The Properties of Printable PET Film and Its Applications in Heat Sealing

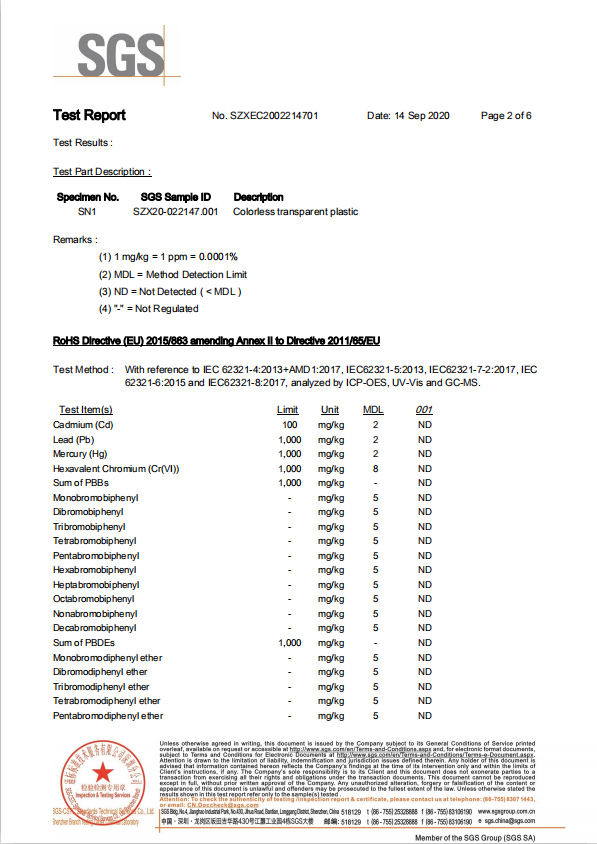

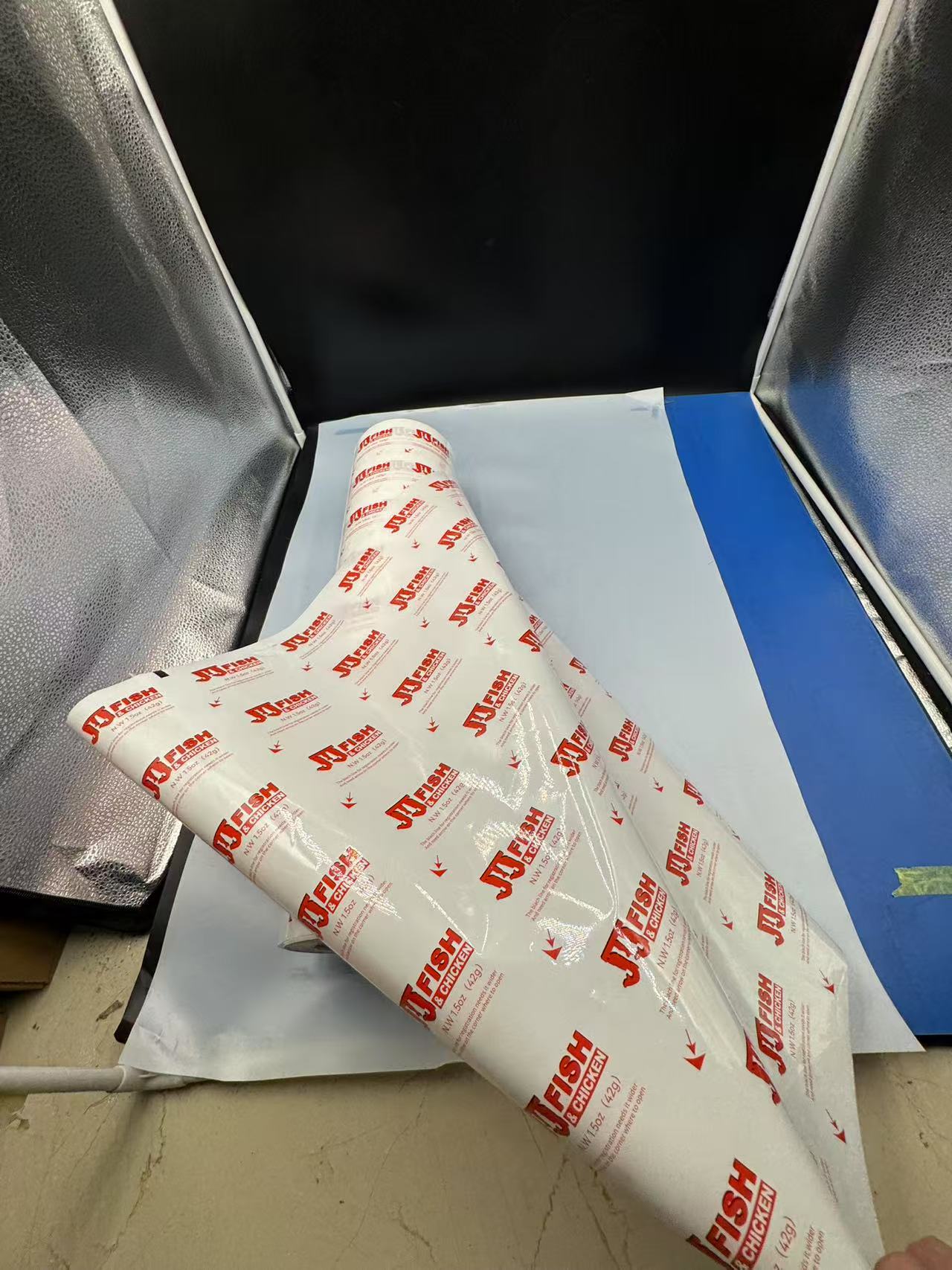

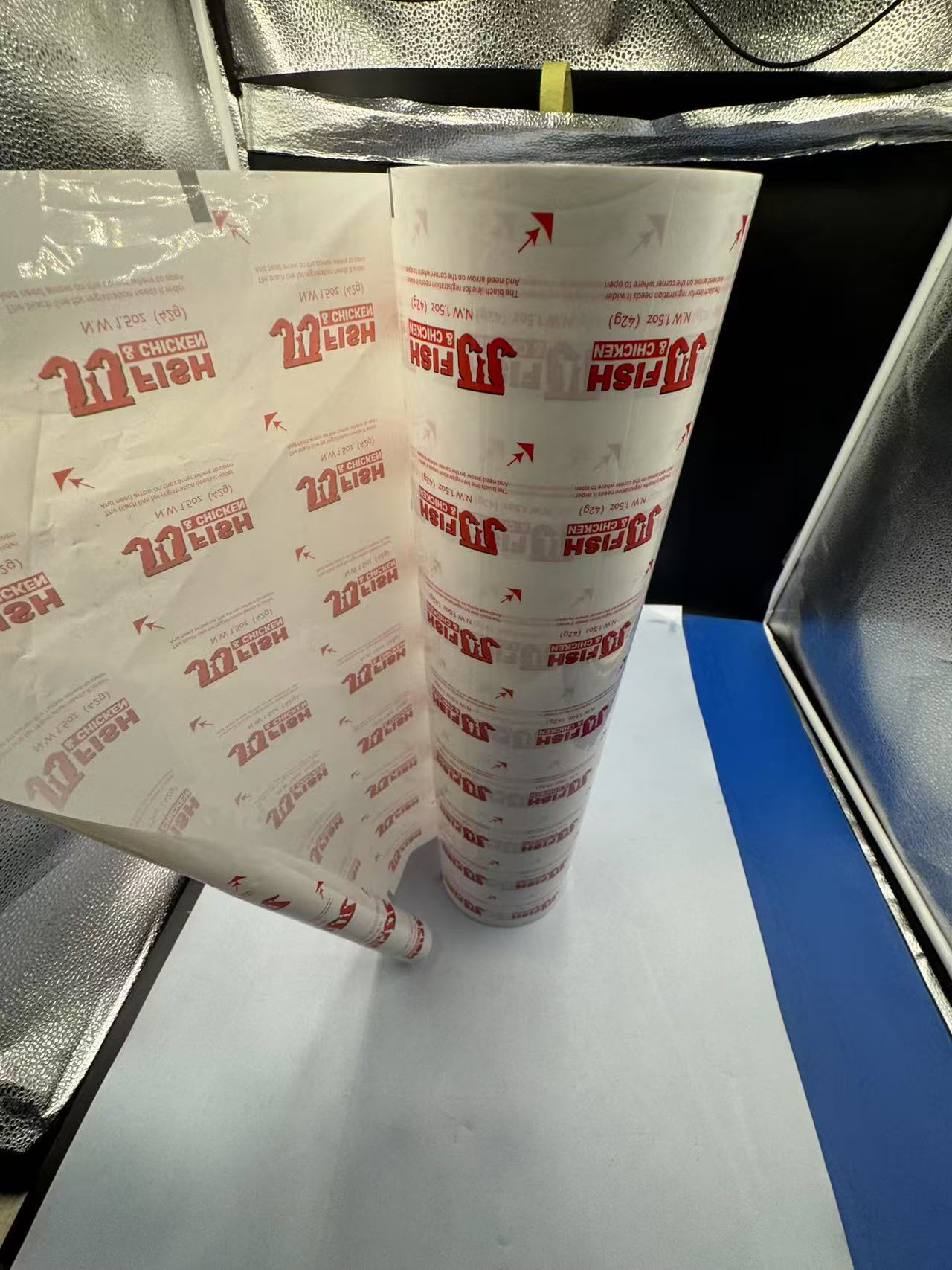

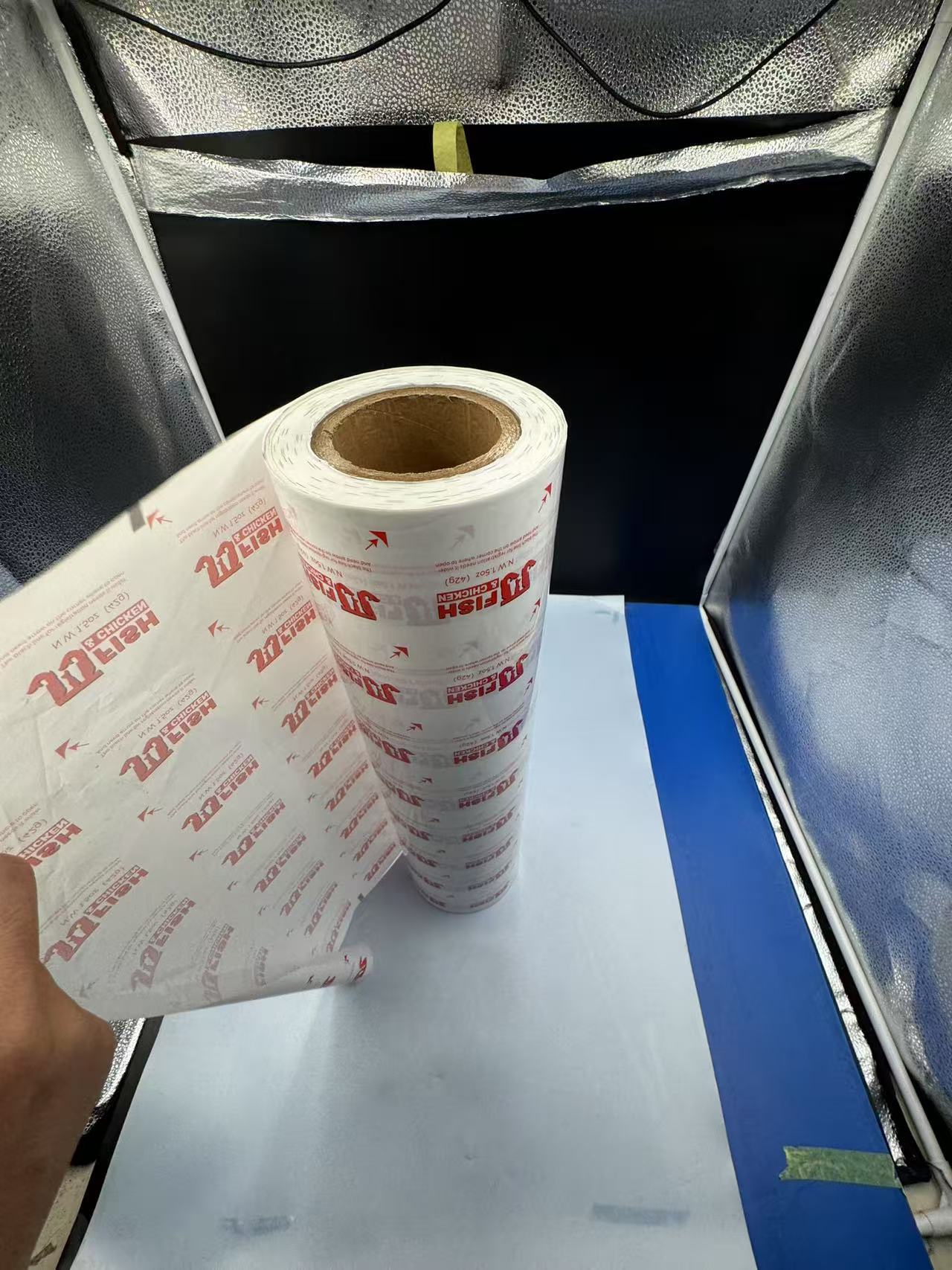

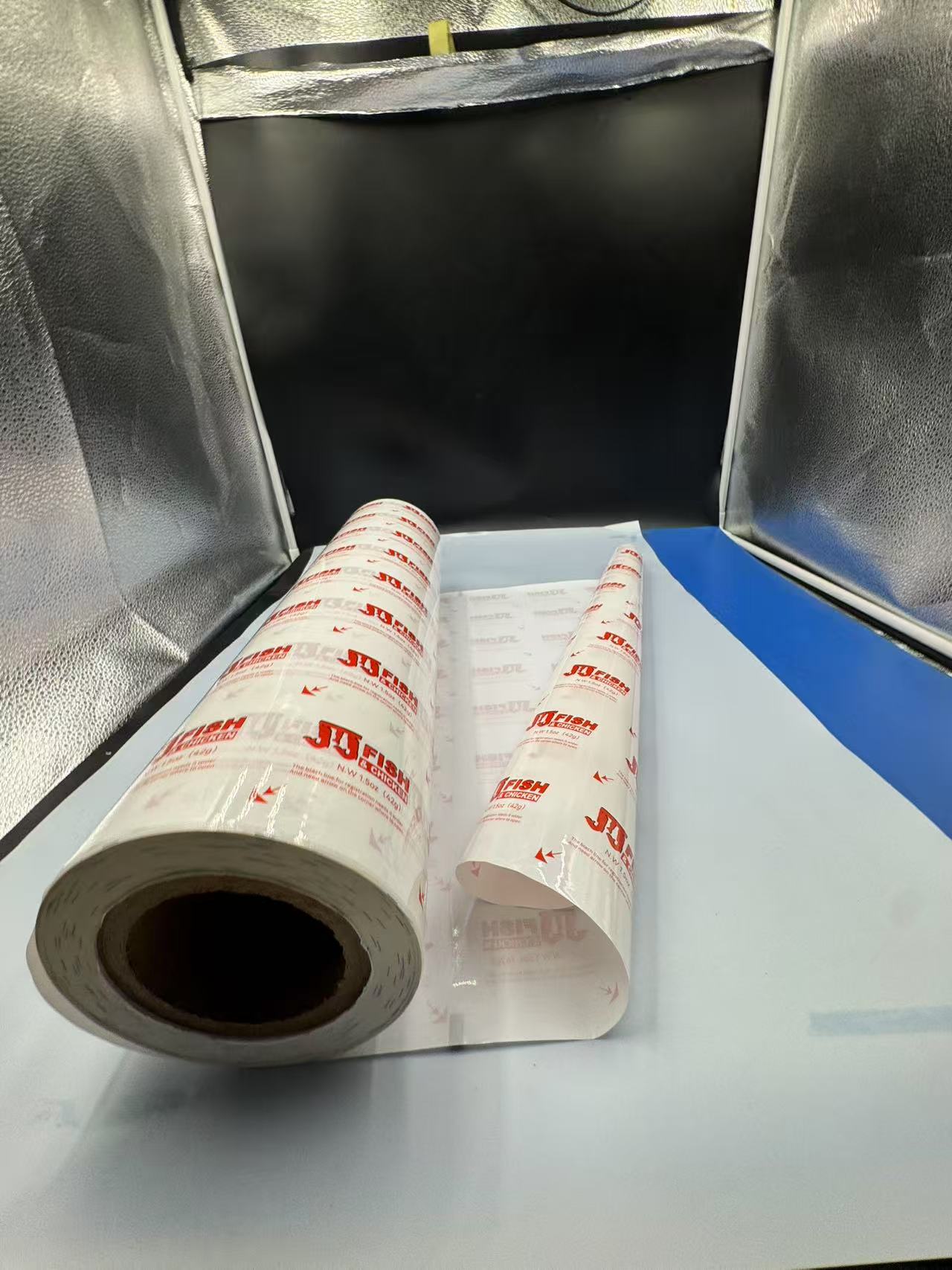

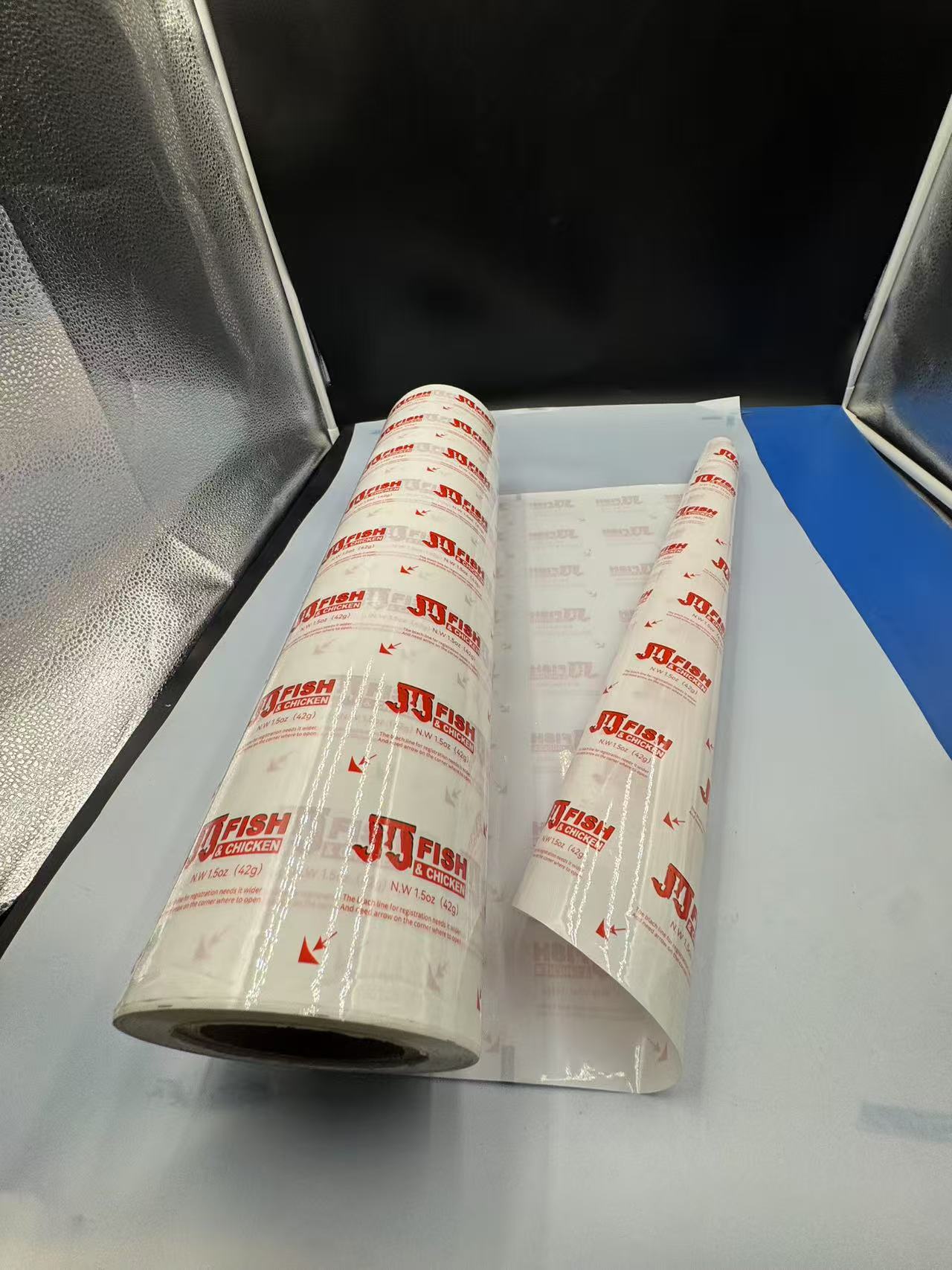

Name: PET printable film

Size: T:0.012-0.025MM*W:100-800MM

Materialpet

Color:WHITE/ transparent/customized

PackagingCartons/customized

OEM/ODMAccepeted

MOQ1000KG

UsageVegetable/Fruit/Meat,food tray cover

FeatureHigh durability, eco-friendly, compression resistance

AdvantageCompetitive price, consistent quality, 24 hours online service

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

