The Characteristics of Milky White Transparent PP Film and Its Role in Blister Packaging for Tableware

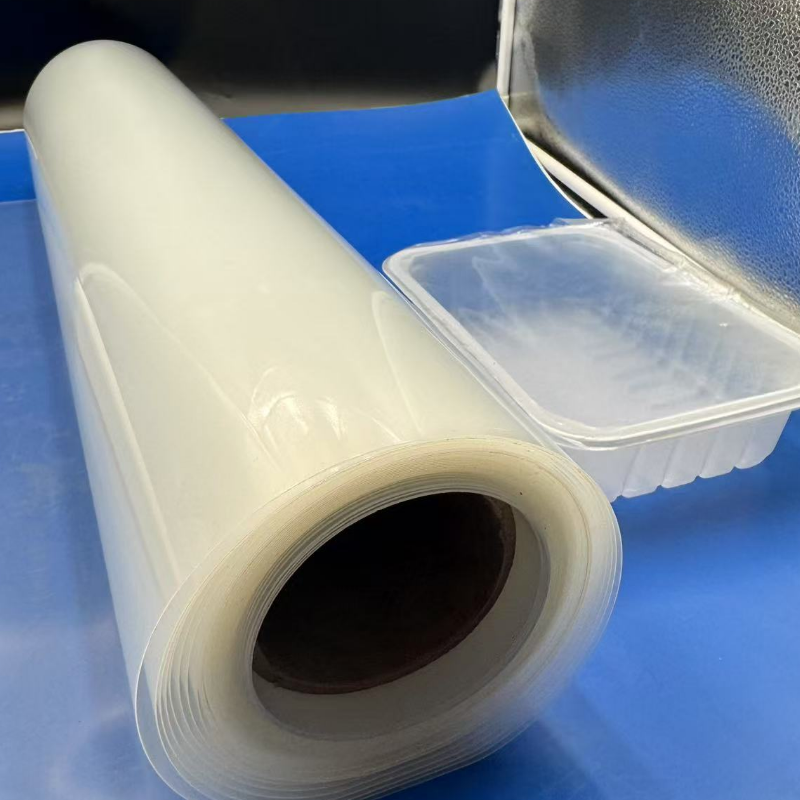

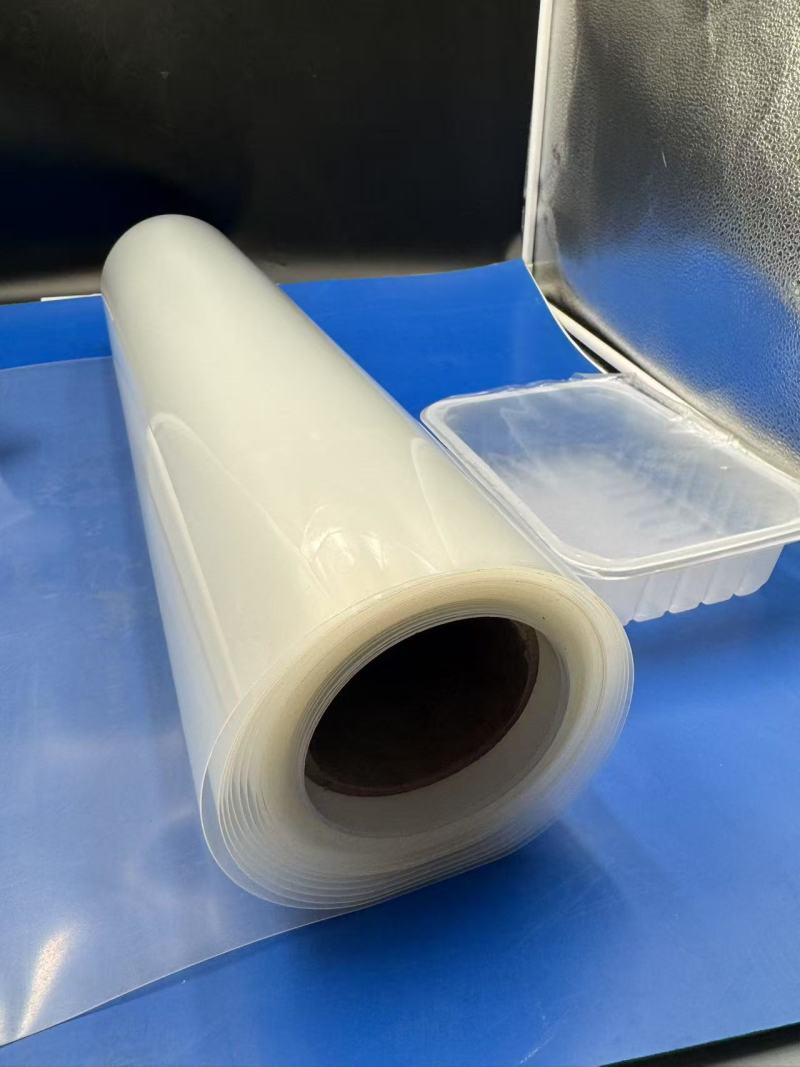

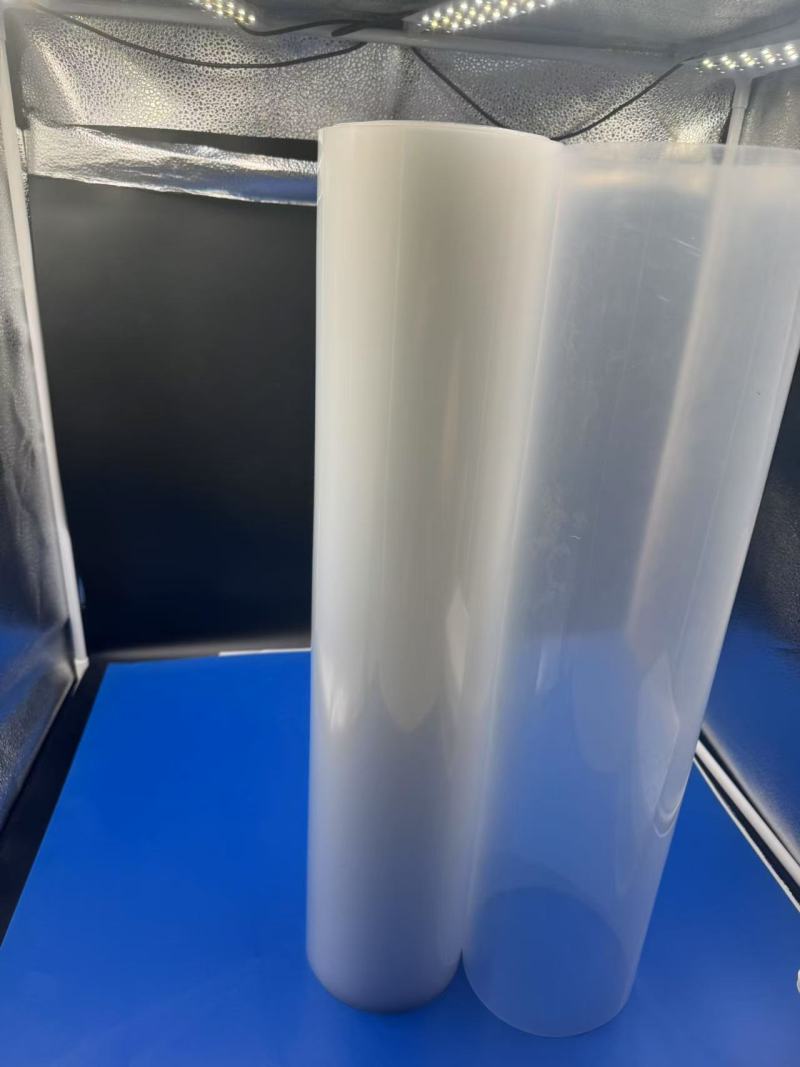

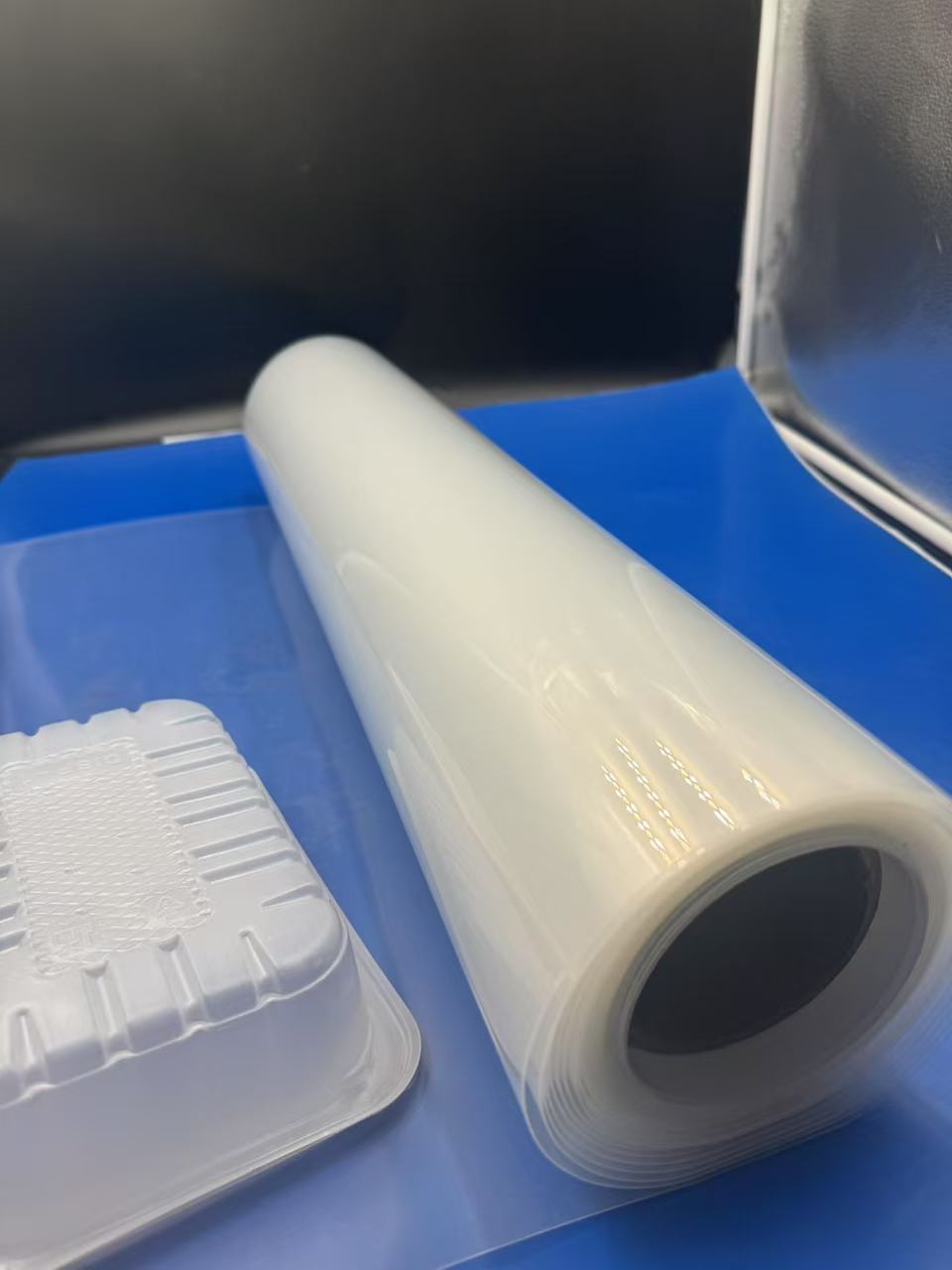

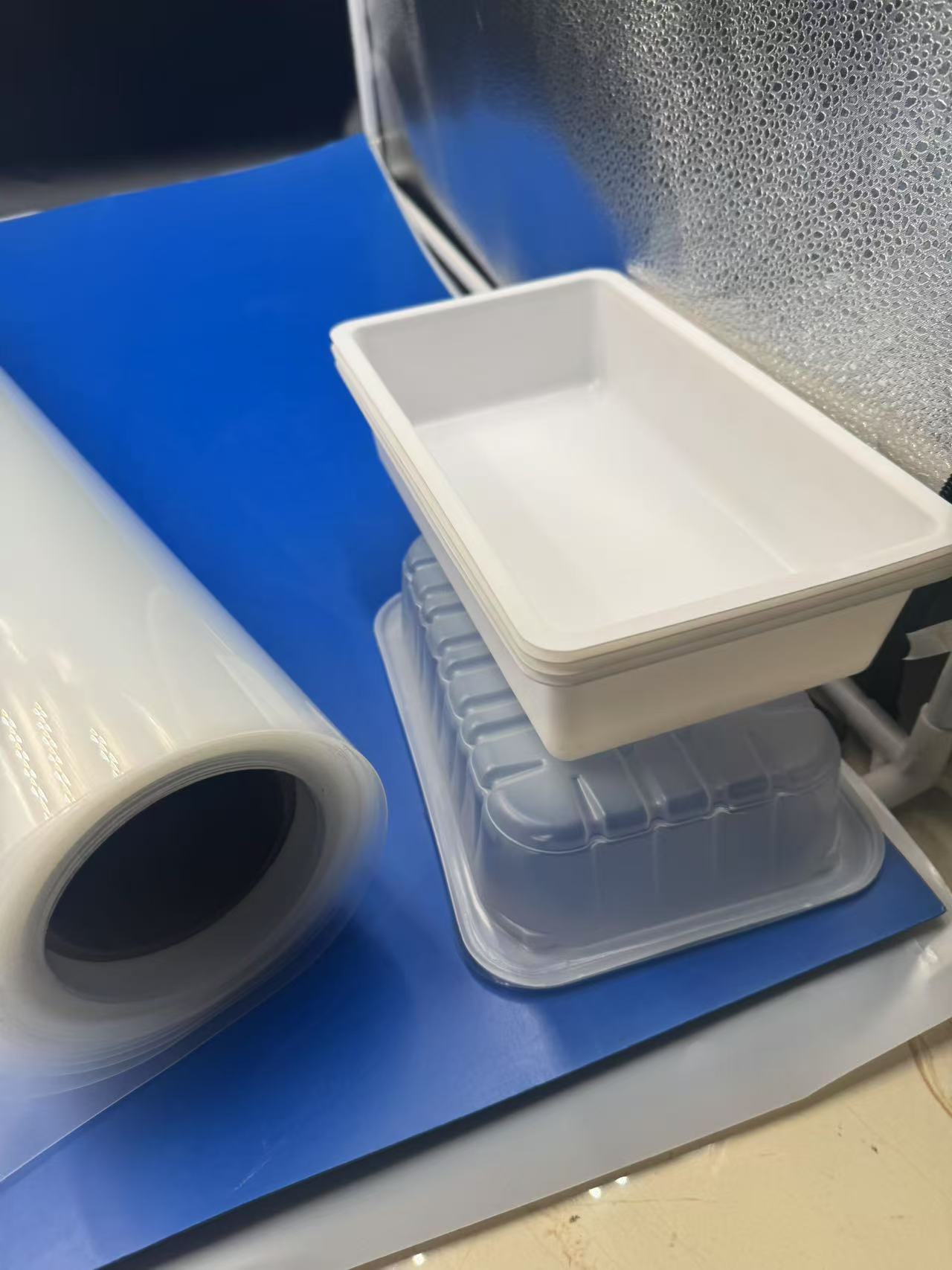

NamePP Plastic film roll

SizeTk:0.1-0.9mm, h100-1200mm

MaterialPET/PP/Customized

Color/printingTransparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

UsageVegetable/Fruit/Meat

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

Polypropylene (PP) film, particularly in its milky white transparent variant, has emerged as a versatile and practical material in the packaging industry. Known for its unique blend of properties, this thermoplastic film is increasingly utilized in blister packaging for tableware, such as forks, spoons, knives, and trays. This article delves into the defining characteristics of milky white transparent PP film and explores its application in protecting and presenting tableware. By weaving together technical insights and real-world examples, we aim to illustrate why PP film is a compelling choice in this domain, balancing functionality, cost-efficiency, and aesthetic appeal.

Key Properties of Milky White Transparent PP Film

PP film stands out due to its distinct physical, chemical, and processing attributes, which make it suitable for a wide range of packaging needs. The milky white transparent version, in particular, offers a subtle translucency that differentiates it from fully clear or opaque alternatives. Below are the core properties that define its utility.

