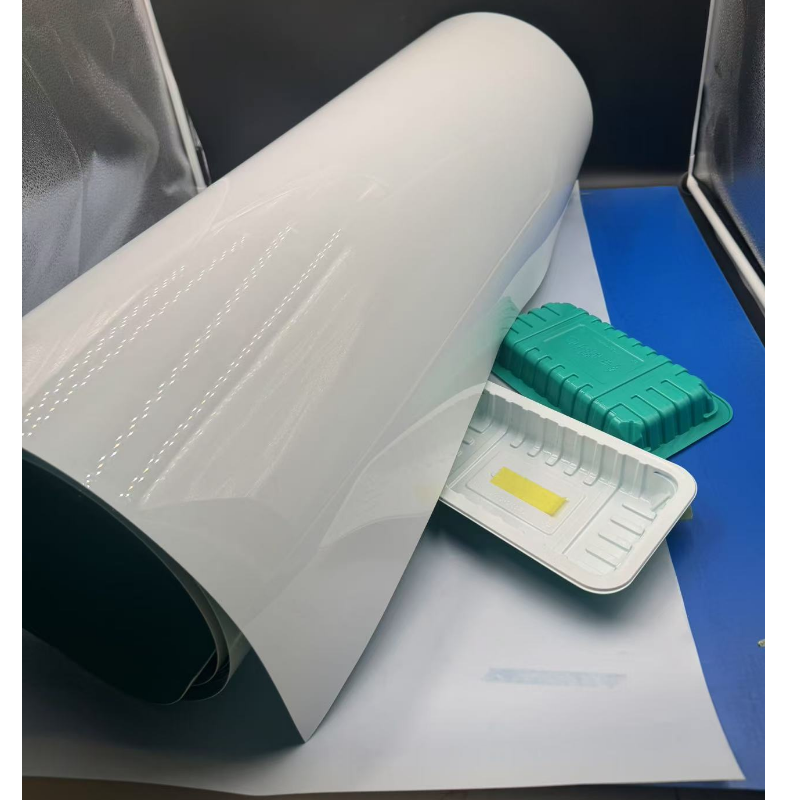

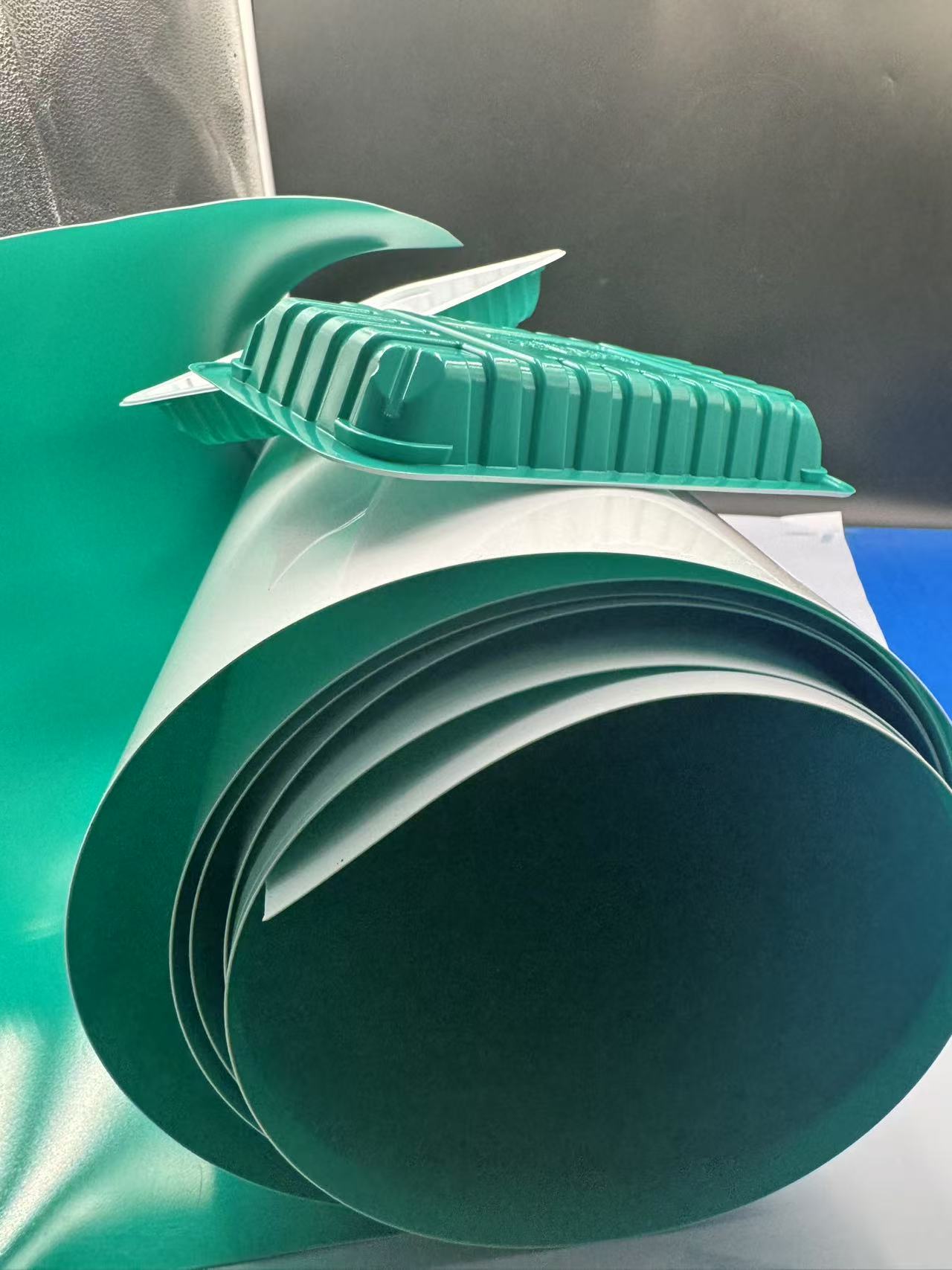

The Characteristics and Applications of Two-Color PP Film in Disposable Cutlery Blister Packaging and Food Packaging

