Unveiling the Versatility of PET Film: From Packaging to High-Tech Applications

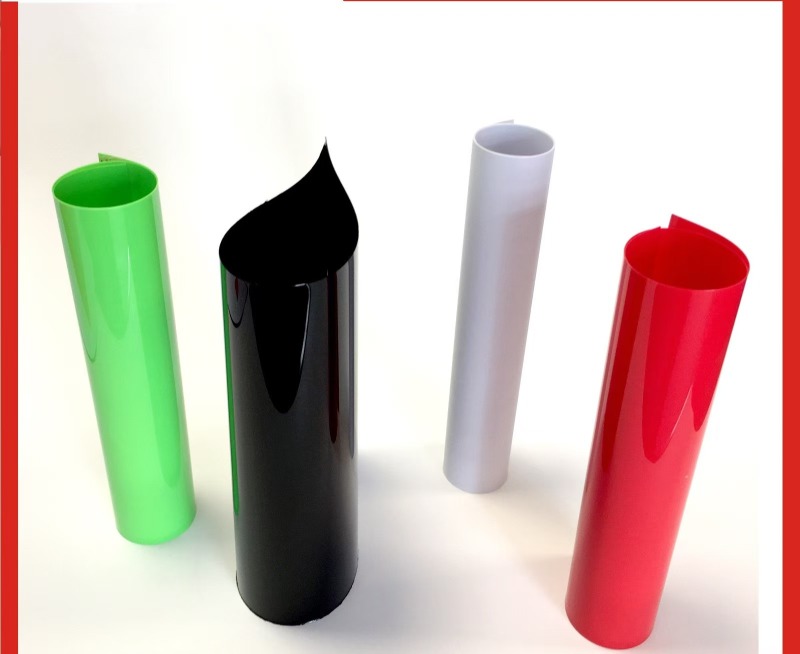

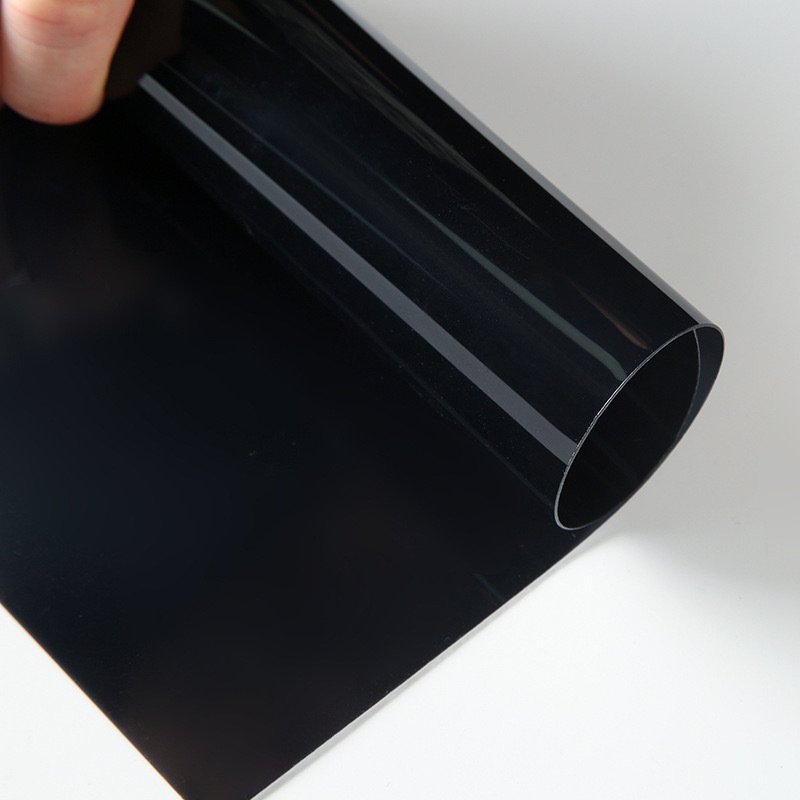

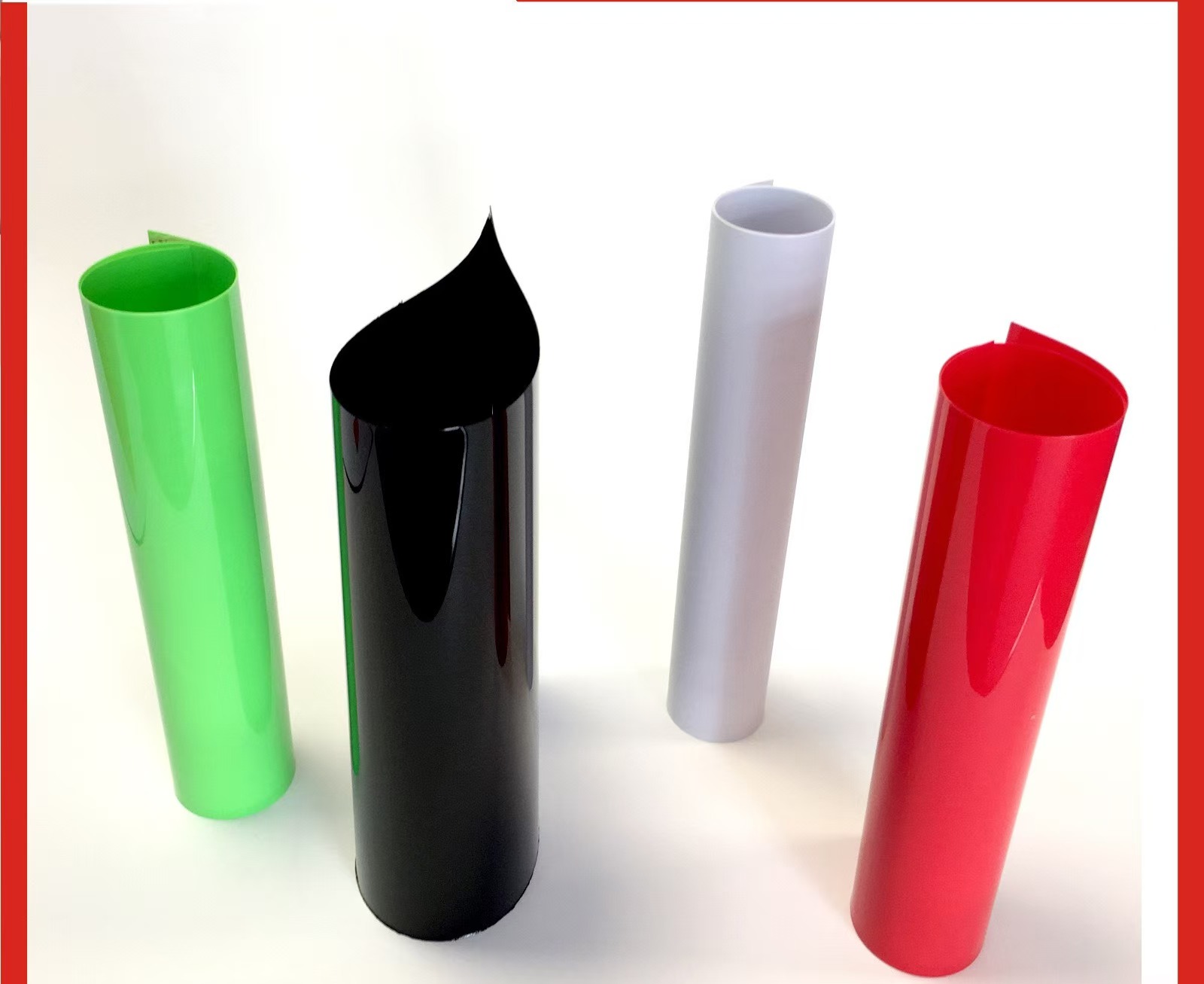

Material: PET Printable sheet

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

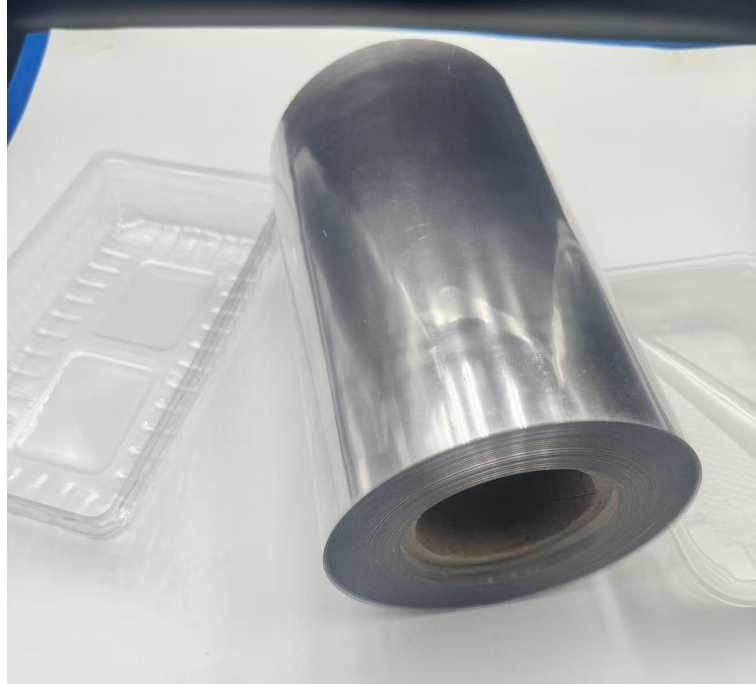

