The Applications of High - Transparency PP Film in Multiple Fields

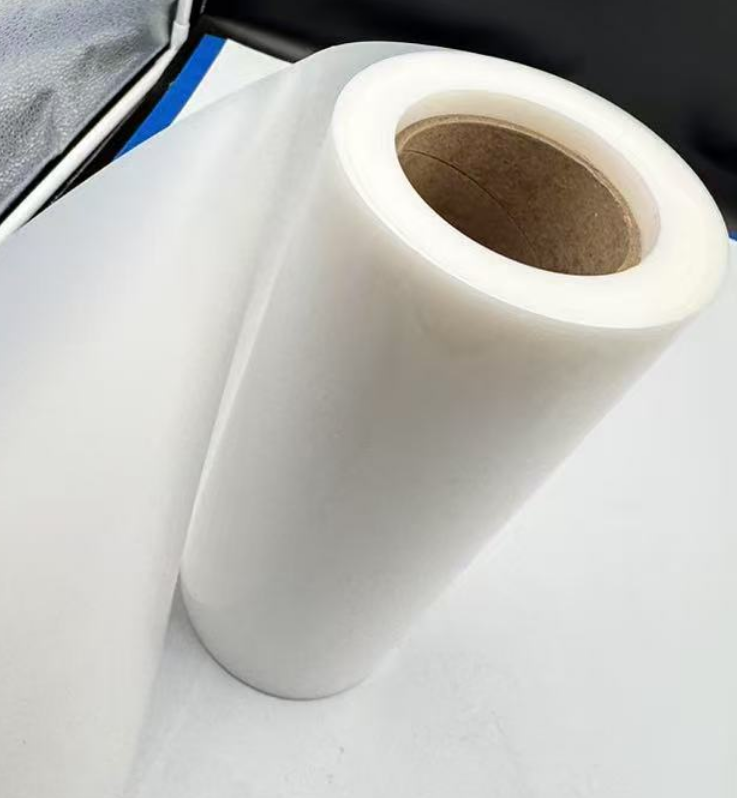

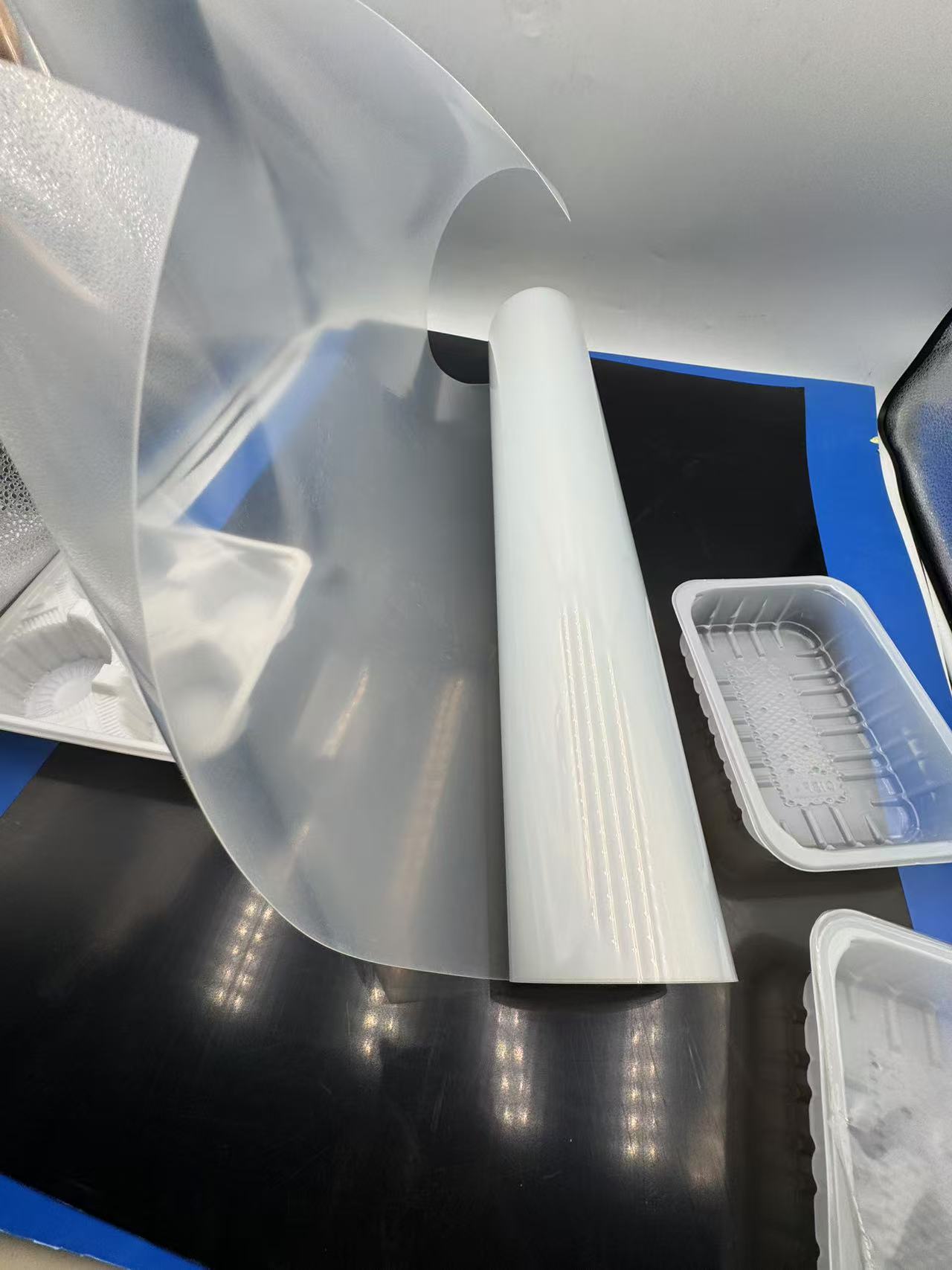

Material: PP Thermal formed sheet

Thickness 0.25-0.9mm/customization

Size: 300mm/Customization

GRADE: Food grade film

color: black/white/ customization

location: china

usage :for food tray ,mircronwave food container

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Applications of High-Transparency PP Film to Many Fields

I. Introduction

In this era of rapid development in the field of materials science, high-transparency PP film has prominently shown its advantages of unique properties and wide applicability in many aspects.

From the daily food packaging to the sophisticated insulation for batteries, the quiet changing of life and industrial production is done by high-transparency PP film. The following article will explain in detail the fantastic applications of high-transparency PP film in food blister packaging, fresh meat freezing boxes, microwave-heatable takeout packaging, and battery insulation.

II. Properties of High-Transparency PP Film

(I) Exceptional Transparency

High-transparency PP film has very high transparency, almost equal to that of glass. This property makes the products inside the packaging clearly visible. Whether it is colorful food or exquisitely designed goods, they can be perfectly presented through high-transparency PP film.

(III) Chemical Stability

PP film shows good chemical resistance against many chemical substances: It cannot have any chemical reactions with components in foods such as oils, acids, and alkalis, since it is resistant; hence, it assures that foods will retain their quality and be safe to eat. A very important characteristic,

(V) Hygiene and Safety

High-transparency PP film is up to the stringent food hygiene standards, nontoxic, and odorless. Thus, all kinds of food packaging will not be harmful to human health.

III. Applications of High - Transparency PP Film in Food Blister Packaging

(I) Display Effect and Marketing Advantage

Food blister packaging needs to highlight the appearance of the product to attract consumers' attention. The high transparency of high-transparency PP film makes the food stand out on the shelves.

(II) Protection of Food Quality

It has very good barrier properties and can block the influence of external factors, such as oxygen, water vapor, and dust, on food. In blister packaging of nuts, PP film will avoid the entry of oxygen to make nuts oxidize and deteriorate, thus extending the shelf life of the food.

(III) Environmental Protection and Sustainability

With the enhancement of environmental awareness, the environmental friendliness of packaging materials has gained increasing attention. PP films have high transparency and are recyclable, which makes them accordant with the concept of environmental protection. Many food enterprises have used PP film materials to package the blister in an attempt to reduce environmental damages. Besides, the energy used in the producing line for PP film is relatively low compared to other types. This not only helps enterprises establish a good social image but also satisfies the demands of consumers for environmentally friendly products.

