 0.012mm/customization

Size: A4/Customization

GRADE: Food grade film

color: white/fog/matt/ clear customization

location: china

usage: for food protection, food heat-sealing box,lamination

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

The Diverse Applications of Transparent CPP Film

Abstract: This paper comprehensively discusses various and extensive applications of Transparent CPP or Casting Polypropylene Film across various industries. It covers the unique physical and chemical properties of the film, including excellent transparency, high tensile strength, good heat sealability, and moisture barrier properties. With detailed analysis and a multitude of practical examples, it shows how important Transparent CPP Film is to enhance product quality and extend shelf life, adding value to aesthetically pleasing packaging and functional solutions in areas that range from food packaging and medical device protection to textile laminating and industrial applications.

Keywords: Transparent CPP Film; Food Packaging; Medical Applications; Textile Laminating; Industrial Use

1. Introduction

Transparent CPP film has emerged recently as one of the most important materials in today's manufacturing and packaging sectors. This kind of film material is in a high degree demanded in various areas owing to its set of very useful properties combined in it. This paper reviews different usages of such unique film material and discusses its advantages concerning several industries.

2. Properties of Transparent CPP Film

2.1 Transparency

One of the most striking features of Transparent CPP Film is its transparency. It allows a clear, unobstructed view of the contents it encloses. This property is of utmost importance in packaging applications where product visibility is crucial for consumer appeal and identification. For instance, in food packaging, such as fresh fruits, confectioneries, and ready-to-eat food items, the transparency of the film helps consumers to assess the quality, color, and texture of the product, which may influence them to make a purchase decision. In the case of consumer electronics packaging, it enables the display of the device's features and design, enhancing its marketability.

2.2 Tensile Strength

CPP Film has a relatively high tensile strength, which means that it can bear significant stretching and pulling forces without tearing or breaking. This property is very important in applications where the film is subjected to mechanical stress during handling, processing, or transportation. Tensile strength means that in the packaging of heavy or bulky items, such as industrial parts or large consumer goods, the film will hold the product well and protect it from damage. Examples include the wrapping of metal components that will endure the rigors of shipping and storage without shifting or exposure of the parts. 2.3 Heat Sealability

Excellent heat sealability is one of the major reasons for the wide use of Transparent CPP Film in packaging. It allows for easy and efficient sealing of packages, creating an airtight and moisture-proof enclosure. This is important in maintaining freshness and quality in food products and preventing spoilage due to oxidation, moisture absorption, or microbial contamination. This film has its broad application in the food industry for snack pack sealing, pouches for frozen foods, and bakery product wrappers. Since heat sealing can be precisely controlled, this provides an avenue for manufacturers to make consistent and reliable seals that are important in maintaining product integrity and meeting regulatory requirements.

2.4 Moisture Barrier Properties

Another important characteristic of Transparent CPP Film is its capability to act as a moisture barrier. It effectively blocks the ingress of water vapor, protecting the contents from the deleterious effects of moisture. In the packaging of hygroscopic products like dry cereals, powdered spices, and pharmaceuticals, the film's moisture barrier properties are indispensable. For example, in the case of pharmaceutical tablets, moisture can cause degradation or loss of potency. The CPP film serves to maintain the stability of drugs so that they remain efficient and safe up until the end-user.

3. Application in Food Packaging

3.1 Fresh Produce Packaging

Fresh produce packaging widely employs Transparent CPP Film. It acts as a barrier to protect the freshness and quality of fruits and vegetables. The transparency allows consumers to easily perceive the contents, which becomes of great essence in perishable commodities where the freshness is ascertained by the appearance of the commodity. For instance, in the case of strawberry packaging, film prevents moisture loss and physical injury while showing the bright red color and tempting appearance of the berries. It also slows down the respiration rate of the produce, extending its shelf life. Besides, the film can be perforated, which can provide adequate gas exchange for maintaining the fresh produce in a better way.

3.2 Snack and Confectionery Packaging

Transparent CPP Film is one of the favorite packaging materials for snacks and confectionery. It gets used to package chips and cookies, chocolates, jellies, and candies, among other things. The excellent heat sealability and moisture barrier properties of the film ensure that the snacks stay crispy and the confectioneries retain their texture and flavor. The transparency of the film makes the product look very attractive on store shelves for consumers. For instance, a box of chocolates wrapped in Transparent CPP Film not only protects the delicate chocolates from melting and moisture but also presents them in an elegant and enticing manner. The film can also be printed with high-quality graphics and branding information, enhancing the marketing appeal of the products.

