T345 The Application of Transparent BOPP/PET Composite Film in Food and Beverage Packaging

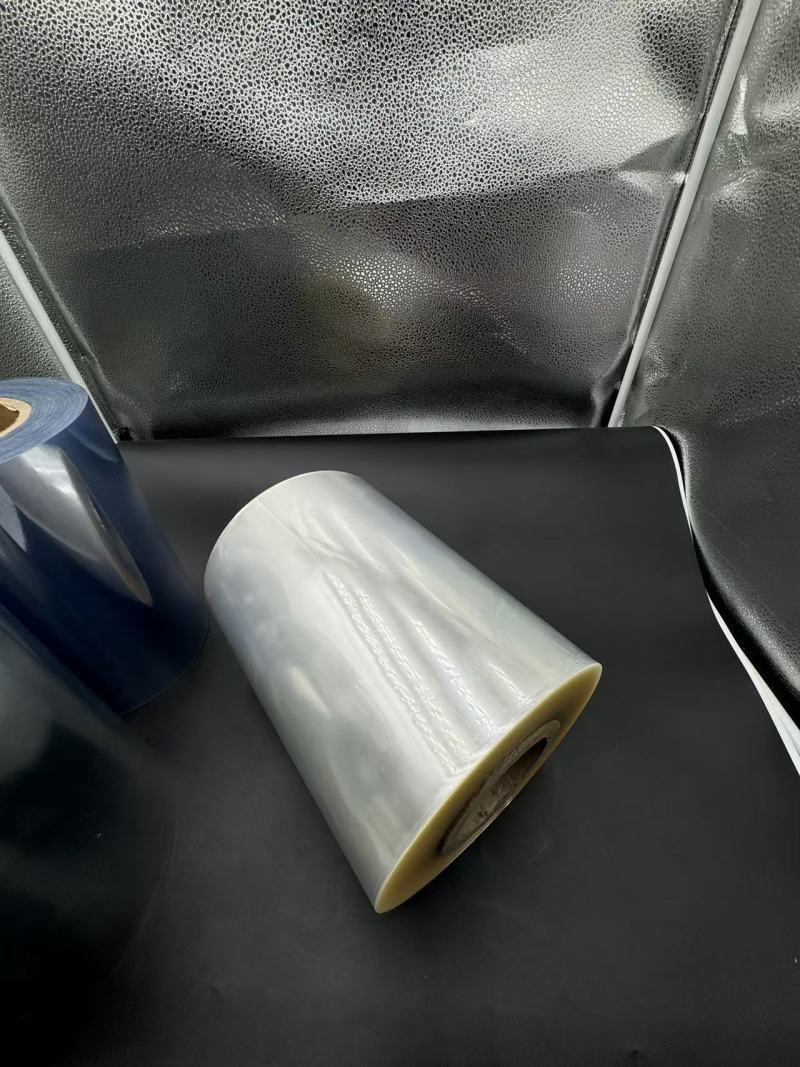

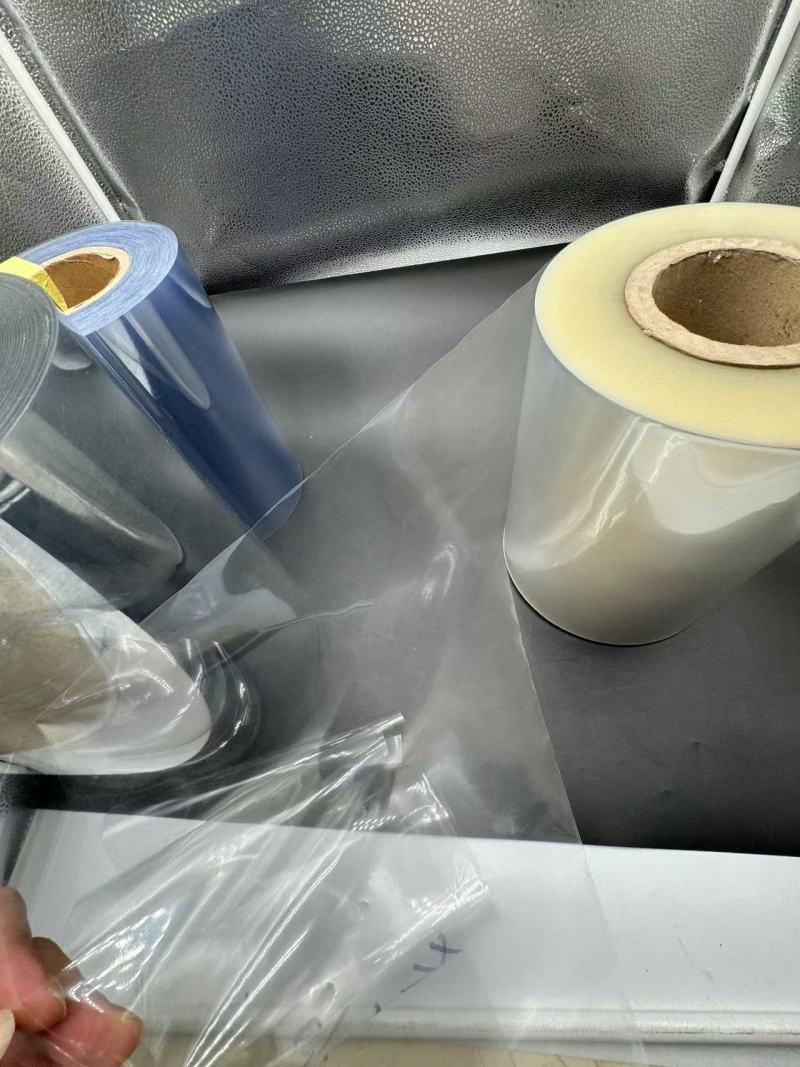

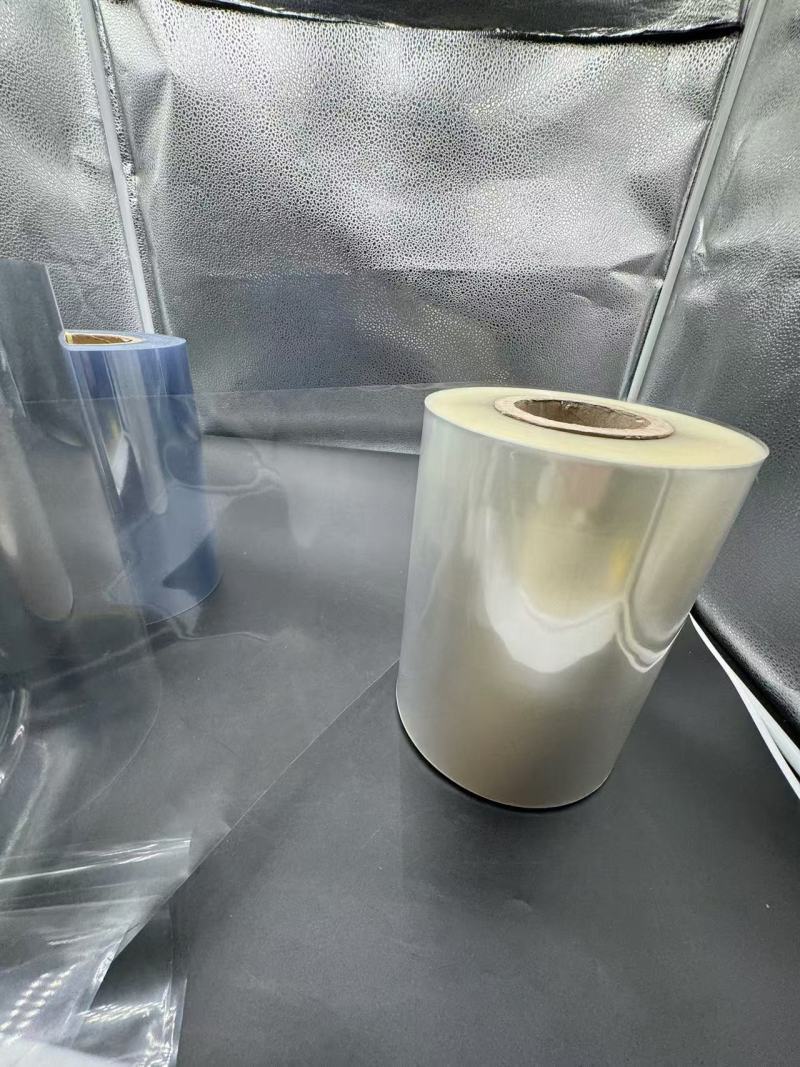

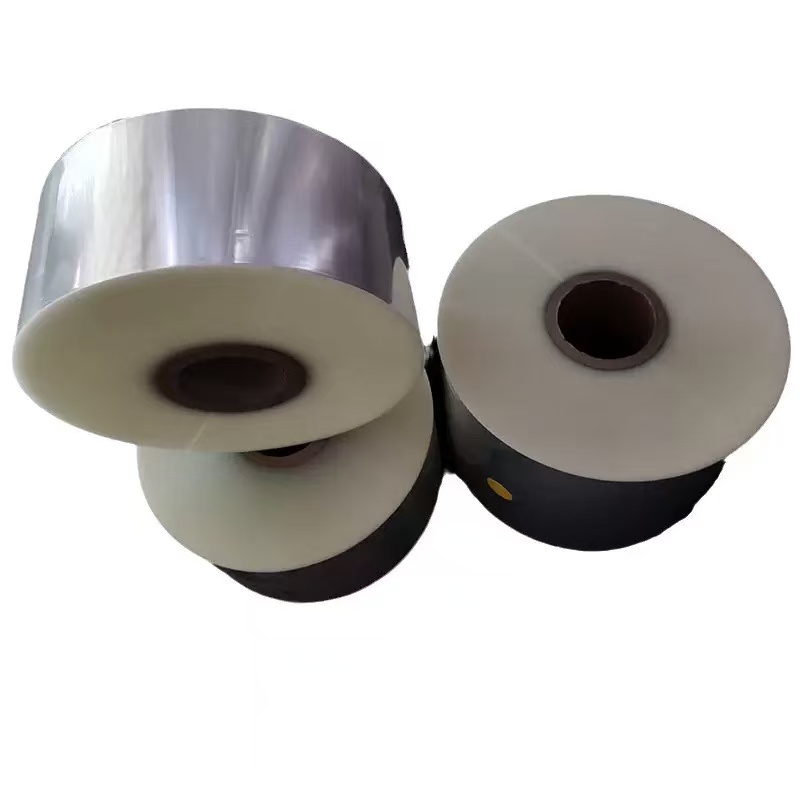

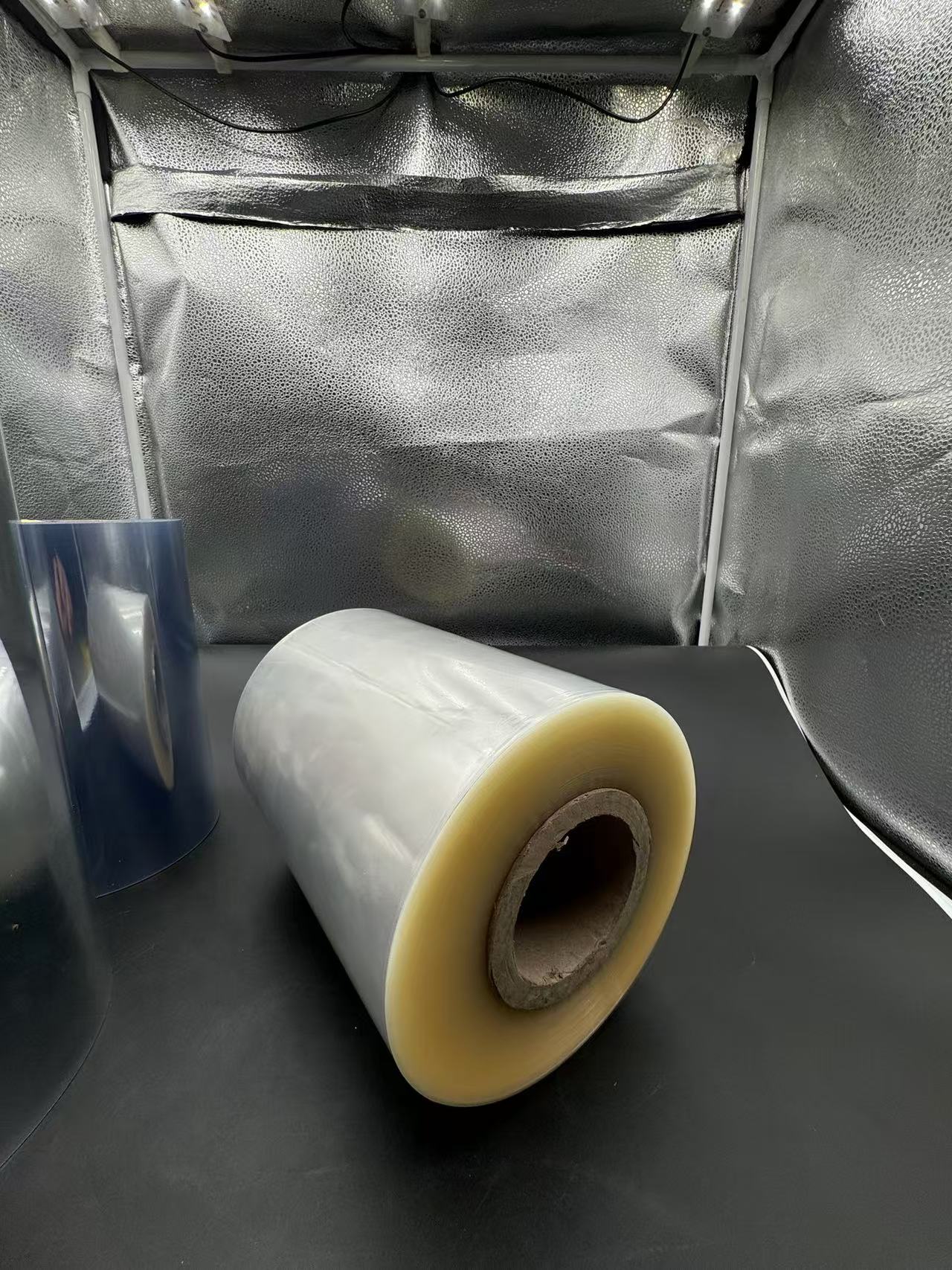

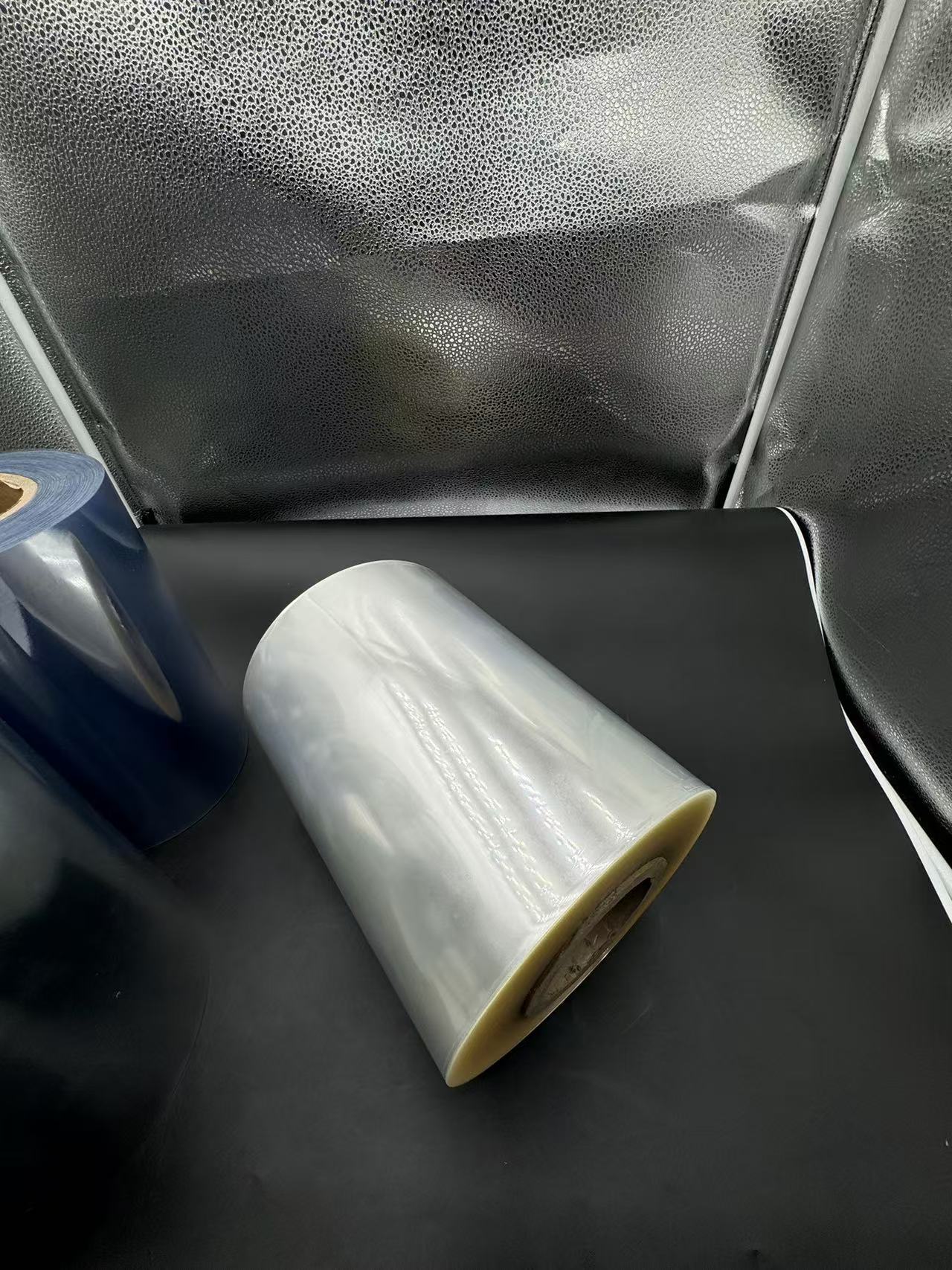

Material: BOPP/PET COMPOSITE FILM

Thickness 0.060mm/customization

Size: 200/Customization

GRADE: Food grade film

color: white/Tranparent customization

location: china

Usage : for food tray plant tray

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

The Application of Transparent BOPP/PET Composite Film in Food and Beverage Packaging

In the highly competitive and quality - conscious world of food and beverage packaging, the choice of packaging material plays a crucial role in product preservation, marketing, and consumer acceptance. Transparent BOPP/PET (biaxially oriented polypropylene/polyethylene terephthalate) composite film has emerged as a popular and versatile option, offering a unique combination of properties that meet the stringent requirements of this industry. This article will explore the various aspects of using this composite film in food and beverage packaging, including its material properties, manufacturing process, applications, advantages, and challenges.

Material Properties of Transparent BOPP/PET Composite Film

Chemical Composition and Structure

The BOPP/PET composite film is composed of two distinct layers, each with its own chemical and physical characteristics. BOPP is a polypropylene - based material that has been stretched in two directions during manufacturing, which imparts excellent tensile strength and clarity. The molecular chains of polypropylene in BOPP are oriented, giving it enhanced mechanical properties. PET, on the other hand, is a polyester with a rigid and stable molecular structure. It provides good barrier properties against moisture, gases, and odors. The combination of these two layers in a composite structure results in a material that benefits from the strengths of both components.

