Exploring the Versatility of PVC Film in Pharmaceutical Blister Packaging

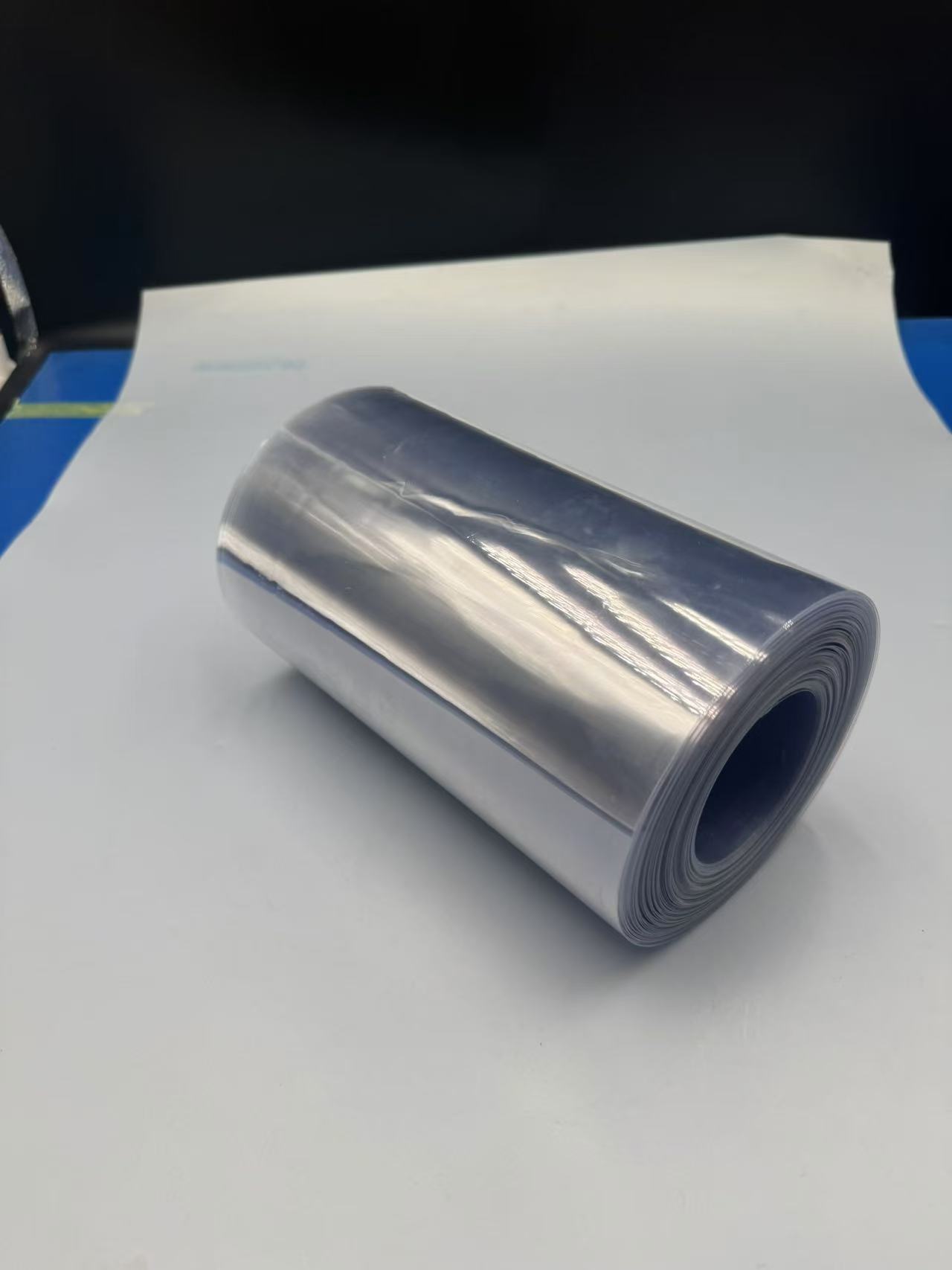

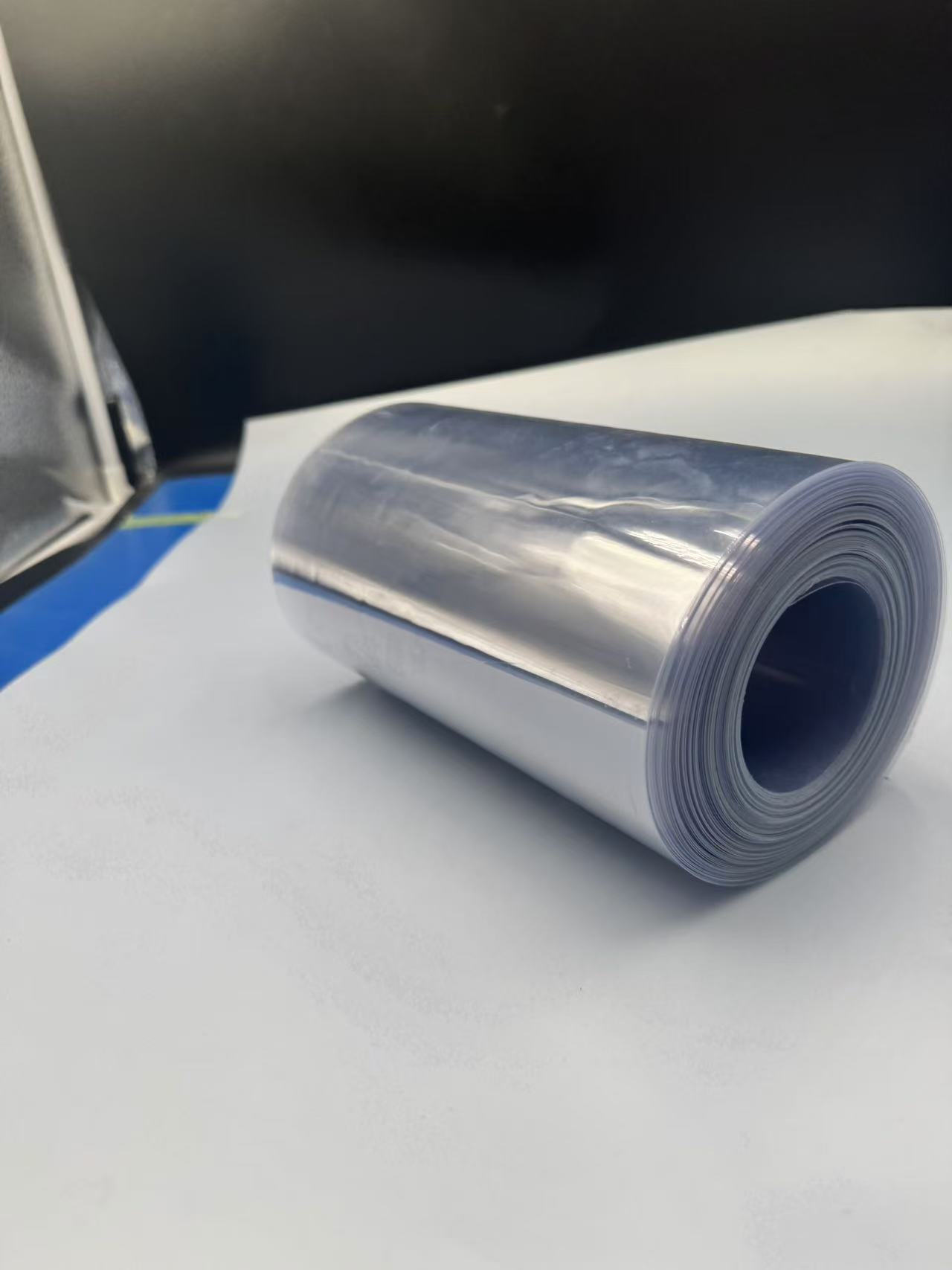

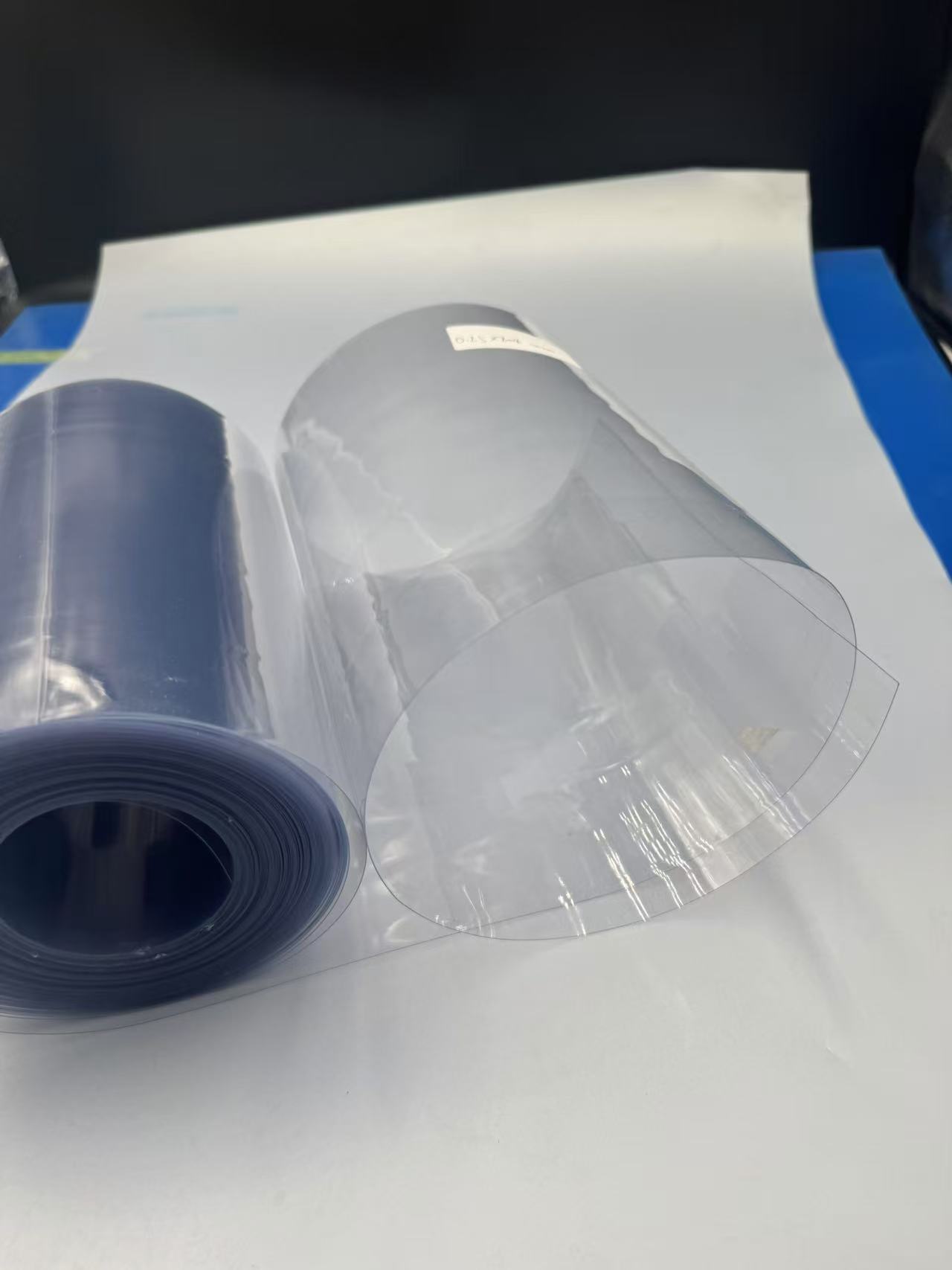

Material: PVC ROLL

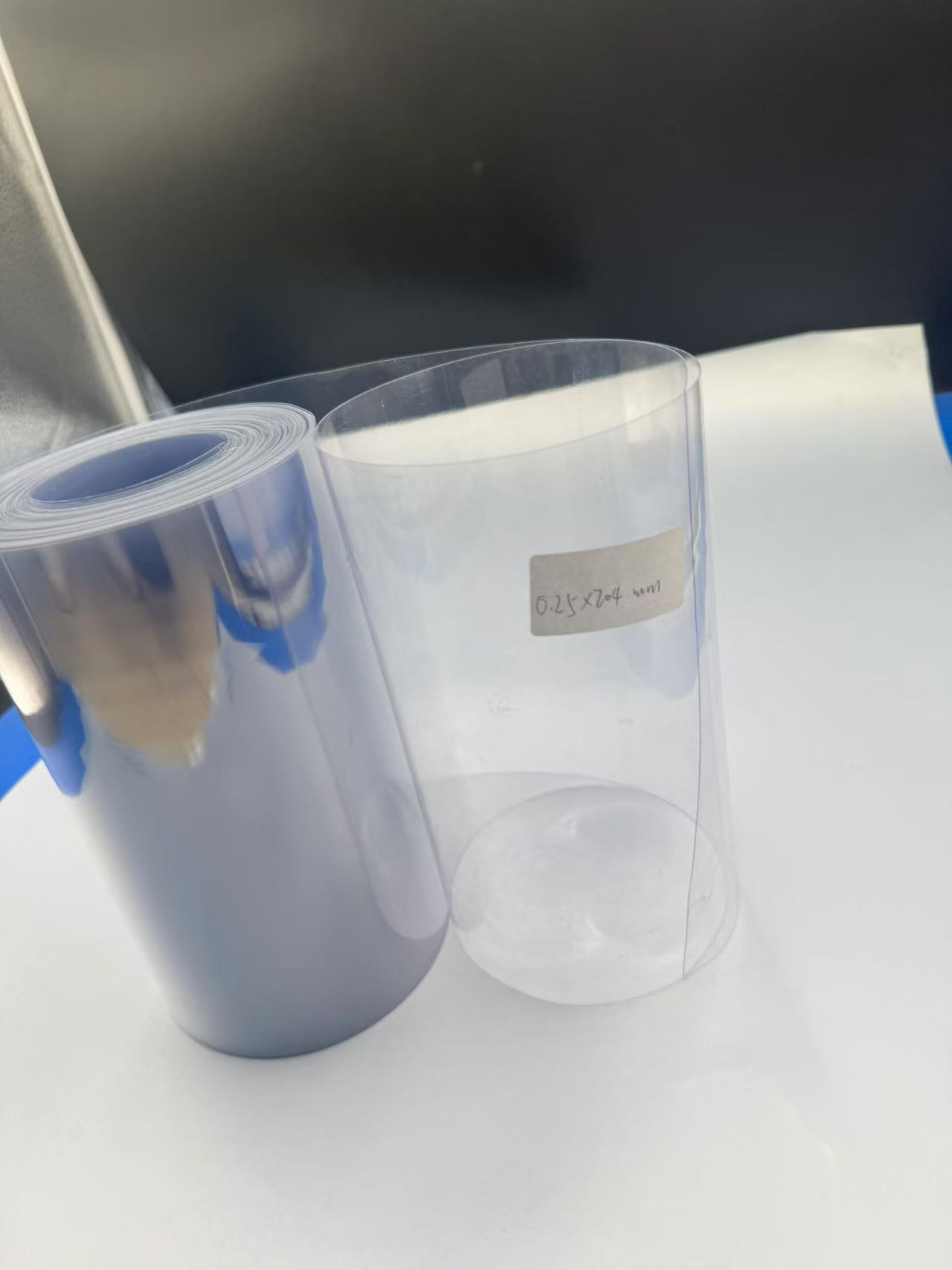

Thickness 0.45-0.018mm-customization

Size: 80MM/130MM/Customization

GRADE: pharma grade film

color: white/ customization

location: china

Usage: Pharmaceutical, dried food container

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Transparent PVC film, a versatile thermoplastic derived from polyvinyl chloride, has become a cornerstone in the packaging industry, particularly for dry food and pharmaceutical blister applications. Known for its clarity, durability, and cost-effectiveness, PVC film offers a practical solution for protecting products while allowing consumers to see what lies within. Whether encasing a crisp biscuit or a life-saving tablet, this material balances functionality with aesthetics, making it a preferred choice across diverse sectors. This article explores the characteristics of transparent PVC film and its critical role in packaging dry foods and pharmaceuticals, highlighting its unique advantages with vivid examples and solid reasoning.

