The Remarkable Properties and Applications of Transparent BOPET Film in Printable Composite Packaging

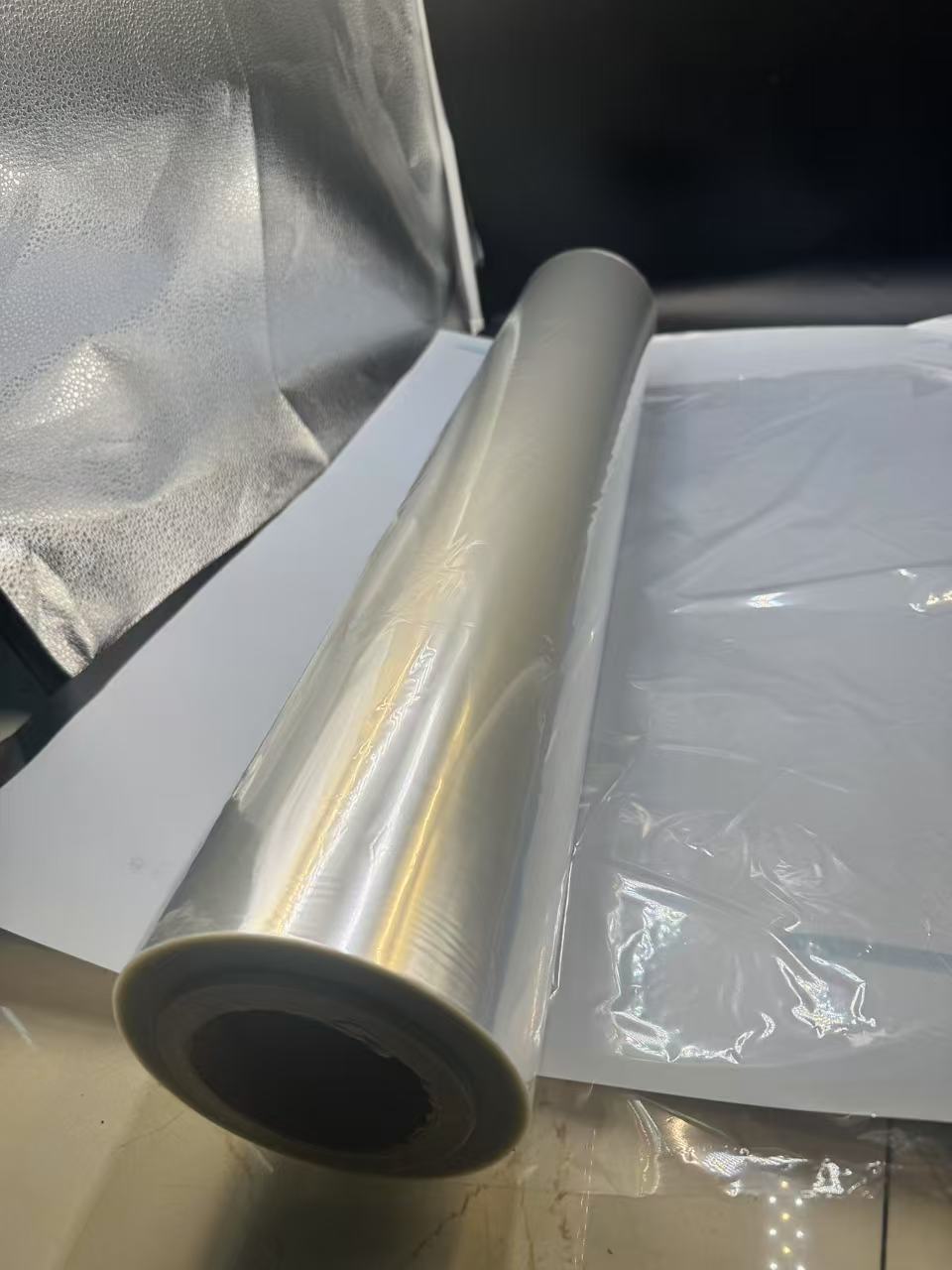

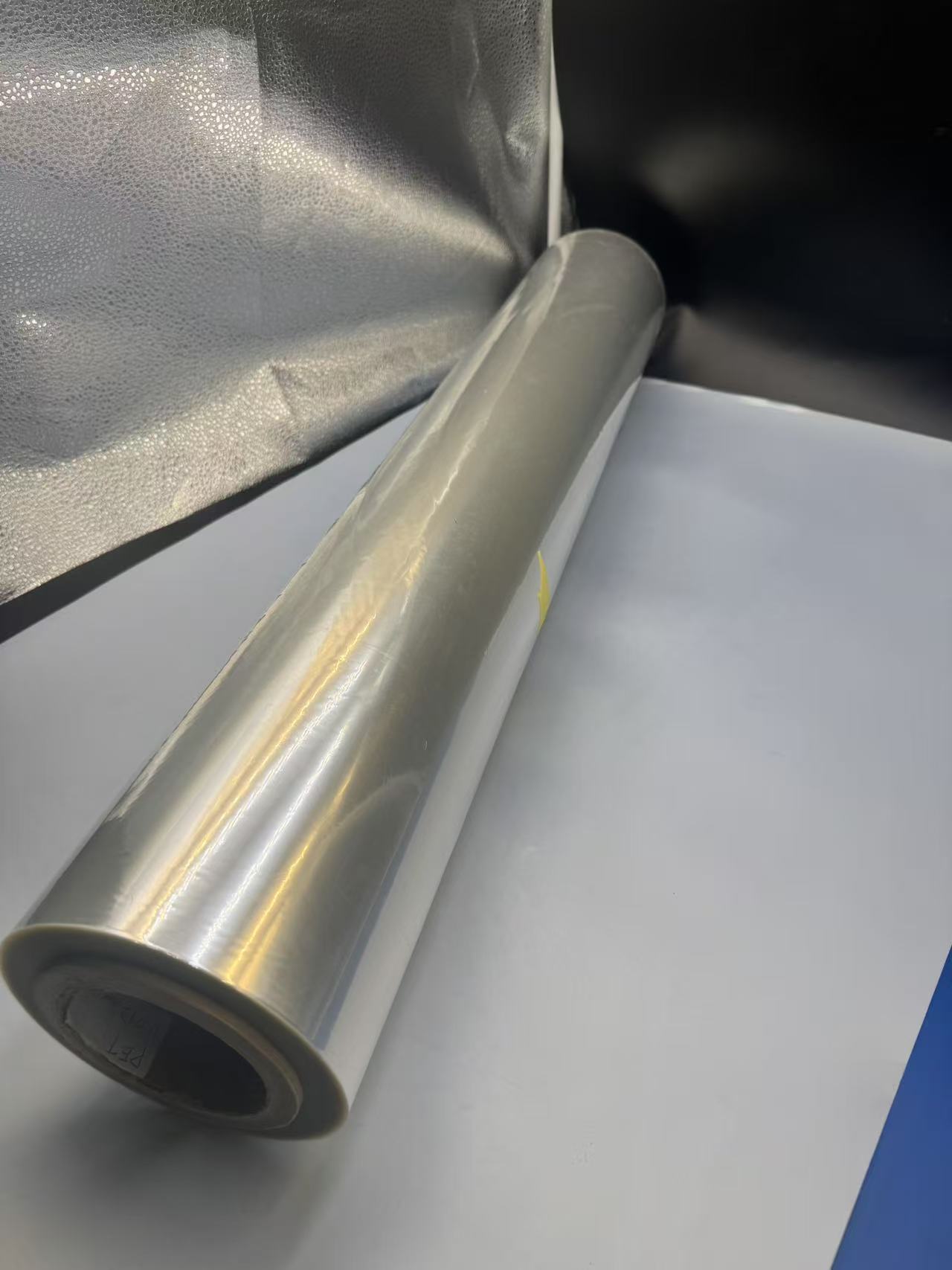

NameBOPET PRINTABLE film roll

SizeTk:0.012-0.023mm, h100-1200mm

MaterialPETG/Customized

Color/printingTransparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

UsageVegetable/Fruit/Meat, snack, nuts ,foods

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

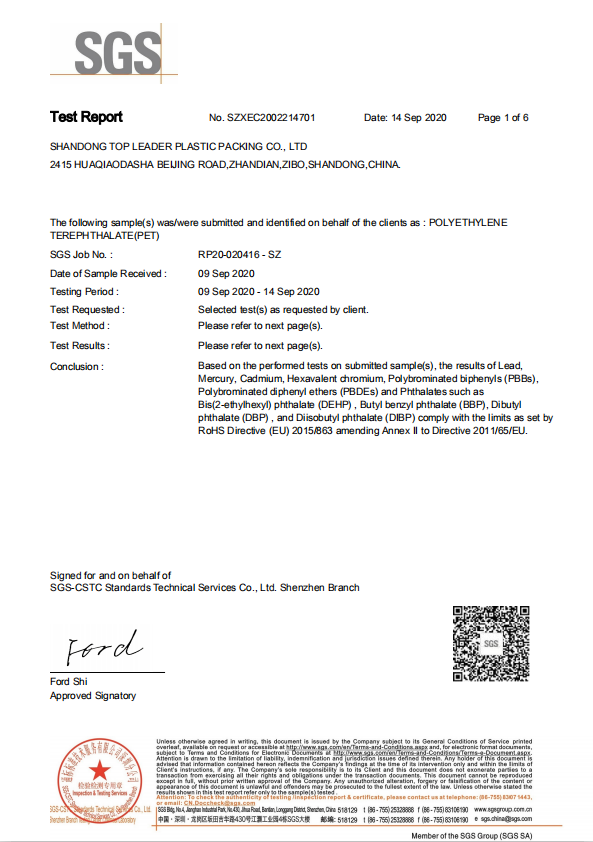

- TOPLEADER

- 中国

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

Transparent BOPET (Biaxially Oriented Polyethylene Terephthalate) film has emerged as a cornerstone material in the realm of flexible packaging, particularly for