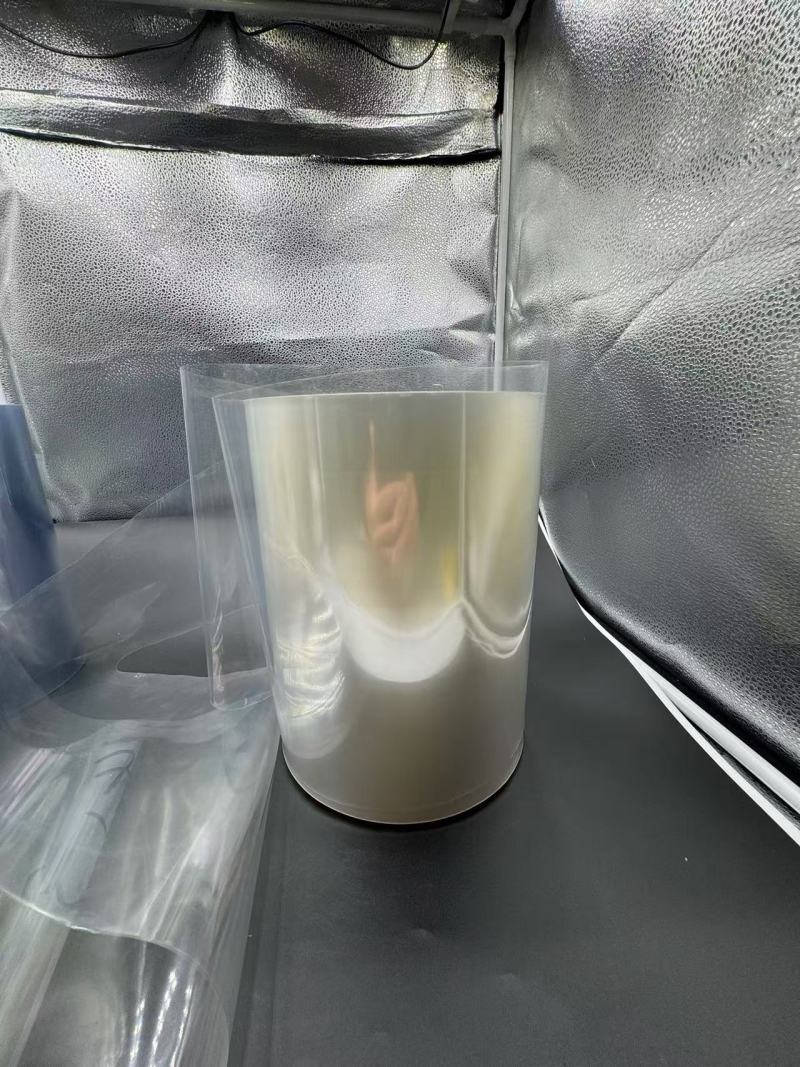

Transparency and Clarity

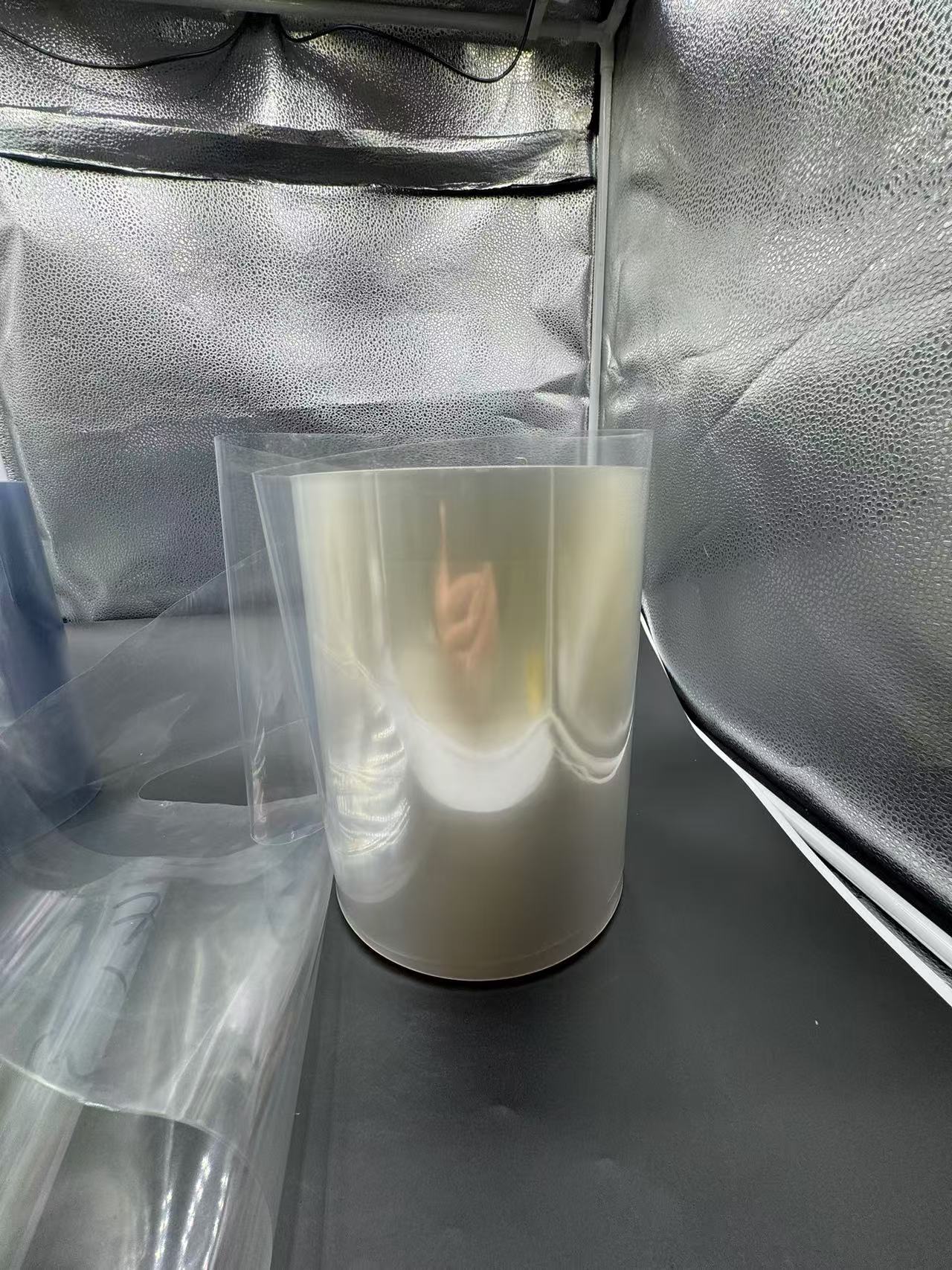

One of the most appealing features of the transparent BOPP/PET composite film is its high level of transparency and clarity. This allows consumers to clearly see the contents of the packaged food or beverage, which is essential for product marketing and consumer confidence. The smooth surface and uniform thickness of the film contribute to its excellent optical properties. Whether it's a colorful array of candies, a refreshing bottle of juice, or a delicious slice of cake, the contents are presented in an attractive and inviting manner through the clear film.

Mechanical Properties

The composite film exhibits remarkable mechanical properties. BOPP provides good tensile strength, which means it can withstand stretching and pulling forces without tearing easily. This is particularly important during the packaging process when the film is being formed and sealed. The rigidity of the PET layer further enhances the overall strength of the composite, making it resistant to punctures and impacts. For example, in the packaging of food items with sharp edges or in the handling of beverage bottles, the film can protect the product from damage. The flexibility of the BOPP also allows the film to conform to different shapes and sizes of packages, ensuring a snug and secure fit.

Barrier Properties

In food and beverage packaging, barrier properties are of utmost importance. The BOPP/PET composite film offers excellent protection against moisture, gases, and odors. The PET layer acts as a reliable barrier to moisture, preventing it from reaching the food or beverage and causing spoilage. For instance, in the case of dry snacks like chips or crackers, the film keeps them crispy by blocking out moisture. The film also restricts the passage of gases such as oxygen and carbon dioxide. This is crucial for maintaining the freshness and quality of products. For example, in the packaging of carbonated beverages, the film helps to retain the carbonation and prevent the loss of flavor and fizziness. The barrier properties also protect the contents from absorbing unwanted odors from the external environment or from emitting odors that could affect other products.

Heat Resistance

The composite film has good heat resistance, which is beneficial in various packaging applications. It can withstand the temperatures typically encountered during the filling and sealing processes of hot - filled food and beverage products. For example, in the packaging of hot soups or sauces, the film remains stable and does not deform or lose its integrity. Additionally, the heat resistance allows for the use of heat - sealing techniques to create a secure and airtight package. This ensures the product's freshness and extends its shelf life.

Chemical Resistance

Both BOPP and PET have good chemical resistance, making the composite film suitable for a wide range of food and beverage products. It can resist the action of acids, alkalis, and common food - related chemicals. This property is essential as many food and beverage products have different chemical compositions. For example, in the packaging of acidic fruit juices or pickled foods, the film does not react with the contents and maintains its structural and barrier properties.

