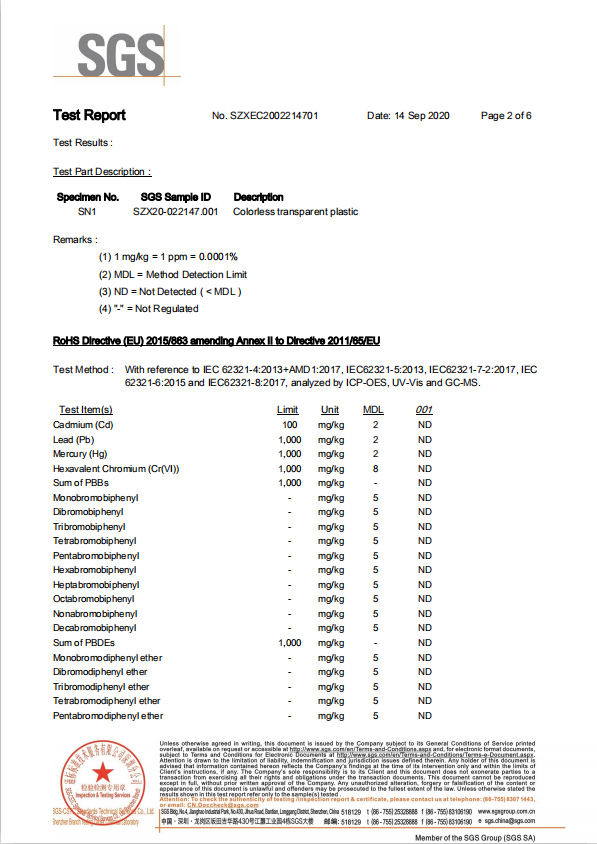

PET191PET Grid Film: The Versatile Solution for Electronic Component Carriers

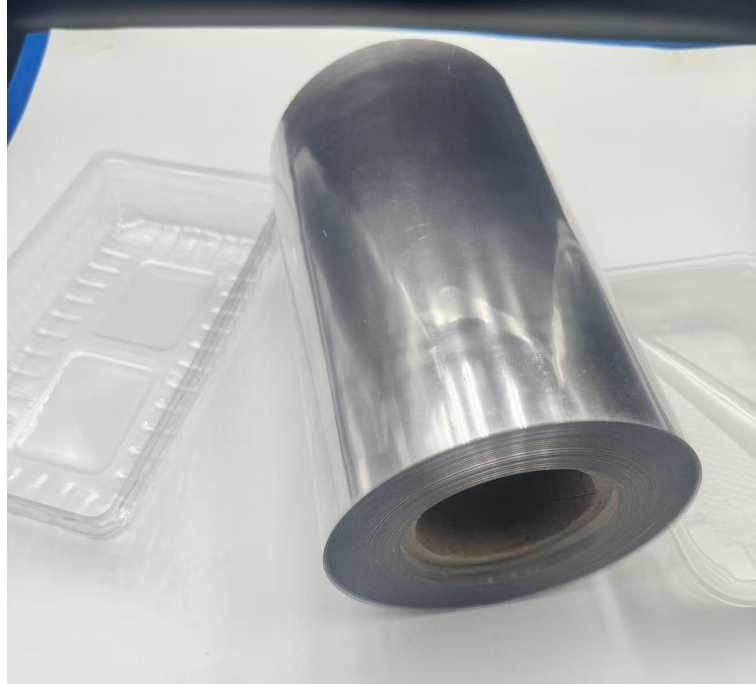

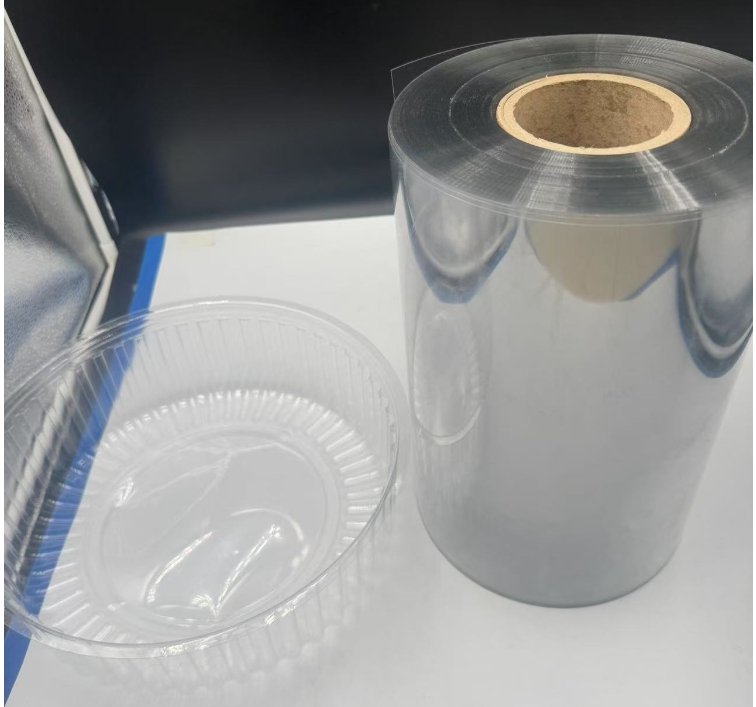

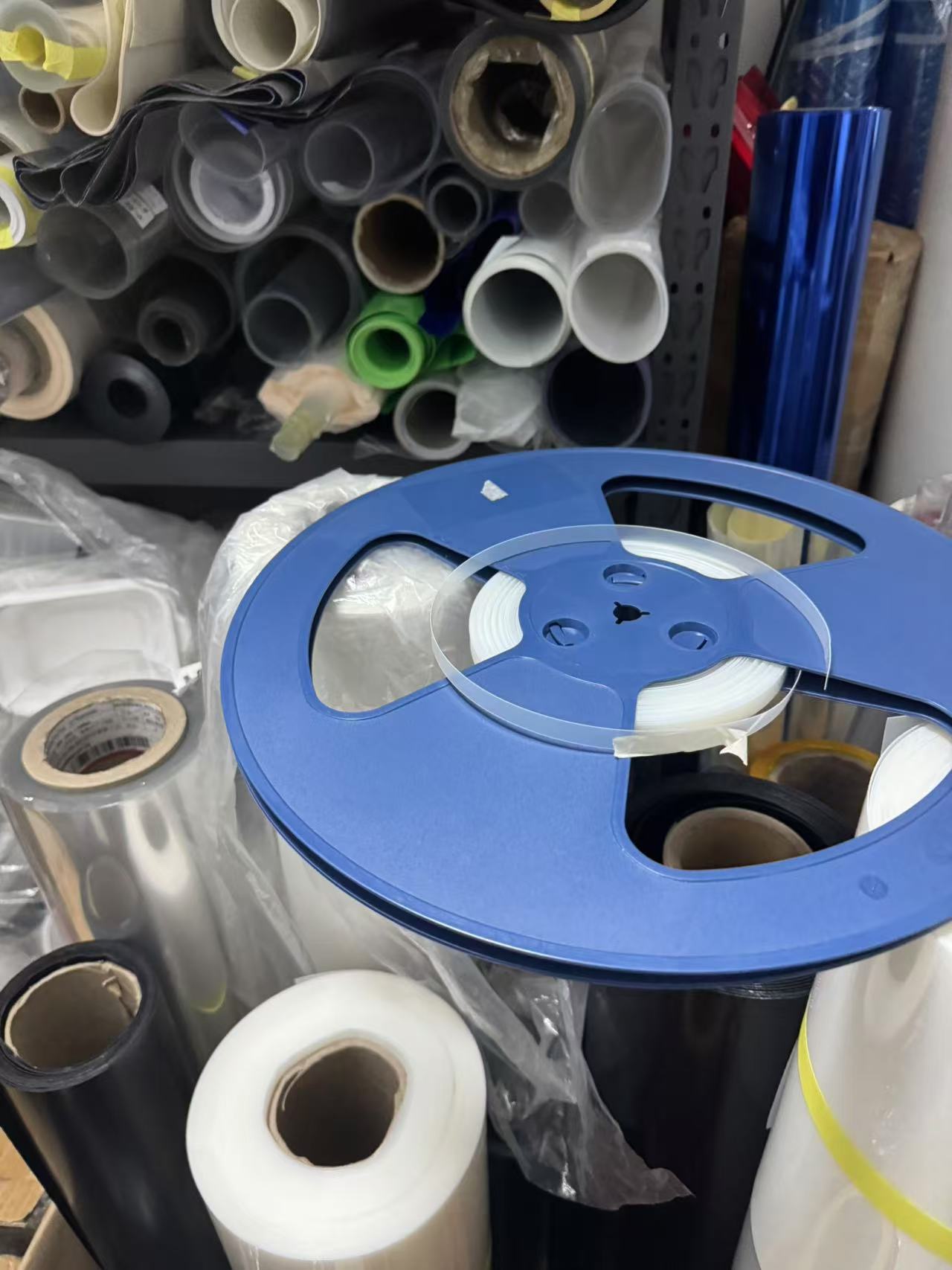

Material: PET antistatic film

Thickness 0.1mm/customization

Size: 100mm/Customization

GRADE: TOP grade film

color: transparent/white/ customization

location: china

usage :for Electronic Component Carriers

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

PET Grid Film: The Versatile Solution for Electronic Component Carriers

I. Introduction

A. What is PET Grid Film?

PET grid film is a remarkable material composed of polyethylene terephthalate (PET), a thermoplastic polymer renowned for its outstanding mechanical and chemical properties. It is distinguished by a grid-like pattern, meticulously engineered to confer specific benefits in diverse applications. The grid's dimensions, shape, and density can be adjusted to suit particular uses, endowing it with enhanced strength and functionality compared to a conventional PET film.

B. Importance of Electronic Component Carriers

Electronic component carriers are the bedrock of the electronics industry. They furnish a stable and organized platform for an array of components such as integrated circuits, resistors, capacitors, and more. A well-designed carrier not only secures components during manufacturing and assembly but also shields them from external elements like mechanical shock, moisture, and electromagnetic interference. In the highly intricate and miniaturized domain of modern electronics, the precision and dependability proffered by these carriers are indispensable for the overall performance and durability of electronic devices.

II. Properties of PET Grid Film

A. High Transparency

A prominent characteristic of PET grid film is its remarkable transparency. This enables effortless visual inspection of the electronic components placed atop or beneath it. During production, technicians can promptly assess the alignment, integrity, and any potential flaws of the components without the need to remove the film. This transparency also facilitates the