The Versatile Properties and Applications of Transparent PVC Film in Blister Packaging and Beyond

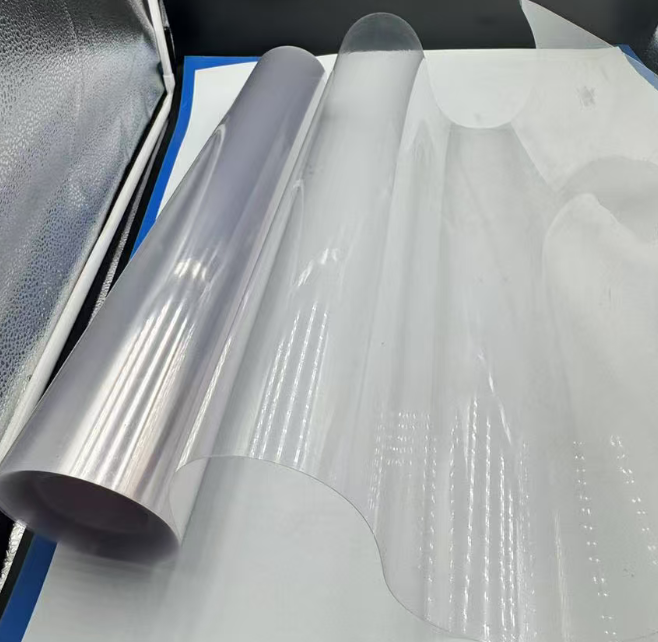

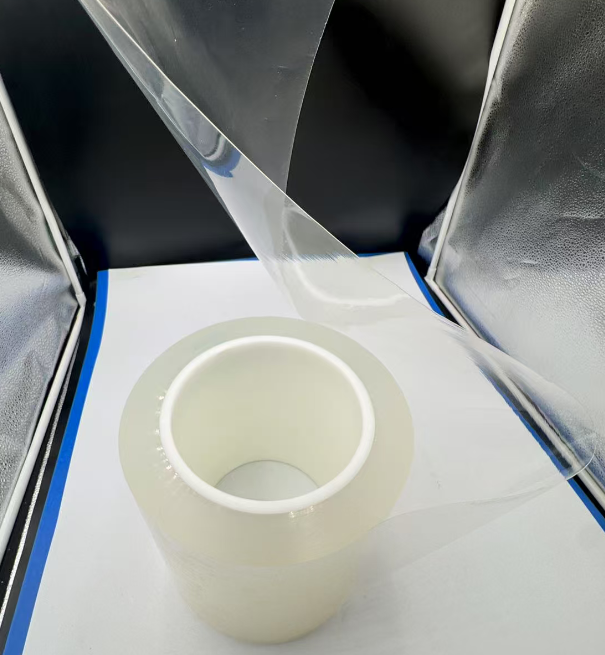