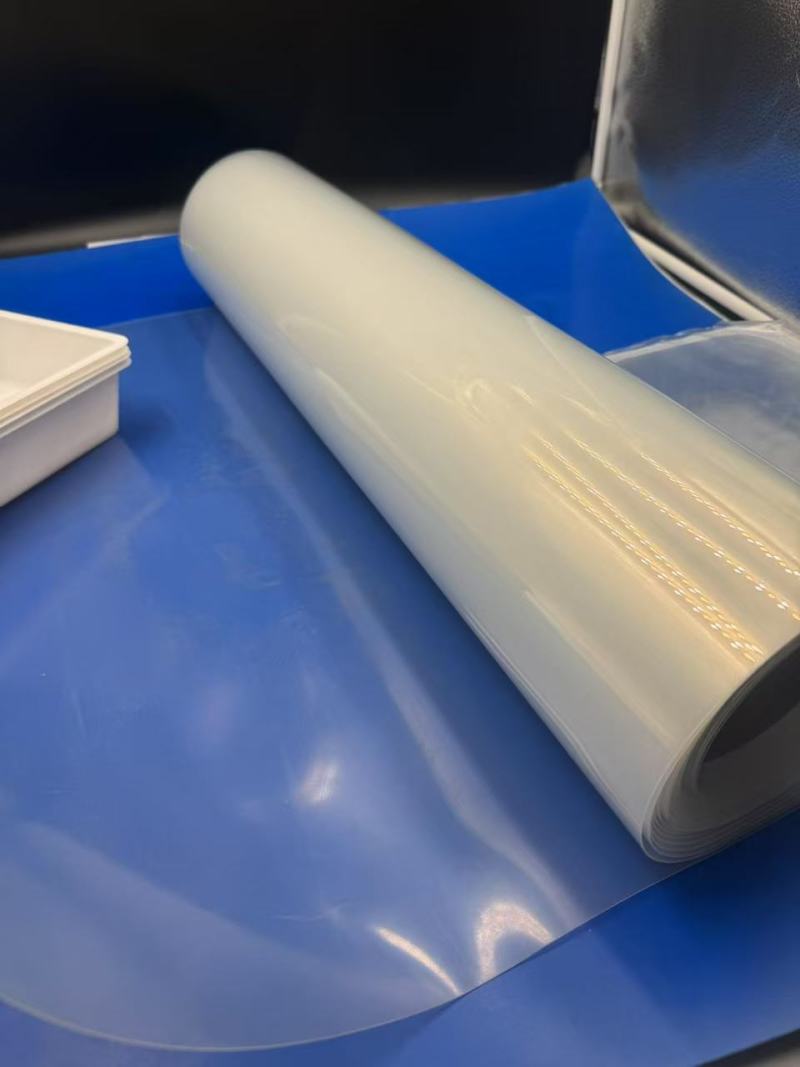

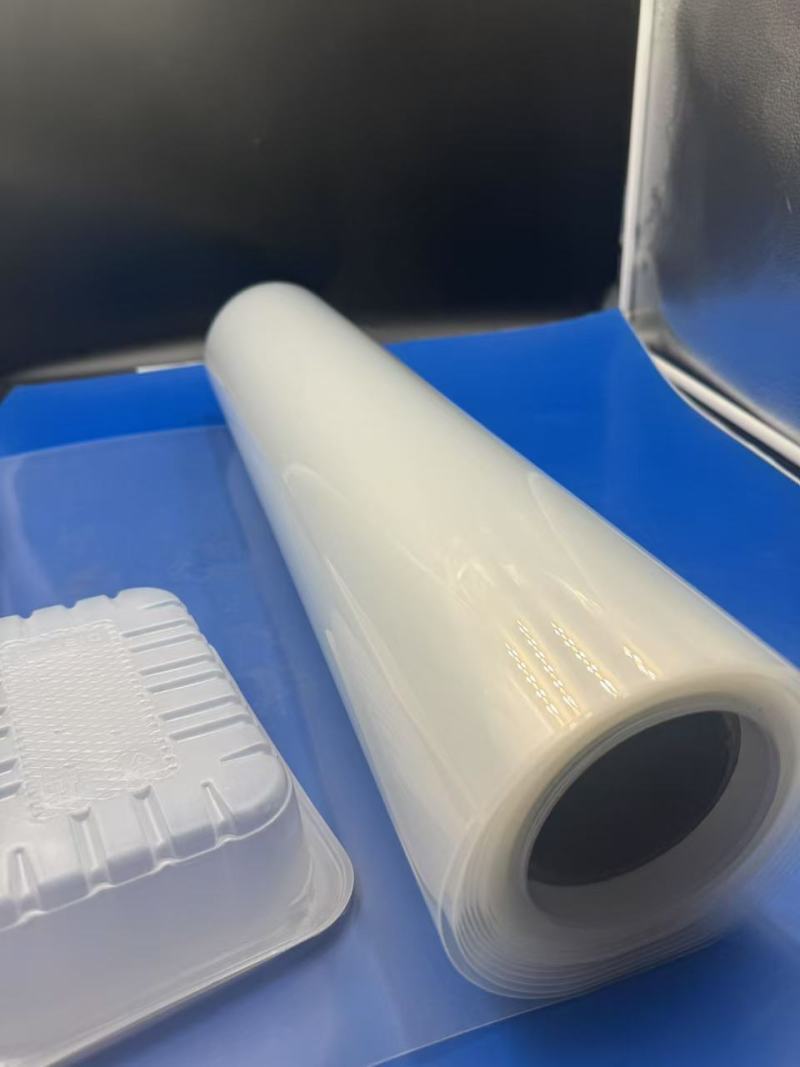

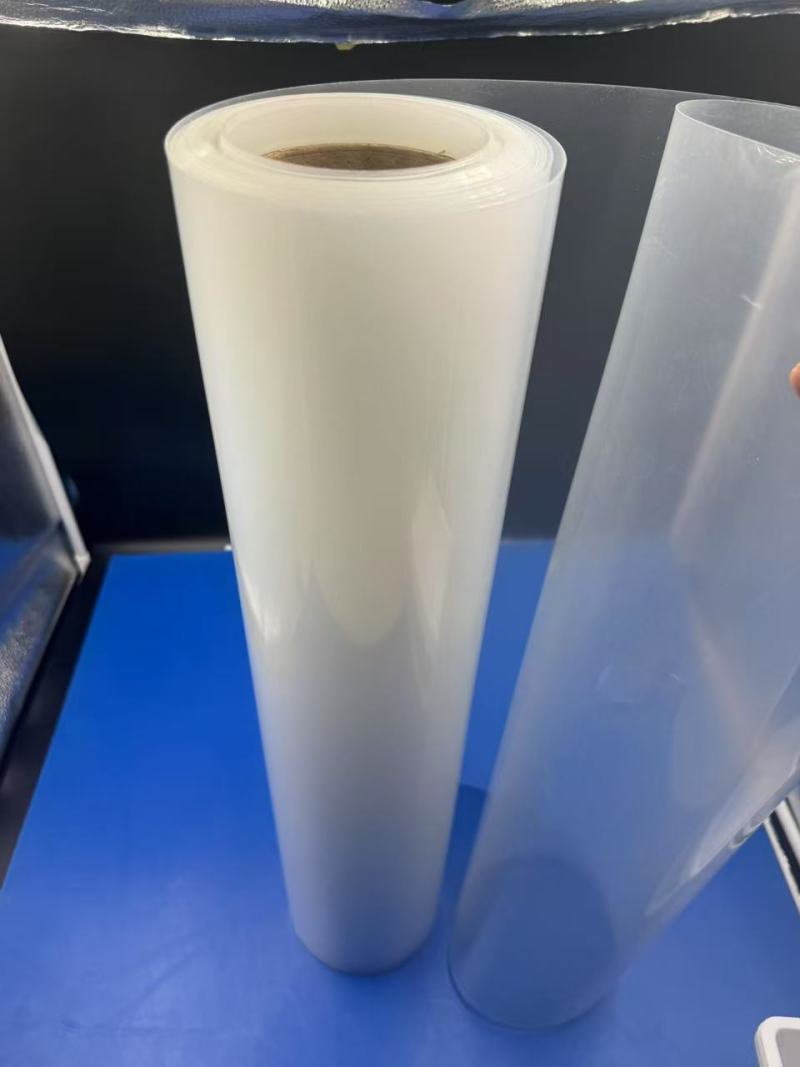

Subtle Translucency

Unlike fully transparent films like PET, milky white PP film provides a soft, diffused transparency that obscures fine details while still allowing light to pass through. This gives packaged tableware a clean, sophisticated look without fully exposing the contents. For instance, a stack of white plastic spoons in a PP film blister pack appears neatly silhouetted, offering a hint of the product without revealing imperfections or minor scratches.