Manufacturing Process of Transparent BOPP/PET Composite Film

Raw Material Preparation

The production of BOPP/PET composite film begins with the careful selection and preparation of the raw materials. High - quality polypropylene and polyethylene terephthalate resins are chosen, and various additives may be incorporated. For BOPP, additives such as antioxidants are used to prevent degradation during processing and storage. The resins are then melted and mixed thoroughly to ensure a homogeneous blend. For the PET layer, similar quality control measures are taken to ensure the purity and stability of the resin.

Extrusion and Orientation of BOPP Layer

The melted polypropylene blend for the BOPP layer is extruded through a flat die to form a thin sheet. This sheet is then rapidly cooled to solidify it. After cooling, the BOPP sheet is subjected to a biaxial orientation process. This involves stretching the film in both the machine direction and the transverse direction at a specific temperature range. The orientation process aligns the polymer chains, significantly improving the mechanical and optical properties of the BOPP layer. The degree of stretching and the temperature conditions are carefully controlled to achieve the desired thickness, strength, and clarity.

Preparation and Lamination of PET Layer

The PET layer is prepared separately. The polyethylene terephthalate resin is melted and extruded to form a thin sheet. This sheet is then cooled and processed to have the appropriate thickness and surface quality. The PET sheet is then laminated onto the pre - formed BOPP layer. The lamination process can be carried out using adhesive lamination or co - extrusion lamination techniques. In adhesive lamination, a suitable adhesive is applied between the BOPP and PET layers to ensure strong bonding. In co - extrusion lamination, the two layers are extruded simultaneously and combined in a molten state, creating a seamless bond. The lamination process is carefully monitored to ensure uniform adhesion and the absence of air bubbles or defects.

Quality Control and Finishing

After lamination, the BOPP/PET composite film undergoes rigorous quality control procedures. The thickness of the film is measured precisely using advanced gauges to ensure it meets the specified requirements. The transparency, mechanical strength, and barrier properties are tested using specialized equipment. Any defects such as pinholes, scratches, or delamination are detected and the defective portions are removed or the entire roll is rejected. The film is then wound onto rolls of the appropriate size and length, ready for further processing into food and beverage packaging.

Applications of Transparent BOPP/PET Composite Film in Food Packaging

Snacks and Confectionery Packaging

For snacks like potato chips, popcorn, and nuts, as well as confectionery items such as chocolates, candies, and gummies, the transparent BOPP/PET composite film is an ideal choice. The transparency showcases the delicious appearance of the products, attracting consumers. The barrier properties keep the snacks crisp by preventing moisture ingress and protect the confectionery from melting or losing their flavor due to exposure to air or moisture. The mechanical strength of the film ensures that the packages can withstand the rigors of handling and transportation without tearing or puncturing. For example, a bag of potato chips packaged in this composite film remains intact and the chips stay fresh and crispy until opened.