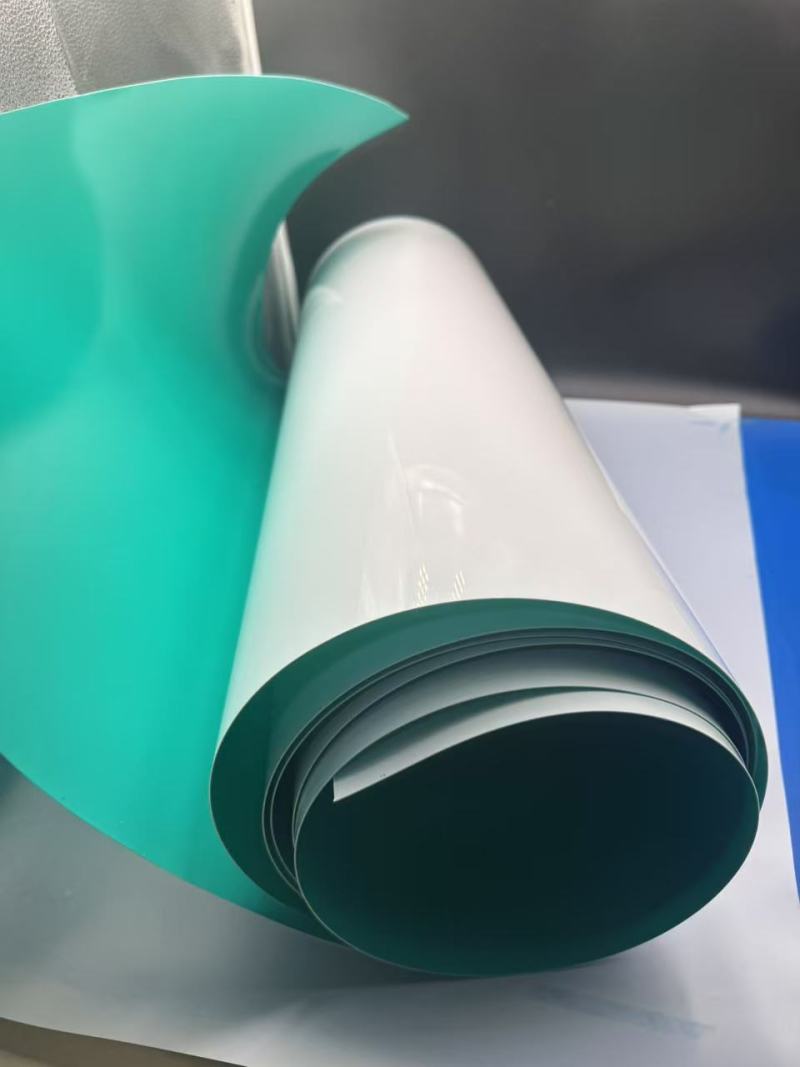

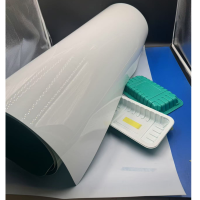

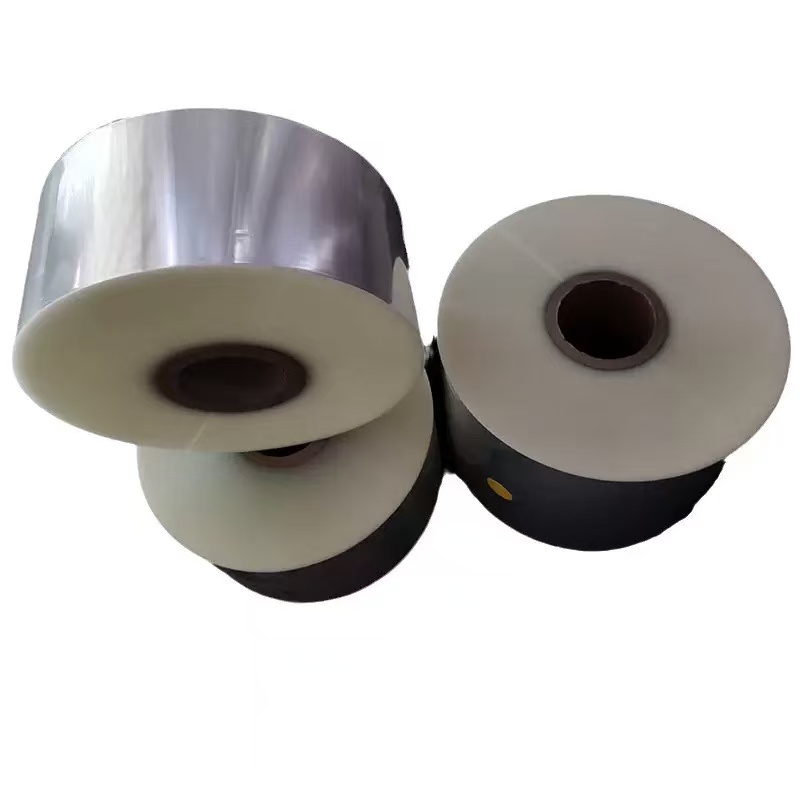

Material: PP Thermal formed sheet

Thickness 0.25-0.9mm/customization

Size: 300mm/Customization

GRADE: Food grade film

color: black/white/ customization

location: china

usage :for food tray ,mircronwave food container

- TOPLEADER

- 中国

- 15WORKING DAYS

- 5000T/M

- Information

- Video

- Download

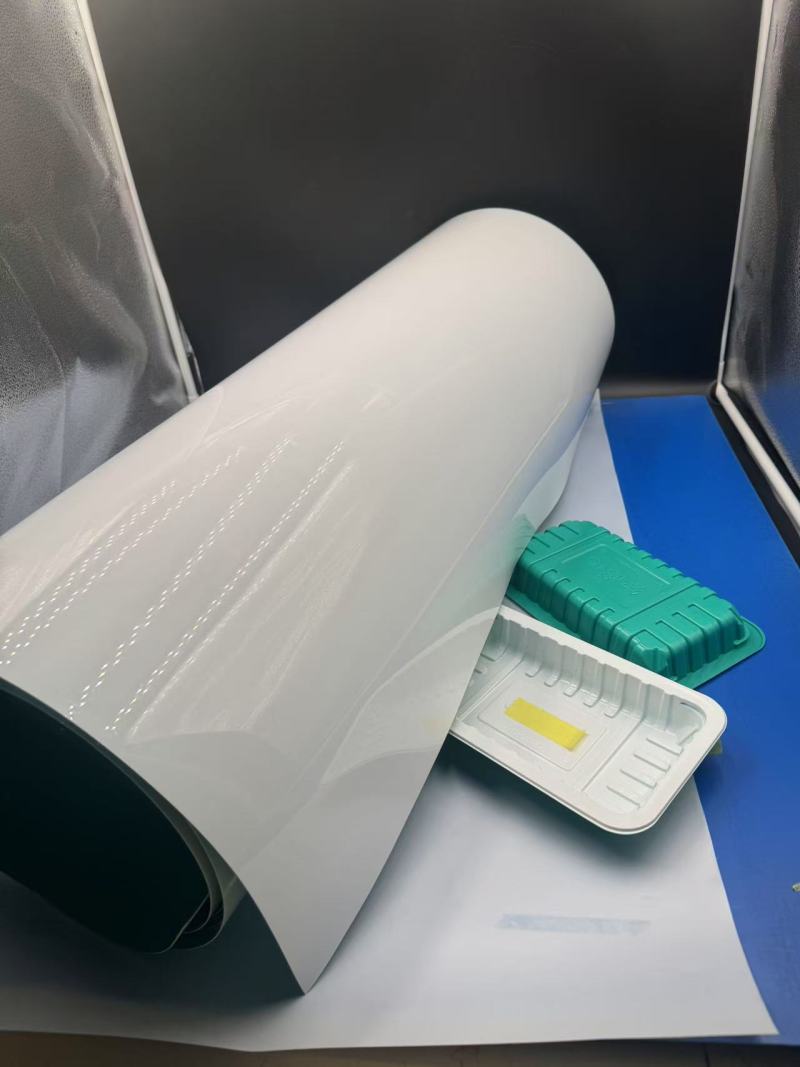

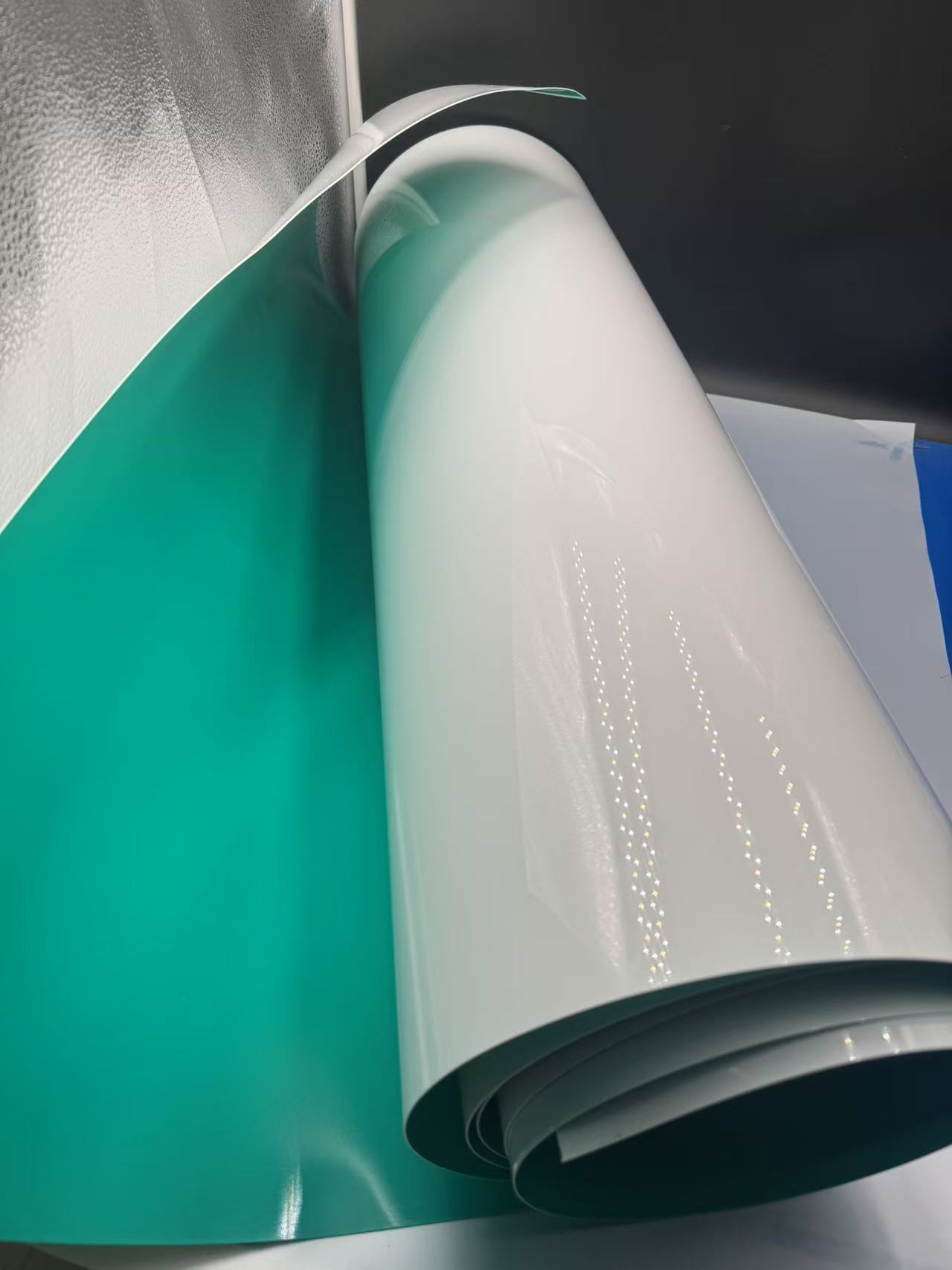

Polypropylene (PP) film has long been a staple in the packaging industry due to its remarkable versatility, cost-effectiveness, and durability. Among its various forms, two-color PP film stands out as an innovative option, blending functionality with aesthetic appeal.  This specialized film, created by co-extruding or laminating two distinct color layers of polypropylene, offers unique characteristics that make it an ideal choice for applications such as disposable cutlery blister packaging and food packaging. In this article, we will explore the defining properties of two-color PP film and delve into how these attributes translate into practical, efficient, and visually appealing packaging solutions.

This specialized film, created by co-extruding or laminating two distinct color layers of polypropylene, offers unique characteristics that make it an ideal choice for applications such as disposable cutlery blister packaging and food packaging. In this article, we will explore the defining properties of two-color PP film and delve into how these attributes translate into practical, efficient, and visually appealing packaging solutions.

