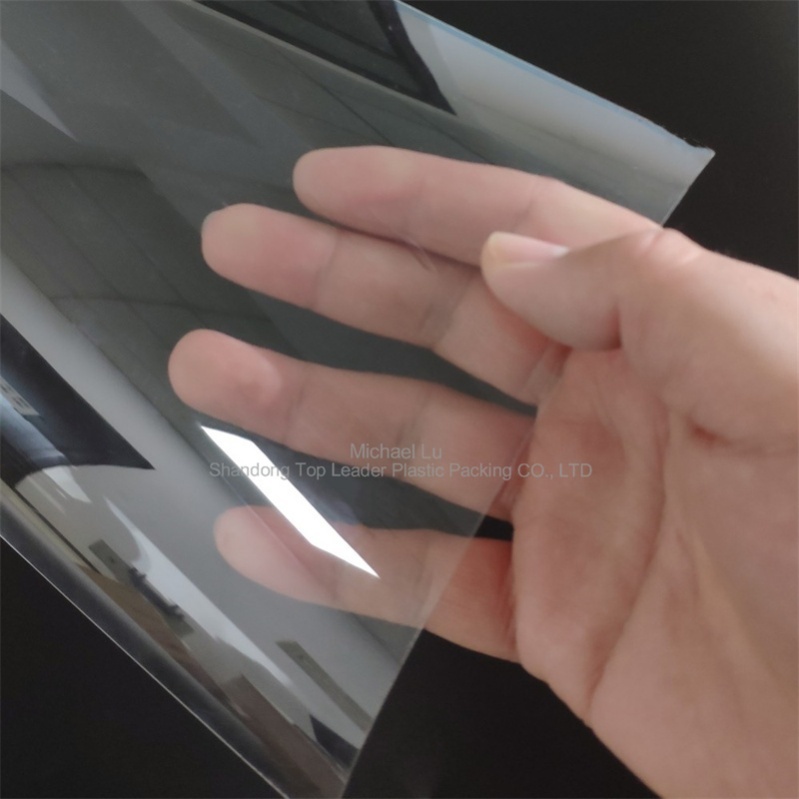

Transparent PETG hard sheet, food grade recyclable material, heat sealable

Excellent transparency: PETG sheet boasts a transparency of over 90%, offering excellent visual quality and clearly displaying the contents. It is suitable for packaging applications requiring high transparency, such as food and cosmetics packaging, enhancing product presentation and appeal.

- top leader plastic

- China

- 15 business days

- 1500 tons/month

- Information

PETG sheet is a material with many excellent properties. The following are some of its characteristics:

Excellent transparency: PETG sheet boasts a transparency of over 90%, offering excellent visual quality and clearly displaying the contents. It is suitable for packaging applications requiring high transparency, such as food and cosmetics packaging, enhancing product presentation and appeal.

Excellent physical properties: With excellent impact resistance and rigidity, the material is strong and durable, capable of withstanding certain levels of impact and compression, effectively protecting the contents. It also offers excellent processability and can be processed using a variety of methods, including sawing, die-cutting, drilling, and laser cutting. It can also be cold-bent, hot-bent, glued, welded, and polished. Cold-bending does not cause whitening, resulting in a bright appearance.

Excellent heat-sealing properties: PETG sheet exhibits excellent heat-sealing properties, making it easy to seal and maintain a high-quality seal. It can be used to heat-seal two or more sheets together to form complete packaging containers, such as blister packs and folding boxes, ensuring a sealed and complete package and preventing leakage and contamination. Environmental friendliness: PETG rigid sheet is a recyclable material and can be recycled without polluting the environment. This material complies with environmental protection concepts and requirements, promoting resource recycling and environmental protection.

Food safety: Made of PETG, it complies with all major food regulations, such as those of the US FDA and EU EFSA. It is non-toxic and odorless, causing no contamination to food, and can be used directly for food containers and packaging, ensuring food safety.

Advantages of Folding Box Manufacturing: High Design Flexibility: Various shapes and sizes can be designed to meet different needs, from simple folding boxes to complex multi-folding boxes and special-shaped boxes, meeting the packaging needs of different products and providing personalized packaging solutions.

Easy to Process and Form: Excellent thermoformability allows for molding without preheating, with high precision and low shrinkage, typically around 0.5%. Excellent deep formability makes it less prone to cracking during the folding process, and maintains a uniform thickness, ensuring the quality and appearance of the folding box. Exquisite Appearance: Transparent PETG sheet has high transparency and excellent gloss, making folding boxes with a bright and high-quality appearance, enhancing the product's premium quality and added value, attracting consumers' attention.

Cost-Effectiveness: Compared to some other high-performance packaging materials, PETG sheet is relatively affordable. While meeting packaging requirements, it effectively controls packaging costs, offering a high cost-effectiveness ratio.

Applications

Food Packaging: Used for packaging a variety of foods, such as candy, biscuits, pastries, fruits, vegetables, meat, and seafood. It can be made into transparent lunch boxes, trays, blister packs, folding boxes, and other formats, showcasing the food's appearance while ensuring its hygiene and safety.

Cosmetics Packaging: Can be used to package cosmetics such as lipstick, eye shadow, blush, and perfume. Transparent packaging boxes and display stands enhance the cosmetics' brand image and visual appeal.

Electronic and Electrical Packaging: Used for packaging electronic and electrical products, such as mobile phones, tablets, headphones, and chargers. It can be made into blister trays and packaging boxes, protecting and displaying the products. Medical device packaging: Due to its high transparency, impact resistance and good hygienic properties, it can be used to package medical devices such as syringes, infusion sets, medical catheters, surgical instruments, etc., to ensure the safety and sterility of medical devices during transportation and storage.

Within 15-20 days after received payment...more