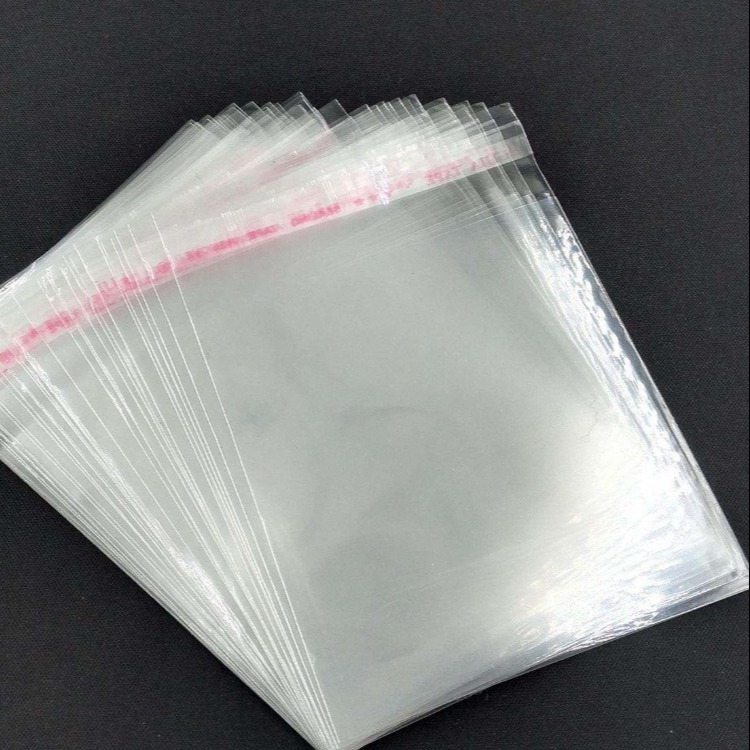

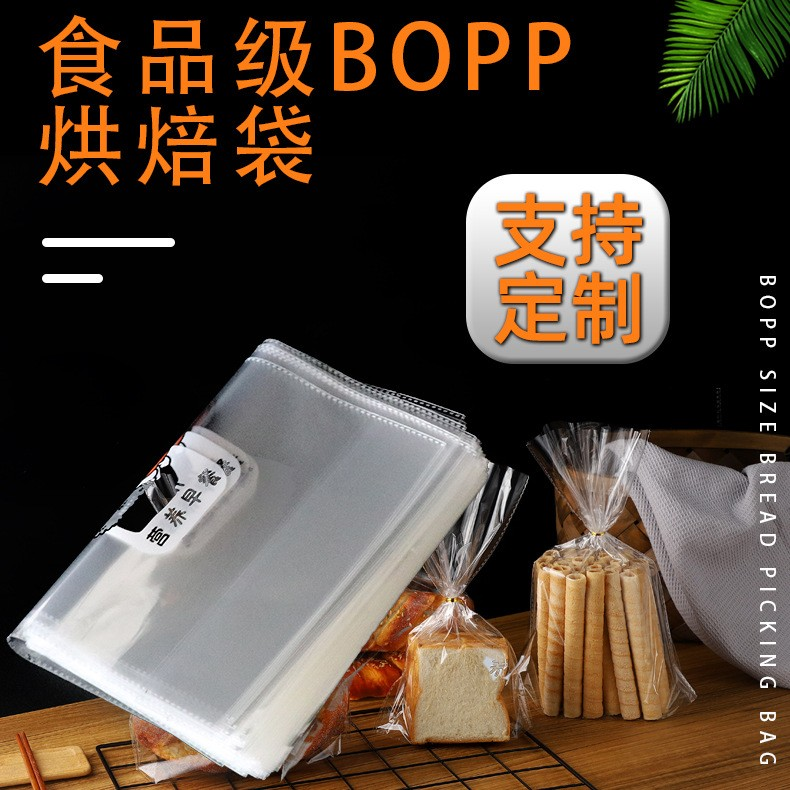

Bakery Product Packaging

Bakery products such as bread, cakes, pastries, and cookies benefit from the use of BOPP/PET composite film. The film helps in retaining the freshness and softness of the baked goods by providing a barrier against moisture loss. The transparency allows consumers to see the appealing texture and color of the bakery items, enhancing their desirability. The film can also be heat - sealed, creating an airtight package that extends the shelf life of the products. For instance, a loaf of bread wrapped in the composite film stays fresh and soft for a longer period compared to traditional paper packaging.

Ready - to - eat Meal Packaging

In the packaging of ready - to - eat meals, the BOPP/PET composite film offers multiple advantages. It provides a good barrier against moisture, gases, and odors, ensuring that the different components of the meal, such as the main dish, side dishes, and sauces, remain fresh and do not mix flavors. The transparency allows consumers to easily identify the contents of the meal. The film's heat resistance is also beneficial as some ready - to - eat meals may require reheating, and the package can withstand the heat without deforming. For example, a tray of pre - cooked lasagna packaged with the composite film can be stored and reheated conveniently while maintaining its quality.

Applications of Transparent BOPP/PET Composite Film in Beverage Packaging

Bottled Water and Soft Drink Packaging

Transparent BOPP/PET composite film is used in the labeling and outer packaging of bottled water and soft drinks. The transparency of the film allows the brand logo, product information, and attractive designs to be clearly visible, enhancing the marketing appeal. The film provides a protective layer against scratches and minor impacts, keeping the bottles looking clean and presentable. The barrier properties also help in protecting the contents from external contaminants and maintaining the quality of the water or soft drink. For example, a bottle of mineral water with a label made from the composite film looks more professional and the water inside remains pure and fresh.

Juice and Beverage Carton Packaging

For juice cartons and other beverage cartons, the BOPP/PET composite film can be used as a laminate on the outer surface. It provides additional strength and protection to the carton, preventing it from collapsing or getting damaged. The transparency allows for the display of colorful and eye - catching designs, making the cartons stand out on the supermarket shelves. The film's barrier properties help in retaining the flavor and nutritional value of the juices and other beverages by reducing the ingress of oxygen and the egress of volatile compounds. For instance, a carton of freshly squeezed orange juice with a BOPP/PET laminate stays flavorful and retains its vitamin C content for a longer time.

Wine and Alcoholic Beverage Packaging

In the packaging of wine bottles and other alcoholic beverages, the composite film can be used for decorative sleeves or labels. The transparency and smooth surface of the film allow for high - quality printing and embossing, creating a luxurious and elegant look. The film provides a protective layer against dust and minor scratches, enhancing the presentation of the bottles. The barrier properties also help in maintaining the quality of the alcoholic beverages by protecting them from light and air. For example, a bottle of fine wine with a decorative sleeve made from BOPP/PET composite film looks more prestigious and the wine inside is better preserved.

Advantages of Using Transparent BOPP/PET Composite Film in Food and Beverage Packaging

Product Protection and Preservation

The combination of the BOPP and PET layers in the composite film provides excellent protection and preservation for food and beverage products. The barrier properties against moisture, gases, and odors help in maintaining the freshness, flavor, texture, and nutritional value of the contents. This is crucial for extending the shelf life of the products and reducing food waste. The mechanical strength of the film protects the products from physical damage during handling, transportation, and storage.

Visual Appeal and Marketing

The transparency and clarity of the BOPP/PET composite film make it an excellent marketing tool. Consumers can clearly see the product inside, which can attract their attention and influence their purchasing decisions. The smooth surface of the film allows for high - quality printing and decoration, enabling brands to create eye - catching and informative packaging. Whether it's a colorful snack package or an elegant wine bottle sleeve, the film enhances the visual appeal of the product and helps in building brand identity.

Versatility in Packaging Design

The composite film is highly versatile in terms of packaging design. It can be formed into different shapes and sizes, such as bags, pouches, wraps, labels, and laminates. This allows for creative and customized packaging solutions to meet the specific requirements of different food and beverage products. The film can also be combined with other packaging materials, such as paperboard or plastic trays, to create hybrid packaging systems that offer enhanced functionality.

Heat Resistance and Processing Ease

The heat resistance of the BOPP/PET composite film makes it suitable for various heat - related packaging processes, such as heat - sealing, hot - filling, and sterilization. This simplifies the packaging process and ensures the integrity of the package. The film is also easy to process using standard packaging equipment, such as film extruders, laminators, and printers. This reduces production costs and improves production efficiency.