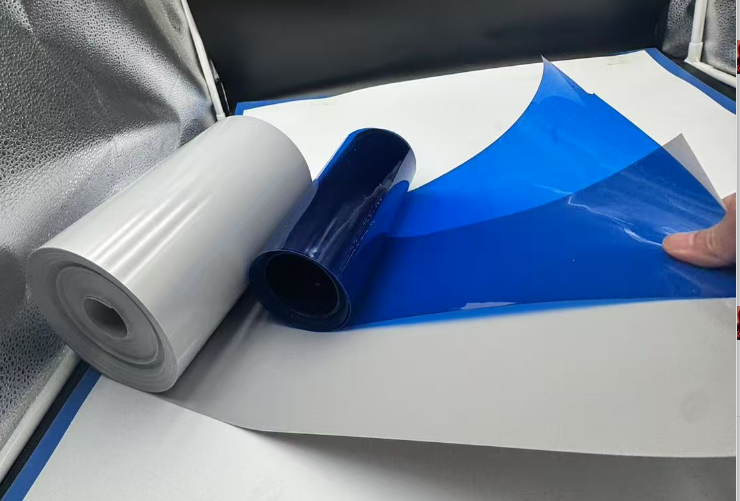

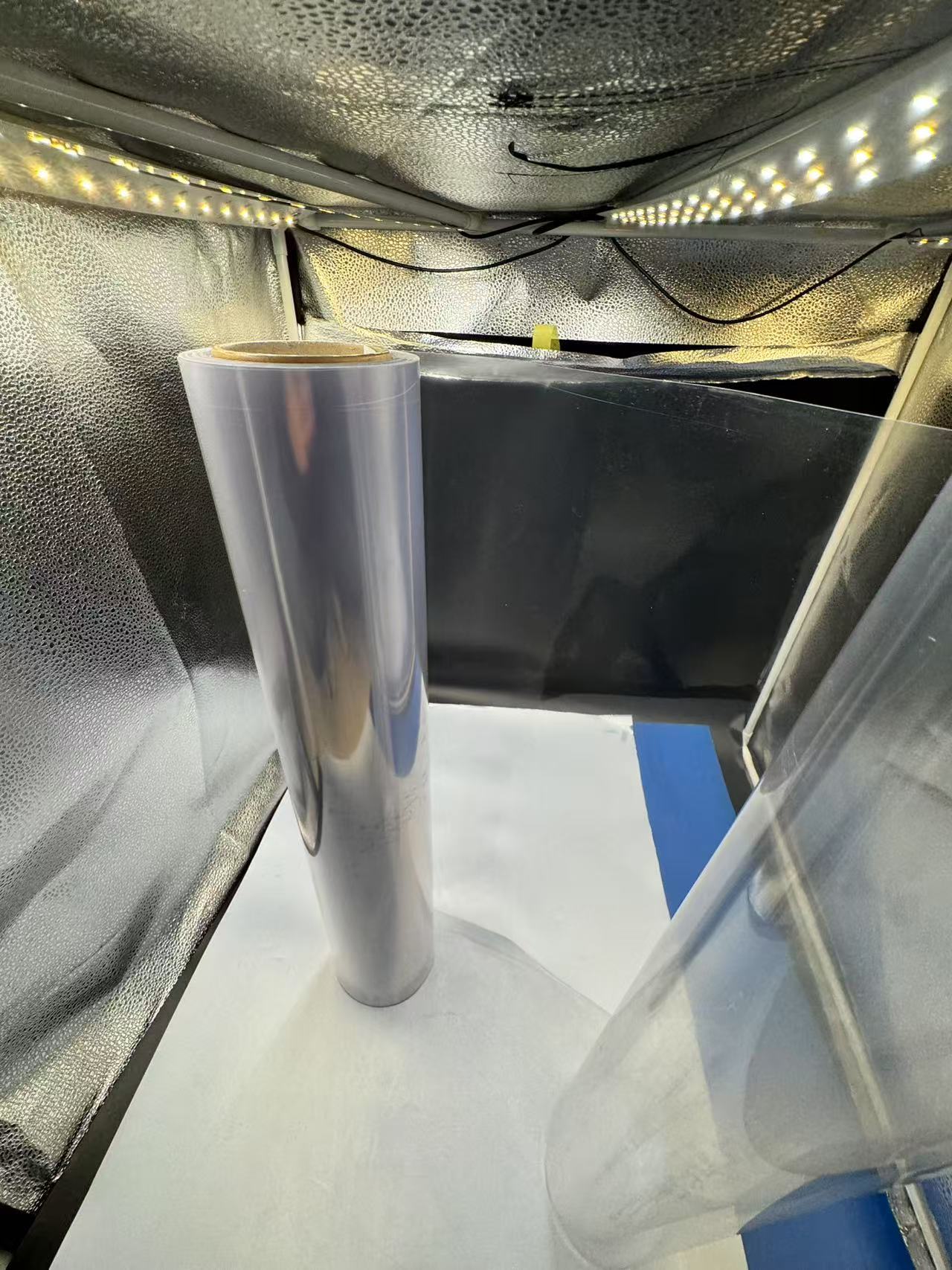

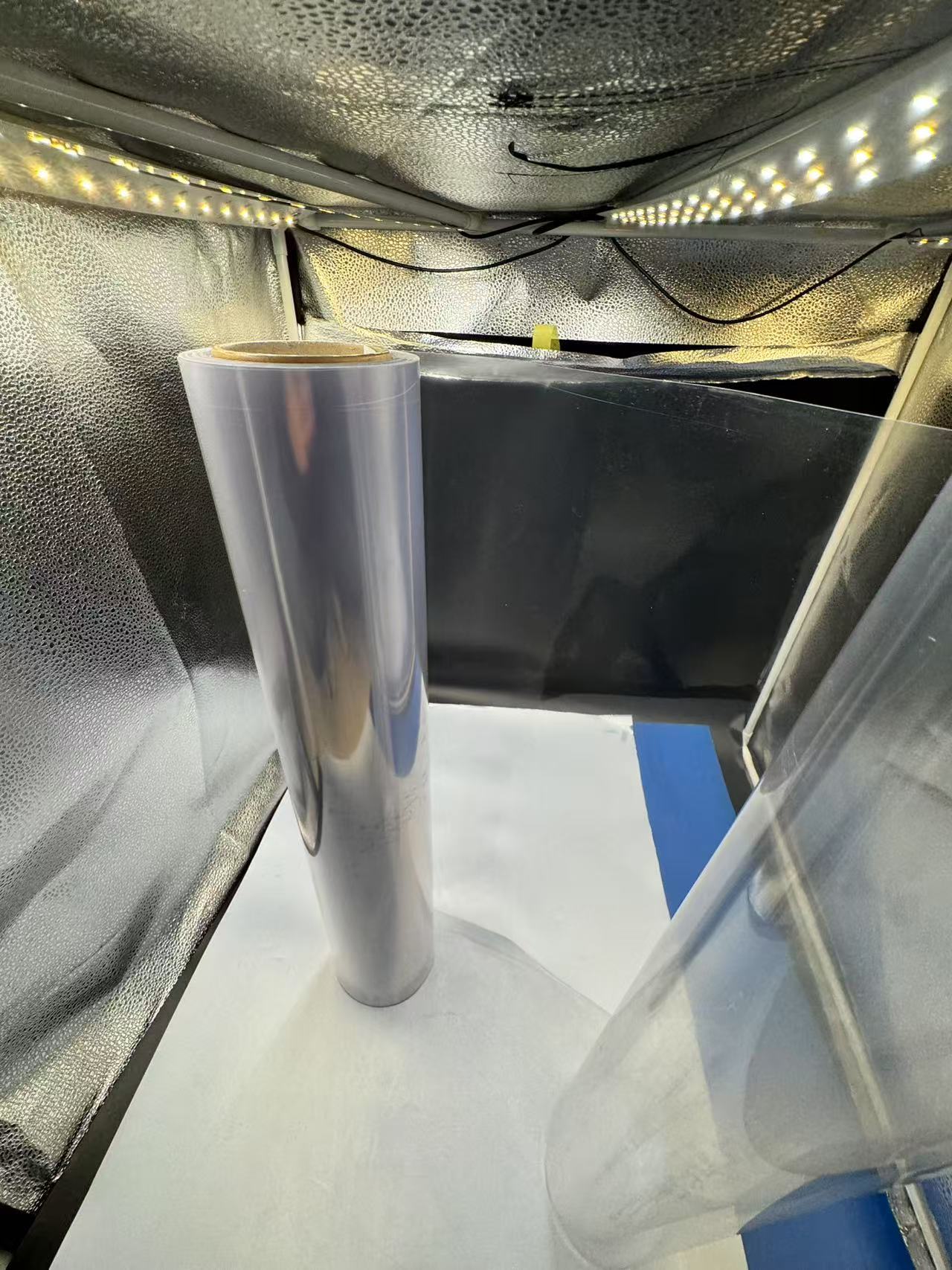

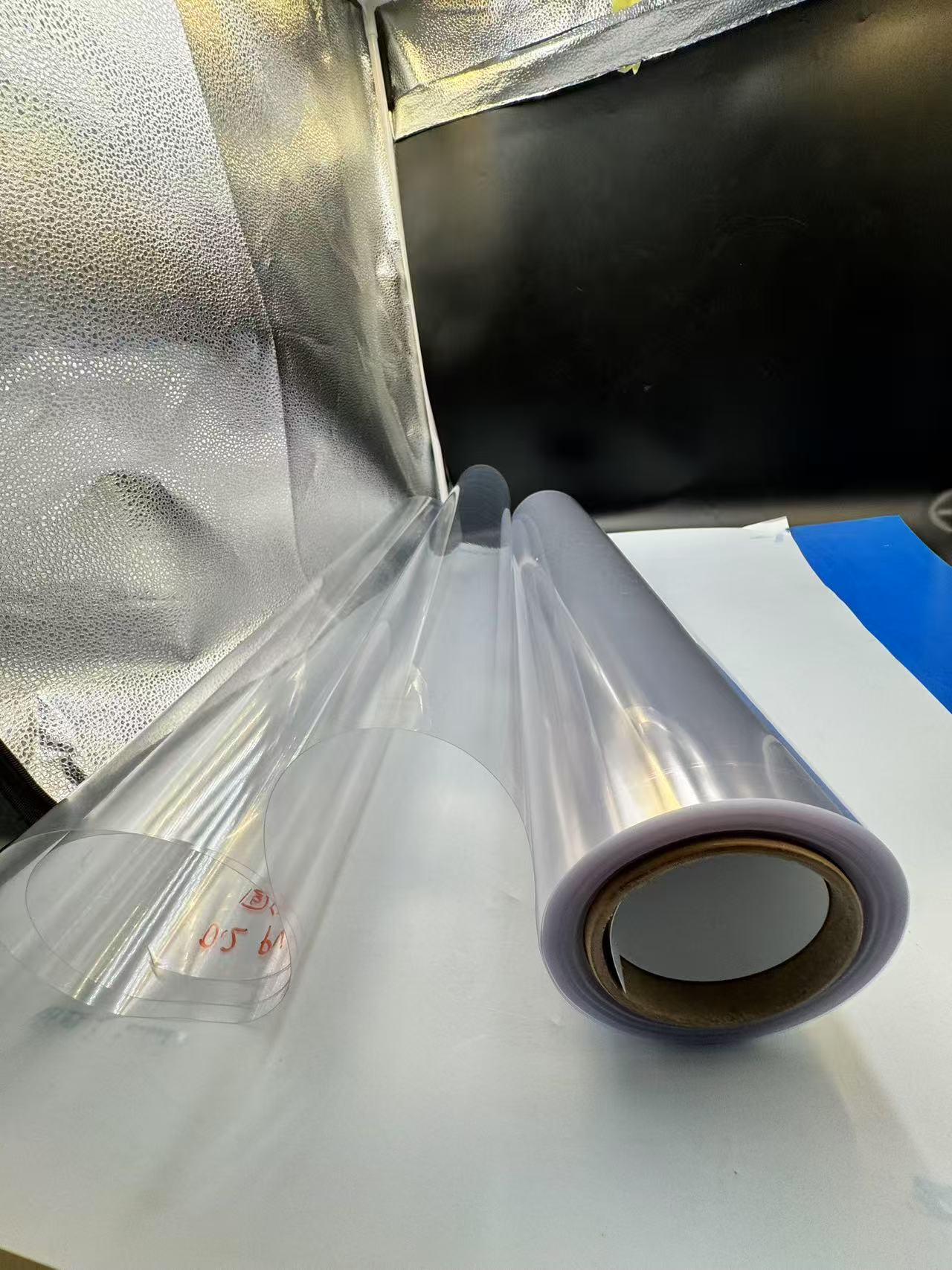

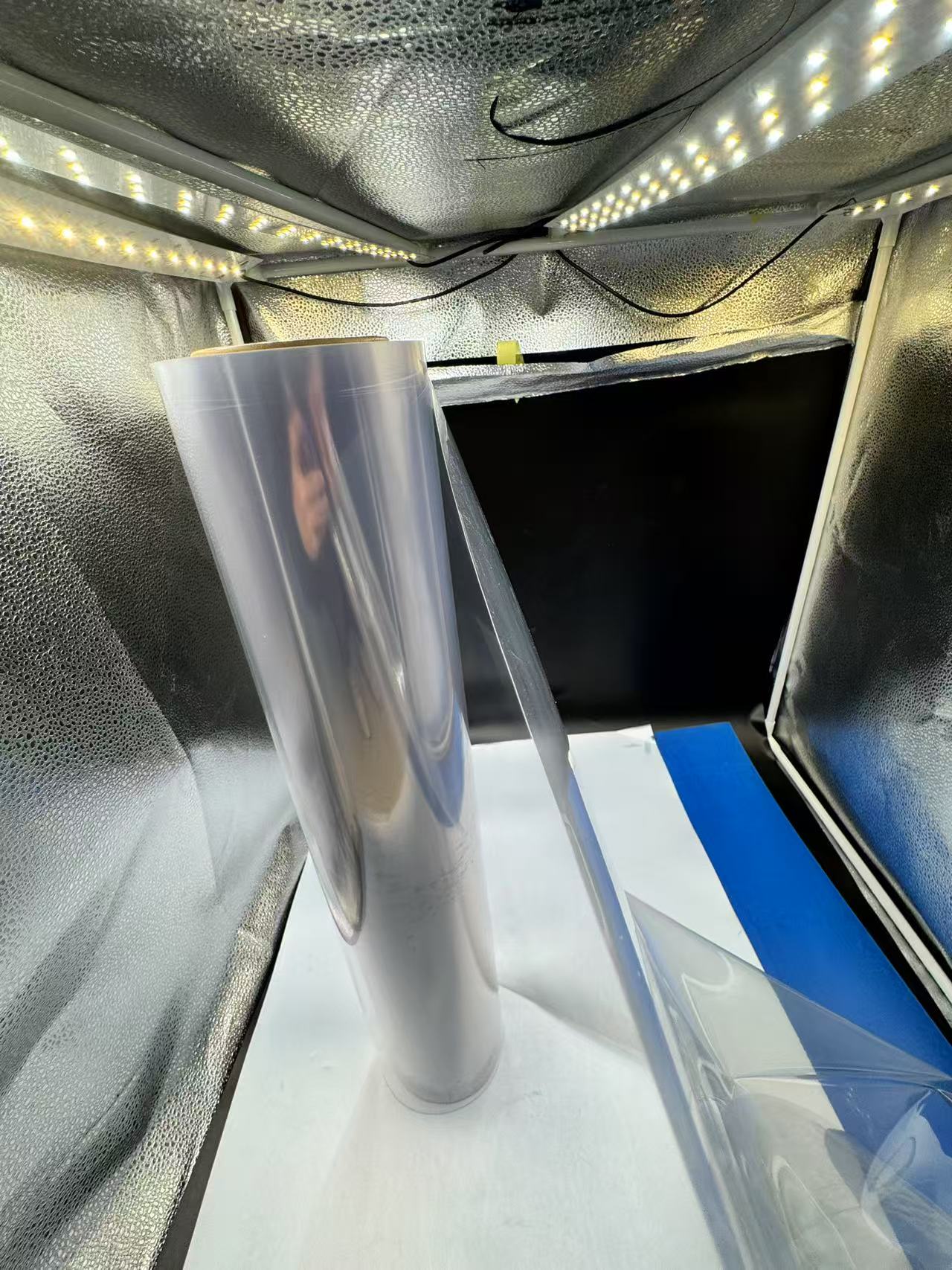