3.3 Frozen Food Packaging

In the case of frozen food products, several benefits are derived from using Transparent CPP Film. It is able to withstand the low temperatures of freezers without becoming brittle or losing its integrity. The film's moisture barrier properties prevent freezer burn, which can occur when moisture in the food evaporates and then recondenses on the surface, leading to a loss of quality and taste. It works, for example, in frozen pizza packaging, keeping the crust from drying out, and keeping the toppings off from freezer burn. This is very important; it will still be mouth-watering upon baking. Packaging film allows easy identification by consumers in terms of what is inside such frozen foodstuffs packed in every package. Therefore, making a selection in a supermarket freezer will be very easy.

4. Use in Medical and Pharmaceutical Wrappers

4.1 Pharmaceuticals Blister Packets

CPP transparent film finds extensive application in pharmaceutical blister packaging. Transparency allows for visual inspection of the tablets or capsules to ensure no defects or foreign particles. The heat sealability of the film provides a way to create compartments for each dose, which offers protection and tamper evidence. Its moisture barrier properties are critical to the stability and potency of the drugs. In aspirin tablet packaging, for example, the CPP film protects against moisture and oxygen degradation of the active ingredient, ensuring that the tablet remains effective up to the expiration date. The film can also be printed with information such as the name of the drug, dosage, and expiration date to enable proper medication and inventory management.

4.2 Medical Device Packaging

CPP film with Transparency is used to pack different devices in the medical field, ranging from small-sized syringes and catheters to surgical tools of bigger size. The film's high tensile strength avoids physical damage to the packed device during storage and transportation. It enables good transparency for easy identification and visual inspection of the contents. For instance, when sterile syringes are being packaged, the film protects the view of the syringe that it is intact and visible to all healthcare providers with confidence in its sterility and functionality. The heat sealability of the film provides a secure and sterile enclosure that allows no chance of contamination on the medical devices.

5. Application in Textile Laminating

5.1 Garment and Fabric Lamination

CPP Transparent Film is used to laminate garments and fabrics. It can also be applied to the surface of fabrics for added protection and functionality. In the manufacture of raincoats and outdoor clothes, for instance, the film is laminated onto the fabric to make it waterproof and windproof. The transparency of the film allows the original color and pattern of the fabric to show through, thus not affecting the aesthetic appeal of the garment. The film is also used for garment accessories, such as handbags and wallets, by lending a glossy and protective finish that contributes to the durability and aesthetics of these accessories. Due to their flexibility, films also do not interfere with the drape and feel of the fabric for comfort during wear. 5.2 Home Textile Lamination

Transparent CPP Film also finds its application in home textile industries for the lamination of tablecloths, curtains, and upholstery fabrics. The transparency of the film protects the fabric from staining, spilling, wear, and tear. For example, a tablecloth could be laminated with CPP film, whose cleaning is very easy with spills being wiped off from the top without reaching the fabrics. Transparency of the film preserves the beauty of fabric design and lets it be used for enhancing room decoration. In the case of curtains, it can protect fabrics against UV and prevent faded effects by sunlight exposure. Additionally, the lamination provides some degree of stiffness to the fabrics and thus makes them look smarter.

6. Industrial and Other Applications

6.1 Protection of Industrial Products

Transparent CPP Film has a wide application in the industrial sector for the protection of various products. It can be used to wrap metal parts, machinery components, and electronic equipment during storage and transportation. The high tensile strength and moisture barrier properties of the film prevent corrosion, rust, and damage from moisture and dust. For example, in the automotive industry, engine parts are often wrapped in CPP film to protect them from scratches and environmental factors during shipping. The transparency of the film allows for quick visual inspection of the parts without the need to remove the packaging, saving time and effort in inventory management and quality control.

6.2 Stationery and Office Supplies Packaging

In the stationery and office supplies industry, Transparent CPP Film is used for packaging items such as notebooks, folders, and pens. The film's transparency showcases the product inside, making it more attractive to consumers. The heat sealability allows for easy packaging and sealing of the products. For example, a notebook wrapped in Transparent CPP Film is protected from dust and moisture while its cover design is clearly visible. The film can also be printed with branding and promotional information, adding value to the marketing of the office supplies.

6.3 Agricultural and Horticultural Applications

Transparent CPP Film has a few applications in agriculture and horticulture. It is used as greenhouse film to create a controlled environment for plant growth. Since the film is transparent, sunlight passes through it, enabling the plants to get the required light for photosynthesis. It has very good heat sealability and moisture barrier properties, which help in maintaining the temperature and humidity inside the greenhouse for the healthy growth of plants. The film can also be used for mulching, covering the soil around plants to prevent weed growth, conserve moisture, and increase soil temperature. In the packaging of agricultural products, like seeds and fertilizers, the film protects the contents from moisture and physical damage, ensuring quality and effectiveness.