Characteristics of Two-Color PP Film

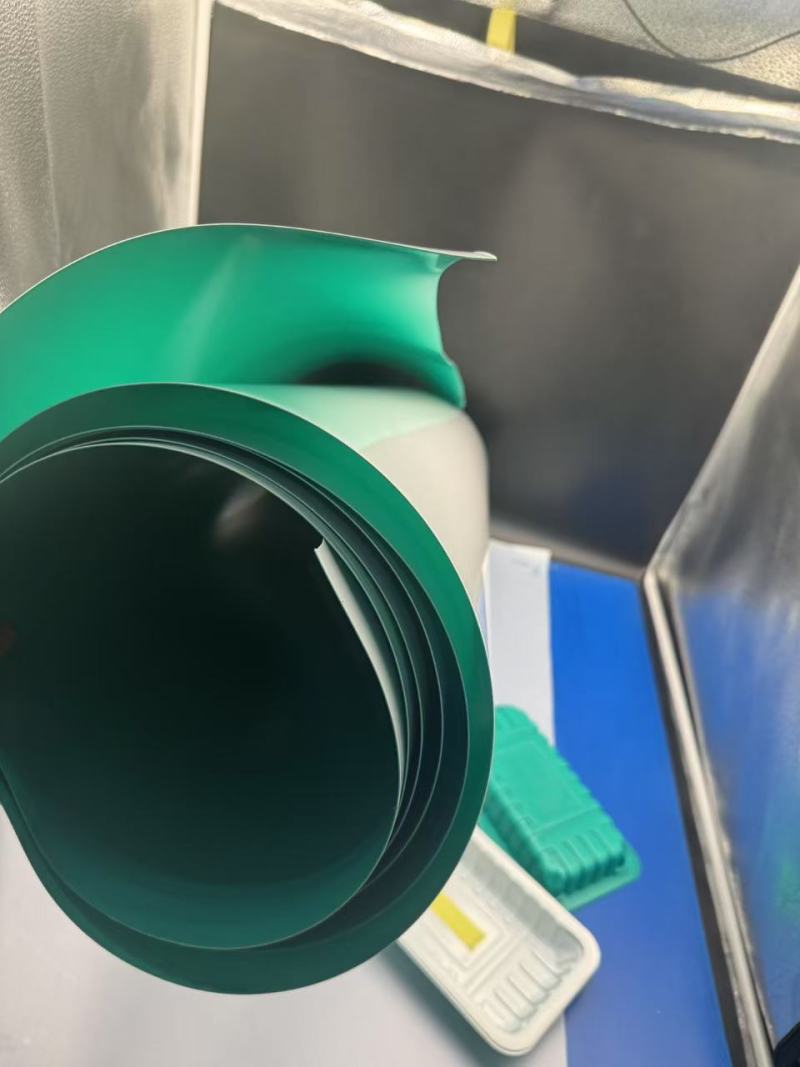

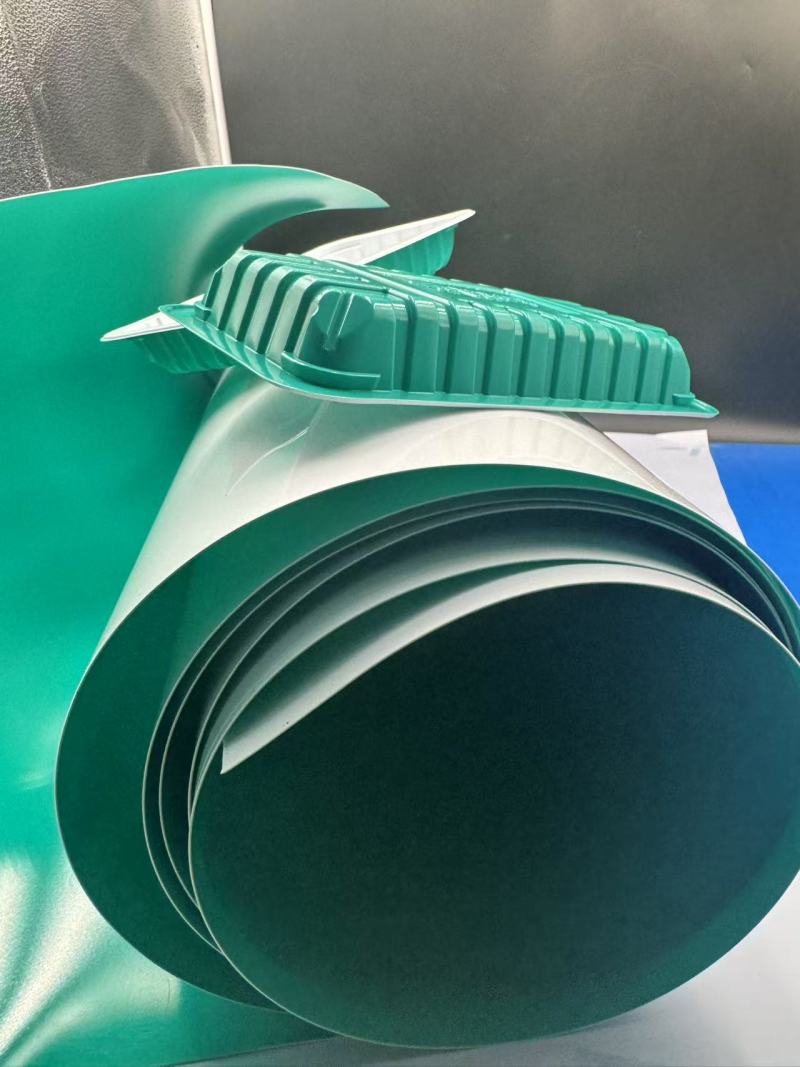

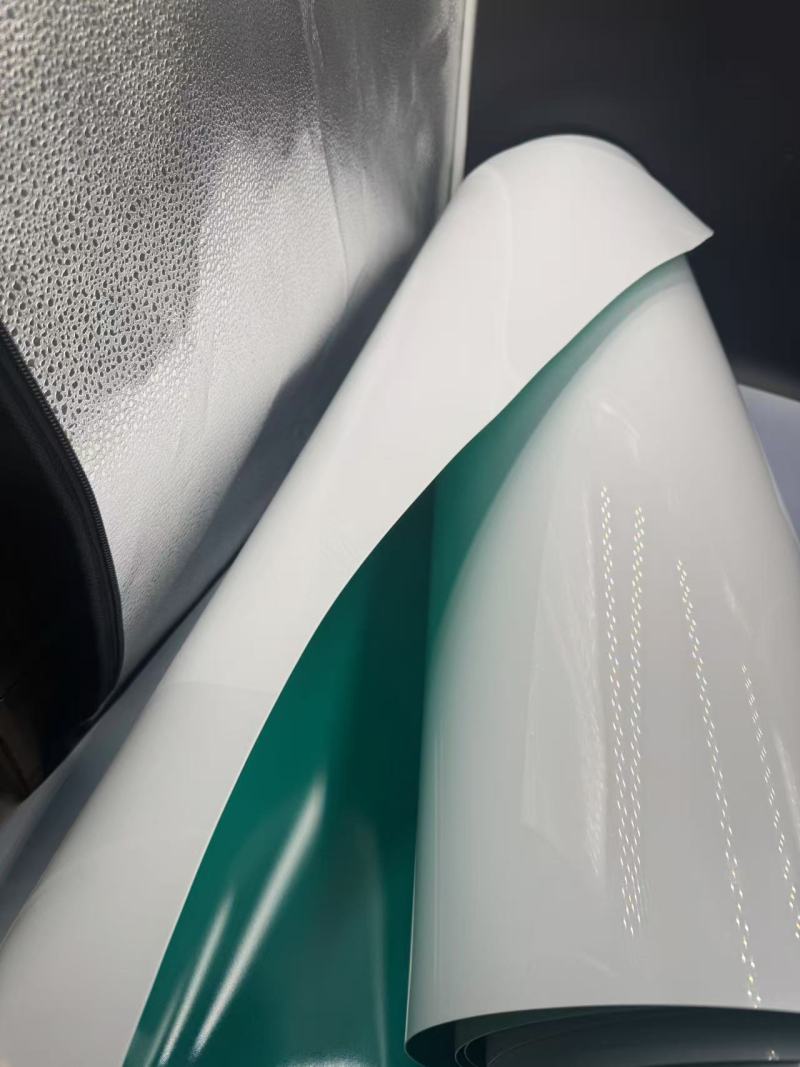

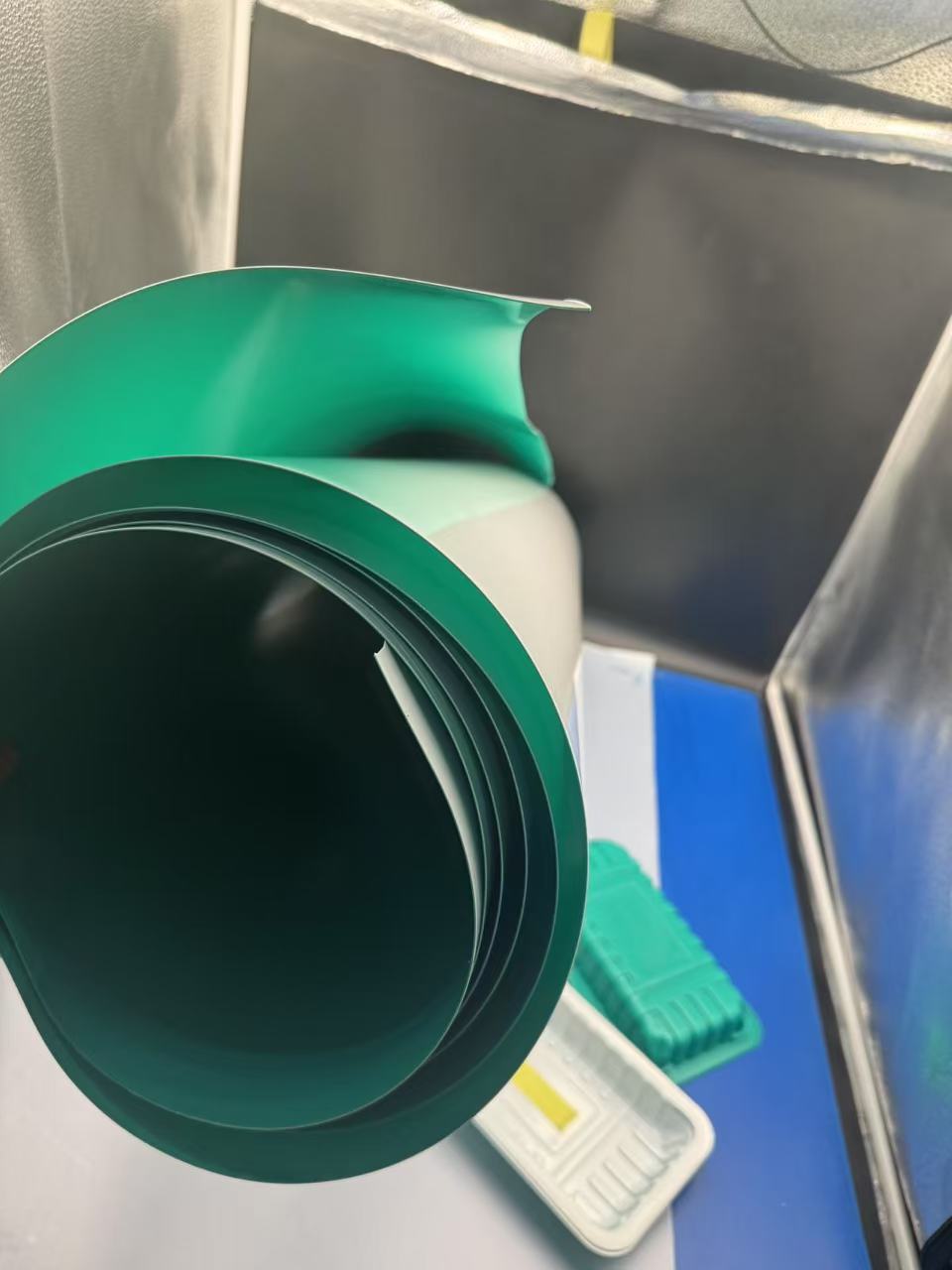

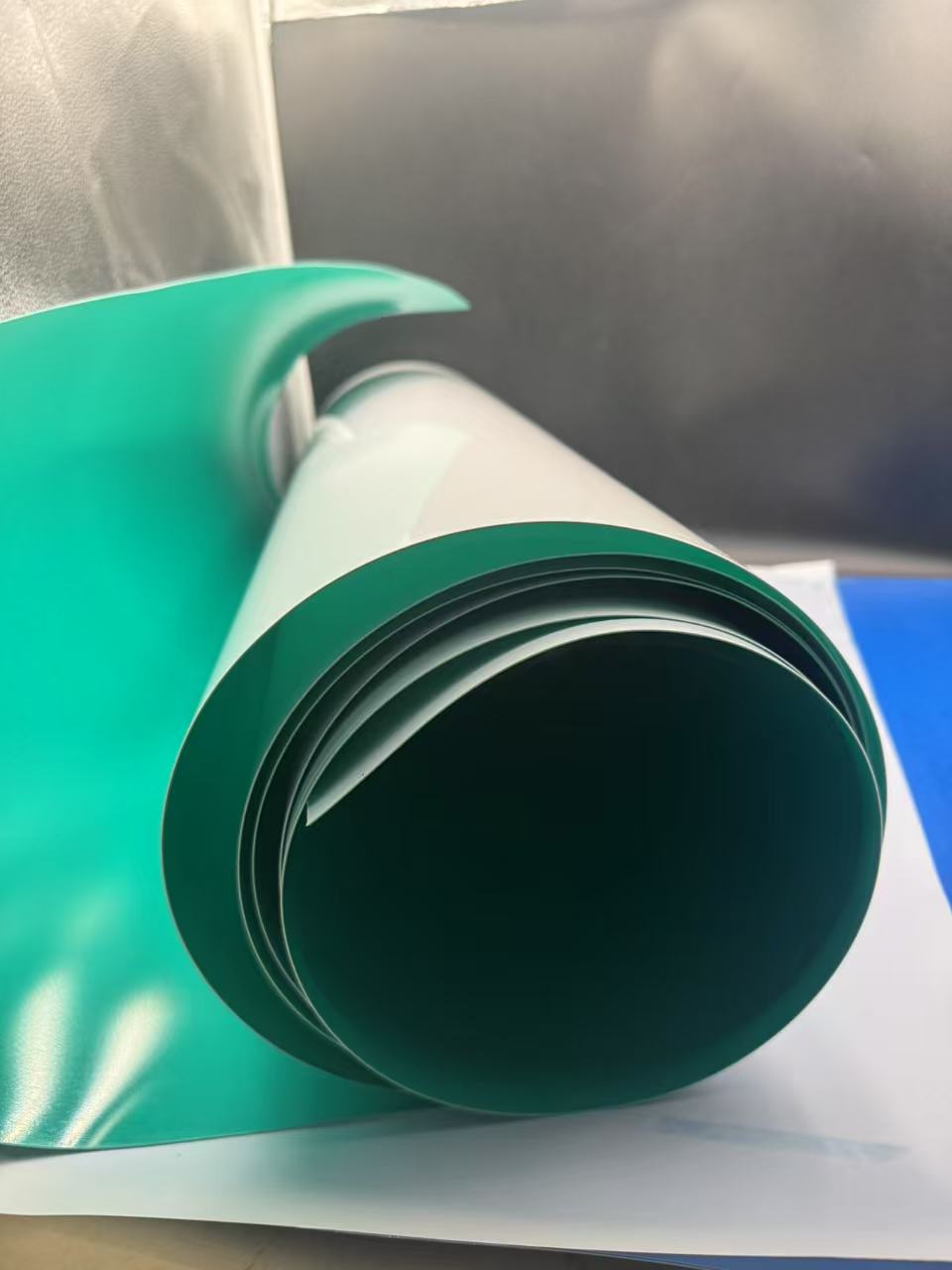

Two-color PP film is engineered through advanced manufacturing processes, typically involving co-extrusion, where two layers of PP resin—each infused with different pigments—are extruded simultaneously to form a single, unified sheet. This results in a film with a dual-tone appearance, offering both practical and decorative benefits. Let’s break down its key characteristics:

Mechanical Strength and Durability

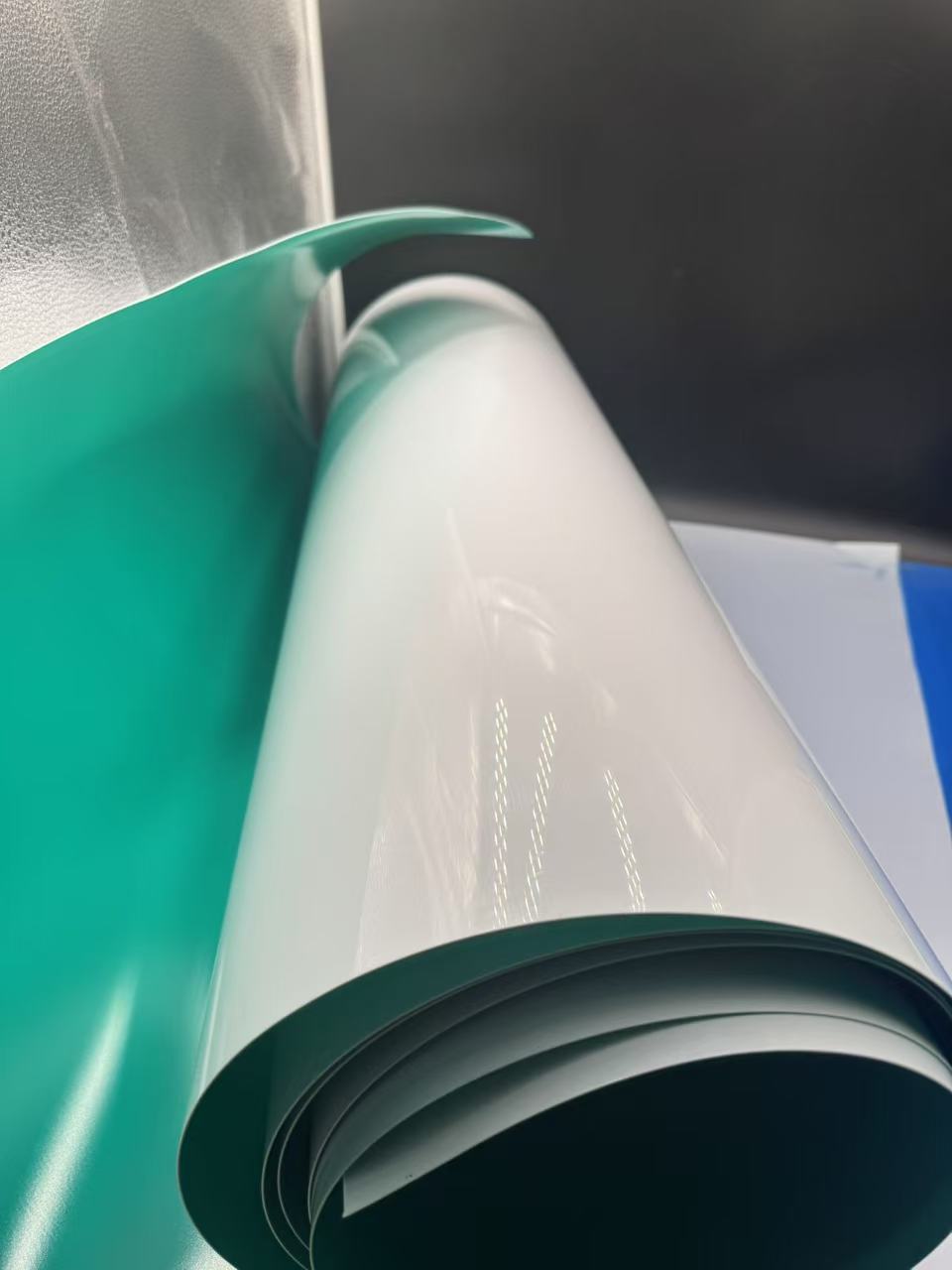

