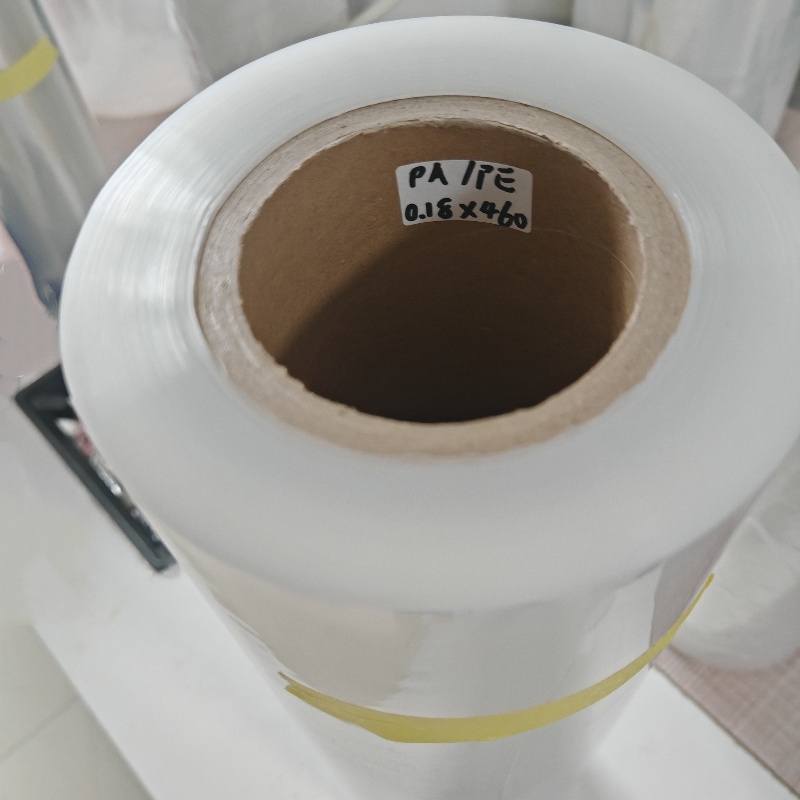

Thermoformable PA/PE top film, Coextruded Barrier Film

PA/PE top & bottom films in vacuum packaging

multi-layered plastic film PA/PE lidding film for MAP packaging

Thermoformable PA/PE top film, Coextruded Barrier Film

extend the freshness of products and extends their shelf life.

- top leader plastic

- China

- 15 business days

- 1500 tons/month

- Information

A/PE film is a versatile packaging material that combines the exceptional strength of polyamide (PA) with the flexibility and moisture resistance of polyethylene (PE). It is widely used in vacuum packaging and modified atmosphere packaging, effectively extending product freshness and shelf life. The following is a detailed introduction to its applications in these packaging applications:

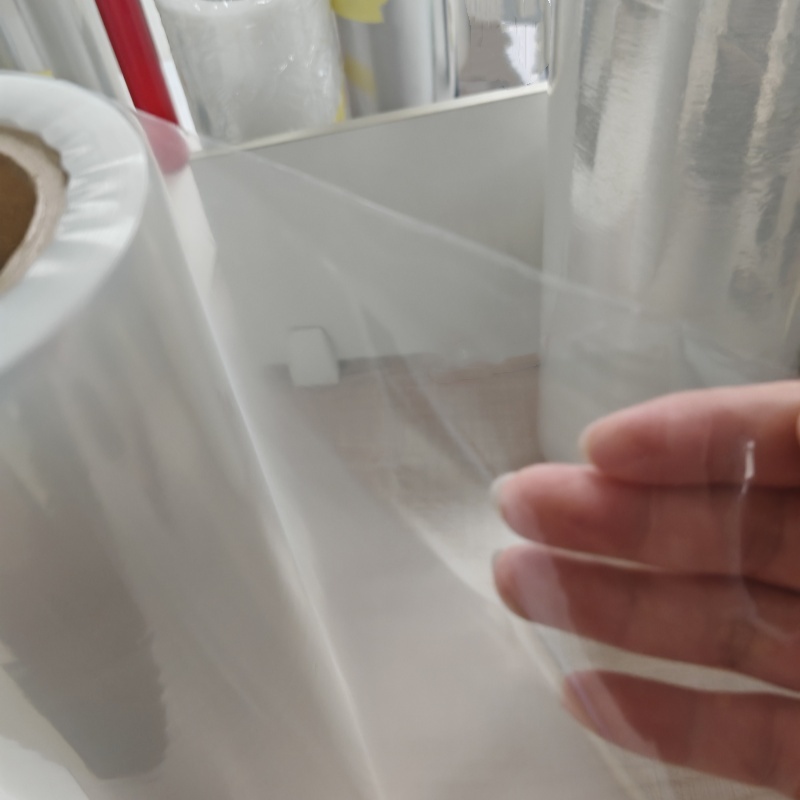

The characteristics and functions of PA/PE top and bottom films: PA offers excellent gas barrier properties, mechanical strength, and puncture resistance, while PE offers excellent flexibility, moisture resistance, and heat-sealing properties. In vacuum packaging, the PA/PE top film is typically thin, such as 90 microns, primarily leveraging its barrier properties to prevent oxygen and moisture from entering the package while maintaining a certain degree of transparency for easy product display. The bottom film is relatively thick, such as 150 microns. In addition to providing certain barrier properties, it also features excellent thermoformability, allowing it to be formed into specific shapes on packaging equipment to accommodate the product.

PA/PE lid film in modified atmosphere packaging: Modified atmosphere packaging requires precise control of the gas composition within the package to extend the shelf life of the product. The PA/PE cover film plays a key role in this process. The PA/EVOH/PE structure, with EVOH serving as an oxygen barrier layer and PA and PE providing mechanical strength and heat sealability, respectively, is suitable for packaging oxygen-sensitive products such as chilled meat. The PA/PE/PP structure offers moderate oxygen barrier properties and is suitable for packaging chilled meat and poultry.

A/PE film is a versatile packaging material that combines the exceptional strength of polyamide (PA) with the flexibility and moisture resistance of polyethylene (PE). It is widely used in vacuum packaging and modified atmosphere packaging, effectively extending product freshness and shelf life. The following is a detailed introduction to its applications in these packaging applications:

The characteristics and functions of PA/PE top and bottom films: PA offers excellent gas barrier properties, mechanical strength, and puncture resistance, while PE offers excellent flexibility, moisture resistance, and heat-sealing properties. In vacuum packaging, the PA/PE top film is typically thin, such as 90 microns, primarily leveraging its barrier properties to prevent oxygen and moisture from entering the package while maintaining a certain degree of transparency for easy product display. The bottom film is relatively thick, such as 150 microns. In addition to providing certain barrier properties, it also features excellent thermoformability, allowing it to be formed into specific shapes on packaging equipment to accommodate the product.

PA/PE lid film in modified atmosphere packaging: Modified atmosphere packaging requires precise control of the gas composition within the package to extend the shelf life of the product. The PA/PE cover film plays a key role in this process. The PA/EVOH/PE structure, with EVOH serving as an oxygen barrier layer and PA and PE providing mechanical strength and heat sealability, respectively, is suitable for packaging oxygen-sensitive products such as chilled meat. The PA/PE/PP structure offers moderate oxygen barrier properties and is suitable for packaging chilled meat and poultry.

Thermoformed PA/PE top film and co-extruded barrier film: Thermoformed PA/PE top film is typically produced using a co-extrusion process, where resins with different properties, such as PA, EVOH, and PE, are melt-extruded separately through multiple extruders and then converged at a single die for final formation. This co-extruded barrier film offers excellent overall performance. Composed of resins such as PA, EVOH, and PE, the multi-layer co-extruded film exhibits high barrier properties, strong toughness, and puncture resistance. It effectively blocks oxygen and moisture vapor, extending the product's shelf life and quality, while also exhibiting excellent heat sealability and flexibility.

Thermoformed PA/PE top film and co-extruded barrier film: Thermoformed PA/PE top film is typically produced using a co-extrusion process, where resins with different properties, such as PA, EVOH, and PE, are melt-extruded separately through multiple extruders and then converged at a single die for final formation. This co-extruded barrier film offers excellent overall performance. Composed of resins such as PA, EVOH, and PE, the multi-layer co-extruded film exhibits high barrier properties, strong toughness, and puncture resistance. It effectively blocks oxygen and moisture vapor, extending the product's shelf life and quality, while also exhibiting excellent heat sealability and flexibility.

Within 15-20 days after received payment...more