printable composite structures. Renowned for its exceptional mechanical, optical, and barrier properties, BOPET film serves as a versatile substrate in industries ranging from food to pharmaceuticals. This article explores the unique characteristics of BOPET film and its pivotal role in printable composite packaging, highlighting its technical advantages and real-world applications with vivid detail.

Exceptional Properties of BOPET Film

BOPET film is produced through a biaxial orientation process, where PET resin is stretched in both machine and transverse directions, resulting in a material with superior strength and clarity. Its key properties make it an ideal choice for composite packaging:

Mechanical Strength: BOPET film boasts high tensile strength and dimensional stability, enabling it to withstand the stresses of high-speed printing, lamination, and filling processes. For instance, a 12-micron BOPET film can endure tensile forces exceeding 200 MPa, ensuring durability during manufacturing and transportation.

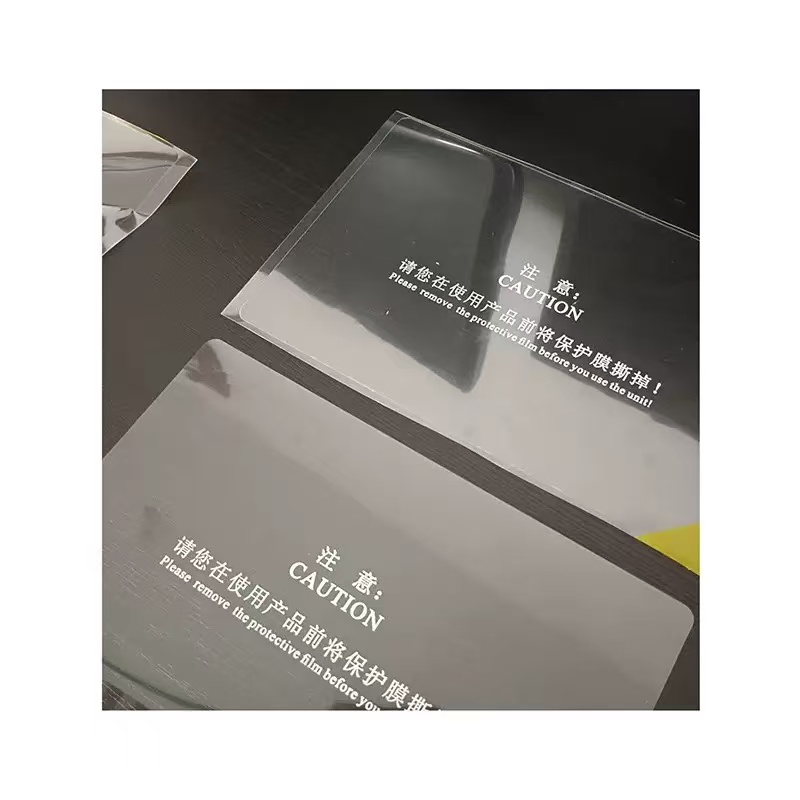

Optical Clarity: With transparency levels often exceeding 90%, BOPET film provides a crystal-clear window for product visibility, enhancing shelf appeal. This is critical in retail, where brands leverage vibrant graphics printed on BOPET film to attract consumers. Imagine a snack pouch where the glossy, see-through BOPET layer showcases golden potato chips, instantly drawing attention.