PP film is renowned for its high tensile strength and resistance to bending fatigue. Two-color PP film inherits these traits, boasting a tensile strength that can reach up to 35.7 MPa in standard forms, though specialized grades can exceed this value. This strength ensures that the film can withstand the rigors of thermoforming and vacuum forming processes commonly used in blister packaging, as well as the stresses of transportation and handling in food packaging applications. Its durability translates to reliable protection for packaged goods, reducing the risk of damage or deformation.Thermal Resistance

One of the standout features of PP film is its high melting point, typically ranging from 160°C to 170°C. Two-color PP film retains this heat resistance, making it suitable for packaging items that require sterilization or exposure to elevated temperatures, such as microwaveable food containers or hot-fill liquid packaging. This thermal stability ensures that the film maintains its structural integrity and color vibrancy even under challenging conditions.Barrier Properties

While standard PP film offers moderate barrier properties against moisture and gases, two-color PP film can be enhanced with additives or coatings to improve its performance. For instance, its water vapor transmission rate (WVTR) can be tailored to hover around 0.91–0.95 g/cm³, providing adequate protection for food items against humidity. Although its oxygen barrier is not as robust as some alternatives like PVDC-coated films, it suffices for short-to-medium shelf-life products, making it a practical choice for disposable cutlery and certain food packaging needs.

