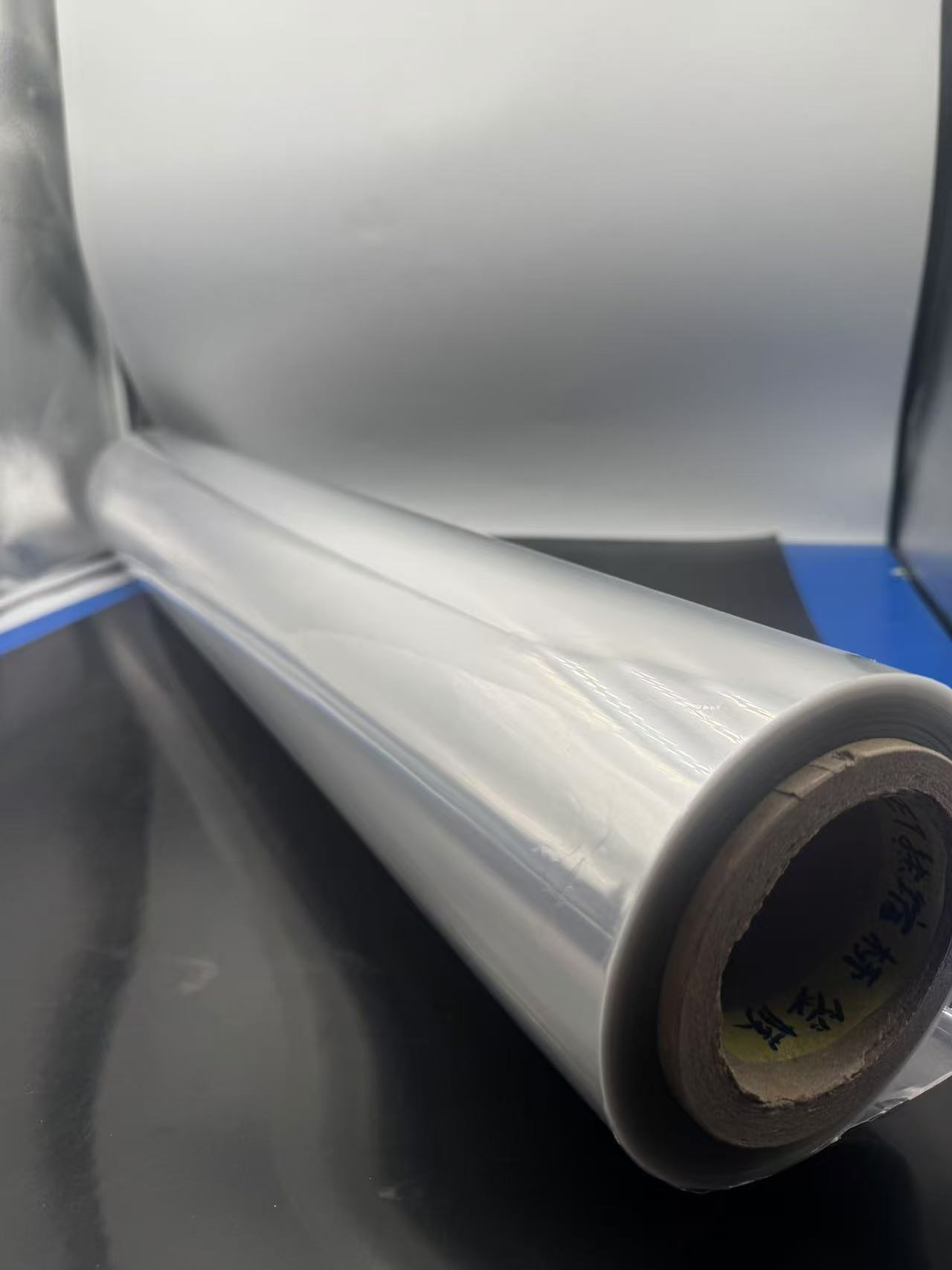

pet shrink film with printing for bottle,costmetic ADs packing

Material: PET Printable sheet

Thickness 0.012mm/customization

Size: 100mm/Customization

GRADE: Food grade film

color: transparent/white/ customization

location: china

usage :for bottle

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

Transparent Printable PET Film: A Versatile Material in Diverse Applications

Introduction

In the dynamic world of new material development, transparent printable polyethylene terephthalate film has emerged into prominence as highly important and useful material.

Ordinary polyester is a crystalline polymer. The common PET film can get only a heat-shrinkage rate of less than 30% through special processing. In order to get polyester film with a higher heat-shrink rate, modification is necessary, which implies that ordinary polyester should be modified into a copolymer in the preparation of high-heat-shrink polyester film. The highest heat-shrinkage rate of PET film can be achieved after copolymer modification to over 70%. The background given on the heat-shrinkage properties of PET leads to the setup of the unique features of the transparent printable PET film.

1. Characteristics of Transparent Printable PET Film

1.1 Printability

Of a distinctive nature in the transparent printable PET film is its excellent printability. The films have special surface treatments that make them receptive to a wide range of printing inks and techniques, from offset printing, flexography, to digital printing.