Barrier Performance: BOPET film offers excellent resistance to gases, moisture, and aromas, protecting packaged goods from spoilage. While standalone BOPET film provides moderate oxygen transmission rates (OTR) of around 100 cc/m²/day at 12 microns, its barrier properties are significantly enhanced when laminated with materials like aluminum foil or metallized films.

Thermal Stability: With a melting point around 260°C, BOPET film maintains integrity during heat-sealing and sterilization processes, making it suitable for applications like retort pouches used for ready-to-eat meals.

Surface Versatility: The smooth, uniform surface of BOPET film is ideal for high-quality printing and coating. It accepts various inks and adhesives, ensuring sharp, vibrant designs that resist smudging or fading. Corona-treated BOPET films, for example, achieve surface energies above 42 dynes/cm, promoting excellent ink adhesion.

These properties collectively position BOPET film as a material that balances functionality with aesthetic appeal, addressing the stringent demands of modern packaging.

Applications in Printable Composite Packaging

In composite packaging, BOPET film is typically laminated with other substrates like polyethylene (PE), polypropylene (PP), or foil to create structures tailored to specific products. Its role in printable composite packaging is multifaceted, serving as a print carrier, barrier layer, and structural component. Below are key applications, illustrated with practical examples:

Food Packaging: BOPET film is a staple in flexible pouches for snacks, confectionery, and frozen foods. A typical structure might involve a 12-micron BOPET film printed with a brand’s logo, laminated to a 50-micron PE layer for sealing. This composite ensures the product remains fresh while the glossy BOPET surface enhances visual appeal. For instance, coffee pouches often use metallized BOPET film to block light and oxygen, preserving aroma and flavor for months.

Pharmaceutical Packaging: In blister packs and sachets, transparent BOPET film provides clarity for dosage visibility while maintaining sterility. Its chemical inertness prevents interactions with sensitive drugs, and its puncture resistance protects against tampering. A composite of BOPET film and foil, for example, is used in unit-dose packaging for tablets, ensuring compliance with regulatory standards like USP <661>.

Stand-Up Pouches: The rise of stand-up pouches for detergents, pet food, and beverages owes much to BOPET film’s rigidity and printability. A structure like BOPET/foil/PE combines the film’s strength and aesthetics with foil’s barrier properties and PE’s sealability. Picture a vibrant juice pouch on a supermarket shelf, its BOPET film layer showcasing a tropical fruit design that resists scratches during handling.

Retort and Microwaveable Packaging: BOPET film’s thermal stability shines in retort pouches, which undergo high-temperature sterilization (up to 135°C). A composite of BOPET film, nylon, and PP can endure these conditions, making it ideal for ready meals. The film’s clarity also allows consumers to inspect the food, building trust in the product’s quality.

Sustainable Packaging Innovations: As sustainability gains traction, BOPET film is evolving. Recyclable mono-material structures using high-barrier BOPET film are being developed to replace multi-layer composites. Additionally, bio-based BOPET films are emerging, reducing reliance on fossil-based PET while maintaining performance.

Technical Advantages in Printing Processes

The printability of BOPET film is a game-changer in composite packaging. Its smooth surface supports advanced printing techniques like flexography, gravure, and digital printing, delivering high-resolution graphics. For example, gravure printing on BOPET film achieves resolutions up to 200 lines per inch, ensuring intricate designs remain crisp. The film’s dimensional stability prevents stretching or distortion during multi-color printing, which is critical for brand consistency.

Moreover, BOPET film can be treated or coated to enhance functionality. Anti-fog coatings on BOPET film ensure clarity in humid conditions, ideal for fresh produce packaging. UV-resistant coatings protect printed designs from fading, extending shelf life in outdoor displays. These adaptations make BOPET film a dynamic canvas for brands to communicate their identity.

Challenges and Future Directions

Despite its advantages, BOPET film faces challenges. Its reliance on multi-layer composites can complicate recycling, prompting research into single-polymer solutions. Additionally, while BOPET film is cost-effective compared to alternatives like BOPA (biaxially oriented polyamide), its production requires precise control to avoid defects like haze or gel formation, which can compromise clarity.

Looking ahead, innovations in BOPET film are promising. Nanotechnology is enhancing its barrier properties, with nano-coated BOPET films achieving OTRs below 10 cc/m²/day. Digital printing advancements are also reducing setup costs, enabling short-run, customized packaging. These developments ensure BOPET film remains at the forefront of packaging innovation.

Within 15-20 days after received payment...more