Aesthetic Appeal and Customization

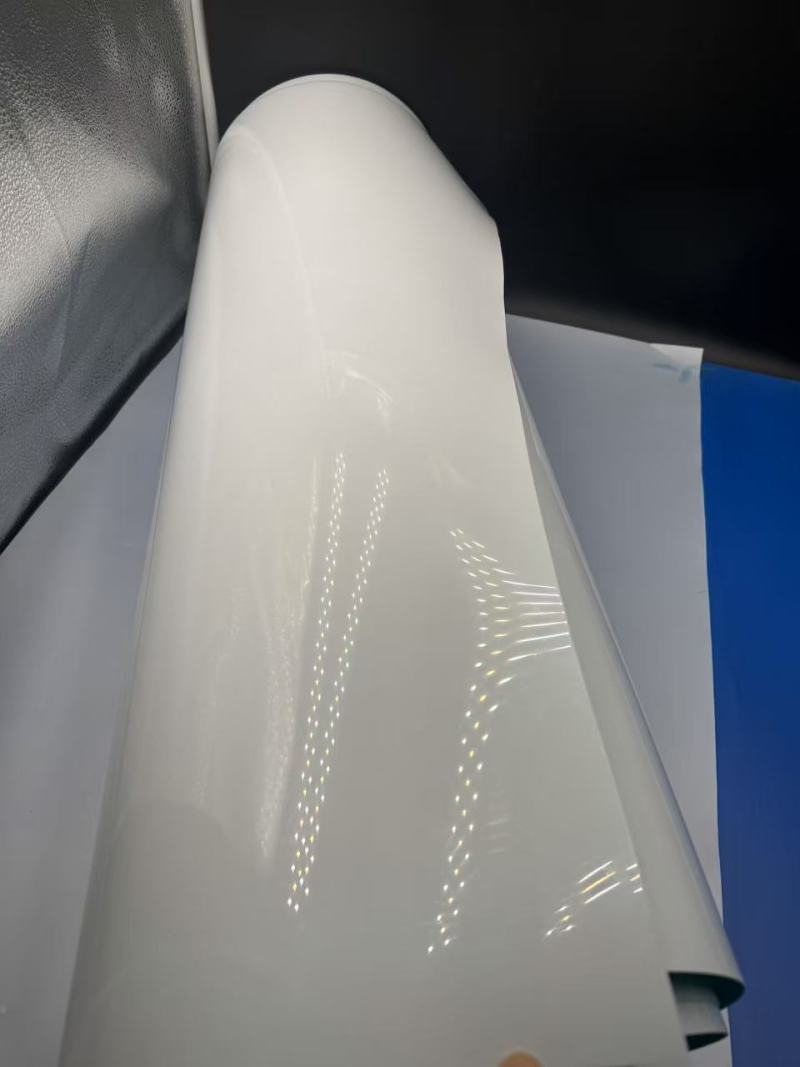

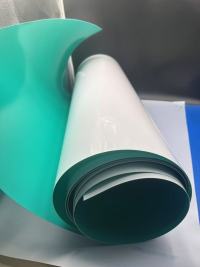

The dual-color design of two-color PP film sets it apart from its monochromatic counterparts. By combining two distinct hues—such as a vibrant outer layer paired with a neutral inner layer—manufacturers can create visually striking packaging that enhances product visibility on retail shelves. This customization extends beyond aesthetics; the film can be engineered with specific thicknesses (typically 0.3–2 mm) and widths (up to 900 mm), allowing it to meet diverse packaging requirements while maintaining a premium look.

Non-Toxic and Food-Safe

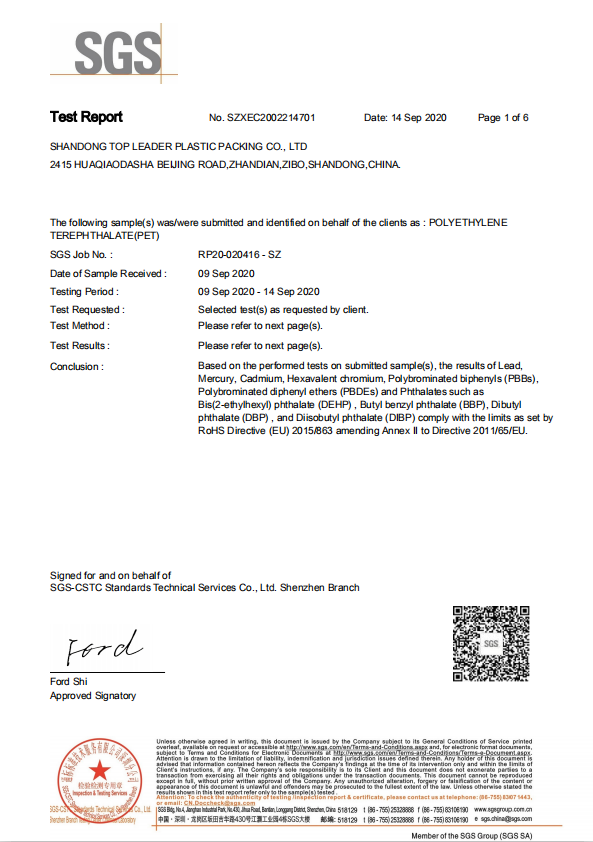

Two-color PP film, when produced with food-grade resins and additives, complies with stringent safety standards such as those set by the FDA and EU food legislation. Its non-toxic, odorless, and tasteless nature ensures that it does not impart unwanted flavors or contaminants to food or utensils, making it an excellent candidate for direct food contact applications.

Cost-Effectiveness and Processability

Despite its enhanced visual appeal, two-color PP film remains an economical option due to the widespread availability of PP resin and the efficiency of co-extrusion processes. Its excellent thermoformability—achieved at mold temperatures of 160°C–220°C—enables seamless shaping into blisters, trays, and containers, reducing production costs and waste.

Applications in Disposable Cutlery Blister Packaging

Disposable cutlery, such as plastic spoons, forks, and knives, has become indispensable in fast-paced modern lifestyles, from takeout meals to outdoor events. Blister packaging, characterized by a pre-formed plastic cavity sealed with a backing, is a popular method for presenting and protecting these items. Two-color PP film elevates this application in several compelling ways.