employment of optical sensing technologies, which can be integrated into the assembly line for automated inspection and quality control. For instance, in the fabrication of high-resolution display panels, the transparency of PET grid film ensures that the underlying components, such as thin-film transistors and liquid crystal layers, can be precisely monitored and adjusted if necessary.

B. Good Electrical Insulation

PET grid film exhibits excellent electrical insulation capabilities. In an electronic device, where numerous components with varying electrical potentials are in close proximity, the threat of electrical short circuits is ever-present. The PET grid film functions as a reliable barricade, impeding the flow of electric current between adjacent components that are not intended to be electrically connected. This insulation is vital for maintaining the proper operation of each component and the overall circuitry. For example, in a printed circuit board (PCB) assembly, the film can be utilized to segregate different sections of the board, guaranteeing that signals are routed accurately and that no unwanted electrical interactions occur.

C. Durability

The durability of PET grid film is another crucial aspect that renders it highly suitable for electronic component carriers. It can endure a gamut of environmental conditions, including temperature fluctuations, humidity, and mechanical stresses. In the manufacturing environment, components are frequently subjected to handling, transportation, and assembly procedures that could potentially damage them. The PET grid film serves as a protective shield, diminishing the risk of scratches, abrasions, and breakages. Moreover, throughout the lifespan of an electronic device, it can withstand the typical wear and tear, ensuring the continued safeguarding of the components. For example, in portable electronic devices like smartphones and tablets, which are constantly in motion and exposed to diverse conditions, the PET grid film contributes to maintaining the integrity of the internal components.

III. Uses of PET Grid Film in Electronic Component Carriers

A. Protection of Electronic Components