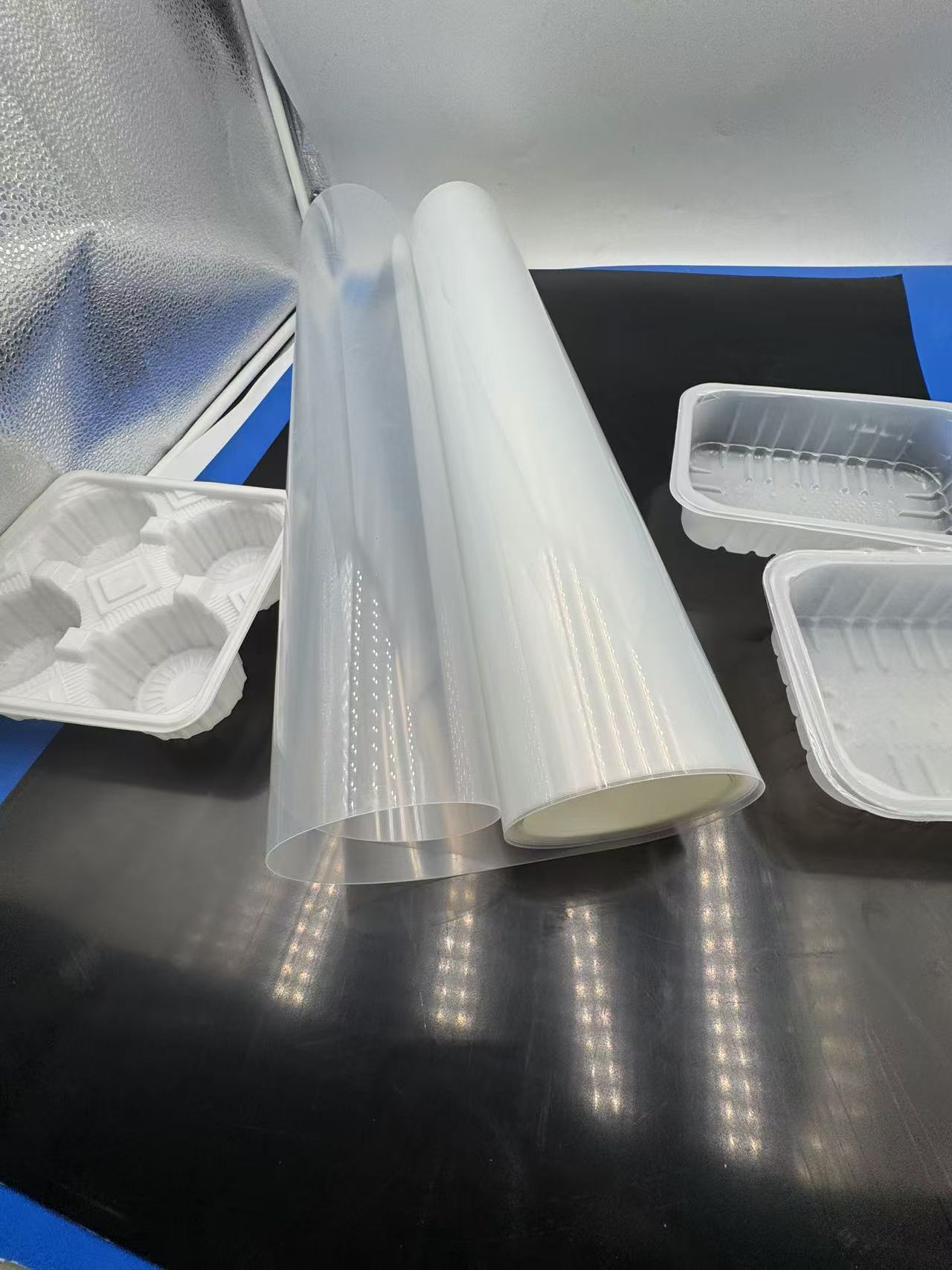

IV. Applications of High - Transparency PP Film in Fresh Meat Freezing Boxes

(I) Adaptability to Low Temperature

There is a demand for fresh meat freezing boxes to maintain good performance even in a low-temperature environment. High-transparency PP film maintains good flexibility even at low temperatures and does not become brittle, rupture, and the like, unlike some other materials. If fresh meat is frozen in boxes made of high-transparency PP film, then after long-term frozen storage, the PP film can tightly wrap fresh meat to avoid moisture loss and maintain freshness and taste in the fresh meat. During the defrosting process, PP film can also be adapted to temperature changes without cracking or deforming.

