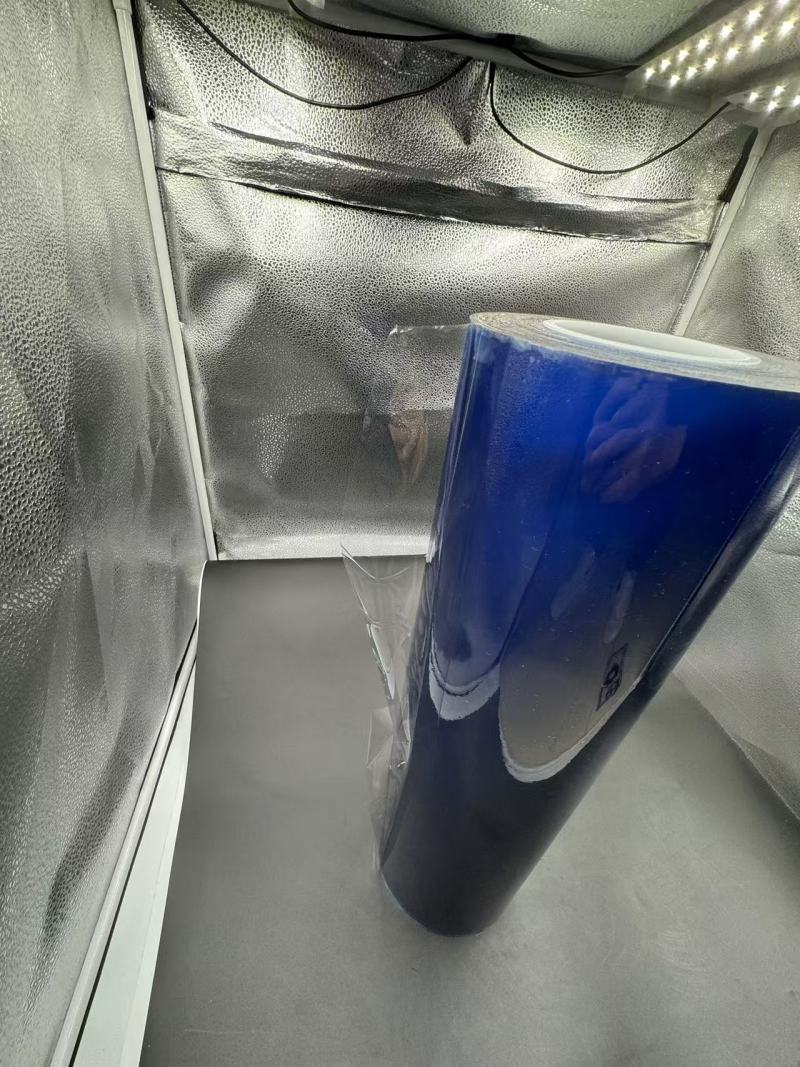

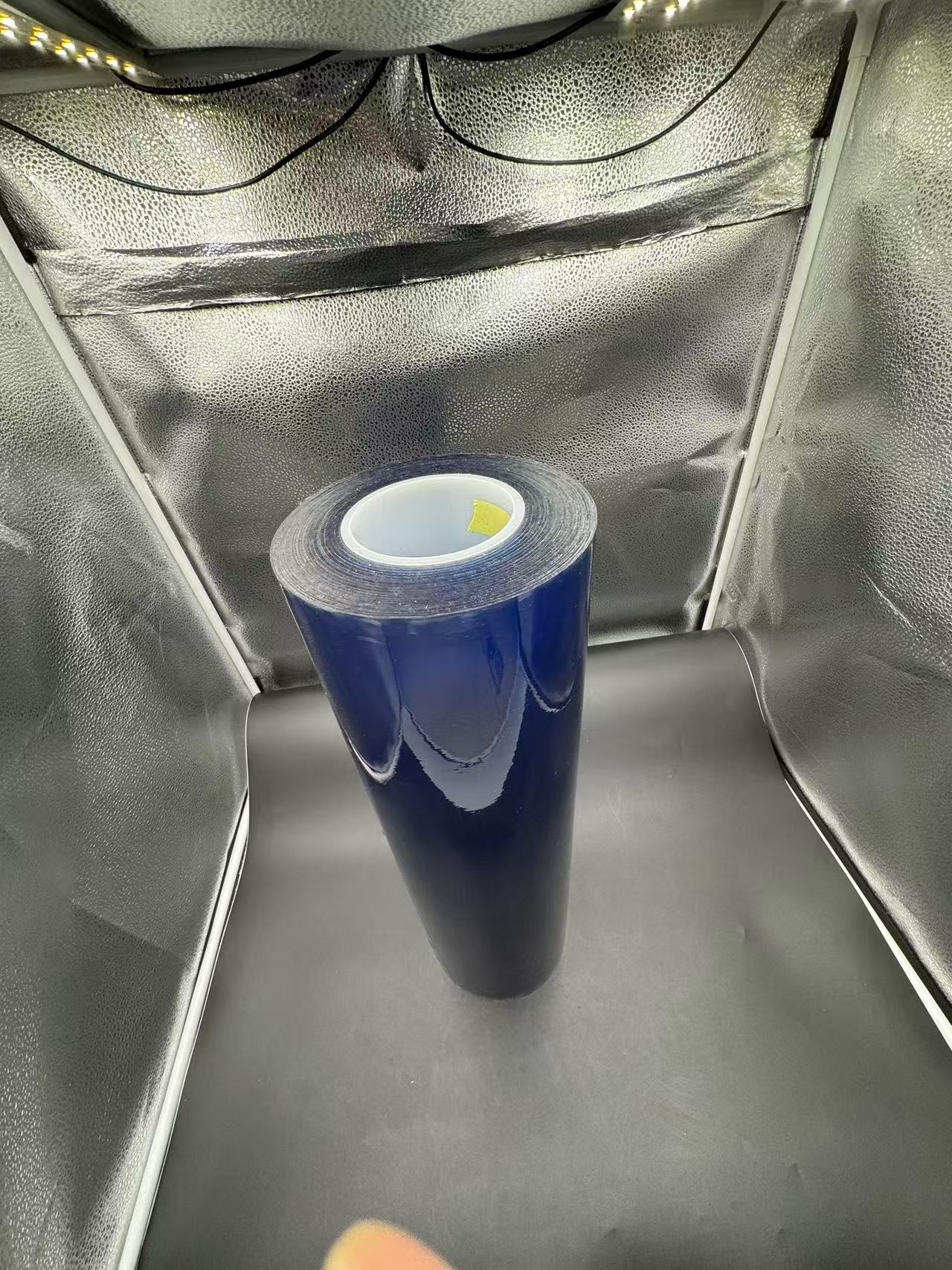

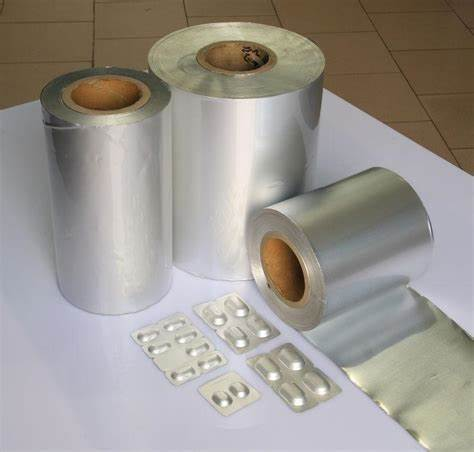

TL-PVC-0065 0.085 MM thickness film for High Barrier Lamination Composite Film

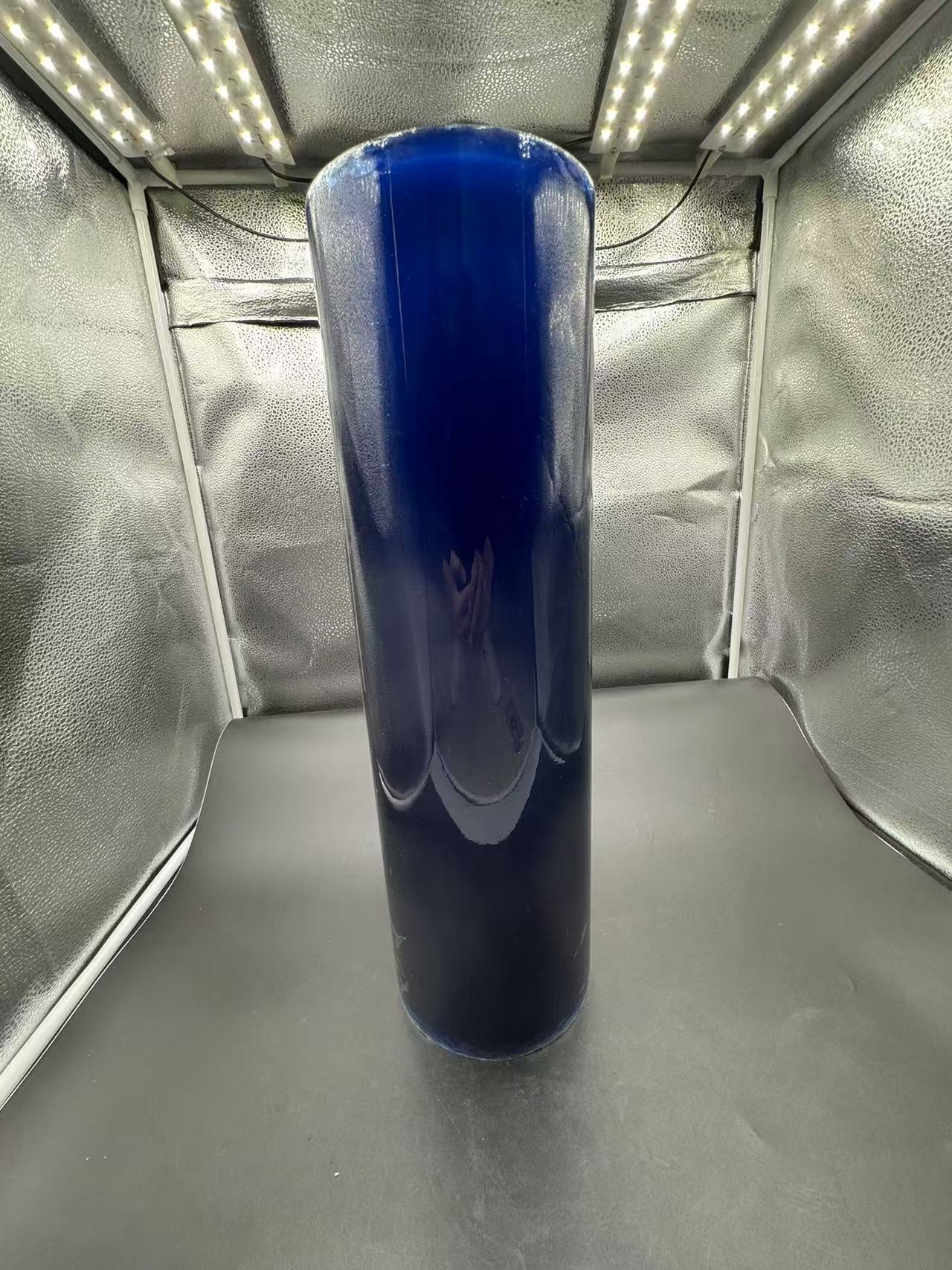

Material: PVC ROLL

Thickness 0.085-0.018mm-customization

Size: 80MM/130MM/600/Customization

GRADE: pharma grade film

color: transparent/ customization

location: china

Usage: Pharmaceutical, dried food

- TOPLEADER

- china

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Transparent Soft PVC Film in High Barrier Lamination Composite Film: Applications in Packaging and Beyond

Abstract: This comprehensive article explores the diverse applications of transparent soft PVC film in high barrier lamination composite films for packaging and other areas. It delves into the properties of PVC film, its advantages in lamination, and its role in enhancing product protection, aesthetics, and functionality. Through real-world examples and detailed descriptions, the article showcases the versatility and importance of this material in modern packaging and related industries.

I. Introduction

In today's fast-paced world, packaging plays a crucial role in protecting products, enhancing their appeal, and ensuring their safe transportation and storage. High barrier lamination composite films have emerged as a popular choice for a wide range of applications due to their excellent barrier properties, durability, and aesthetic appeal. Transparent soft PVC film is a key component in many of these composite films, offering unique properties that contribute to their effectiveness and versatility.