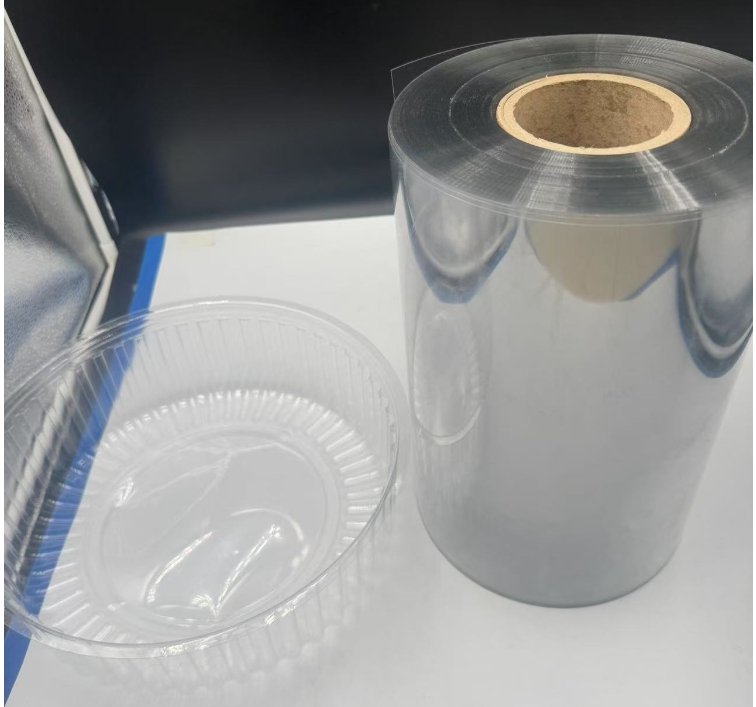

usage :for food tray plant tray

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Introduction to PET Film

Polyethylene Terephthalate, popularly known as polyester film, is a versatile film material used hugely in several industries due to its unique properties. PET film is derived from polyethylene terephthalate, a thermoplastic polymer resin of the polyester family. First introduced in the 1950s, it subsequently became a staple in packaging, electronics, and automotive industries, among many others, for its strong features, which include high tensile strength, excellent clarity, and resistance to chemicals and heat.

