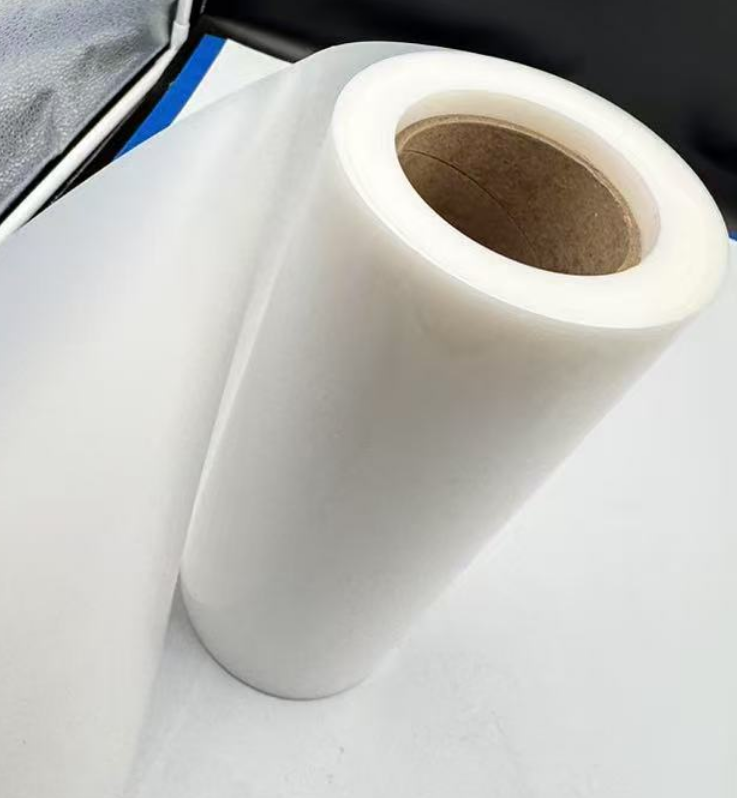

natural color translucent pp film polypropylene

white frosted PP film for vacuum thermoforming

White Frosted PP Film: Premium Material for Versatile Applications

Thicknesses range from 0.1mm to 1.0mm, catering to diverse project requirements.

- top leader plastic

- China

- 10-15 working days

- 1600 tons/month

- Information

Related introduction of white PP film for vacuum thermoforming:

Characteristics

Physical properties: White PP film is usually milky white, with uniform appearance, tough texture, smooth surface, and certain stiffness, which is convenient for operation and shaping during vacuum thermoforming. The density is generally between 0.89-0.91g/cm³, which is relatively light and conducive to reducing the weight of the product.

Thermal properties: It has good heat resistance and can withstand high temperatures during vacuum thermoforming. It can still maintain good stability at a temperature of about 150℃, and is not prone to deformation, discoloration and other problems. The softening point is about 140℃, and the operating temperature range is generally -30℃-140℃.

Mechanical properties: It has high tensile strength and can withstand external forces such as stretching and bending during vacuum thermoforming without breaking. It has good tear resistance and puncture resistance, which can ensure that the film products after molding have certain strength and durability.

Processing performance: good fluidity, can quickly and evenly fill the mold cavity during vacuum thermoforming to form various complex shapes, good fit with the mold, can accurately replicate the outline and details of the mold, and the size of the molded product is high.

Application

Food packaging field: used to make various food packaging boxes, trays, cups and other packaging containers, such as biscuit boxes, cake trays, yogurt cups, etc., can provide good sealing and preservation, protect food from moisture and deterioration.

Electronic and electrical field: can be made into shells, parts packaging, etc. of electronic and electrical products, such as mobile phone packaging boxes, computer accessories packaging boxes, etc., which play a role in protecting and fixing electronic and electrical products, and have good insulation properties.

Production process

Raw material preparation: Select suitable polypropylene resin particles as raw materials, and add appropriate amounts of additives such as plasticizers, stabilizers, lubricants, etc. as needed to improve the performance of the film.

Extrusion molding: Put the raw materials into the extruder, and after heating, melting, extrusion and other processes, form a sheet or tubular blank with uniform thickness.

Stretching orientation: The blank is stretched longitudinally and transversely through the stretching equipment to orient the molecular chains in the stretching direction, thereby improving the strength, transparency and dimensional stability of the film.

Thermoforming: The stretched film is heated to the softening temperature and placed in a vacuum thermoforming mold. The film is attached to the mold surface by vacuuming. After cooling and shaping, the desired vacuum thermoforming product can be obtained.

Within 15-20 days after received payment...more