The foremost application of PET grid film in electronic component carriers is to offer protection to the components. As previously mentioned, it acts as a buffer against physical impact, safeguarding against accidental drops or bumps during handling and transportation. Additionally, it forms a barrier against moisture, which can lead to corrosion and damage of the delicate electronic components. Dust and other particulate matter are also repelled, preventing them from settling on the components and potentially causing short circuits or other malfunctions. For instance, in the packaging of sensitive microchips, the PET grid film is often employed as an inner lining to ensure that the chips remain in pristine condition until they are installed in the final device.

B. Electrical Insulation

Beyond its role in shielding against physical and environmental factors, PET grid film plays a pivotal role in providing electrical insulation within the component carrier. It is used to isolate different components with disparate electrical characteristics, ensuring that electrical signals travel only along the intended paths. This is especially critical in complex electronic circuits where precise control of signal routing is essential. For example, in a power supply unit, the film can be used to separate the high-voltage and low-voltage sections, precluding any accidental arcing or short circuits that could damage the components or pose a safety hazard.

C. Carrier for Electronic Parts

PET grid film can also serve as an efficient carrier for electronic parts during the manufacturing process. It offers a flat and stable surface upon which components can be positioned and manipulated. This is particularly advantageous in automated assembly lines where precise placement of components is obligatory. The grid structure of the film can even be exploited to assist in the alignment of components, with the grid lines serving as reference points. For example, in the production of surface mount technology (SMT) components, the PET grid film can be used to hold the minute components in place prior to their soldering onto the PCB, ensuring accurate positioning and minimizing the risk of misalignment.