7. Quality Control and Testing

7.1 Quality Control Measures in Production

To ensure that the quality of Transparent CPP Film is high, a number of quality control measures are taken during its production. These include the monitoring of the thickness of the film to ensure uniformity because the performance of the film could be affected by variations in thickness. Specific standards are followed in measuring transparency by using optical instruments. Regular tests in tensile strength and elongation show the endurance of the film to different mechanical forces it may go through. The heat sealability is tested for proper sealing parameters: temperature, pressure, and time of sealing. MVTR testing is done to characterize the moisture barrier properties of the film. For example, at a production facility, samples of the film are taken at regular intervals and tested in a laboratory equipped with advanced testing equipment. Any deviation from the set standards of quality is then corrected immediately to maintain the integrity of the production process.

7.2 Testing for Specific Applications

Depending on the application, other tests may be necessary. Food packaging requires testing the film for conformance to food safety regulations, which includes migration testing to ensure that no harmful substances leach into the food. Sterility testing and compatibility testing with the drugs are necessary in pharmaceutical packaging. In textile laminating, adhesion testing between the film and the fabric is conducted to ensure a strong and durable bond. For instance, the development of a new pharmaceutical blister packaging using Transparent CPP Film involves extensive compatibility testing to ensure that the film does not interact with either the active ingredients or excipients of the drug to guarantee the safety and efficacy of the medication.

8. Environmental Impact and Sustainability

8.1 Recycling and Disposal

Transparent CPP Film is recyclable, and efforts are being made toward improving its recycling infrastructure. However, the rate of recycling is still relatively low in comparison with some other plastics. In many cases, it may just end up in landfills, taking a long time to degrade. To overcome this issue, some manufacturers are considering using biodegradable additives or developing compostable variants of CPP film. Proper waste management and recycling education will also help consumers and companies recycle the film. For instance, some communities are creating recycling programs strictly for plastic films, of which Transparent CPP Film is a part, so as to reduce the amount of waste that goes to landfills.

8.2 Sustainable Manufacturing Practices

Manufacturers are trying to make the production of Transparent CPP Film more sustainable by adopting more sustainable manufacturing practices. This involves the use of renewable energy sources in the production process, limiting water usage, and optimization of the production process to limit waste generation. Some companies are also investing in research and development to find alternative raw materials that are more environmentally friendly. For instance, the introduction of bio-based polypropylene during the production of CPP film can potentially bring down the carbon footprint emanating from the material. Moreover, manufacturers are improving the energy efficiency of their production equipment such as extruders and laminators to reduce energy consumption and, subsequently, reduce the emission of greenhouse gases.

9. Future Trends and Innovations

9.1 Smart Packaging Solutions

The future of Transparent CPP Film in packaging is very likely to develop into smart packaging solutions. For instance, it is envisaged that the film will be embedded with sensors capable of detecting changes in temperature, moisture, or gas composition inside the package. This would be especially helpful in food and pharmaceutical packaging, where product quality and safety are of utmost importance. The sensor-equipped CPP film would instantly notify the consumer or manufacturer of the product's exposure to conditions that are not favorable to it, such as high temperatures, which might spoil or degrade the product. Besides, the film may be designed to have self-healing properties; minor scratches and punctures would automatically be healed without affecting the shelf life and integrity of the package.

9.2 Nanotechnology Applications

Nanotechnology would definitely play an important role in enhancing the properties of transparent CPP film. The addition of nanoparticles to the film will increase barrier properties, thereby improving its barrier efficiency for preventing the ingression of moisture, oxygen, and other gases. The addition of nanoclays could improve mechanical strength and resistance to heat. Nanocoatings can also be applied to the film for antibacterial or antifungal properties, which will be useful in food and medical packaging. In the textile industry, nanotechnology can be used to provide a stronger and more breathable lamination, which will enhance the performance and comfort of the laminated fabrics.

9.3 Customization and Personalization

With the increase in demand for customized and personalized products, Transparent CPP Film is likely to provide more options in this regard. Unique textures, colors, and finishes will be able to be manufactured by producers in various ways to fulfill the specific needs of various industries and consumers. Packaging films could be printed with personalized messages, images, or QR codes that may contain further information or marketing opportunities. For instance, a package of food could have a personalized label printed on the CPP film with the name of the consumer or some special message to enhance the consumer's attachment to the product. In the textile industry, customized laminates could be made for fashion designers and consumers who want unique and exclusive fabric finishes.

10. Conclusion

Transparent CPP Film has proved extremely versatile in a wide variety of applications related to food packaging, medical and pharmaceutical, textile laminating, industrial, and other industries. Its unique properties are transparency, tensile strength, heat sealability, and moisture barrier properties, which make it an invaluable asset in enhancing product quality and protection, and also promote marketing. However, like any other material, ther