(II) Blocking Blood-water and Hygiene

Fresh meat will have blood-water seepage during the freezing and thawing process. The high-transparency PP film has an excellent barrier function, effectively blocking blood-water from seeping out and ensuring cleanliness and hygiene in packaging. This not only prevents further contamination by/ of other foodstuffs/ environment but it also blocks loss of blood-water in preventing the nutritional component - taste deterioration in fresh meat. Simultaneously, this provides hygiene and safety to PP films so that no potential harm can arise to human health due to its direct contact with fresh meat.

III. Clarity

When consumers are buying fresh meat, they want to clearly see the quality of the meat. The highly transparent high-transparency PP film will enable consumers to directly observe the color and texture, freshness of the fresh meat, and therefore increase the consumer's trust in the product. High-transparency PP film fresh meat freezing boxes in supermarket freezers will make the fresh meat catch the eyes of consumers, attracting the attention of consumers and hence stimulating sales.

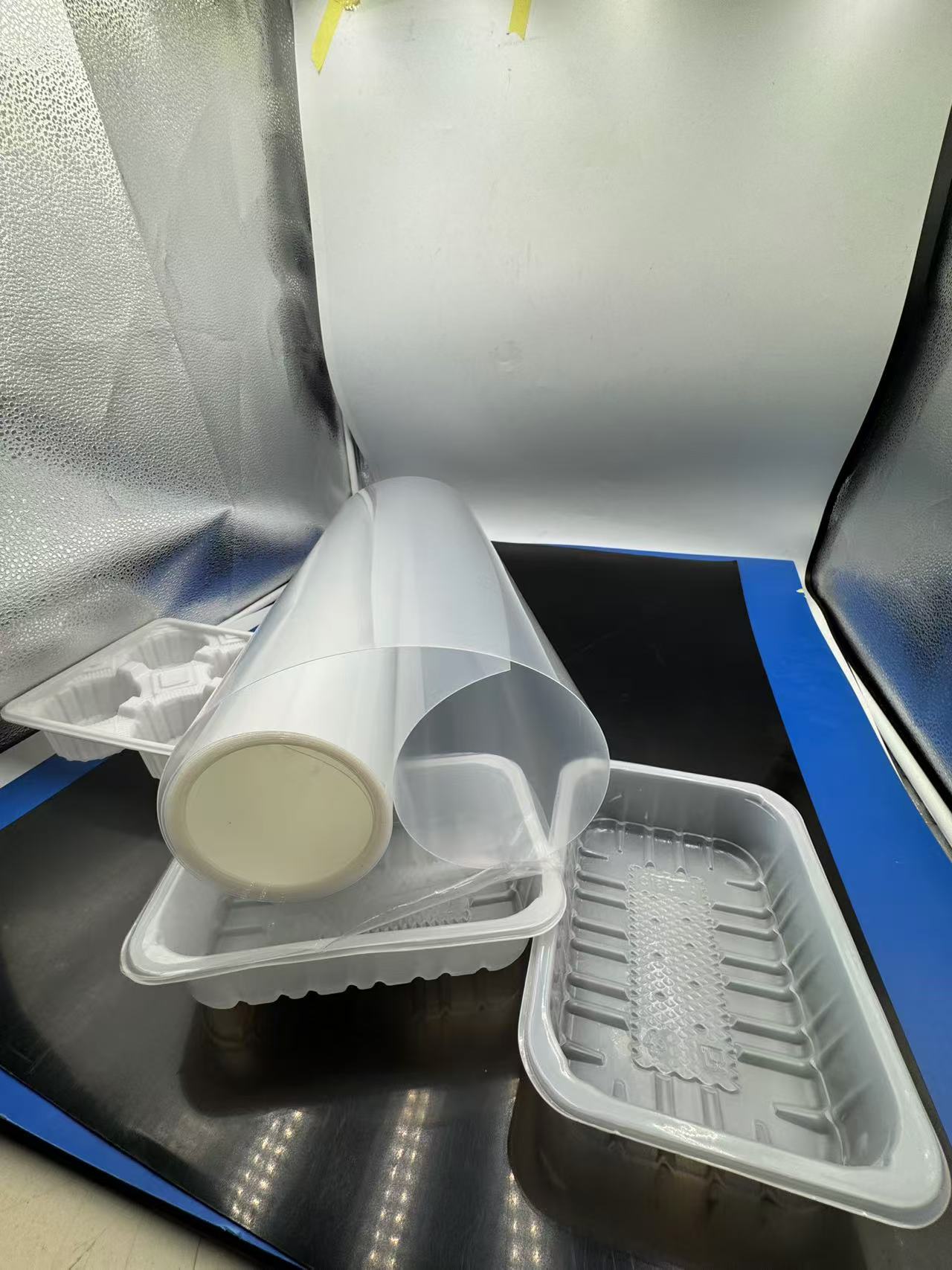

V. Applications of High-Transparency PP Film in Microwave-Heatable Takeout Packaging

(I) Adaptability in the Microwave

Microwave-heatable takeout packaging should be safely used in a microwave oven. High-transparency PP film has good temperature-resistance performance and can bear high temperature produced during microwave heating without melting, deforming, or releasing harmful substances. In cases when consumers heat food packaged with PP film in a microwave oven, the PP film can keep the integrity of the package and assure uniform heating of the food, with no negative impact on the quality and flavor of the food.

(II) Convenience and Practicality

Takeaway packages can be heated in a microwave oven, and high-transparency PP film makes the package light and easy to carry. In this fast-paced modern life, people hope that the take-out packaging is convenient to heat up, carry, and use directly. PP film packaged meets these requirements. Whether in the office, at home, or outdoors, consumers can easily heat the takeout food in a microwave oven and enjoy delicious food. Besides, the transparency of PP film can make consumers observe the state of the food without opening the package, which is more convenient.

(III) Enhancing the Quality Image of Take-out

High-quality take-out packaging can enhance the quality image of take-out. The high transparency and good texture of high-transparency PP film make the takeout packaging look high-grade and hygienic. High-transparency PP film packaging will enhance the favorability of consumers to the brand for takeout merchants. In the highly competitive takeout market, exquisiteness in packaging has become one of the important factors for the standing out of the merchant.