Flexibility and Toughness

PP film is renowned for its flexibility combined with excellent tear resistance. This toughness ensures that the film can endure stretching and bending during the packaging process and handling afterward. Imagine a blister pack of disposable knives being tossed into a shopping cart—PP film’s resilience prevents it from splitting or puncturing, keeping the contents secure.

Heat Resistance and Formability

With a melting point typically ranging from 130°C to 171°C, PP film exhibits good heat resistance, making it ideal for thermoforming in blister packaging. It softens under controlled heat, allowing it to be molded into precise shapes that snugly fit tableware items. This property ensures that a tray of plastic cups, for example, can be encased in a PP film blister pack with cavities tailored to each cup’s contours.

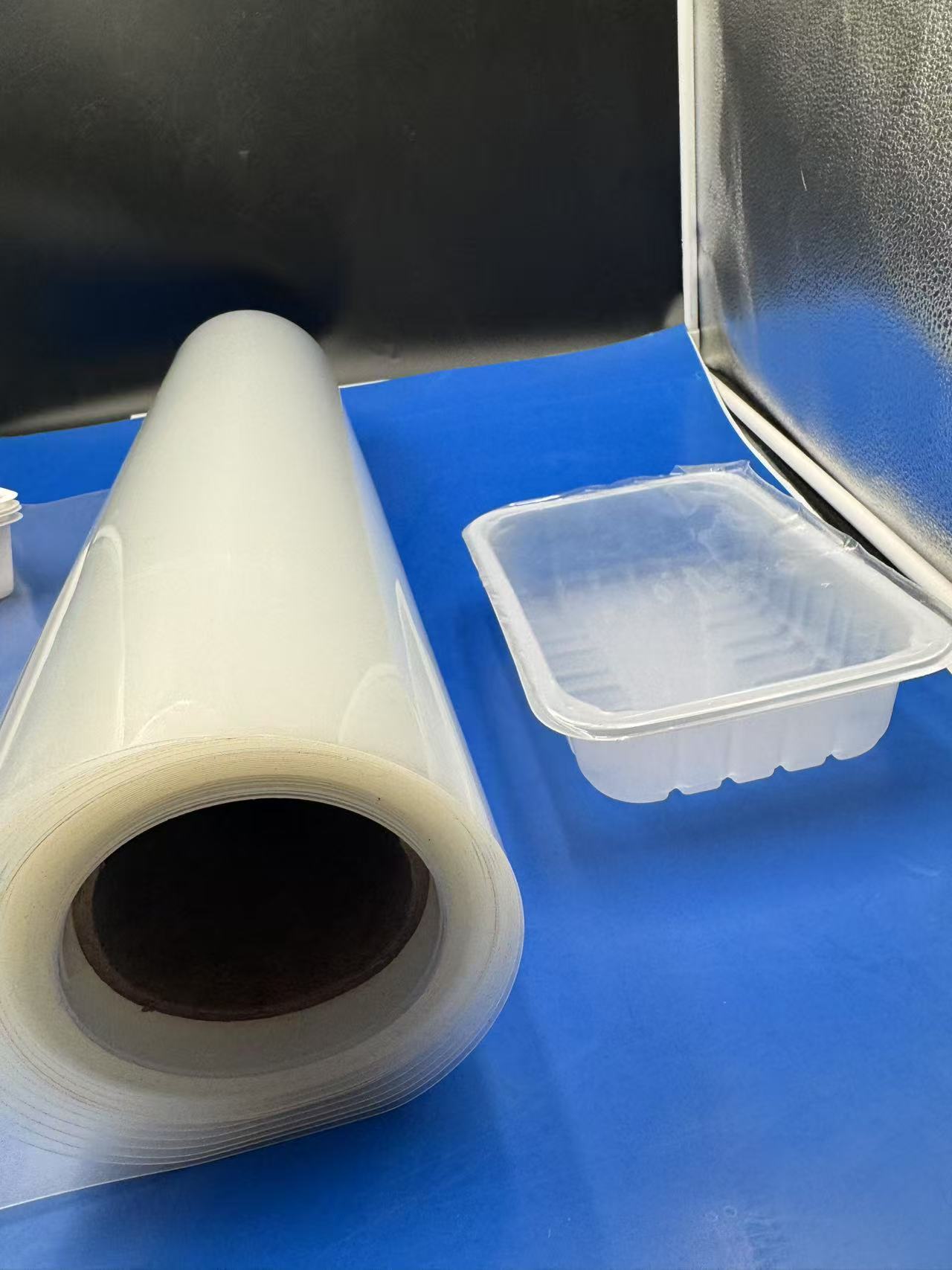

Moisture and Chemical Resistance

PP film is naturally resistant to moisture, grease, and many chemicals, providing a protective barrier for tableware. This is particularly valuable in environments where packaging might encounter water splashes or oily residues, such as in a kitchen goods aisle. A blister pack of forks wrapped in PP film, for instance, remains unaffected by a nearby spill, preserving the hygiene and appeal of the product.

Lightweight and Cost-Effective

PP film is lighter than many competing materials, such as PVC or thicker PET films, which reduces shipping costs and material usage. Its affordability also makes it an attractive option for mass production of tableware packaging. For manufacturers producing thousands of disposable plates, PP film offers an economical yet reliable solution without compromising quality.