Enhanced Product Presentation

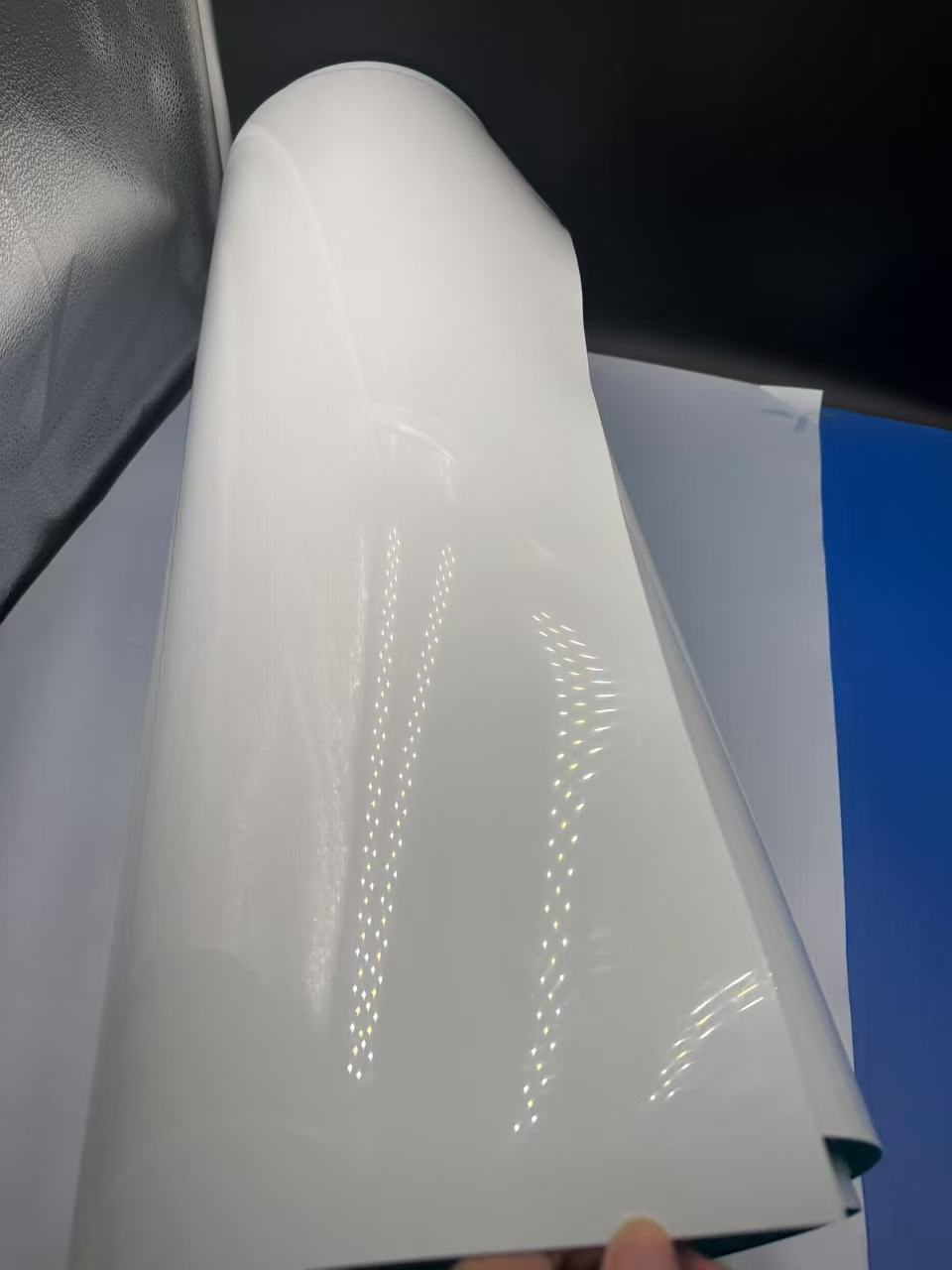

Imagine a sleek, transparent blister pack encasing a set of disposable cutlery, with a glossy black outer layer contrasting against a crisp white inner lining. This dual-tone effect not only catches the eye but also conveys a sense of quality and sophistication. The film’s clarity and color contrast highlight the cutlery’s design, making it more appealing to consumers browsing crowded shelves. Retailers benefit from this visual edge, as it differentiates their products from competitors using plain, single-color packaging.

Robust Protection During Transport

The mechanical strength of two-color PP film ensures that cutlery remains secure within its blister pack. During shipping or storage, the film resists punctures and tears, safeguarding the utensils from contamination or breakage. For instance, a 0.5 mm thick two-color PP film can endure significant pressure without compromising its shape, providing a reliable barrier between the cutlery and external elements like dust or moisture.

Efficient Manufacturing Process

In blister packaging production, two-color PP film is heated and molded into precise cavities using thermoforming or vacuum forming techniques. Its consistent thickness and flexibility allow for deep draws and intricate shapes, accommodating cutlery of varying sizes—whether a slender teaspoon or a sturdy knife. The film’s low molding shrinkage (1.0%–2.5%) ensures that the final blisters retain their intended dimensions, minimizing defects and ensuring a snug fit around each utensil.

Sustainability Considerations

While PP is not inherently biodegradable, its recyclability offers an eco-friendly advantage. Two-color PP film can be collected and reprocessed into new packaging materials, aligning with growing consumer demand for sustainable solutions. Manufacturers can further enhance this by using recycled PP resin in one of the color layers, reducing the environmental footprint without sacrificing performance.

Applications in Food Packaging

Food packaging demands a delicate balance of safety, preservation, and presentation—qualities that two-color PP film delivers with finesse. From trays for frozen meals to wrappers for snacks, this film adapts to a variety of food-related needs.

Preservation of Freshness

Consider a tray of pre-cut fruit sealed with two-color PP film, featuring a green outer layer symbolizing freshness and a clear inner layer showcasing the vibrant contents. The film’s moderate moisture barrier properties help prevent water loss, keeping the fruit succulent for longer periods. For frozen foods like dumplings or ice cream, its low-temperature resistance (down to -20°C or lower with additives) ensures that the packaging remains intact even in subzero conditions, preventing freezer burn and maintaining product quality.

Microwaveable Convenience

The thermal resistance of two-color PP film makes it a natural fit for microwaveable food containers. A brightly colored lid—say, red on the outside and white on the inside—can withstand the heat of reheating without warping or leaching harmful substances into the food. This convenience appeals to busy consumers who value quick meal preparation without compromising safety or taste.

Branding and Consumer Appeal

Food packaging is as much about marketing as it is about protection. Two-color PP film allows brands to incorporate their signature colors directly into the packaging, reinforcing brand identity. For example, a snack company might use a yellow-and-blue film to wrap granola bars, aligning with its logo while ensuring the product stands out in a vending machine. The film’s smooth surface also supports high-quality printing, enabling detailed nutritional information or promotional designs to be displayed clearly.

Versatility Across Food Types

From rigid trays for deli meats to flexible pouches for sauces, two-color PP film adapts to diverse food packaging formats. Its chemical resistance protects against oils and greases, making it suitable for fatty foods like fried snacks or buttery pastries. For dry goods like cereals, the film’s lightweight nature reduces shipping costs, while its toughness prevents crushing during transit.

Challenges and Future Potential

While two-color PP film excels in many areas, it’s not without limitations. Its oxygen barrier properties are less impressive than those of multilayer films like PET/PE or PVDC-coated options, which may limit its use for highly perishable goods requiring extended shelf life. However, advancements in co-extrusion technology and the incorporation of barrier-enhancing additives could address this gap, broadening its applicability.

Looking ahead, the potential for two-color PP film is vast. As consumer preferences shift toward sustainable yet visually appealing packaging, manufacturers might explore bio-based PP resins or compostable additives to create an eco-friendlier version. Innovations in pigmentation could also yield even more striking color combinations, further enhancing its role in premium packaging.

Within 15-20 days after received payment...more