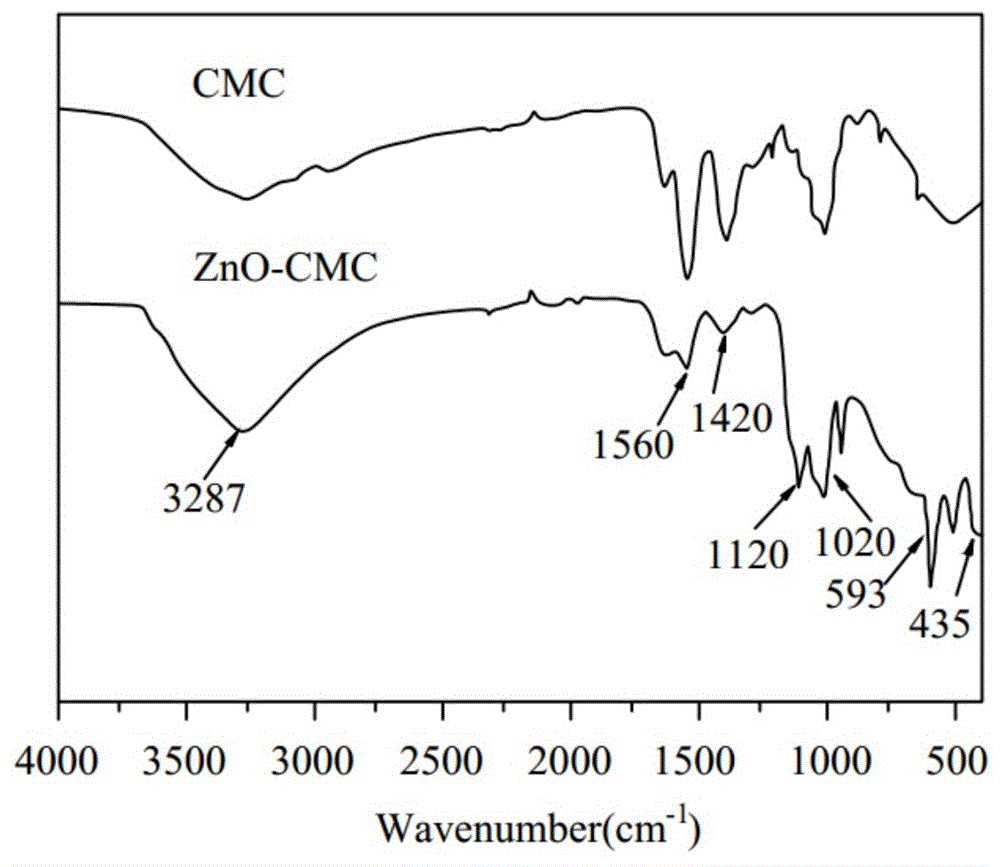

II. Properties of Transparent Soft PVC Film

A. Transparency

Transparent soft PVC film is highly transparent, allowing products to be clearly visible. This transparency enhances the aesthetic appeal of packaged goods and enables consumers to see the product inside, increasing their confidence in the quality and freshness of the contents.

B. Flexibility

PVC film is extremely flexible, making it easy to conform to the shape of various products. This flexibility allows for tight packaging and reduces the risk of damage during handling and transportation.

C. Durability

PVC film is known for its durability and resistance to punctures, tears, and abrasion. This makes it an ideal choice for packaging applications where the product needs to be protected from mechanical damage.

D. Chemical Resistance

PVC film has good chemical resistance, which means it can withstand exposure to a variety of chemicals without degrading. This property is important for packaging products that may come into contact with chemicals during storage or transportation.

E. Heat Sealability

PVC film can be heat-sealed easily, providing a secure seal that prevents leakage and contamination. This heat sealability also allows for efficient packaging processes and reduces the risk of packaging failures.