Section 1: Properties of Transparent PVC Film

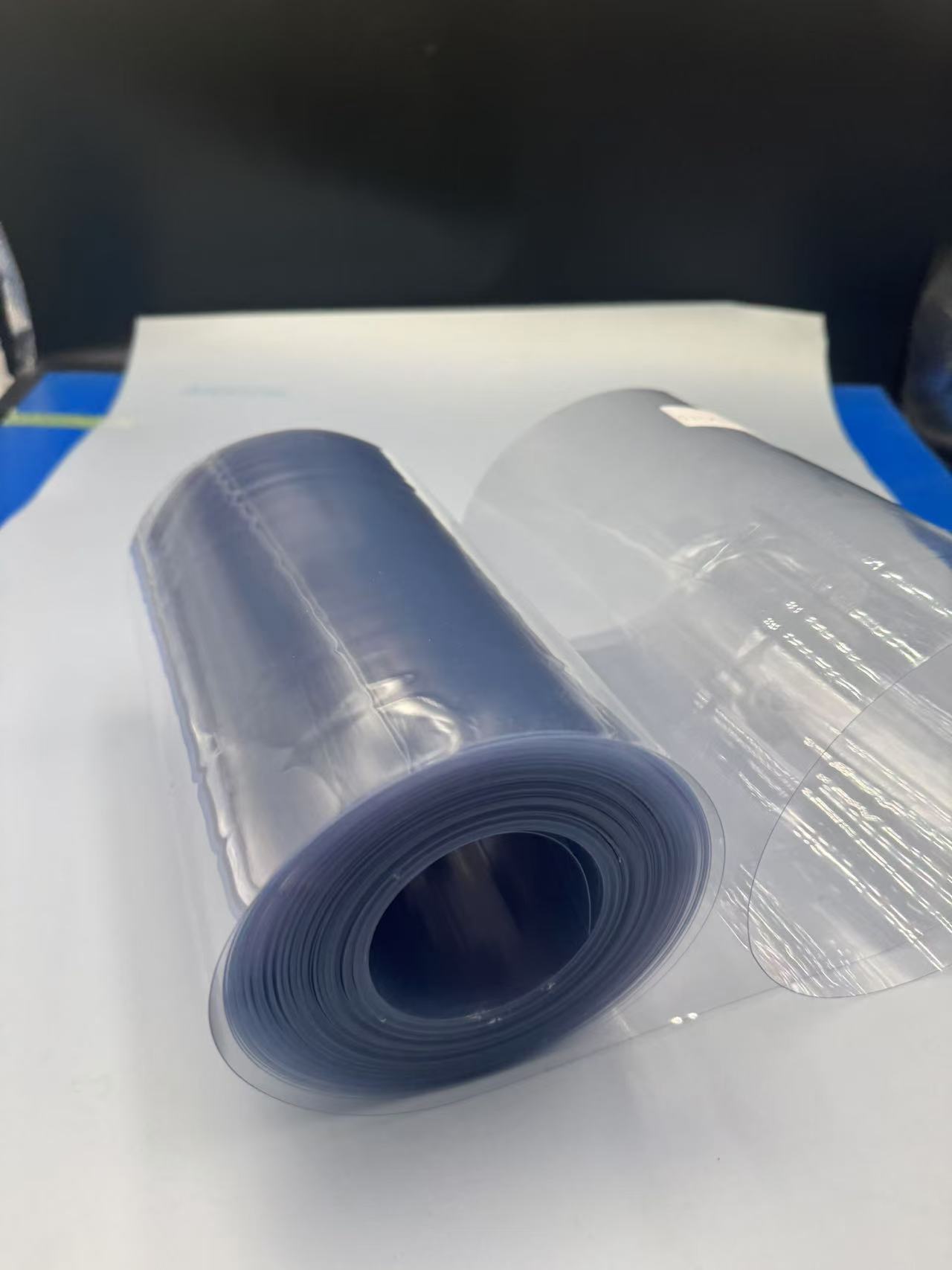

PVC film is produced by extruding polyvinyl chloride resin into thin sheets, often plasticized to enhance flexibility and tailored for specific uses. Its transparent variant stands out for its ability to combine visual appeal with protective qualities, making it ideal for both dry food and pharmaceutical blister packaging.

1.1 Physical Characteristics

The transparency of PVC film is one of its defining features, with light transmittance often exceeding 85%. This clarity allows consumers to inspect contents—whether it’s the golden hue of a cracker or the pristine white of a tablet—without breaking the seal. With a tensile strength of 20–50 MPa, depending on formulation, PVC film offers sufficient robustness to withstand handling and transport, yet remains pliable enough for thermoforming into blister cavities or wrapping dry goods.

Its thickness, typically ranging from 150 to 300 micrometers for packaging, ensures a lightweight yet sturdy barrier. PVC film’s low water vapor transmission rate (WVTR), around 0.5 g/m²/day at 23°C and 85% relative humidity, is particularly valuable for moisture-sensitive products, preventing degradation and extending shelf life.

1.2 Chemical and Thermal Stability

Chemically, PVC film is inert to most substances, resisting acids, alkalis, and oils commonly found in food and drug formulations. This inertness ensures that it does not impart odors or flavors to dry foods like nuts or cereals, nor does it react with pharmaceutical compounds. Thermally, it performs reliably between -10°C and 60°C, suitable for storage in varied environments—from a pantry shelf to a pharmacy counter.