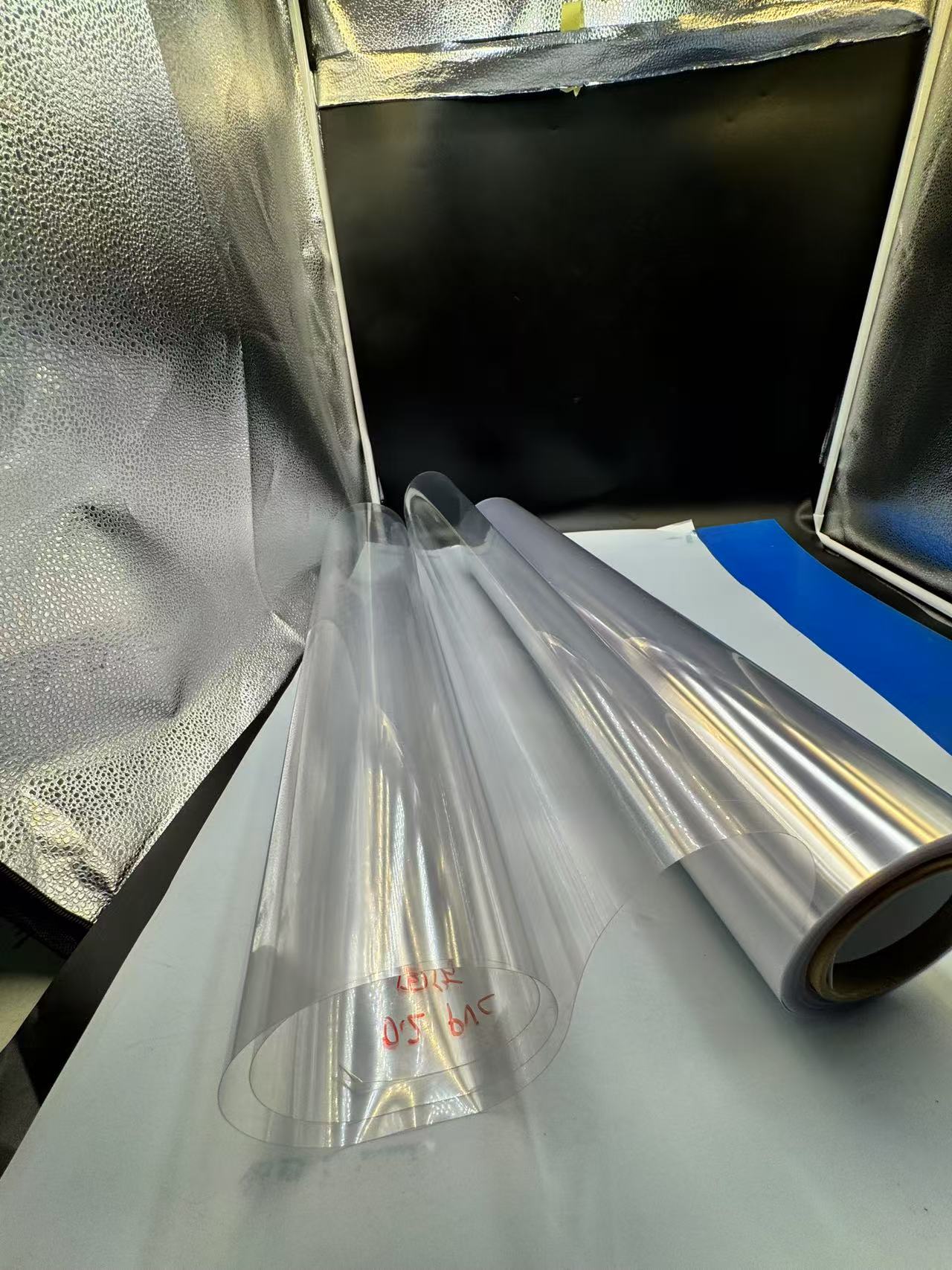

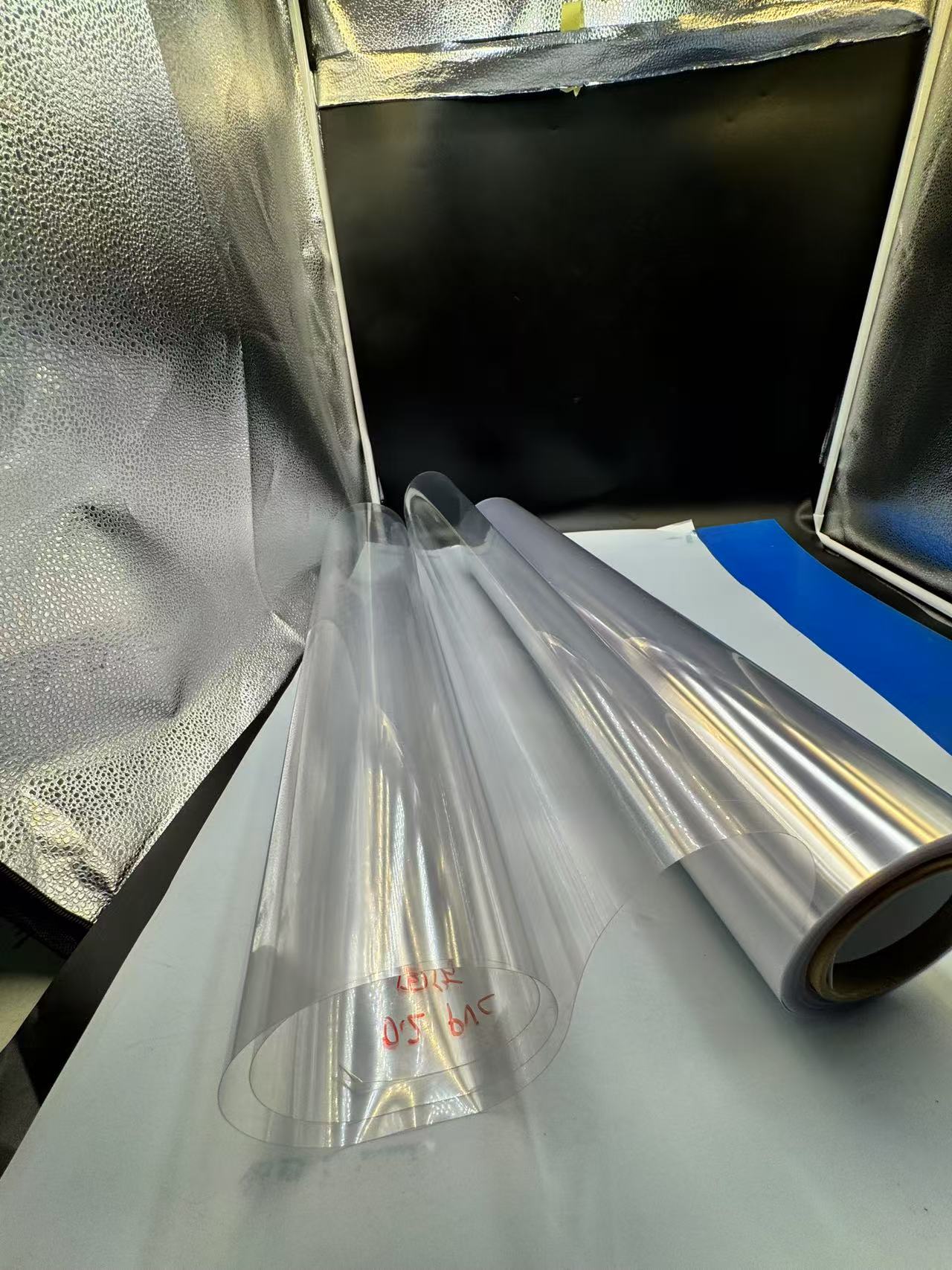

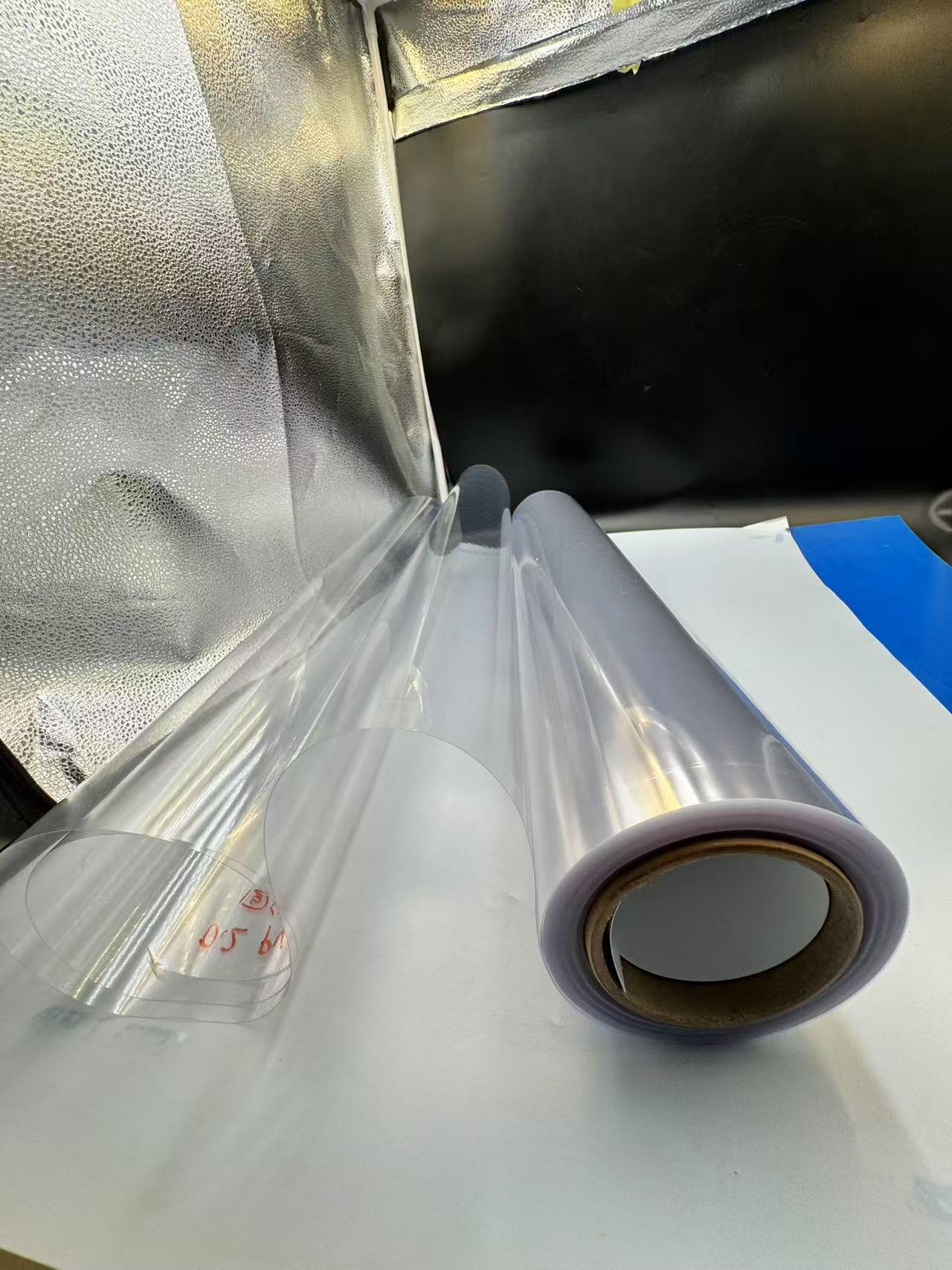

NamePVC Plastic film roll

SizeTk:0.1-0.9mm, h100-1200mm

MaterialPET/PVC/Customized

Color/printingTransparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

UsageThermoforming, molding ,folding

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

- TOPLEADER

- 中国

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

The Versatile Properties and Applications of Transparent PVC Film in Blister Packaging and Beyond