Polyethylene Terephthalate (PET) film has emerged as a cornerstone material in various industries, particularly in packaging, due to its remarkable properties and adaptability. Among its many forms, printable PET film stands out for its ability to combine aesthetic appeal with functional excellence. This article delves into the characteristics of PET film that make it a preferred choice and explores its specific applications in heat sealing, a critical process in packaging technology. With a focus on evidence-based insights and vivid examples, we’ll uncover why printable PET film is a game-changer in today’s market.

Key Properties of Printable PET Film

Printable PET film is a thermoplastic polymer renowned for its durability, clarity, and versatility. Let’s break down its defining characteristics:

Mechanical Strength and Durability

PET film boasts exceptional tensile strength, making it resistant to tearing and puncturing. Studies have shown that PET films can withstand stresses up to 200 MPa, depending on thickness and processing conditions. This robustness ensures that products packaged with PET film remain protected during transportation and storage. For instance, a roll of 12-micron PET film can endure significant mechanical stress without compromising its integrity, a trait invaluable in high-speed packaging lines.

Thermal Stability

One of the standout features of PET film is its ability to maintain structural integrity across a wide temperature range, typically from -40°C to 150°C. This thermal resilience is critical in heat sealing applications, where the film must endure elevated temperatures without deforming or losing its properties. Research indicates that PET film’s melting point hovers around 250°C, well above the typical heat sealing range of 120°C to 180°C, ensuring reliability in sealing processes.Surface Printability

The “printable” aspect of PET film refers to its ability to accept high-quality printing through techniques like flexography, gravure, or digital printing. This is facilitated by its smooth, non-porous surface, which allows inks to adhere effectively. Specially treated PET films, such as corona-treated or chemically coated variants, enhance ink adhesion further, delivering vibrant graphics and branding. Imagine a snack package with crisp, colorful logos that resist fading—printable PET film makes this possible.Barrier Properties

PET film offers excellent resistance to moisture, gases, and odors, safeguarding the contents of a package. Its oxygen transmission rate (OTR) can be as low as 5 cc/m²/day for a 12-micron film, while its water vapor transmission rate (WVTR) is similarly impressive. These barrier qualities are vital for heat-sealed packaging, where maintaining product freshness is paramount, such as in coffee pouches or pharmaceutical blister packs.

Transparency and Aesthetic Appeal

With a light transmission rate exceeding 90%, PET film provides crystal-clear visibility, making it ideal for showcasing products like fresh produce or cosmetics. This optical clarity, combined with its printability, allows manufacturers to create visually appealing packages that stand out on shelves.

Printable PET Film in Heat Sealing Applications

Heat sealing is a widely used technique in packaging that involves bonding two surfaces together using heat and pressure, often to create airtight or tamper-evident seals. Printable PET film excels in this domain due to its unique combination of properties. Below, we explore its role in heat sealing with detailed examples and technical insights.