1.3 Cost-Effectiveness and Processability

PVC film’s affordability is a key driver of its popularity. Its production is streamlined and scalable, leveraging well-established manufacturing techniques to keep costs low. Additionally, its compatibility with high-speed thermoforming and sealing equipment makes it a favorite for large-scale packaging operations, delivering efficiency without compromising quality.

Section 2: PVC Film in Dry Food Packaging

Dry food packaging demands materials that preserve freshness, prevent contamination, and appeal to consumers. Transparent PVC film meets these needs with finesse, offering a clear window into products like snacks, cereals, and dried fruits while safeguarding their quality.

2.1 Protection Against Moisture and Contaminants

Dry foods such as crackers or granola are prone to losing their crispness when exposed to humidity. PVC film’s low WVTR acts as a shield, keeping moisture at bay. For instance, a pack of rice cakes wrapped in transparent PVC film remains crunchy even in a humid kitchen, its texture intact from factory to table. The film also blocks dust and insects, ensuring that a bag of almonds stays hygienic and safe for consumption.

2.2 Visual Appeal and Consumer Trust

The transparency of PVC film enhances the shopping experience by showcasing the product’s quality. Imagine a supermarket shelf lined with packets of dried apricots—the vibrant orange fruit visible through the PVC film entices buyers, signaling freshness and authenticity. This visibility builds trust, a crucial factor in food purchasing decisions, and sets PVC film apart from opaque alternatives like paper or foil.