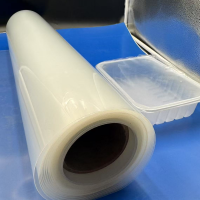

PP Film in Blister Packaging for Tableware

Blister packaging, with its pre-formed plastic cavities sealed against a backing, is a go-to method for tableware due to its ability to protect and display products effectively. Milky white transparent PP film enhances this application by leveraging its unique properties to meet practical and visual demands. Let’s explore how it functions in this context, with vivid scenarios to bring its benefits to life.

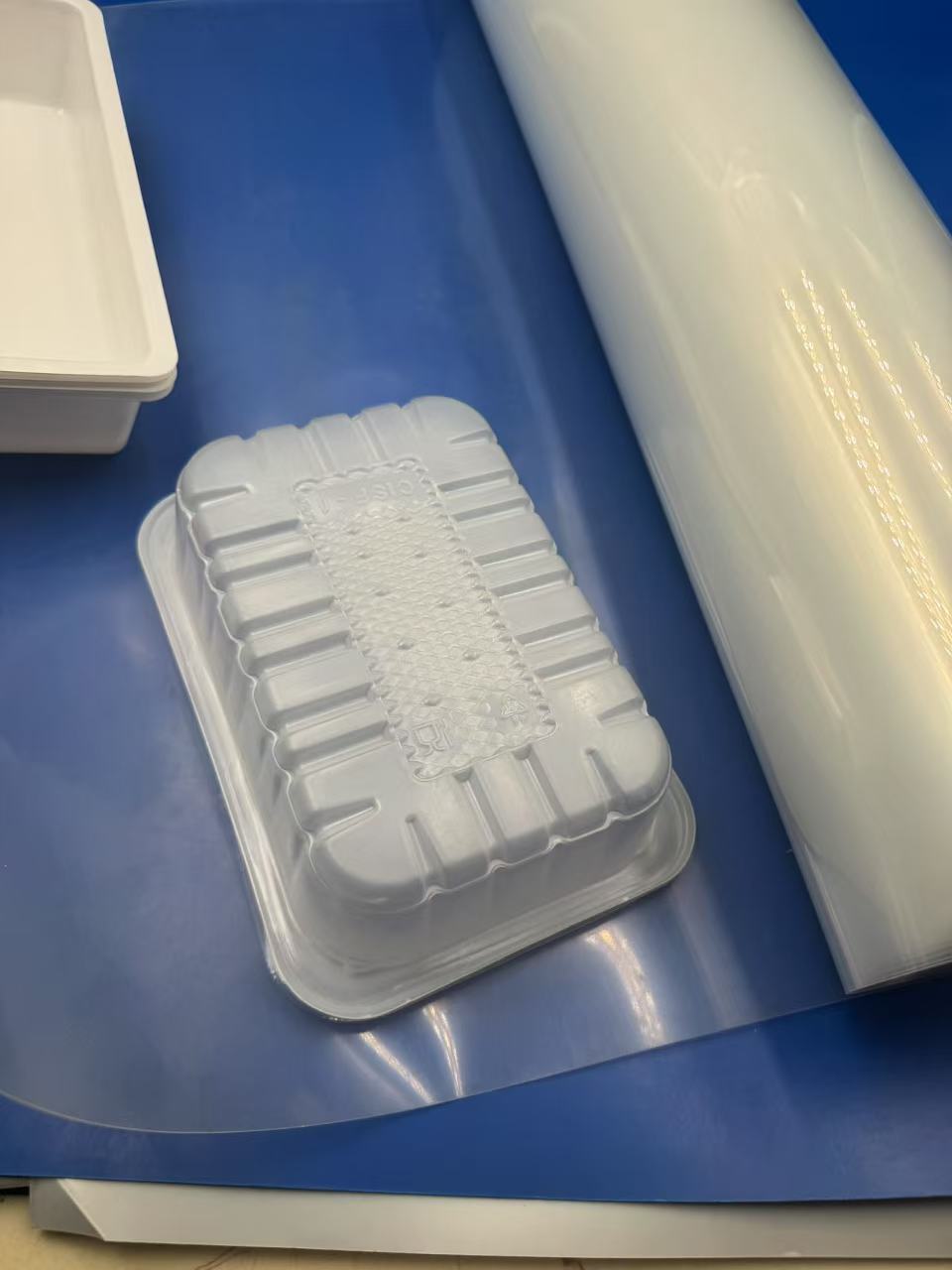

1. Thermoforming for Custom Fit

The blister packaging process relies heavily on thermoforming, where PP film is heated and shaped into cavities that house tableware. Its heat resistance and formability allow for smooth molding, creating packs that securely hold items in place. Picture a set of reusable plastic spoons packaged for a camping kit—the PP film forms a blister pack with individual slots, ensuring each spoon stays put during transit or outdoor use.

This precision is especially useful for irregularly shaped tableware. A manufacturer might use PP film to encase a stack of nested bowls, where the film’s flexibility accommodates the curves and edges, resulting in a snug, protective fit.