III. High Barrier Lamination Composite Films

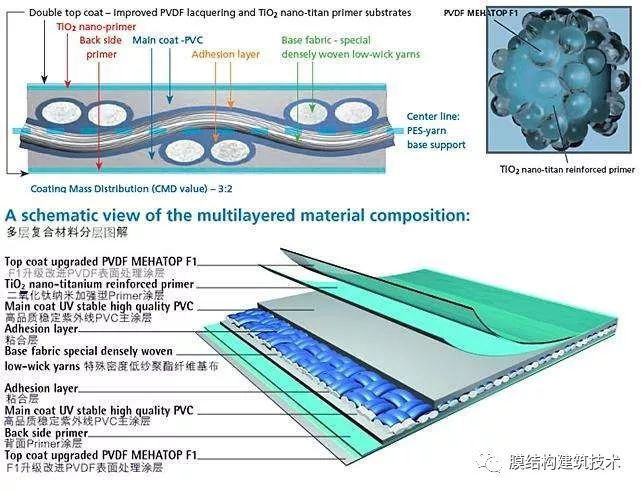

A. Definition and Composition

High barrier lamination composite films are multilayer films that combine different materials to provide enhanced barrier properties. These films typically consist of a base layer, a barrier layer, and a sealant layer. Transparent soft PVC film can be used as the base layer or as one of the intermediate layers in these composite films.

B. Barrier Properties

The barrier properties of high barrier lamination composite films are crucial for protecting products from moisture, oxygen, light, and other environmental factors. PVC film, when combined with other barrier materials, can significantly improve the barrier performance of the composite film.

C. Applications

High barrier lamination composite films are widely used in various industries, including food and beverage, pharmaceuticals, cosmetics, and electronics. They are used to package products such as snacks, beverages, drugs, cosmetics, and electronic components.

IV. Applications of Transparent Soft PVC Film in Packaging

A. Food Packaging

1. Freshness Preservation

PVC film is often used in food packaging to preserve the freshness of perishable products. Its excellent barrier properties help to prevent moisture and oxygen from entering the package, thereby extending the shelf life of the food.

2. Visual Appeal

The transparency of PVC film allows consumers to see the food inside, enhancing its visual appeal. This can be particularly important for products such as fruits, vegetables, and baked goods, where appearance is an important factor in consumer purchasing decisions.

3. Tamper-Evident Packaging

PVC film can be used to create tamper-evident packaging, providing consumers with assurance that the product has not been tampered with. Tamper-evident features can include seals, shrink bands, or blister packs.

4. Convenience Packaging

PVC film is also used in convenience packaging, such as single-serve pouches and sachets. These packages are easy to open and use, making them convenient for consumers on the go.

B. Pharmaceutical Packaging

1. Product Protection

In the pharmaceutical industry, packaging must provide a high level of protection to ensure the integrity and efficacy of drugs. PVC film, when combined with other barrier materials, can help to protect drugs from moisture, oxygen, and light, which can degrade the active ingredients.

2. Child-Resistant Packaging

PVC film can be used to create child-resistant packaging, which is essential for drugs that may be harmful if ingested by children. Child-resistant features can include special closures or packaging designs that are difficult for children to open.

3. Blister Packaging

Blister packaging is a common form of pharmaceutical packaging that uses PVC film as the base material. Blister packs provide a clear view of the product and offer excellent protection against damage and contamination.

C. Cosmetic Packaging

1. Aesthetic Appeal

Cosmetic packaging often requires a high level of aesthetic appeal to attract consumers. Transparent soft PVC film can be used to create beautiful and eye-catching packaging designs that showcase the product inside.

2. Protection

PVC film provides protection to cosmetics from moisture, air, and light, which can affect the quality and stability of the product. It also helps to prevent leakage and spillage during transportation and storage.

3. Pump and Spray Bottles

PVC film is used in the production of pump and spray bottles for cosmetics. The flexibility of PVC allows for easy dispensing of the product and provides a secure seal to prevent leakage.

D. Electronic Packaging

1. Static Protection

Electronic components are sensitive to static electricity, which can damage them. PVC film can be treated with antistatic agents to provide static protection during packaging and transportation.

2. Impact Resistance

Electronic products need to be protected from impact and shock during handling and transportation. PVC film, when combined with other cushioning materials, can provide excellent impact resistance.

3. Transparency for Inspection

The transparency of PVC film allows for easy inspection of electronic components without opening the package. This can be useful for quality control and ensuring that the product is in good condition.

V. Other Applications of Transparent Soft PVC Film

A. Advertising and Signage

PVC film is widely used in advertising and signage applications due to its transparency, durability, and ease of printing. It can be used to create banners, posters, window decals, and other promotional materials.