VI. Application to Battery Insulation of High-Transparency PP Film

(I) Electrical Insulation Performance

In the battery, the electrical insulation performance is very important in insulating materials. High-transparency PP film has very excellent electrical insulation performance and effectively avoids current leakage, guaranteeing the safety and stability of the battery. Whether a lithium-ion battery, lead acid battery, or any other type of battery, this high-transparency PP film can be used as an insulation layer to avoid internal short circuits in the battery for extended lifetime.

(II) Chemical Stability and Battery Life

The inner chemical environment of the battery is rather complex; insulating materials should be resistant to erosion by chemical substances. High-transparency PP film has good chemical stability that is able to maintain stability in the chemical environment inside the battery without any chemical reaction with components such as electrolytes in the battery. This not only ensures the normal service life of the battery but also extends the service life of the battery. As an example, applying high-transparency PP film in the battery packs of electric vehicles can enhance the reliability and durability of the battery and support large-scale application. (III) Process Adaptability

In the course of battery manufacturing, the insulation material should possess good process adaptability. High-transparency PP has good flexibility, excellent processing performance, and it can be set in proper shapes and sizes with the dimensions depending on batteries. Being hot-pressed, coated, or under any other processes, this layer could be combined tightly with other parts of a battery for reliable insulation. This process adaptability has made high-transparency PP film widely used in battery manufacturing, improving the production efficiency and quality of batteries.

VII. Conclusion

High-transparency PP film, with its excellent transparency, good mechanical properties, chemical stability, temperature-resistance performance, and hygiene and safety, plays an important role in many fields such as food blister packaging, fresh meat freezing boxes, microwave-heatable takeout packaging, and battery insulation. It meets not only the performance requests of packaging and insulating materials in many industries but also makes great contributions to the enhancement of product images, promotion of sales, and ensuring product quality and safety.

Due to the continuous development of science and technology, changes in market demand, high-transparency PP film will be able to enter a wider range of applications, constantly being optimized and innovated, adding more convenience to people's lives and industrial production. Transparency-high PP film will always play a pivotal role in developing and furthering the course of various industries, be it at the level of daily life or high-technology industry.

Within 15-20 days after received payment...more