Properties of PET Film

Strength and Resistance to Breakage:

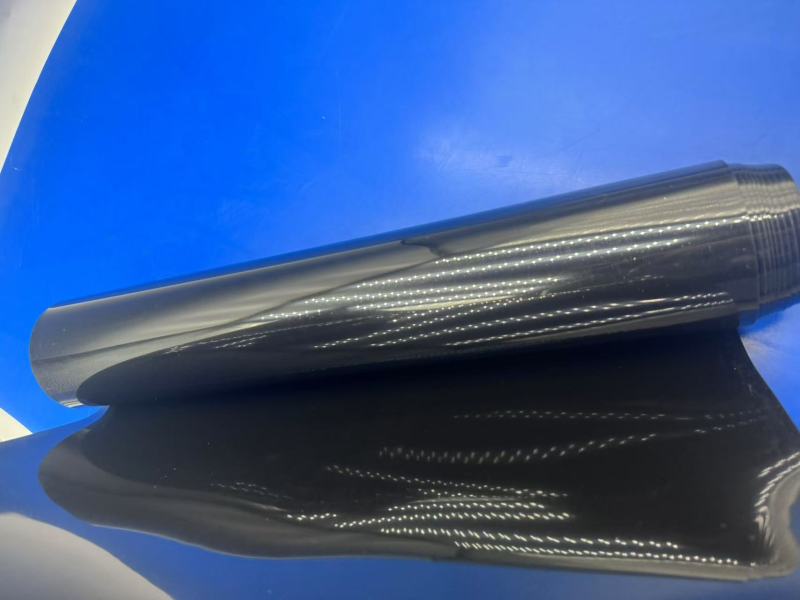

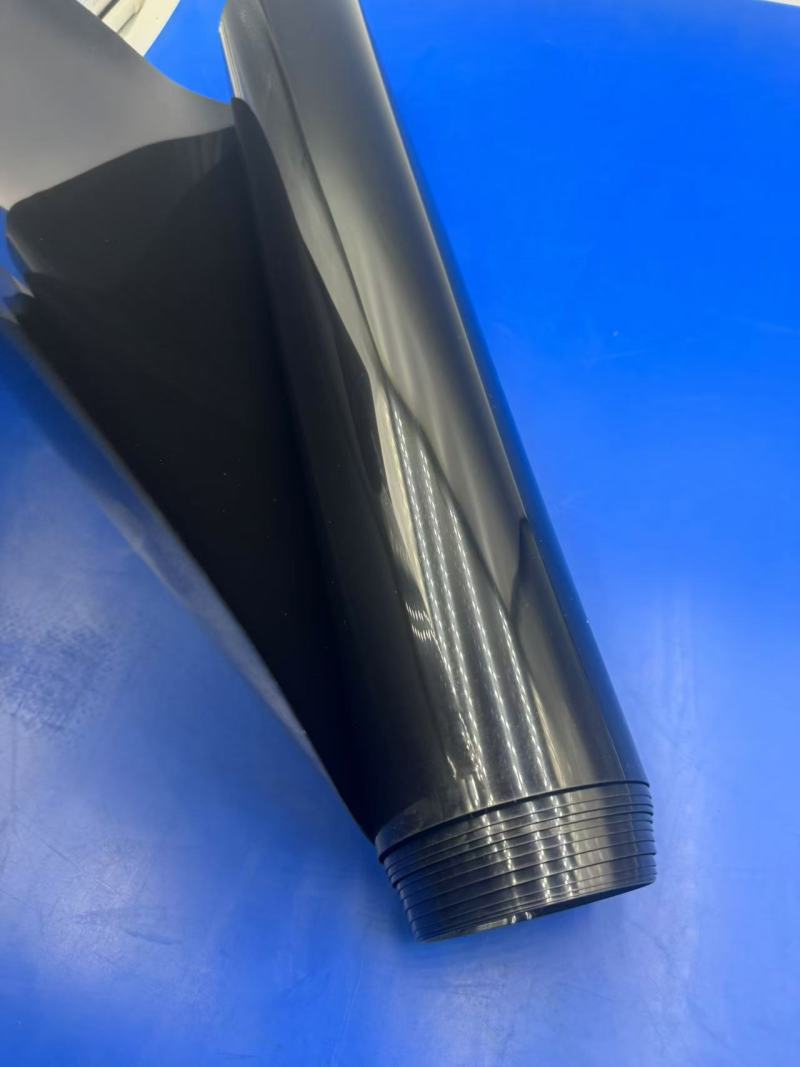

PET films boast of high tensile strength, giving them a tear and puncture-resistant nature. This strength comes from the biaxial orientation wherein the polymer chains are aligned in two directions, hence improving the mechanical properties of the film.