IV. Advantages of PET Grid Film in Electronic Component Carriers

A. Cost-Effective

One of the significant advantages of incorporating PET grid film in electronic component carriers is its cost-effectiveness. When compared to many other materials possessing similar properties, such as certain ceramics or specialized polymers, PET grid film is relatively inexpensive. This makes it an alluring option for manufacturers, especially when engaged in large-scale production of electronic devices. The lower cost of the material does not compromise its performance, enabling companies to uphold high-quality standards while keeping production costs in check. For example, in the mass production of consumer electronics like smartphones and smartwatches, the utilization of PET grid film can substantially reduce the overall cost of the component carriers without sacrificing the requisite protection and functionality.

B. Lightweight

PET grid film is exceptionally lightweight, which is a substantial advantage in the context of electronic devices. In today's market, consumers crave portable and lightweight electronics, and every gram matters. The use of PET grid film as a component carrier contributes to reducing the overall weight of the device, enhancing its portability and ease of handling. This is especially crucial for handheld devices such as tablets and e-readers, where a lighter weight can augment the user experience. Additionally, the lightweight nature of the film also has implications for transportation costs, as lighter devices necessitate less energy for movement and shipping.

C. Easy to Process

Another advantage of PET grid film is its ease of processing. It can be readily cut, shaped, and laminated using standard manufacturing techniques. This flexibility empowers manufacturers to customize the film according to their specific requirements. For example, they can trim the film into diverse shapes and sizes to fit the exact dimensions of the component carrier they are designing. Lamination can be employed to combine the PET grid film with other materials, such as adhesives or protective coatings, to further enhance its properties. This ease of processing facilitates efficient production lines and rapid turnaround times, which are vital in the fast-paced electronics industry.

VI. Applications of Electronic Component Carriers with PET Grid Film

A. Consumer Electronics

In the domain of consumer electronics, PET grid film is ubiquitously employed in a multitude of devices. In smartphones, it serves as a component carrier for the internal circuitry, safeguarding the components from physical damage and providing electrical insulation. It also aids in reducing the overall weight of the device, augmenting its portability. In tablets, the film is utilized in a similar fashion, guaranteeing the proper operation of the components and enhancing the user experience via its lightweight and protective qualities. Additionally, in e-readers, PET grid film can be used to secure the display components in place and shield them from moisture and dust.

B. Automotive Electronics

The automotive electronics industry is another arena where PET grid film finds extensive utilization. In dashboard displays, it functions as a component carrier to protect the delicate display components from vibrations, temperature variations, and moisture. The film also supplies electrical insulation, ensuring that the signals transmitted to the display are accurate and dependable. In infotainment systems, PET grid film can be used to carry and protect the diverse electronic components such as the central processing unit (CPU), memory chips, and audio/video components. In engine control units (ECUs), the film is employed to isolate different electrical components and avert short circuits, which could have grave consequences for the vehicle's performance and safety.

C. Industrial Electronics

In industrial electronics, PET grid film is deployed in a wide array of applications. In control panels, it serves as a component carrier to hold and protect the various switches, buttons, and indicators. The film furnishes electrical insulation and protection from physical damage, ensuring that the control panel operates correctly. In sensors and actuators, PET grid film can be used to carry the sensitive components and shield them from environmental factors such as moisture and dust. It also helps to electrically isolate the components, ensuring that signals are accurately transmitted and received.

VIII. Conclusion

A. Summary of Key Points

PET grid film has emerged as a highly versatile and valuable material in the sphere of electronic component carriers. Its unique properties, including high transparency, excellent electrical insulation, and durability, render it ideal for protecting and transporting electronic components. The advantages it presents, such as cost-effectiveness, lightweight nature, and ease of processing, further augment its allure to manufacturers. The manufacturing process of PET grid film is well-defined, permitting the production of top-quality films customized to specific applications. Its applications span across consumer electronics, automotive electronics, and industrial electronics, attesting to its extensive utility.

B. Future Prospects

Looking forward, the future prospects of PET grid film in electronic component carriers are auspicious. Technological advancements are poised to enhance its performance and functionality, while market demand is expected to drive its continued expansion. Environmental considerations also offer an avenue for PET grid film to become a more sustainable option in the electronics industry. As the electronics industry continues to evolve, PET grid film is well-positioned to play an even more significant role in ensuring the reliability and efficiency of electronic component carriers.

Within 15-20 days after received payment...more