Transparent PVC (Polyvinyl Chloride) film is a cornerstone material in the packaging industry, prized for its clarity, durability, and cost-effectiveness. Its unique properties make it an ideal choice for blister packaging applications across diverse sectors, including hardware, electromechanical components, dry and cold food, and mold-based thermoforming. This article explores the defining characteristics of transparent PVC film and its pivotal role in these specialized packaging applications. Through technical insights, vivid examples, and data-driven analysis, we highlight why PVC film remains a preferred material for precision packaging solutions.

Key Characteristics of Transparent PVC Film

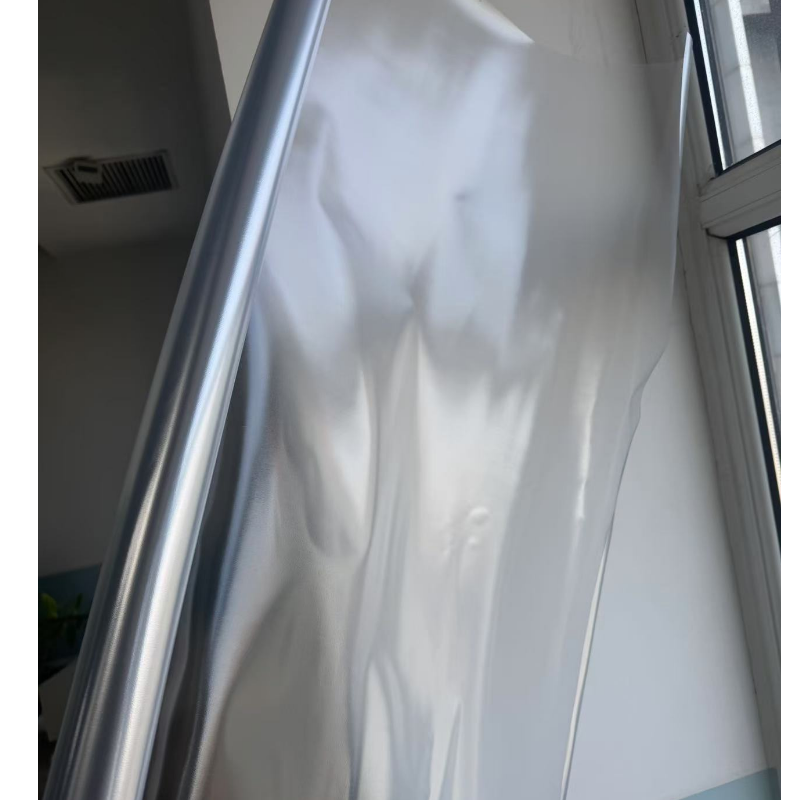

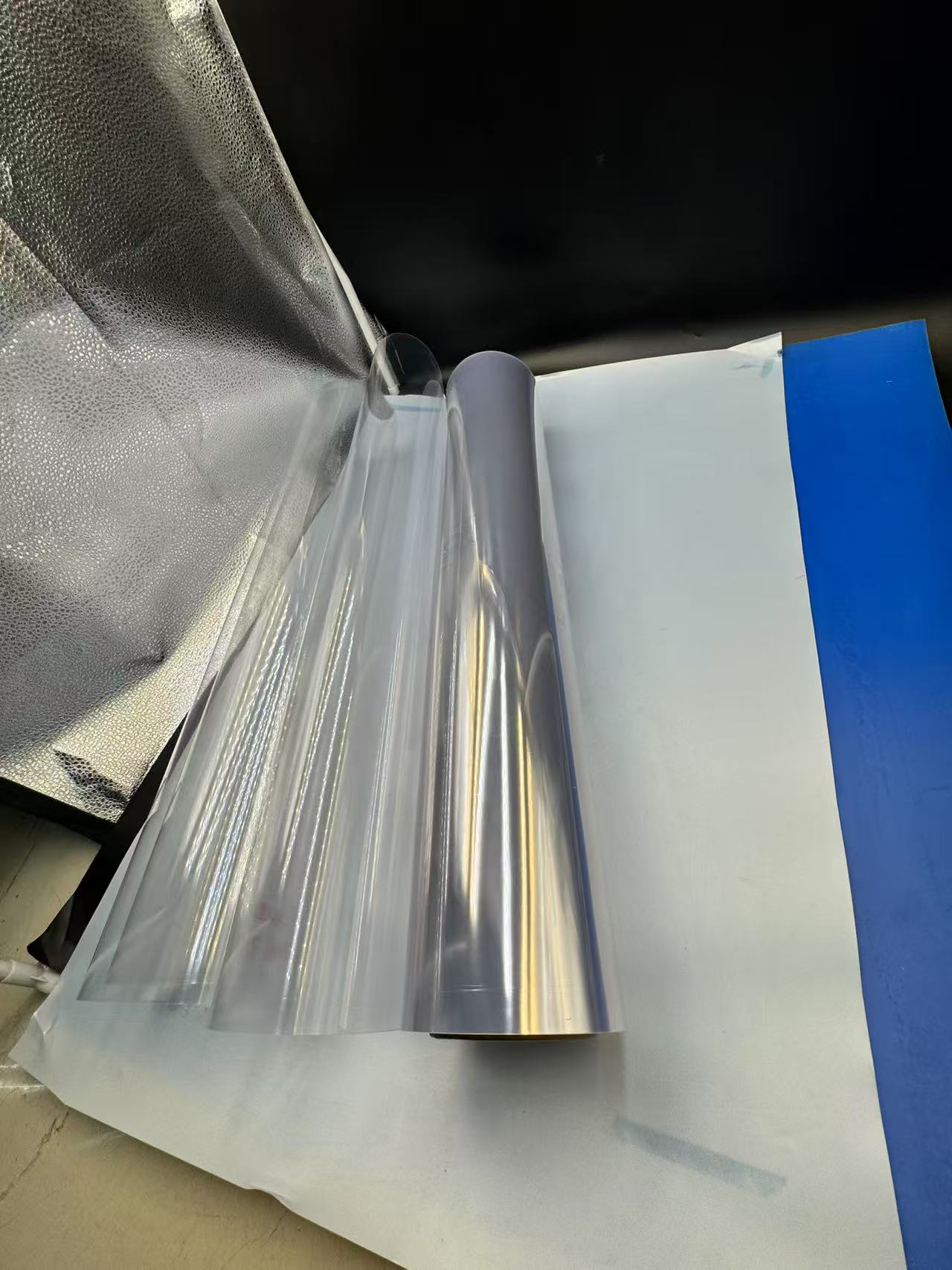

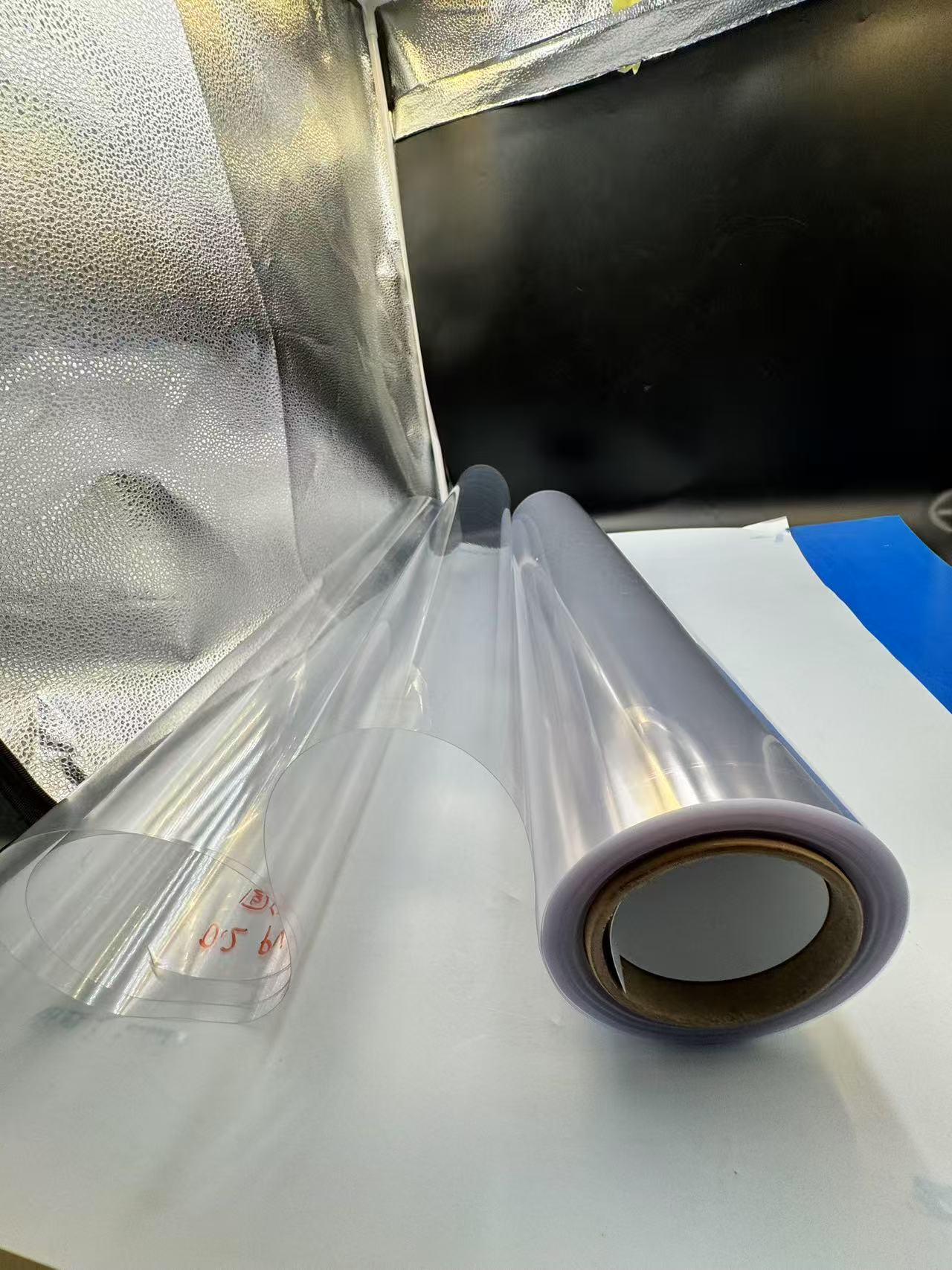

PVC film, produced via calendering or extrusion, is a rigid or semi-rigid material that balances optical, mechanical, and chemical properties. These attributes make it exceptionally suited for blister packaging and thermoforming, where precision, protection, and aesthetics are paramount.

- Optical Clarity: Transparent PVC film offers excellent light transmission, typically exceeding 85%, providing a crystal-clear view of packaged products. This clarity is critical for retail applications, where consumers need to inspect items like tools or food without opening the package. For example, a blister pack for screws made from PVC film showcases the product’s size and finish, enhancing buyer confidence.

- Mechanical Strength: With tensile strengths ranging from 40–60 MPa for rigid PVC films (0.2–0.5 mm thick), PVC film resists punctures, tears, and impacts, ensuring product protection during handling and transport. A 0.3 mm PVC film blister pack, for instance, can withstand stacking pressures in retail displays, maintaining its shape and integrity.

- Thermoformability: PVC film excels in vacuum forming and thermoforming, softening at relatively low temperatures (120–150°C) and conforming to complex mold shapes. This property enables the creation of precise blister cavities for items like electronic components or food portions. Manufacturers report that PVC film achieves draw ratios of up to 2.5:1, allowing for deep-draw packaging without compromising wall thickness.