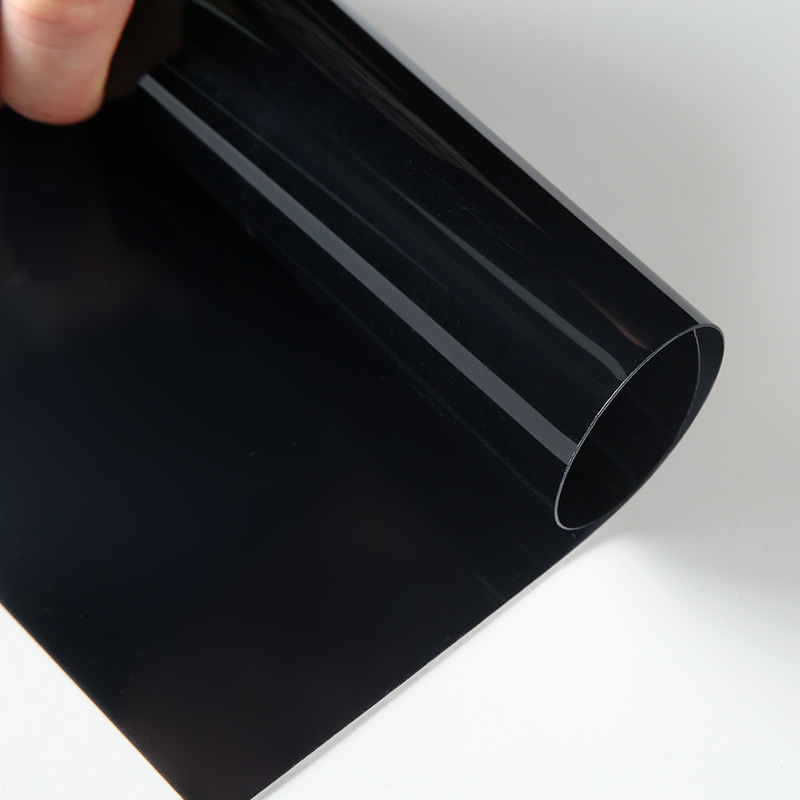

Clarity and Optical Properties:

This is an optically clear film that makes it excellent for all applications where transparency is necessary, like in packaging, displays, and protective films. The gloss imparts aesthetic value to the products.

Thermal Stability:

PET film retains stability within a broad temperature range. That is why it can serve in both high-temperature uses, such as ovenable trays, and low-temperature ones, such as freezer packaging.

Chemical Resistance:

It is resistant to a wide range of chemicals; hence, it is used in packaging where the contents are likely to come in contact with the film for extended periods. This resistance includes acids, bases, solvents, and oils.

Barrier Properties:

PET films have excellent barrier properties to gases-both oxygen and carbon dioxide-along with moisture and odor. This is very useful for food packaging to extend shelf life.

Electrical Properties:

Owing to its dielectric strength, PET finds application in electrical insulation in various forms: in capacitors, transformers, and flexible printed circuits.

Environmental Impact:

Though PET is recyclable, its environmental impact includes concerns on degradation time. However, these are being tackled with new innovations in recycling and biodegradable additives.

Applications of PET Film

Packaging Industry:

Food and Beverage: The barrier properties of PET films make them useful in packaging to keep the product fresh. Examples include snack bags, beverage labels, and retort pouches.

Medical Packaging: The inert nature and barrier properties of the material make it suitable for sterile medical packaging, including blister packs for pharmaceuticals.

Electronics:

Insulation: PET has excellent dielectric properties; hence, it is very suitable for insulation in electronic components.

Exhibits excellent transparency and rigidity, hence finds wide application as a cover in liquid crystal displays, touchscreen, and photovoltaic cells.

Automotive:

PET films have applications related to dashboards, sun visors, and wire insulation because of their good thermal stability and mechanical strength.

Printing and Graphics:

Its very good printability and surface quality make it suitable for several graphic applications such as labels, decals, and banners.