2. Protection with a Soft Aesthetic

The toughness and moisture resistance of PP film make it an excellent shield for tableware during storage, shipping, and retail display. Its milky white translucency adds a layer of sophistication, softening the appearance of the contents. For example, a blister pack of disposable forks in a grocery store might catch a shopper’s eye with its clean, diffused look—distinct from the stark clarity of PET or the dullness of opaque materials.

During transport, this resilience shines. A shipment of PP film-packaged trays bouncing in a delivery van remains intact, with the film absorbing minor impacts and repelling dust or dampness, ensuring the trays arrive ready for use.

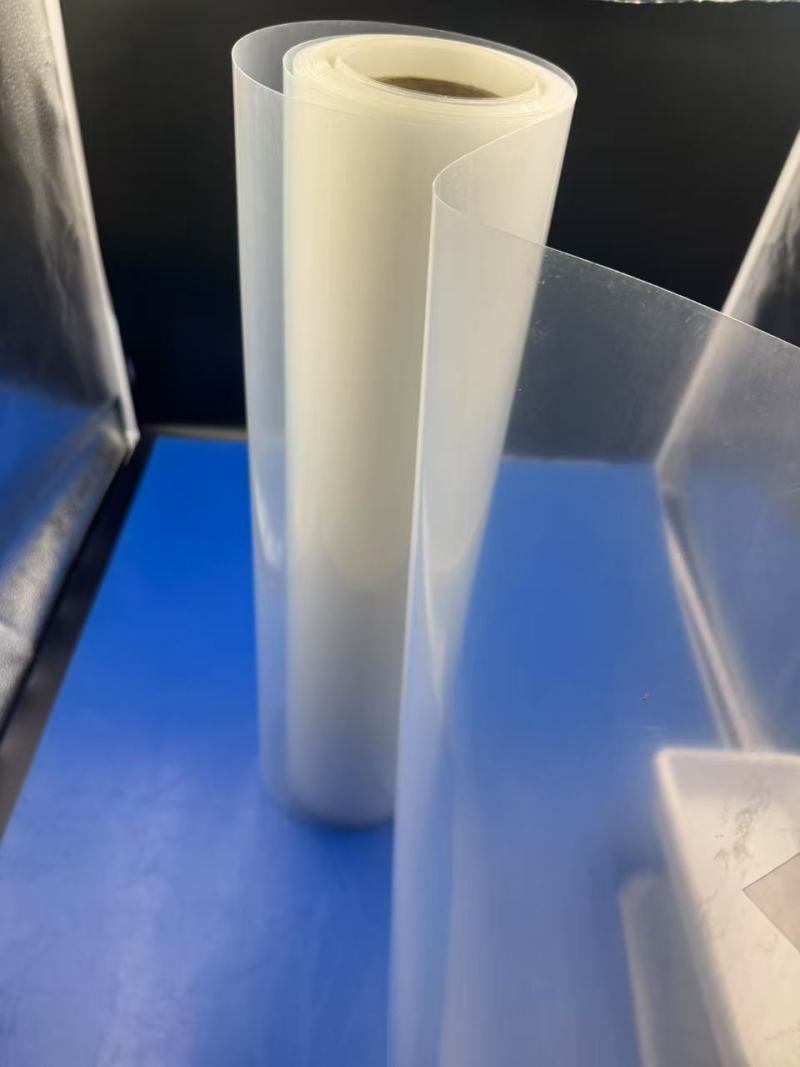

3. Balancing Visibility and Privacy

While fully transparent films showcase every detail, PP film’s milky white finish strikes a middle ground—offering visibility while maintaining a degree of subtlety. This is ideal for tableware where branding or hygiene is prioritized over intricate design exposure. Consider a pack of biodegradable knives in a PP film blister: the translucency hints at the eco-friendly material, but the milky hue keeps the focus on the pack’s sleek, minimalist presentation rather than minor surface variations.

In a retail setting, this balance can enhance shelf appeal. Two packs of cups—one in clear PET, the other in PP film—might sit side by side. The PP film version exudes a refined, understated charm, appealing to customers who value both practicality and style.

4. Sustainability and Practicality

PP film is recyclable, though its recycling rates lag behind PET due to infrastructure differences. Still, its lightweight nature reduces material consumption, aligning with sustainable packaging goals. For disposable tableware, such as picnic plates, PP film provides an efficient, low-impact packaging option. A company launching a line of compostable cutlery might choose PP film to complement the eco-friendly product, knowing that the film’s recyclability supports their green ethos.

In practice, this could mean a festival vendor opting for PP film blister packs for spoons and forks. The lightweight packaging cuts transport costs, while the recyclable film resonates with environmentally conscious attendees.

5. Scalability for Diverse Needs

The cost-effectiveness and versatility of PP film make it a scalable solution for tableware manufacturers of all sizes. Small businesses entering the market with niche products—like reusable bamboo spoons—can rely on PP film for affordable, high-quality packaging. Meanwhile, large-scale producers of plastic cups can churn out thousands of blister packs, confident that PP film’s durability and low cost will keep operations profitable.

Within 15-20 days after received payment...more