2.3 Practical Examples

In practice, PVC film is often used for tray-sealing dry snacks or wrapping individual portions. A vivid example is the packaging of biscotti: each piece is nestled in a thermoformed PVC film tray, sealed with a foil lid. The clarity reveals the rustic texture and chocolate drizzle, while the film’s durability protects against breakage during shipping—a perfect marriage of form and function.

Section 3: PVC Film in Pharmaceutical Blister Packaging

In the pharmaceutical world, blister packaging is a gold standard for delivering solid-dose medications like tablets and capsules. Transparent PVC film forms the backbone of these packs, offering protection, visibility, and patient-friendly features.

3.1 Drug Stability and Protection

Pharmaceuticals require stringent protection from environmental factors like moisture and light. PVC film’s low WVTR is a boon for hygroscopic drugs—those that absorb water—such as aspirin, which can degrade into less effective compounds if exposed to humidity. A blister pack of aspirin crafted from PVC film ensures each tablet remains potent, whether stored in a dry clinic or a damp bathroom.

While its oxygen barrier (approximately 100–200 cm³/m²/day) is moderate, PVC film can be paired with coatings like PVDC to enhance performance for oxygen-sensitive drugs. For light-sensitive medications, colored PVC film variants are available, though the transparent form excels where visibility is prioritized.

3.2 Patient Safety and Compliance

Blister packs with PVC film isolate each dose, preventing cross-contamination and overdosing—a critical feature for drugs like warfarin, where precision is vital. The film’s clarity allows patients to confirm the presence of each tablet, reducing errors. Picture an elderly patient managing a daily regimen of vitamins: the transparent PVC film reveals the pills’ colors and shapes, paired with a foil lid marked with days of the week, simplifying adherence.

3.3 Tamper Evidence

PVC film enhances security by providing tamper-evident packaging. Once sealed, a blister pack cannot be opened without tearing the film or foil, a safeguard against counterfeiting. For example, a pack of antihistamines in a PVC film blister offers peace of mind—any tampering would be glaringly obvious, ensuring the patient receives a genuine product.

3.4 Real-World Application

Consider ibuprofen, a common pain reliever. Packaged in PVC film blisters, its white tablets gleam through the transparent film, reassuring users of their quality. The film’s durability protects the tablets during global distribution, while its affordability keeps production costs manageable—a win for manufacturers and consumers alike.

Section 4: Advantages and Challenges of Transparent PVC Film

PVC film’s dominance in dry food and pharmaceutical packaging stems from its strengths, though it faces some limitations that warrant consideration.

4.1 Key Advantages

Clarity: Its transparency enhances product visibility, boosting consumer confidence and aiding quality checks.

Moisture Resistance: The low WVTR protects dry foods and drugs from humidity, preserving freshness and efficacy.

Cost-Effectiveness: Affordable production and processing make PVC film a budget-friendly option for mass-market goods.

Versatility: It adapts to diverse packaging needs, from food trays to blister packs, with ease.

4.2 Limitations and Solutions

PVC film’s moderate oxygen barrier may not suffice for highly sensitive pharmaceuticals, necessitating laminates like PVDC or Aclar, which increase costs. Environmentally, its chlorine content raises disposal concerns—incineration can release dioxins if mismanaged—though modern recycling and waste management mitigate this risk. For dry foods requiring high aroma retention, such as spices, additional barriers may be needed, as PVC film allows some gas transmission.

Conclusion

Transparent PVC film stands as a versatile champion in packaging dry foods and pharmaceuticals, blending clarity, protection, and affordability into a single material. From keeping biscuits crisp to safeguarding tablets, its properties cater to the practical and aesthetic demands of both industries. While challenges like environmental impact and barrier limitations exist, innovations in coatings and recycling ensure its continued relevance. As global markets expand and consumer expectations rise, PVC film remains a clear, reliable choice—literally and figuratively—delivering safety and satisfaction in every pack.

Within 15-20 days after received payment...more