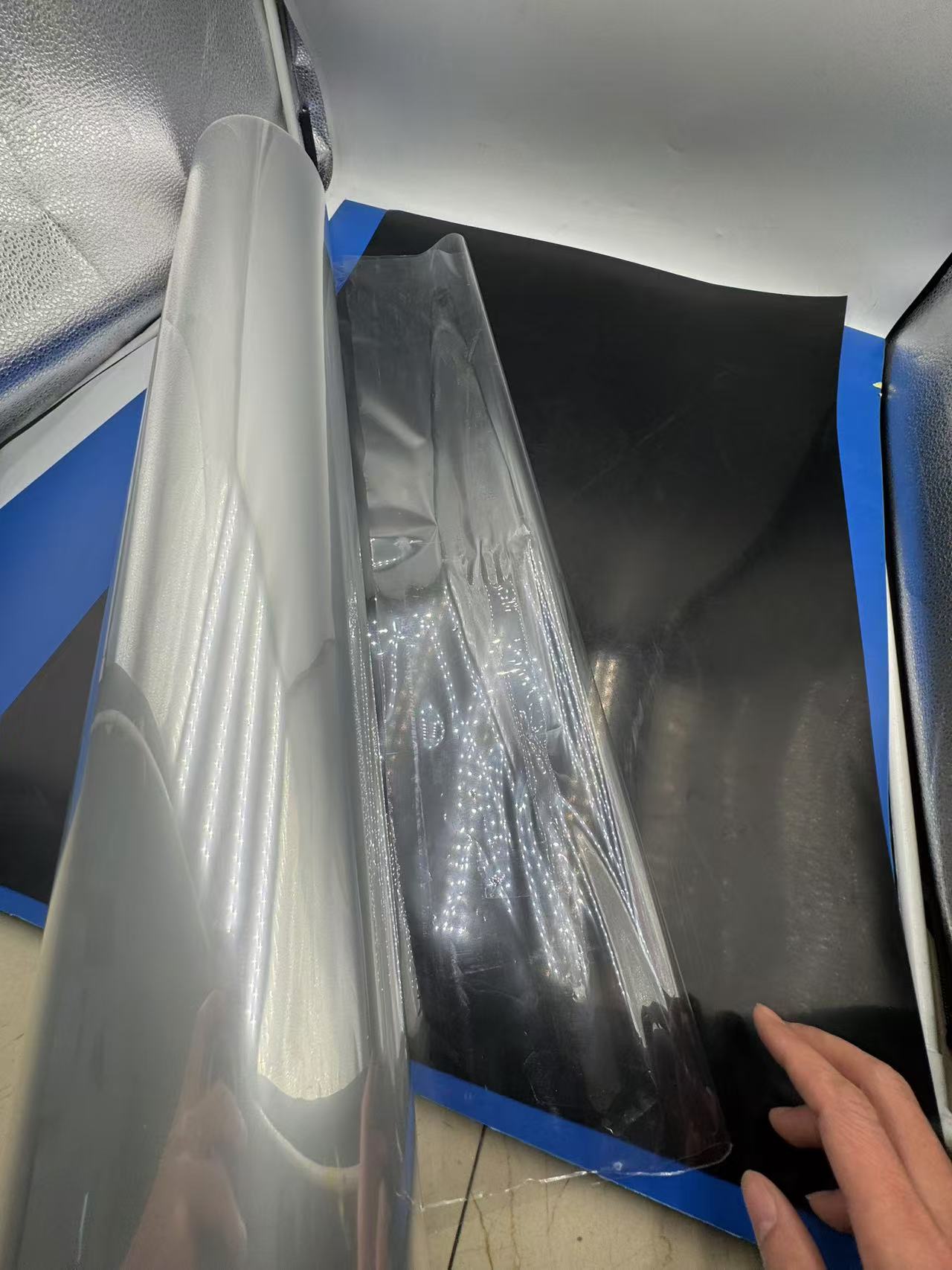

1.2 Transparency

Another important characteristic of the PET film is that it is transparent. It features high-clarity transparency, something that is quite valuable in many different applications. It provides a kind of packaging where consumers can view the enclosed product with utmost clarity,

1.3 Mechanical Properties PET film has very good mechanical strength. It is not torn easily and can be stretched to a certain extent without breaking.

1.4 Heat - Shrinkage Properties As identified earlier, different formulation variations make various heatshrinkage properties for the PET films possible.

2. Applications in the Packaging Industry

2.1 Food Packaging

2.1.1 Fresh Produce Packaging

Another highly used transparent printable PET film is in the packaging of fresh produce. The fact that it is transparent allows consumers to see through it the quality of fruits and vegetables-for instance,

2.1.2 Bakery Product Packaging

PET film has been used in the bakery industry for bread, cake, and pastry packaging. It can avoid moisture loss, which is quite vital for baked goods in order to maintain texture and freshness.