- Chemical Resistance: PVC film is inert to oils, greases, and many chemicals, making it ideal for packaging hardware and electromechanical parts exposed to lubricants or solvents. Its resistance to acidic or alkaline substances also suits food packaging, where it prevents interactions with items like sauces or pickled products.

- Cost-Effectiveness and Processability: Compared to alternatives like PET or PP, PVC film is often 15–25% cheaper per ton, based on industry pricing data. Its compatibility with high-speed thermoforming and sealing lines enhances production efficiency, with lines capable of producing 50–100 blister packs per minute. PVC film also supports printing and coating, enabling vibrant designs or anti-static treatments.

- Barrier Properties: While PVC film has moderate barrier properties (oxygen transmission rate of ~150–200 cc/m²/day at 0.3 mm), it provides sufficient protection for dry or low-moisture products. For enhanced barriers, PVC film can be laminated with materials like PVDC, reducing OTR to below 10 cc/m²/day for sensitive applications.

These properties make PVC film a versatile, reliable material for blister packaging, balancing functionality with economic advantages.

Applications of PVC Film in Specialized Packaging

PVC film’s adaptability shines in blister packaging for hardware, electromechanical components, dry and cold food, and mold-based thermoforming. Below, we explore its applications in detail, supported by practical examples and technical insights.

- Hardware Packaging

PVC film is widely used for blister packaging of hardware items like screws, nails, bolts, and tools. Its clarity and strength create secure, visually appealing packs that protect products while showcasing their details. A typical structure involves a 0.25–0.4 mm PVC film thermoformed into a cavity, sealed to a cardboard or foil backing.

For instance, imagine a retail display with a PVC film blister pack containing a set of precision screwdrivers. The transparent film highlights the tools’ sleek design, while its puncture-resistant walls protect against damage during shipping. PVC film’s chemical resistance ensures that oily or greased hardware does not degrade the packaging. Industry data indicates that PVC film blister packs reduce product loss due to damage by up to 30% compared to paper-based alternatives, making them a cost-effective choice for hardware manufacturers.

- Electromechanical Components

In the electromechanical sector, PVC film is used to package delicate components like connectors, circuit breakers, or small motors. Its anti-static variants prevent electrostatic discharge (ESD), safeguarding sensitive electronics. The film’s thermoformability allows for custom cavities that securely hold irregularly shaped parts, minimizing movement during transport.

Consider a PVC film blister pack for a set of electrical connectors. The transparent film allows technicians to verify part specifications without opening the pack, while its robust structure protects against impacts. Anti-static PVC film, with surface resistivity below 10^9 ohms/sq, ensures ESD protection, critical for components used in automotive or aerospace applications. Manufacturers report that PVC film packaging reduces component failure rates by up to 15% during storage and transit.

- Dry and Cold Food Packaging

PVC film is a popular choice for blister packaging of dry and cold foods, such as snacks, frozen desserts, or bakery items. Its food-safe properties, compliant with FDA and EU 10/2011 regulations, ensure no migration of harmful substances. The film’s clarity enhances product appeal, while its moderate barrier properties protect against moisture and air for shelf-stable or refrigerated foods.

Picture a PVC film blister tray holding a selection of frozen macarons. The transparent film showcases the desserts’ vibrant colors, enticing consumers, while its rigidity prevents crushing during stacking in freezers. For dry snacks like crackers, a PVC film blister pack with a foil backing extends shelf life by up to 12 months, as per industry shelf-life studies. The film’s sealability ensures airtight closures, preserving crunchiness and flavor. PVC film’s low-temperature performance also makes it suitable for cold storage, maintaining flexibility down to -20°C.

- Mold-Based Thermoforming

In mold-based thermoforming, PVC film is used to create custom packaging or components, such as trays, inserts, or clamshells. Its ability to conform to intricate molds makes it ideal for applications requiring high precision, such as medical device trays or cosmetic packaging. The film’s smooth surface supports coatings like anti-fog or UV-resistant layers, enhancing functionality.

For example, a PVC film tray for a surgical kit features precisely molded compartments to hold scalpels and syringes securely. The transparent film allows medical staff to verify contents, while its chemical resistance ensures compatibility with sterilization processes. Thermoforming studies show that PVC film achieves mold replication accuracy within 0.1 mm, critical for high-precision applications. The film’s cost-effectiveness also makes it viable for short-run or custom projects, with setup costs 20% lower than PET-based alternatives.

- Sustainable Packaging Trends

While PVC film has faced scrutiny for environmental concerns, advancements are improving its sustainability. Recyclable PVC film grades are emerging, compatible with specialized recycling streams. Additionally, lightweight PVC film designs reduce material usage by up to 10%, as reported in recent packaging studies. For instance, a lightweight PVC film blister pack for hardware uses 15% less material than traditional designs, lowering its carbon footprint.

A practical example is a recyclable PVC film blister tray for cold food, designed for circular economy initiatives. The tray’s clarity and strength remain uncompromised, while its recyclability aligns with consumer demand for eco-friendly packaging. Such innovations are helping PVC film maintain its relevance in a sustainability-driven market.

Technical Advantages in Processing and Customization

PVC film’s processability is a key strength in blister packaging. During thermoforming, the film is heated to its softening point, stretched over molds, and cooled to form precise shapes. Its uniform thickness distribution ensures consistent wall strength, critical for deep-draw blisters. Manufacturers report that PVC film achieves cycle times of 3–5 seconds per blister, enhancing production efficiency.

The film’s compatibility with various sealing methods, including heat sealing and RF (radio frequency) sealing, ensures secure closures for backings like foil or cardboard. PVC film also supports surface treatments, such as corona treatment, which increases surface energy to above 38 dynes/cm for better ink adhesion. This enables high-resolution printing via flexography or gravure, with resolutions up to 150 lines per inch, ideal for branding on blister packs.

Customization options further enhance PVC film’s appeal. Anti-static coatings, UV-resistant layers, or colored tints can be applied to meet specific needs. For example, a tinted PVC film blister pack for hardware improves UV protection, extending product shelf life in outdoor retail settings. These adaptations make PVC film a dynamic material for diverse packaging requirements.

What's your delivery time?

Within 15-20 days after received payment...more

Within 15-20 days after received payment...more

Get the latest price? We'll respond as soon as possible(within 12 hours)