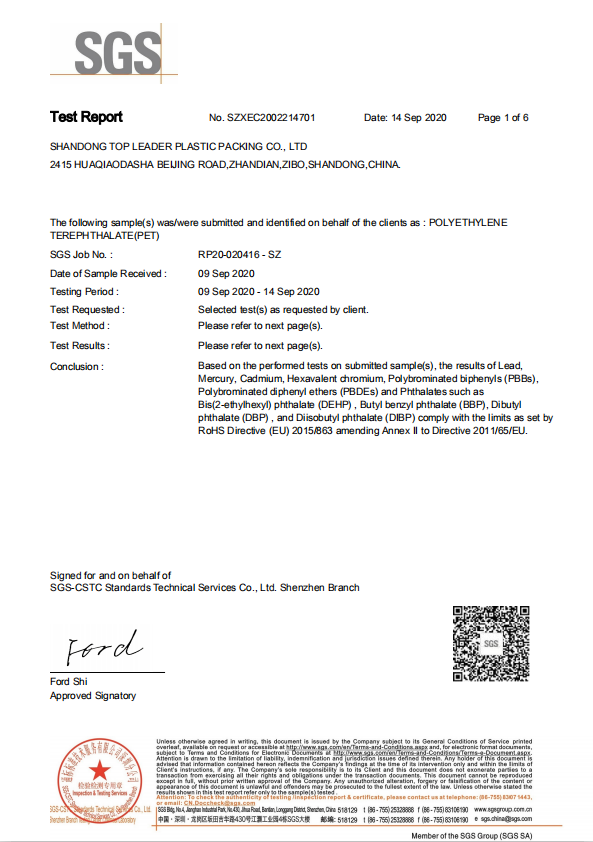

Chemical Resistance and Food Safety

The chemical resistance of the composite film ensures that it does not react with the food and beverage products it packages. This is essential for maintaining food safety and quality. The film complies with relevant food contact regulations and standards, giving consumers confidence in the safety of the packaged products.

Case Studies of Transparent BOPP/PET Composite Film in Food and Beverage Packaging Applications

Case Study 1: Snack Brand's Packaging Upgrade

A popular snack brand was looking to improve its packaging to enhance product freshness and visual appeal. They switched from a single - layer plastic film to a transparent BOPP/PET composite film for their chip bags. After the switch, they noticed a significant reduction in the number of stale or broken chips reported by consumers. The transparency of the film also allowed them to showcase the variety and quality of their chips more effectively, leading to an increase in sales. The brand was able to use more vibrant and detailed designs on the packaging, further enhancing its marketability.

Case Study 2: Juice Company's Packaging Innovation

A juice company wanted to improve the shelf life and flavor retention of their freshly squeezed juices. They adopted a BOPP/PET composite film laminate for their juice cartons. The barrier properties of the film helped in maintaining the freshness and taste of the juices for a longer period. The transparency of the film allowed them to display the natural color and pulpiness of the juices, attracting more consumers. The company also reported a decrease in packaging - related spoilage and an improvement in the overall quality of their products.

Case Study 3: Wine Labeling and Packaging Enhancement

A winery was seeking to enhance the presentation and protection of their wine bottles. They started using a BOPP/PET composite film for their wine labels and decorative sleeves. The transparency and smooth surface of the film enabled them to create high - quality, embossed labels that gave a luxurious feel to the bottles. The film's barrier properties protected the wine from light and air, ensuring better preservation. The winery noticed an increase in customer interest and sales, especially in the premium wine segment, due to the enhanced packaging.

Challenges and Solutions in Using Transparent BOPP/PET Composite Film in Food and Beverage Packaging

Cost Considerations

The production of BOPP/PET composite film can be relatively more expensive than some single - layer packaging materials. To address this, manufacturers can look for ways to optimize the production process, such as improving the efficiency of extrusion and lamination. Bulk purchasing of raw materials and negotiating better deals with suppliers can also help in reducing costs. Additionally, considering the long - term benefits of the film, such as extended shelf life and reduced product waste, can justify the higher initial investment.

Recycling and Environmental Concerns

The recycling of BOPP/PET composite film can be more complex than that of single - layer films due to the presence of two different materials. However, efforts are being made to develop effective recycling methods. One approach is to use mechanical recycling techniques that can separate the BOPP and PET layers. Another solution is to encourage consumers to separate the packaging properly and promote the development of recycling infrastructure. Some manufacturers are also exploring the use of biodegradable or compostable alternatives to reduce the environmental impact.

Adhesion and Lamination Issues

During the lamination process, ensuring proper adhesion between the BOPP and PET layers is crucial. If the adhesion is weak, it can lead to delamination, which can affect the performance and appearance of the packaging. To overcome this, manufacturers need to use high - quality adhesives and carefully control the lamination process parameters, such as temperature, pressure, and curing time. Regular quality control checks can help in detecting and correcting any adhesion issues early on.

Heat Sealability and Compatibility with Filling Processes

In some cases, achieving consistent and reliable heat sealability of the BOPP/PET composite film can be a challenge. Different products and filling processes may require specific heat seal conditions. To address this, manufacturers can conduct extensive testing to determine the optimal heat seal parameters for different applications. They can also work with equipment suppliers to ensure that the packaging machinery is compatible with the film's heat seal requirements. Additionally, using additives or modifying the film's composition can improve its heat sealability.

Conclusion

Transparent BOPP/PET composite film has revolutionized the food and beverage packaging industry with its unique combination of properties. It offers excellent product protection, visual appeal, versatility in design, heat resistance, and chemical resistance. Despite the challenges related to cost, recycling, adhesion, and heat sealability, there are solutions available to overcome them. As the demand for high - quality and sustainable packaging continues to grow, the BOPP/PET composite film is likely to play an even more significant role in the future. With ongoing research and development, this composite film will continue to evolve and meet the ever - changing needs of the food and beverage packaging market, providing consumers with fresh, safe, and attractively packaged products.

Within 15-20 days after received payment...more