2.2 Packaging of Beverages

In the process of the high-speed development of the PET beverage bottle market, one of the most important uses of transparent printable PET film is found in the field of beverage packaging.

2.3 General Product Packaging

It can be used in various general product package printable transparent PET films that wrap small-sized consumer goods from cosmetics and stationaries to toys. It protects the products from dust, moisture, and minor impacts while being printable for attractive branding.

3. Applications in the Electronic Industry

3.1 Electronic Device Displays

In the electronic industry, transparent printable PET film is used in some electronic device displays. The transparency and smoothness make it suitable for applications in overlays for touch screens and protective display films.

3.2 Packaging of Electronic Components

PET film is also used for the packaging of electronic components. The insulating properties of the film could prevent electrical short-circuits between the components. Mechanical strength of the film ensures protection of the components against mechanical damages during handling and transportation. Small electronic components such as resistors, capacitors, and integrated circuits are often packaged in PET film-based carriers. These carriers can also be printed to include component identification information for easy identification and handling by manufacturers and technicians.

4. Applications in the Labeling Industry

4.1 Shrink - Wrap Labels

As mentioned earlier, shrink-wrap labels are among the major applications of transparent printable PET film. These labels have a wide scope of application across many industries ranging from food and beverage to consumer goods.

4.2 Self - Adhesive Labels

Apart from shrink-wrap labels, other applications involving transparent printable PET film are for self-adhesive labels. These labels are used in product labeling, logistics, and retail.

5. Benefits of Transparent Printable PET Film in Packaging

5.1 Protection Functions

5.1.1 Protection against Moisture, Dust, and Impact

Like all other types of films, transparent printable PET film also has excellent protection functions. It can serve as a barrier to moisture, which prevents products from getting wet and damaged. Besides, it protects the product from dust and dirt, thus keeping it clean.

5.1.2 Rust and Corrosion Prevention

In the case of metal products, PET film avoids rust and corrosion. It creates a barrier between the metal surface and the outside environment,

5.2 Aesthetic Appeal

5.2.1 Branding and Product Display

The PET film is highly printable, hence transparent, which significantly enhances product appearance. The film will provide brands with ideal packaging designs that are eye-catching, while the prints of logos, product images, and marketing messages will be of high quality.

5.2.2 Innovation in Packaging

The unique properties of PET film also allow packaging innovation. New and creative packaging designs, s

5.3 Cost-Effectiveness

5.3.1 Material and Production Costs

From the perspective of material costs, PET film can be cost-effective. As mentioned above, in some packaging applications, it can be much cheaper than traditional materials such as cardboard boxes.

5.3.2 Labor and Transportation Costs

Packaging with PET film will also save labor and transportation costs. Being lighter in weight, the overall weight of the packed products will be reduced,

6. Environmental Considerations

PET is an eco-friendly material to some extent. It is a recyclable polymer. Most PET films, including transparent printable ones, can be recycled through appropriate recycling processes. This is in line with the growing global trend towards sustainable packaging.

7. Challenges and Future Prospects

7.1 Challenges

7.1.1 Compatibility with Printing Inks and Coatings

One of the challenges of using transparent printable PET film is compatibility with various printing inks and coatings. Some inks may not adhere well to the surface of the film, or the coatings may affect the transparency or other properties of the film.

7.1.2 Competition from Other Materials

The material market is highly competitive, and transparent printable PET film has competitors from other types of materials. There are other plastic films and biodegradable emerging materials that compete in market share to the material in packaging and other industries. For it to be able to remain competitive, innovation and enhancement in the properties of the film have to be continuously undertaken by the PET film industry.

7.2 Future Outlook

7.2.1 Technological Changes

The outlook for transparent printable PET film is promising due to ongoing changes in technology. Much further work is being carried out on the formulation of new printing methods that will offer higher quality and functionality on the film. Such could be enabling advanced digital printing technologies to allow higher intricacies and personalization of designs printed on the film. Besides, research is being carried out to enhance the properties of the film, such as heat resistance, barrier properties against gases, and durability.

7.2.2 New Application Areas

With the continuous evolution of industries, new application areas for transparent printable PET film are likely to emerge. For example, in smart packaging, the PET film can be combined with sensors or other smart materials for intelligent packaging that can track product quality and freshness or even the location of the product. Medical applications can involve the packaging of medical devices or as substrate material for printed electronics in certain medical diagnostic devices.

Conclusion

Clear, printability, high-vacuum-dealizable clear transparent printable PET film refers to an exceptionally good, critical, and extensively used material by a number of other industries, mainly packaging, electric, and label industries. Since it combines qualities such as printability, transparency, mechanical strength, and heat-shrink properties, there is no way it cannot remain ideal for manifold products. There are bound to be some obstacles to overcome, such as the issue of compatibility and pressure from other materials. The future prospects look bright for the film. With continuous innovation in technology and the investigation of new application areas, transparent PET will continue to serve modern material demands. It will contribute to even more innovative, sustainable, and efficient design of products and packaging.

Within 15-20 days after received payment...more