1. Compatibility with Heat Sealing Processes

Heat sealing typically involves applying temperatures between 120°C and 180°C for a few seconds, depending on the film thickness and sealing equipment. PET film’s thermal stability ensures it can withstand these conditions without melting or degrading. For example, in the production of stand-up pouches for pet food, a layer of printable PET film is often laminated with a sealant layer (like polyethylene) and subjected to heat sealing. The PET film maintains its structural integrity, while the sealant layer melts to form a strong bond.

The sealing window—the range of temperature and time in which an effective seal forms—is notably wide for PET film-based laminates. Tests have demonstrated that a 25-micron PET film laminated with a 50-micron PE layer achieves peel strengths exceeding 20 N/15 mm, a testament to its reliability in high-performance packaging.

2. Enhancing Seal Integrity

The strength of a heat seal is critical to prevent leaks or contamination. PET film contributes to this by providing a stable substrate that resists stretching or shrinking during the sealing process. In a real-world scenario, consider a medical pouch for sterile instruments. Here, a printable PET film layer ensures the package remains intact and tamper-proof after heat sealing, while its barrier properties protect against moisture and bacteria ingress. Studies show that PET film-based seals can achieve burst pressures of up to 0.5 bar, far exceeding the requirements for most consumer goods.

3. Aesthetic and Functional Synergy

Printable PET film’s ability to carry high-quality graphics enhances its utility in heat-sealed packaging. Take the example of a microwaveable ready-meal tray. The top film, often a PET***film variant, is printed with cooking instructions and branding before being heat-sealed to the tray. The film’s clarity allows consumers to see the food inside, while its heat resistance ensures the seal holds during microwave heating. This dual role—functional sealing and visual appeal—demonstrates PET film’s versatility.

4. Sustainability in Heat-Sealed Packaging

As industries shift toward sustainable practices, PET film offers recyclable options that align with heat sealing needs. Mono-material PET structures, where the film and sealant are both PET-based, are gaining traction. These can be heat-sealed effectively and recycled more easily than multi-material laminates. For instance, a recyclable PET pouch for snacks, sealed at 140°C for 1.5 seconds, maintains product shelf life while reducing environmental impact—a win-win for manufacturers and eco-conscious consumers.

5. Challenges and Solutions

While PET film excels in heat sealing, challenges like seal contamination or inconsistent sealing can arise. Dust or oil on the film surface may weaken the bond, but this can be mitigated by using cleanroom production environments or pre-treating the film. Additionally, optimizing sealing parameters—such as dwell time and pressure—ensures consistent results. In a case study involving coffee packaging, adjusting the sealing temperature from 150°C to 160°C improved seal strength by 15%, highlighting the importance of fine-tuning.

Real-World Examples and Impact

The practical applications of printable PET film in heat sealing are vast and impactful. In the food industry, PET***film is used in flexible pouches for sauces, where its barrier properties and strong seals preserve flavor and extend shelf life. A leading coffee brand, for instance, relies on PET film laminates to create vacuum-sealed bags that lock in aroma, with the outer PET layer printed with eye-catching designs.

In pharmaceuticals, PET film’s role in blister packaging is indispensable. The film is heat-sealed to a foil backing, ensuring drugs remain uncontaminated until use. Its durability withstands the rigors of distribution, while its printability allows for clear dosage instructions.

Even in non-food sectors, such as electronics, PET***film protects components in heat-sealed static-shield bags. The film’s strength and anti-static coatings, combined with reliable seals, safeguard sensitive items from damage.

Conclusion

Printable PET film is a marvel of modern materials science, blending strength, thermal stability, printability, and barrier properties into a single package. Its applications in heat sealing highlight its ability to meet both functional and aesthetic demands, from ensuring seal integrity to enhancing brand visibility. As technology advances and sustainability becomes a priority, PET film continues to evolve, offering innovative solutions for packaging challenges. Whether it’s a glossy snack pouch or a sterile medical pack, printable PET***film proves that versatility and performance can coexist beautifully.

Within 15-20 days after received payment...more