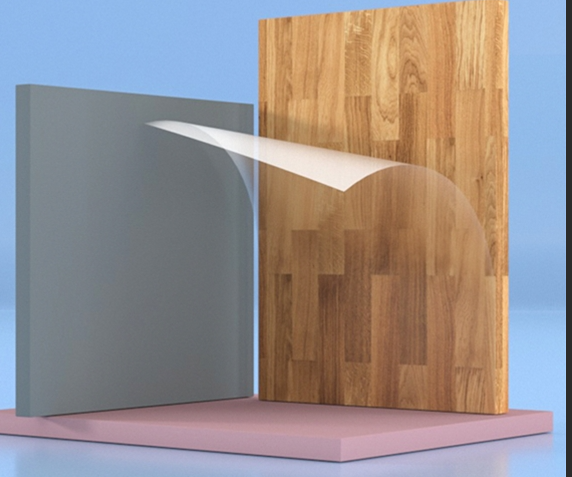

B. Protective Films

PVC film can be used as a protective film for various surfaces, such as furniture, electronics, and automotive parts. It provides protection against scratches, abrasion, and UV radiation.

C. Medical Applications

In the medical field, PVC film is used in the production of medical devices, such as catheters, tubing, and blood bags. It is also used as a protective covering for surgical instruments and equipment.

VI. Manufacturing Process of Transparent Soft PVC Film and High Barrier Lamination Composite Films

A. Extrusion

PVC film is typically produced by extrusion, a process in which molten PVC is forced through a die to form a continuous sheet. The extrusion process can be adjusted to control the thickness, width, and other properties of the film.

B. Lamination

High barrier lamination composite films are produced by laminating multiple layers of materials together. The lamination process can be done using various methods, such as adhesive lamination, extrusion lamination, or co-extrusion lamination.

C. Printing and Finishing

Once the composite film is produced, it can be printed with designs, logos, and other information using various printing methods, such as flexography, gravure printing, or digital printing. Finishing processes such as embossing, matte finishing, or gloss finishing can also be applied to enhance the aesthetic appeal of the film.

VII. Quality Control and Testing of Transparent Soft PVC Film and High Barrier Lamination Composite Films

A. Physical Properties Testing

Physical properties such as thickness, tensile strength, elongation at break, and tear strength are tested to ensure that the film meets the required specifications.

B. Barrier Properties Testing

Barrier properties such as moisture vapor transmission rate (MVTR) and oxygen transmission rate (OTR) are tested to ensure that the composite film provides the desired level of protection to the packaged product.

C. Adhesion Testing

Adhesion between the different layers of the composite film is tested to ensure that the film remains intact during handling and transportation.

D. Print Quality Testing

Print quality is tested to ensure that the designs, logos, and other information are printed clearly and accurately on the film.

VIII. Environmental Impact and Sustainability of Transparent Soft PVC Film and High Barrier Lamination Composite Films

A. Environmental Concerns

PVC film has been the subject of environmental concerns due to its potential to release harmful chemicals during production and disposal. However, advances in technology have led to the development of more environmentally friendly PVC formulations that reduce the release of these chemicals.

B. Recycling and Disposal

Recycling of PVC film and high barrier lamination composite films can be challenging due to the complexity of the materials. However, efforts are being made to develop more efficient recycling processes and to encourage the use of recyclable materials in packaging.

C. Sustainable Alternatives

There are several sustainable alternatives to PVC film and high barrier lamination composite films, such as biodegradable films, compostable films, and recycled materials. These alternatives offer similar properties and performance while reducing the environmental impact.

IX. Conclusion

Transparent soft PVC film plays a vital role in high barrier lamination composite films for packaging and other applications. Its unique properties, such as transparency, flexibility, durability, and heat sealability, make it an ideal choice for protecting products, enhancing their aesthetic appeal, and providing convenience to consumers. As the demand for high-quality packaging continues to grow, the use of PVC film in high barrier lamination composite films is expected to increase. However, it is important to address the environmental concerns associated with PVC film and to explore sustainable alternatives to ensure a more sustainable future for the packaging industry.

Within 15-20 days after received payment...more