Industrial Applications:

Electrical Insulation: Industrially, PET films are used for insulation in motors, transformers, and cables. Membrane Switches: The flexibility of the film makes it suitable for membrane switches used in control panels. Photovoltaic: PET is used as a backsheet in solar panels to protect against moisture ingression and UV radiation. Market Trend and Development

Growth in Demand: The demand for PET films has increased significantly, mainly due to the growth in the packaging industry, which requires materials capable of extending shelf life without quality degradation. The electronics sector is another contributor because it requires thin, flexible, high-performance insulation materials.

Sustainability Innovation:

There is a constant striving to make the PET films more eco-friendly by making them more recyclable, more biodegradable, and finding bio-based alternatives to PET.

Technological Advances:

Some of the recent technological developments include ultra-thin films for microelectronics, barrier coatings for packaging, and conductive properties that allow their use in flexible electronics.

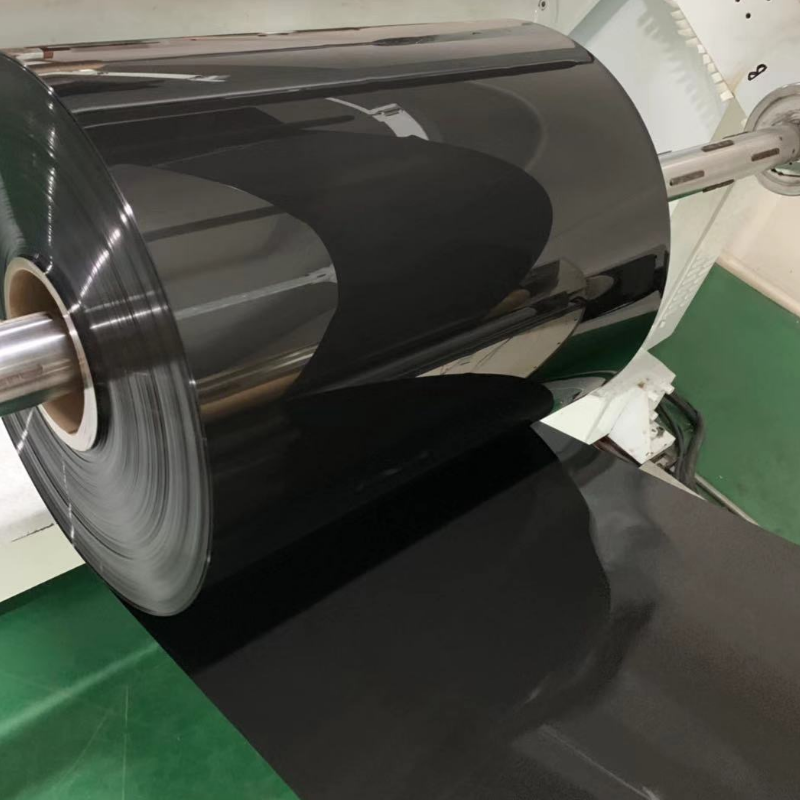

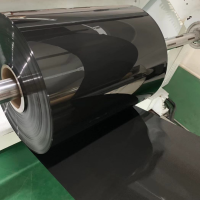

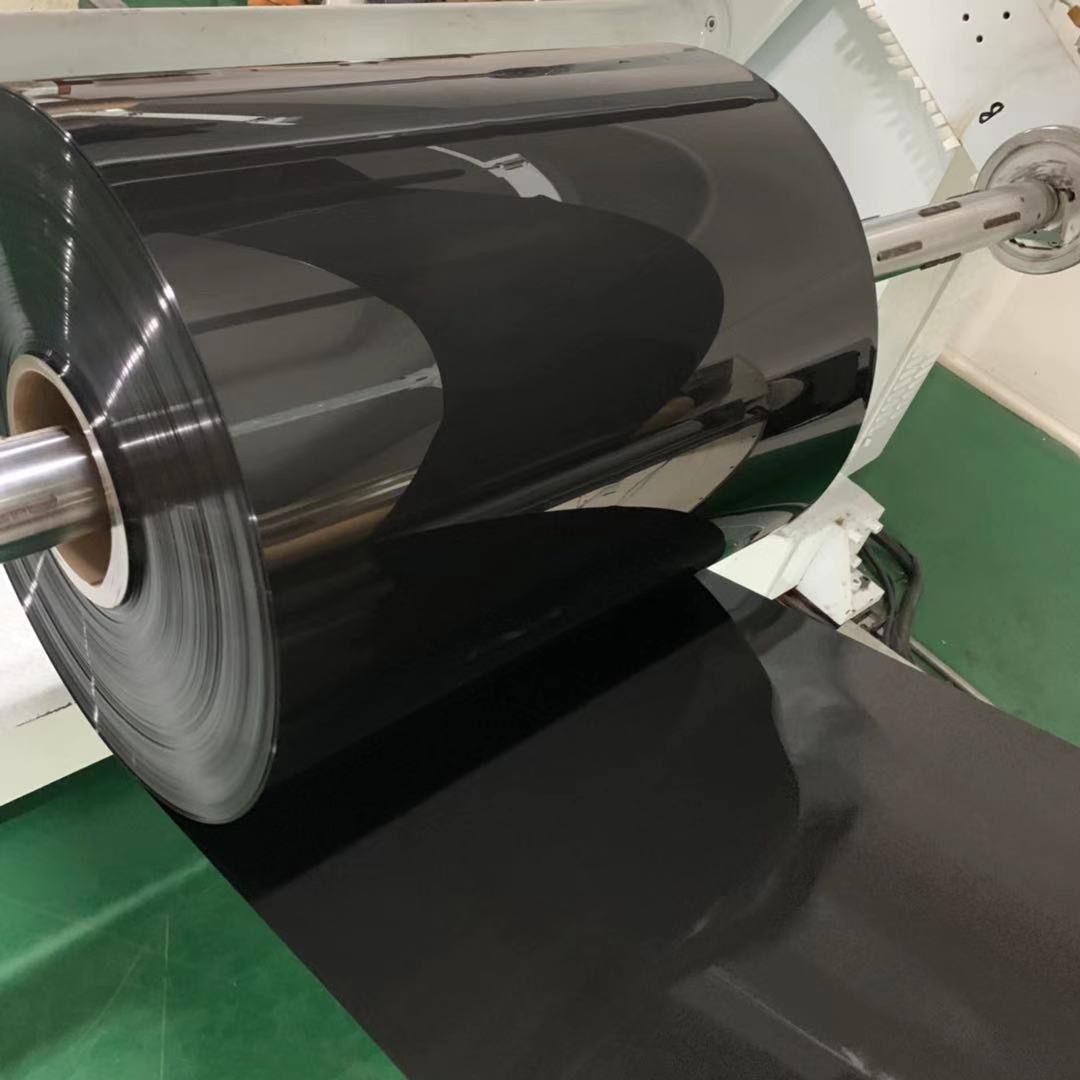

Manufacturing and Processing

Manufacturing Processes: The PET films are produced by techniques such as the T-die extrusion process, followed by biaxial orientation-that is, stretching in machine and transverse directions to acquire desired properties.

Coatings and Treatments:

In order to enhance the properties further, PET films may be coated or treated. For example, metallization provides reflective property with an improved gas barrier, while UV coating enhances durability when used outdoors.

Future Trends

Sustainability: There will likely be a continued focus on the development of PET films from renewable resources or those having improved end-of-life options such as biodegradability or full recyclability.

Functional Enhancement: Development will continue to make multifunctional films and incorporate properties such as anti-microbial, anti-static, or conductive capabilities directly into the film structure.

Smart Packaging: The PET films could contain technologies such as RFID for tracking or sensors that monitor product conditions to help in supply chain efficiency and consumer safety.

Its versatility, due to the specific combination of mechanical, thermal, optical, and chemical properties, has placed PET film in modern industry-from everyday packaging to high technology applications in electronics. The new demands placed on PET for sustainability and functionality continue to evolve. The need to go greener and smarter is thus leading industries towards better solutions; it will innovate PET film further, combining consumer needs with environmental concerns to keep its place in this fast-evolving market.

Within 15-20 days after received payment...more